Which Piston Length is Right for You?

Piston Length can be set in nine positions, from seven inches to eighteen inches. Generally, the longer you

set the piston, the higher you’ll bounce.

That’s because most people can achieve a peak bounce height (measured from the foot-pegs to the ground)

that’s twice the piston length. In other words: if the piston is set at 12 inches, you’ll end up with your feet 24

inches above the ground during a peak bounce. Of course, some athletes can achieve bounces four times the

piston length. It depends on skill and strength (not to mention the number of thrusters engaged).

For novices, we recommend a shorter piston length for greater control, although even advanced users may

prefer a shorter piston length for certain tricks or precision maneuvers. You’ll likely want to increase the pis-

ton length as your skill and confidence grow.

Setting the Piston Length

First, you need to loosen the friction clamp and the locking screw that fix the piston into place.

Both of these are part of the upper mount.

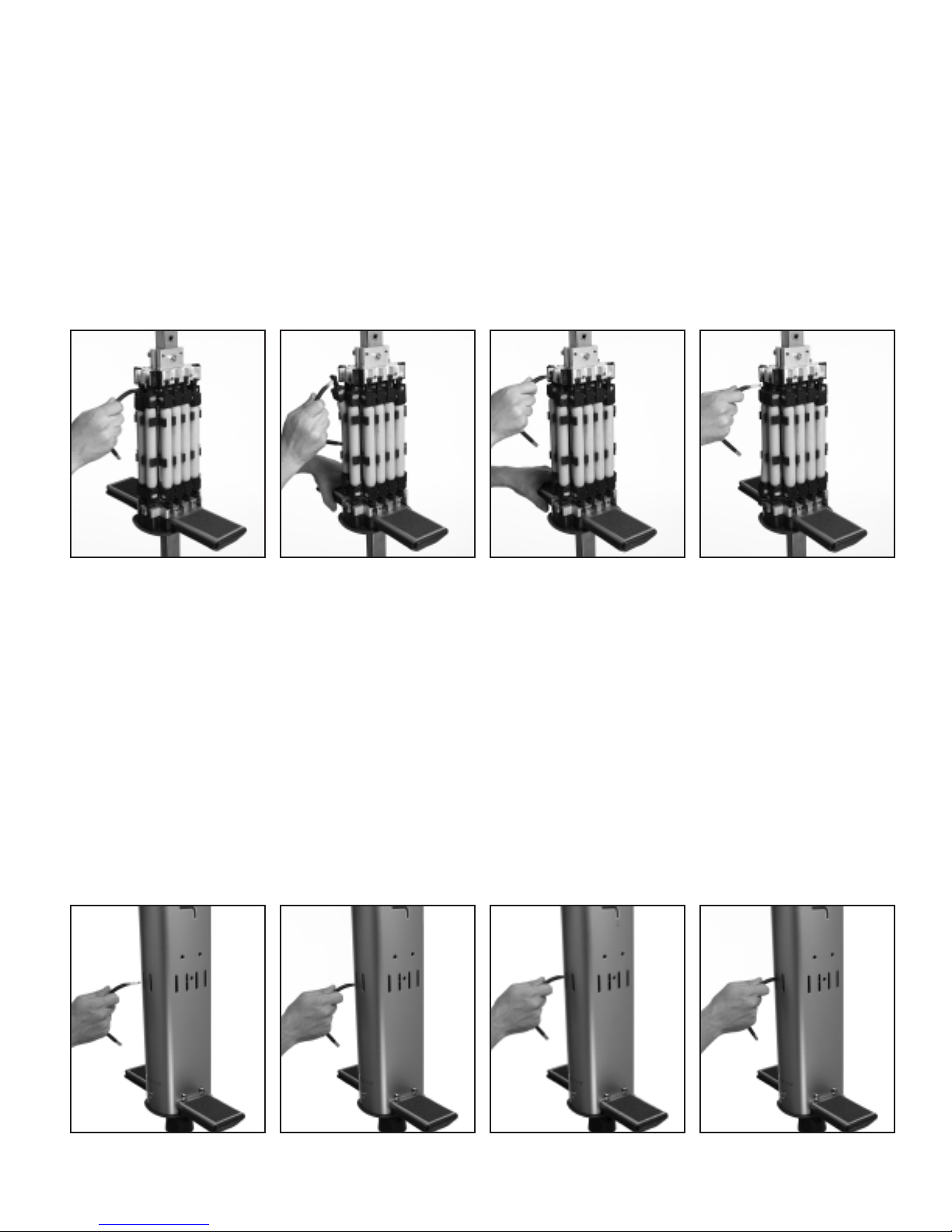

Use the end of the Flybar Tool marked “A” to loosen:

1: the locking screw (the one in the middle). Note: When loosened enough to disengage from the

piston, the head of this screw will project into the hole in the shell, preventing use of the Flybar.

2: the two screws that secure the friction clamp (the ones on the sides). Loosen these just

enough to permit the piston to slide freely (less than one complete turn); then, as you adjust the piston extension, you should hear a click each time

the spring-loaded locator pin (visible in the upper mount) snaps into one of the nine holes that determine piston-length. If the clamp screws are

loosened too much the locator feature will not work.

Note: Only the nine settings, which permit the locking screw to engage a piston

adjustment hole, can be used; otherwise, the Flybar 1200 will not be safe to use.

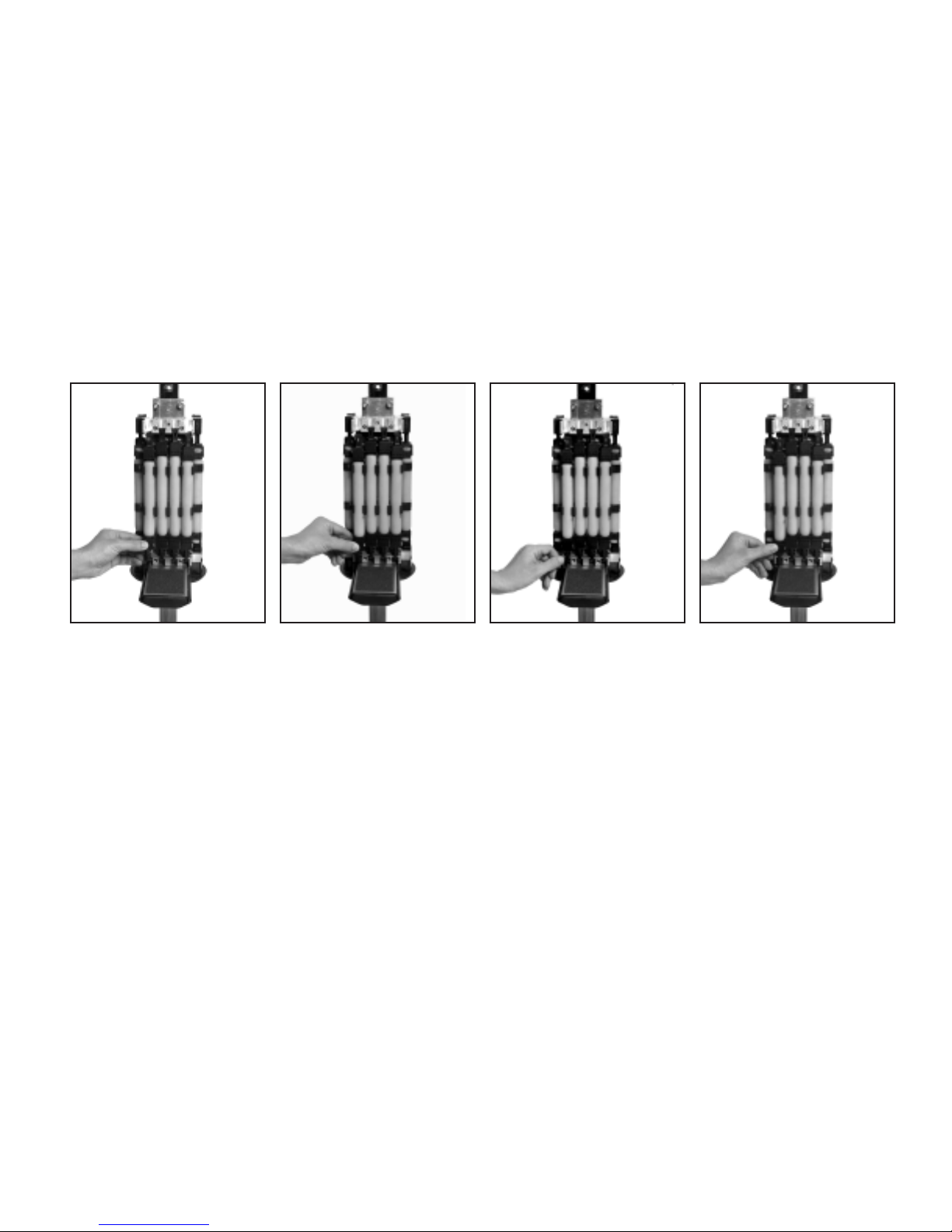

Once you’ve chosen a piston length—and heard the spring-loaded mechanism click into place—you need to secure the piston by tightening:

1: the locking screw. If properly located at a piston hole, it will screw in easily until its head is well clear of the Flybar shell. Do not force the screw:

if it does not screw in easily, adjust the piston position slightly to find a hole.

2: the two clamp screws. These should be tightened firmly, to a torque of at least 3 foot-pounds.

We really can’t stress how important it is to tighten both these devices, as directed.

It is not safe to use the clamp without the locking pin, and vice versa.

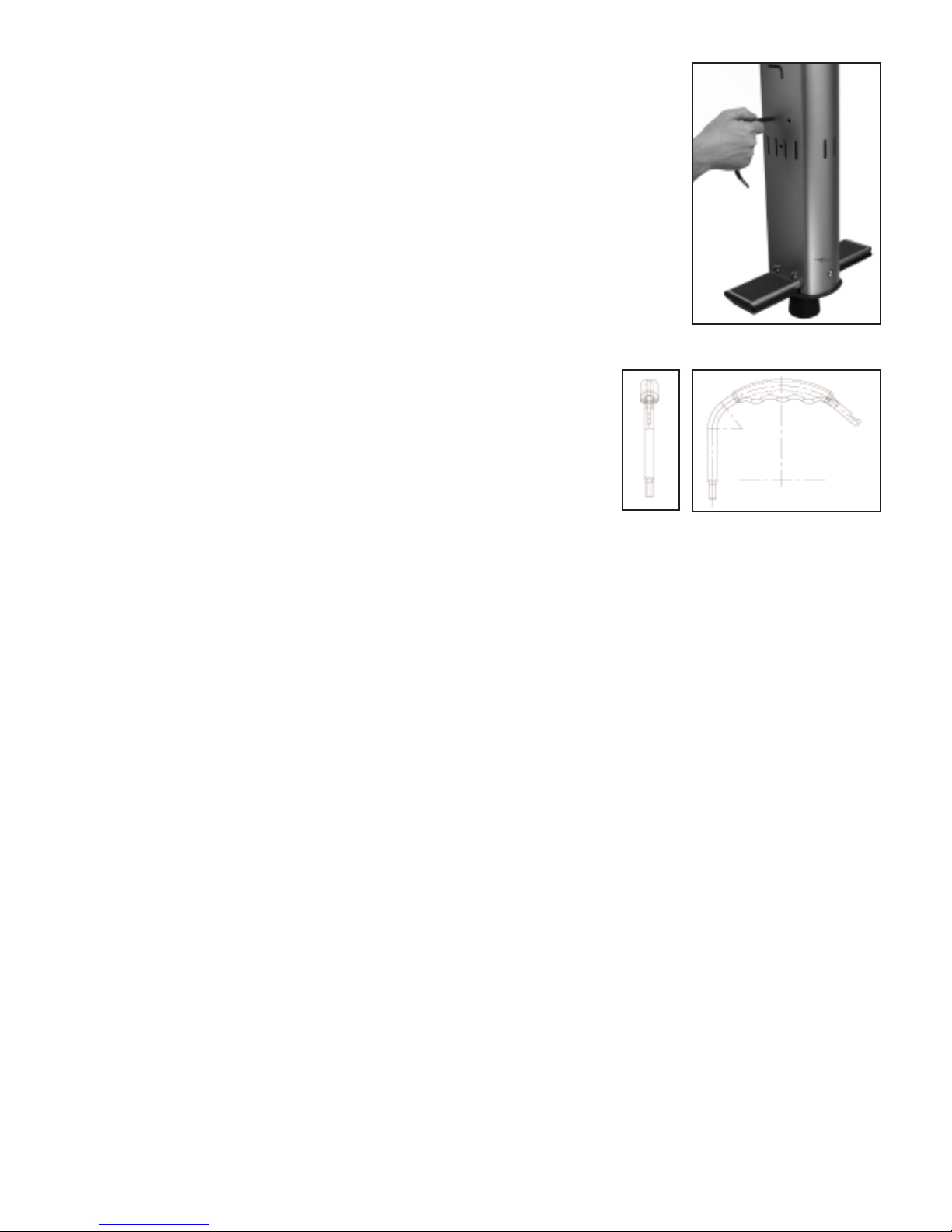

Note: The Flybar 1200’s shell has been designed with round access holes on one side to allow experienced users to adjust piston length even

when the shell is in place. First-time users, however, should definitely perform the operation with the shell off. When replacing the outer shell of

the Flybar 1200, make sure to have the piston adjustment access bolt heads facing the corresponding access holes in the outer shell.

How to Adjust the Handlebars

While most of you should be fine using the Flybar as it comes out of the box, shorter users may find it more comfortable if they invert the position

of the handlebars—which lowers them by 2.5”. Use the “A” end of your Flybar tool to loosen the four screws set deep into the cap. (A couple of

turns should suffice.) Then twist the handlebars down and retighten.

MAINTENANCE

It’s important to examine your Flybar 1200’s mechanism periodically to check that all its parts are in good working order. First, remove the shell by

unscrewing the six screws around the base, and sliding it off.