FLYGT JA-112-S5-3085-460 Maintenance manual

1

Installation, care and maintenance

Jet aerator

894263/04

2

CONTENTS

Safety ________________________ 2

Guarantee ___________________________ 3

Data plate interpretation ___________ 4

Components of standard

Jet aerator unit _________________ 4

Product description ________________ 5

General __________________________________ 5

Technicaldata ____________________________ 5

Materials _________________________________ 5

Applications ______________________________ 5

Transportation and storage ________ 6

Installation ___________________ 7

Safetyprecautions _________________________ 7

Handling equipment ________________________ 7

Generalrecommendations ___________________ 7

Assembling Jet aerator units on site ___________ 7

Sharpened support feet _____________________ 8

Installation in tank _________________________ 8

Operation ____________________________ 9

Beforestart-up ____________________________ 9

Starting jerk ______________________________ 9

Electrical connection _______________ 9

Care and maintenance _____________ 10

Inspections _______________________________ 10

Accessories and tools ______________ 11

Drawings ____________________ 12

NOTE This “Installation, care and maintenance” for the Jet aerator must always be used together with the

“Installation, care and maintenance” for the pump type.

General danger:

Safety instructions in this

manual, which could cause

danger to life if not observed,

have been specifically

highlighted with this general

danger symbol.

Identification of safety and warning symbols

SAFETY

High voltage:

The presence of a dangerous

voltage is identified with this

safety symbol.

WARNING! Non-observance to this warning

could damage the unit or affect

its function.

Pump Ejector Inst Sw. P/N Sales code 50 Hz Sales code 60 Hz

3085 MT JA-112 S 688 48 00 JA-112-S5-3085-460 JA-112-S6-3085-462

3102 MT JA-112 S 688 65 00 JA-112-S5-3102-460 JA-112-S6-3102-463

3127 MT JA-117 S 688 50 00 JA-117-S5-3127-437 JA-117-S6-3127-438

3153 MT JA-117 S 688 47 20 JA-117-S5-3153-432 JA-117-S6-3153-435

3171 MT JA-117 S 688 46 20 JA-117-S5-3171-433 JA-117-S6-3171-435

3202 MT JA-217 S 688 58 20 JA-217-S5-3202-434 JA-217-S6-3202-641

3202 LT JA-317 S 688 57 20 JA-317-S5-3202-610 JA-317-S6-3202-614

3301 MT JA-417 S 688 56 20 JA-417-S5-3301-620 JA-417-S6-3301-624

3085 MT JA-112 P 688 53 00 JA-112-P5-3085-460 JA-112-P6-3085-462

3102 MT JA-112 P 688 66 00 JA-112-P5-3102-460 JA-112-P6-3102-463

3127 MT JA-117 P 688 54 00 JA-117-P5-3127-437 JA-117-P6-3127-438

3153 MT JA-117 P 688 59 20 JA-117-P5-3153-432 JA-117-P6-3153-435

3171 MT JA-117 P 688 60 20 JA-117-P5-3171-433 JA-117-P6-3171-435

3202 MT JA-217 P 688 61 20 JA-217-P5-3202-434 JA-217-P6-3202-641

3202 LT JA-317 P 688 62 20 JA-317-P5-3202-610 JA-317-P6-3202-614

3301 LT JA-417 P 688 51 20 JA-417-P5-3301-620 JA-417-P6-3301-624

3

Conditions of guarantee

Flygt pumps are quality products designed for a long

period of reliable service. Should any complaints be-

Flygt undertakes to remedy faults in products sold by

Flygt provided:

— that the fault is due to defects in design, materials or

workmanship;

— that the fault is reported to Flygt or Flygt’s represen-

tative during the guarantee period;

— that the product is used only under conditions de-

scribed in the care and maintenance instructions and

in applications for which it is intended;

— that the monitoring equipment incorporated in the

product is correctly connected;

— that all service and repair work is done by a work-

shop authorized by Flygt;

— that genuine Flygt parts are used.

Hence, the guarantee does not cover faults caused by

deficient maintenance, improper installation, incorrectly

executed repair work or normal wear and tear.

Flygt assumes no liability for bodily injuries, material dam-

ages or economic losses beyond what is stated above.

GUARANTEE

Official approval applies only providing:

—that the product is used under condition

described in the care and maintenance

instructions and in applications for which

it is intended;

—that the monitoring equipment incorporated

in the product is correctly connected;

—that all service and repair work is done by

a workshop authorized by Flygt;

—that genuine Flygt parts are used.

come necessary during the guarantee period, please

contact the nearest Flygt representative.

In addition to the standard conditions of guarantee, it

should be noted that the units are supplied in assembly

kit form and that it is the installer’s responsibility to

check the proper tightening of all the bolts (use the

torques indicated in the section on “Installation”).

NOTES FOR EX-PRODUCTS

Flygt guarantees that a spare parts stock will be kept

for 15 years after the manufacture of this product has

been discontinued.

The manufacturer reserves the right to alter perfor-

mance, specification or design without notice.

— Only Ex-approved pumps may be used in an explo-

sive or flammable environment.

— Do not open the pump when an explosive gas atmo-

sphere may be present.

— Before starting work on the pump, make sure that

the pump and the control panel are isolated from

the power supply and can not be energized. This

applies to the control circuit as well.

— All mechanical work on the explosion-proof motor

section must be performed by personnel authorized

by Flygt.

— Electrical connection on the explosion-proof motor

must be made by authorized personnel.

— Thermal contacts must be connected to a protec-

tion circuit intended for that purpose according to

the approval of the product.

— The pump may be used only in accordance with the

approved motor data stated on the data plates.

— Intrinsically safe circuits are normally required

(Ex i) for the automatic level control system by

level regulator if mounted in zone 0.

— This equipment must be installed in conformity to

international or national standards ( IEC/EN 60079-

14 ).

— The maintenance operation must be made in con-

formity to the international or national standards (

IEC/EN 60079-17).

— The yield stress of fastener elements in the product

must be in conformity with the value specified in the

table for “Material of fastener” on the approval

drawing or the parts specified in the part list for the

product.

— According to the ATEX directive the Ex-pump must

never run dry or snore. For permitted minimum

water level, see dimensional drawing for the pump.

Dry running at service and inspection is only per-

mitted outside the Ex area.

— The user must know about the risks due to the

electrical current and the chemical and physical

characteristics of the gas and/or vapours present in

hazardous areas.

— Flygt disclaims all responsibility for work done by

untrained, unauthorized personnel.

4

Jet aerator Ejector

Type Inst Hz Impeller Rating kW Imp Ejector Qty Nozzle dia. mm

JA -112-S/P5-3085-460 S/P 50 3085 MT 2 460 4812 1 55

JA -112-S/P5-3102-460 S/P 50 3102 MT 3,1 460 4812 1 55

JA -117-S/P5-3127-437 S/P 50 3127 MT 5,9 437 4817 1 95

JA -117-S/P5-3153-432 S/P 50 3153 MT 9 432 4817 1 95

JA -117-S/P5-3171-433 S/P 50 3171 MT 15 433 4817 1 95

JA -217-S/P5-3202-434 S/P 50 3202 MT 22 434 4817 2 95

JA -317-S/P5-3202-610 S/P 50 3202 LT 37 610 4817 3 95

JA -417-S/P5-3301-620 S/P 50 3301LT 55 620 4817 4 95

JA -112-S/P6-3085-462 S/P 60 3085 MT 2,2 462 4812 1 55

JA -112-S/P6-3102-463 S/P 60 3102 MT 3,7 463 4812 1 55

JA -117-S/P6-3127-438 S/P 60 3127 MT 7,5 438 4817 1 95

JA -117-S/P6-3153-435 S/P 60 3153 MT 11,2 435 4817 1 95

JA -117-S/P6-3171-435 S/P 60 3171 MT 18,6 435 4817 1 95

JA -217-S/P6-3202-641 S/P 60 3202 MT 34 641 4817 2 95

JA -317-S/P6-3202-614 S/P 60 3202 LT 45 614 4817 3 95

JA -417-S/P6-3301-624 S/P 60 3301LT 63 624 4817 4 95

DATA PLATE INTERPRETATION

Jet aerator units are not provided with any special data

plate.

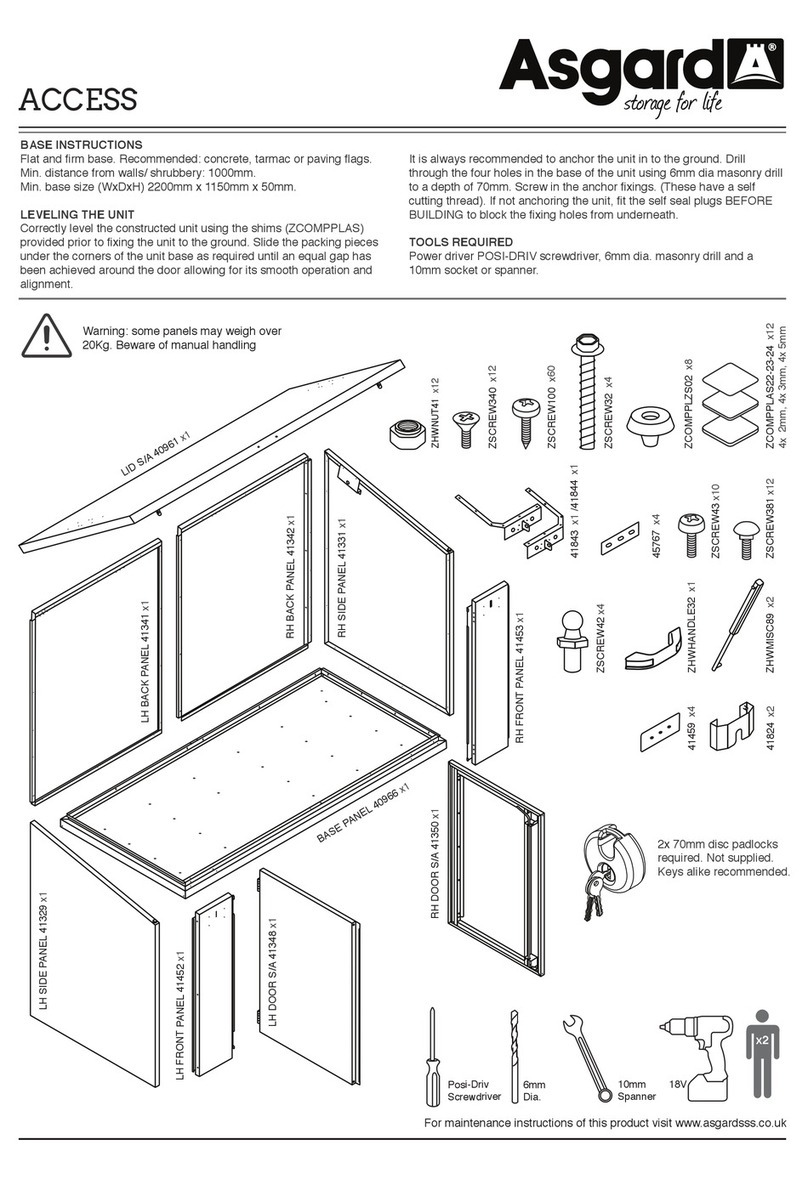

COMPONENTS OF JET AERATOR UNITS

For plate data please refer to the “Installation, care and

maintenance” of the pump that forms part of the Jet

aerator unit.

5

PRODUCT DESCRIPTION

General

This manual provides you with general information on

how to install and maintain your Jet aerator in good

condition for a long time.

The general arrangement drawings of the units (at the

end of the manual), give full particulars of all spare

parts for the auxiliary equipment and the overall dimen-

sions of the self-supporting unit.

The Parts list and the Installation, care and mainte-

nance of the pump that forms part of the Jet aerator

give full technical data of your particular pump.

Technical data

For technical data of your pump, see the Part list and

Installation, care and maintenance.

Flygt self-supporting Jet aerator units are supplied in

assembly kit form because this makes transport easier

and more economical.

Immersion depth for applicable standard unit - see

assembly drawing.

Liquid temperature: maximum 40°C (104 °F).

The pump can only work in full-load conditions if at

least half of the stator housing is covered by the liquid.

Liquid density: maximum 1100 kg/m3(9.2 lb per US

gal).

The pH of the liquid: 5.5 - 14

Depth of immersion: see Technical specification

Air flow data: given at 1 atm. and 20°C (68°F)

Oxygen transfer data: 1 atm, 20°C (68°F) water

temperature and dissolved oxygen content of 0 mg O2/l.

Material

Material of the pump, see the “Installation care and

maintenance” of the pump. (For pump type see page 2).

Inlet and delivery pipes hot-dip galvanised carbon steel

or stainless steel

Ejector body stainless steel/cast iron

Nozzle PE

Diffuser pipe stainless steel AISI304

Screw stainless steel AISI304

Applications

The general instructions in this manual refer to Flygt

submersible pumps.

If you have purchased an explosion proof pump (Ex,

see data plate or spare parts list), follow the special

instructions included in the pump’s “Installation, care

and maintenance” manual.

On the basis of the hydraulic portion, the Jet aerator

unit has been designed to aerate activated sludge

processes with dry solids (DS) content up to 3%. For

installations in aerated stabilisation processes, please

contact your Flygt representative.

Jet aerator units cannot be used in highly corrosive

liquids. pH limits, see chapter “Technical data”.

The aeration unit is self-supporting and does not need

to be fixed to the tank bottom. A large barycentric

handle formed on the inlet pipe makes the unit easy to

retrieve by means of any lifting gear hook of suitable

capacity.

Jet aerator version S

Self supporting, S is the installation system recom-

mended by Flygt. The oxygenation unit is placed on the

bottom of the tank without the need for any kind of

ancoring device. The configuration of the equipment

has been specially designed to ensure that no move-

ment will occur even under the most adverse operating

conditions. When necessary the system can be in-

stalled without emtpying the tank.

Jet aerator version S

6

— In some installations and working

points of the pumps, the noise

level of 70 dB, or the level speci-

fied for each pump, may be ex-

ceeded.

Jet aerator version P

Jet aerator version P

This system provides an automatic connecting foot

fixed to the base of the tank, with the ejector mounted

on it. The pump is then lowered along the guide bars

and automatically connected to the foot. A simple jib

crane is used to raise or lower the pump alone. P in-

stallation is recommended for large size units, where

moving the pump is more practical than moving the

entire Jet aerator unit.

TRANSPORTATION AND STORAGE

WARNING!

— Always lift the machine by the

lifting device, never by the

motor cable.

The pump may be transported and stored in a vertical

or horizontal position. Make sure that the pump cannot

roll or fall over.

flame to thaw the pump. The pump must be run for a

short period after being taken up in order to expel all

remaining water.

For longer periods of storage, the pump must be pro-

tected against moisture and heat. The impeller should

be rotated by hand occasionally (for example every

other month) to prevent the shaft seals from sticking

together. If the pump is stored for more than 6 months,

this rotation is mandatory.

After a long period of storage, the pump should be

inspected before it is put into operation. Pay special

attention to the shaft seal and the cable entry.

Follow the instructions under the heading "Before start-

ing".

The pump is frostproof as long as it is operating or is

immersed. If the pump is hoisted from the sump when

the temperature is below the freezing point, the impeller

and shaft seal may freeze.

A frozen impeller and shaft seal can be thawed by

allowing the pump to stand immersed in the liquid for a

short period before it is started. Never use a naked

7

INSTALLATION

Safety precautions

In order to minimize the risk of accidents in connection

with the service and installation work, the following

rules should be followed:

1. Never work alone. Use a lifting harness, a safety

line and a respirator, as required. Do not ignore the

risk of drowning!

2. Make sure that there is sufficient oxygen and that

there are no poisonous gases present.

3. Check the explosion risk before welding or using

electric hand tools.

4. Do not ignore health hazards. Observe strict clean-

liness.

5. Bear in mind the risk of electrical accidents.

6. Make sure that the lifting equipment is in good

condition.

7. Provide a suitable barrier around the work area, for

example a guard rail.

8. Make sure that you have a clear path of retreat!

9. Use a safety helmet, safety goggles and protective

shoes/gloves.

10. All personnel who work with sewage systems

should be vaccinated against diseases that can

occur.

11. A first-aid kit must be handy.

12. Note that special rules apply to installation in

explosive athmosphere.

Follow all other health and safety rules and local

codes and practices.

Handling equipment

Suitable handling equipment is required to make it easy

to move a Jet aerator unit.

The minimum height between the lifting hook and the

ground must be sufficient to be able to extract the Jet

aerator unit from the tank.

The handling equipment must be suitable for extracting

the pump and lowering it into the sump without having

to repeat the operation.

Overdimensioned handling equipment might cause

damage to the unit.

Make sure that the handling equipment is securely

attached.

Assembling Jet aerator units on site

The various parts should be assembled as indicated in

the general arrangement drawing, using the screws

supplied and applying the tightening torques listed

below – do not forget the flexible washers!

Recommended torque for screws

Screw size Recommended torque (Nm)

M8 17

M10 33

M12 57

M16 140

M20 273

M24 472

General recommendations

For correct installation, see the overall dimensions in

the general arrangement drawing at the end of the

manual.

Check the horizontal positioning of the units according

to the assembly or working drawing.

Units should be installed in such a way that the pri-

mary air and water jet propagates quite freely in water

without meeting obstacles or side walls and that the

direction of flow created does not conflict with flows of

other mixers or Jet aerators installed.

IMPORTANT! The end of the cable may not be sub-

merged. The starting equipment should be firmly fixed

above the maximum liquid level, since water might

make its way, via the cable, into the terminal box or

the motor.

— Keep well away from suspended

loads.

— Use the appropriate handle for

lifting the unit.

— Check that the lifting handle is in

good condition.

Special recommendations: operation in winter

conditions may make a protective hood over the filter

necessary, to prevent ice formation.

8

Position of the support feet

Regulating nut

Installation in tank

If installing in an empty tank, clean any debris or

coarse solid matter out of the sump before putting the

pump unit into operation.

The extension pipe is provided with a holed plate for

retrieving and raising the unit and with three fixing

points at 120° to allow anchoring to the walls by stain-

less steel ropes if necessary (e.g. if the plane on which

the unit rests is uneven or the unit has to deal with

filamentary and coarse solids).

Use a support grip unit and cable holders for suspend-

ing the power cables.

For the suspension of cables we recommend using a

support grip unit, which must be attached to the hole

on top of the suction pipe.

Cables should be kept taut to prevent any possibility of

their being sucked in by the machine.

The horizontal portion of the cable may be tied to the

stainless steel rope mentioned above.

Make sure that cables are not bent or squeezed in

such a way as to be liable to break or wear out.

Installation in full tank

The Jet aerator unit can be installed in a full tank: the

positions of the support feet have been designed to

enable the unit to sit naturally after a short period of

operation.

Sharpened support feet

The sharpened support feet provided sink 1-2 cm into

the tank bottom, ensuring stability of the unit even in

the event of repeated start-ups or persistent vibration

conditions.

If the tank bottom slopes or is very uneven, the bearing

tips need adjusting to provide better seating.

If the tank bottom is even, the lower adjusting nut can

be eliminated.

IMPORTANT! Use the torques required (see “Recom-

mended torque for screws”) to tighten the nut and upper

locknut.

For lined tank or tank made of steel, vibration damping

supports have to be used.

Levelling must be carried out in the same way as indi-

cated for standard sharpened support feet.

For details - see assembly drawing.

9

Before start-up

Check that all visible parts of the pump and of the

installation are undamaged and in good condition.

Check the oil level in the pump.

Remove the fuses or open the master switch and

check that the rotor runs freely when turned by hand.

Check the operation of any monitoring devices incorpo-

rated.

Check the direction of rotation.

The rotor should rotate clockwise as seen from above.

When starting up, the pump will recoil in the opposite

direction to that in which the impeller rotates.

If the direction of rotation is wrong, reverse two phases.

OPERATION

— Watch out for the starting jerk,

which be very powerful.

— Check that the power supply is

disconnected and that the pump

cannot start up again, not even

accidentally, before commencing

any work on it.

Follow carefully the instructions in the manual of the

Flygt submersible pump that forms part of the Jet aera-

tor unit.

ELECTRICAL CONNECTION

— Watch out for the return jet from

the inlet pipe when the machine

stops.

Starting jerk

— In some installations the surface of

the pump and the surrounding

liquid may be very hot.

— Bear in mind the risk of scalding.

— Make sure that the pump cannot

overturn or fall and thereby cause

injury to persons or damage to

property. Make sure that there is no ice on the inlet filter when

starting up.

10

When working on the pump, observe carefully the fol-

lowing precautions:

— make sure that the pump has been drained and

properly flushed with clean water.

— rinse the various components after disassembling

them.

— observe good standards of personal hygiene.

— bear in mind the risk of infections.

— follow the local safety rules.

The pump is intended for use in liquids that may be

harmful to your health. To prevent any harm to eyes and

skin, observe the following rules when working on the

pump:

— always use protective goggles and rubber gloves.

— hold a rag over the oil casing screw when removing it.

Otherwise, pressure that may have built up in the

pump due to leakage of liquid into the pump may

cause splatter into the eyes or onto the skin.

Follow the following procedure if harmful chemicals

come into contact:

with your eyes:

— rinse immediately with running water for 15 minutes,

keeping the eyelids wide open

— contact an oculist

with your skin:

— remove contaminated clothing

— wash the skin with soap and water

— if necessary, consult a doctor.

CARE AND MAINTENANCE

— Make sure that the machine (or

parts of the machine) can't roll

or fall over and injure people or

damage property.

— Check that the power supply is

disconnected and that the pump

cannot start up again, not even

accidentally, before commencing

any work on it.

This also applies to the control

circuit.

NOTE! Flygt does not assume any liability in the event

of such work being done by unauthorised persons.

Inspection

Periodic checks and preventive maintenance mean

more reliable operation over time.

The pump should be inspected at least once a year if it

runs intermittently, andat the intervals indicated below

if it runs continuously in conditions of normal difficulty.

If the conditions are particularly demanding, intensify

the number of inspections.

Interval between inspections and overhaul.

For details regarding service and inspection check

appropriate pump Installation, care and maintainence

manual.

Jet aerator Oil inspect. General

hours overhaul

JA-112-S/P5-3085-460 4000 1-2 year

JA-112-S/P5-3102-460 4000 1-2 year

JA-117-S/P5-3127-437 4000 1-2 year

JA-117-S/P5-3153-432 8000 1-2 year

JA-117-S/P5-3171-433 8000 2-3 year

JA-217-S/P5-3202-434 8000 2-3 year

JA-317-S/P5-3202-610 8000 2-3 year

JA-417-S/P5-3301-620 8000 2-3 year

JA-112-S/P6-3085-462 4000 1-2 year

JA-112-S/P6-3102-463 4000 1-2 year

JA-117-S/P6-3127-438 4000 1-2 year

JA-117-S/P6-3153-435 8000 2-3 year

JA-117-S/P6-3171-435 8000 2-3 year

JA-217-S/P6-3202-641 8000 2-3 year

JA-317-S/P6-3202-614 8000 2-3 year

JA-417-S/P6-3301-624 8000 2-3 year

P- or S-installation

These overhauls require special tools and should be

done in a Flygt workshop.

When the pump is new or the seals have been re-

placed, an inspection after the first week of operation is

recommended.

IMPORTANT! Periodic inspection of the handle and

the fixing elements between the pump and the pipes is

very important.

11

Control and monitoring boards

Suitable control boards for each Jet aerator unit are

available from Flygt.

Contact Flygt for further information.

Inlet pipes

Are part of the set of standard Jet aerator accessories

and are suitable for 3.5 m (11.4 feet) or 5 m (16.4 feet)

immersion depth in normal applications without si-

lencer.

The pipes are provided with a holed plate for retrieval

purposes and with hooks for suspension of the electric

power cable and possible securing to walls by three

stainless steel ropes at mutual spacing of 120°.

End sections

Made of hot-dip galvanised steel for use of protective

basket to exclude leaves. Silencers are available as an

alternative to end sections.

Basket filters to exclude leaves

Made of galvanised perforated sheet steel and capable

of being fitted to the upper end of the end section or of

the silencer.

Silencers

To reduce the noise level from 72-82 dBAat 1 m to

about 60 dBAat 1 m (3.3 feet) where this is necessary.

Vibration damping supports

To be applied to the stands in the case of lined or steel

tanks.

Tools

No particular tools are necessary other than the normal

ones of specialized workshops and those provided for

the electric pump that forms part of the Jet aerator

unit.

For further information on tools available, consult Flygt.

Supplementary information

- List of fixing elements and small parts you will find

on the dimensional drawings at the end of the

manual.

ACCESSORIES AND TOOLS

12

Spare parts are only available on special request!

JA 112-XY-3085-460/462 X = S or P installation

Y = 50 or 60 Hz

13

Spare parts are only available on special request!

JA 112-XY-3085-460/462 X = S or P installation

Y = 50 or 60 Hz

14

Spare parts are only available on special request!

JA 112-XY-3102-460/463 X = S or P installation

Y = 50 Hz or 60 Hz

15

Spare parts are only available on special request!

JA 112-XY-3102-460/463 X = S or P installation

Y = 50 Hz or 60 Hz

16

Spare parts are only available on special request!

JA 117-XY-3127-437/438 X = S or P installation

Y = 50 or 60 Hz

17

Spare parts are only available on special request!

JA 117-XY-3127-437/438 X = S or P installation

Y = 50 or 60 Hz

18

Spare parts are only available on special request!

JA 117-XY-3153-432/435 X = S or P installation

Y = 50 or 60 Hz

19

Spare parts are only available on special request!

JA 117-XY-3153-432/435 X = S or P installation

Y = 50 or 60 Hz

20

Spare parts are only available on special request!

JA 117-XY-3171-433/435 X = S or P installation

Y = 50 or 60 Hz

This manual suits for next models

31

Table of contents