FMC Technologies Sening EPE2 User manual

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Issue / Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

Sening® Innovative Tank Truck Systems

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

ii von iv Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

ii

Further documentation on this product:

Description Order no.

GMVT 805 operating and installation instructions DOK-397E

EPE2-Controller for Meter Draining System

Service Instructions DOK-512E

History

Revision

Date

Editor

Status

Description

Rev. 1.00 February 2006 JS

Release

Basic edition

Rev. 1.01 August 2006 JP Release - new formatting / illustrations

- editorial changes

Rev. 1.02 April 2009 / JS / jp / Release

Minor changes:

- Table 1: DIP switch S1 settings

- Figure 4: Connection label in the device cover

- Drawing 61.351684 / - Drawing 61.351994

- Chapter: special service settings removed

- Appendix: “HyperTerminal“ terminal program settings

removed

Rev. 1.03 March 2010 / JS / jp / Release

Minor changes:

- Figure 5: Connection label in the device cover

- DIP switch S1 settings (from MID version 3.50)

- Figure 3: Schematic structure “Stand-Alone“

- Figure 4: Schematic structure “with MultiFlow”

- Chapter 3.1.1 Text corrections

- New Chapter 3.7 “Parameters in the MultiFlow”

- New Chapter 3.8 “Diagnose in the MultiFlow”

Important note

All explanations and technical details given in this documentation have been produced and

edited by the author with the greatest care. However the possibility of errors cannot be com-

pletely eliminated. We are always very grateful for notification of any errors found.

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 iii of iv

Contents

1General.......................................................................................................................5

1.1 Orientation aids for the manual ...........................................................................5

1.2 Device description ................................................................................................6

1.3 Schematic Structure of GMVT 805 “Stand-Alone residue discharge“ .............7

1.3.1 “Stand-Alone residue discharge“ function................................................................... 8

1.4 Schematic Structure of GMVT 805 “MultiFlow residue discharge“..................9

1.4.1 “MultiFlow residue discharge“ function ..................................................................... 10

2General installation instructions............................................................................ 11

2.1 Preventive measures .......................................................................................... 11

2.1.1 For preventing accidents (caused by ignition of gases) ............................................ 11

2.1.2 To meet the requirements stipulated by standards ................................................... 11

2.1.3 To ensure trouble-free operation .............................................................................. 11

2.1.4 To make the job of the service personnel easier ...................................................... 12

2.2 Maintenance ........................................................................................................ 12

3Commissioning ....................................................................................................... 13

3.1 Adaptation of the operating mode..................................................................... 13

3.1.1 Operating modes...................................................................................................... 14

3.1.1.1 “Stand-Alone residue discharge“ mode ...................................................... 14

3.1.1.2 “MultiFlow residue discharge“ mode........................................................... 14

3.2 Switching outputs in “Stand-Alone residue discharge“ operation ................ 15

3.2.1 Switching output of the solenoid valve for the control air .......................................... 15

3.2.2 Power Out switching output for the flow computer.................................................... 15

3.3 Switching outputs for “MultiFlow residue discharge“ operation ................... 16

3.4 Setting the sensor type ...................................................................................... 16

3.4.1 Setting the sensor switching logic............................................................................. 17

3.5 Further tips for commissioning ......................................................................... 17

3.6 Components overview........................................................................................ 18

3.6.1 Control board REC-1S ............................................................................................. 18

3.6.2 EPE2-Controller Internal overview............................................................................ 18

3.7 Parameters in MultiFflow.................................................................................... 19

3.7.1 Residue removal control with MultiFlow ................................................................... 20

3.8 Diagnosis in MultiFlow ....................................................................................... 22

3.8.1 Inputs and Outputs................................................................................................... 22

3.8.2 CAN Bus .................................................................................................................. 24

3.8.2.1 Testing Links .............................................................................................. 24

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

iv of iv Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

3.8.3 EPE2 ........................................................................................................................25

3.8.4 IO interface...............................................................................................................26

3.8.5 Sensor interface .......................................................................................................27

4Residue discharge function description ...............................................................29

5Display of the operating states ..............................................................................31

6EPE2-Controller Technical data .............................................................................33

7Warranty and Service..............................................................................................35

8Address and contact details...................................................................................37

9Indexes .....................................................................................................................39

9.1 Keyword index.....................................................................................................39

9.2 Table of Figures ..................................................................................................40

9.3 Index of Tables ....................................................................................................40

Anhang A. Drawings and Approvals........................................................................41

Drawings ......................................................................................................................42

E51.351677 - Control unit residue discharge (REC-1)............................................................42

E61.351684 - EPE2 connection to residue discharge (Stand-Alone) - Standard..................... 43

E61.351994 - EPE2 connection to residue discharge (with MultiFlow) ...................................44

Approvals .....................................................................................................................45

EC - Declaration of Conformity...............................................................................................45

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 5

1 General

1.1 Orientation aids for the manual

This manual contains a variety of information. For that you can easily find the required subjects we

have designed some orientation aids for this manual.

•Pictograms

The information in this manual extends from mandatory safety measures and default val-

ues to concrete handling steps and well-intended advice. This information is identified with

suitable pictograms in the left margin to enable better distinction in context.

The following pictograms are used in this manual:

Danger sign. Here: Danger of explosions caused by easily flammable gases and liquids.

Working step. Concrete action statements, e.g. “Press the <Enter>-key”

Positive response message, e.g. “The main menu now appears ”

Negative response message, e.g. “If a fault message appears now...”

Note, Short tip, e.g. “See more detailed information in Chapter XX”

Option, Special Case

Functional Description

NOTE: indicates a special situation.

ATTENTION: particular attention is to be paid.

•The key word register at the end of the documentation enables easier location of theme

areas.

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

6 Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

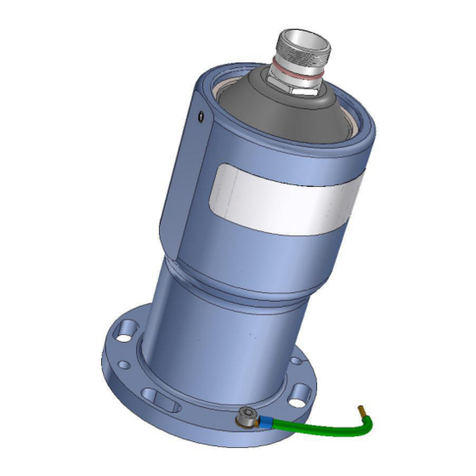

1.2 Device description

The EPE2-Controller (Elektronik Pneumatische Entrestung, type 2) are used for monitoring

the residue discharge of GMVT 805 measuring systems.

The control electronics is designed

for two operating modes. In the

“Stand-Alone residue discharge“

mode the electronics work autono-

mously and during product change

switch off the control air and, time de-

layed, the supply voltage of the flow

computer, using a solenoid valve

(12V, Type MVS1-E11-12).

In the “Restentleerung mit Multi-

Flow (MultiFlow residue discharge)“

mode the SeningTM MultiFlow controls

the residue discharge. The solenoid

valve in the control air can then be omitted. For this purpose the CAN bus connection to the

MultiFlow truck computer is prepared.

The “Stand-Alone residue discharge“ or „MultiFlow residue discharge“ modes are set via

a DIP switch S1 on the REC-1S printed circuit board (see also Figure 6 / page 18).

The EPE2-Controller consists of a

sealed SVC-2S power supply unit

and an REC-1S control board. The

use of the device is limited to prod-

ucts of hazard class AIII, whereby in-

stallation in zone II is permitted. (see

chapter 3.6 “Components overview” /

page 18).

The operating status of the EPE2-

Controller is displayed by a yellow

(power) and a green (status) LED.

(see chapter 5 “Display of the operat-

ing states” / page 31).

The cover can be sealed to prevent manipulation.

If the EPE2-Controller are used as a replacement of the previous EPE controls, then the sole-

noid valve is to be replaced with the one mentioned above (due to different control voltage).

Figure 2: EPE2 Internal overview

Figure 1: EPE2

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 7

1.3 Schematic Structure of GMVT 805 “Stand-Alone residue discharge“

Figure 3: Schematic structure of the device for discharging and refilling

“Stand-Alone residue discharge“

The GMVT 805 with residue discharge system was only

conceived for flow

measurement of combustible liquids of Hazard Class AIII on tank trucks.

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

8 Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

1.3.1 “Stand-Alone residue discharge“ function

The Illustrated EPE2-Controller [11] is fitted with an isolation circuit amplifier and a time relay

and connected as per the electric circuit diagram drawing no. E61.351684 / page 43.

The input circuit (signal from initiator [20]) is monitored for broken wire and short circuit. An

error in the input circuit causes blocking of the output (signal to flow computer electronic me-

ter [12] and to the 3/2-way solenoid valve [21]). The electronic meter [12] is used together

with a mechanical measuring chamber for temperature compensated delivery of mineral oil

products.

The above mentioned time relay is required that fluctuations of the liquid level in the sensing

element causing measurement interruptions (closing of the shut-off valve) deactivate the

elec. meter (interruption of the power supply) not until a delay of at least 8-10 s. The reactiva-

tion of the elec. meter takes place without delay, as well as the interruption of the power sup-

ply to the above 3/2-way solenoid valve [21] and its reactivation.

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 9

1.4 Schematic Structure of GMVT 805 “MultiFlow residue discharge“

Figure 4: Schematic structure of the device for discharging and refilling

“MultiFlow residue discharge“

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

10 Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

1.4.1 “MultiFlow residue discharge“ function

Alternatively for control the type approved MultiFlow electronic meter in connection with the

EPE2-Controller can be used. The wiring is made as per the electric circuit diagram drawing

no. E61.351994 / page 44.

The EPE2-Controller is connected via a data bus directly with the MultiFlow electronic meter

[12]. The electronic MultiFlow meter takes over all control functions as per the EPE2. Hence

the 3/2-way solenoid valve [21] of the switching devices is no longer needed.

If the type approved MultiFlow electronic meter together with the EPE2-Controller is used for

control, the 3/2-way solenoid valve [21] for the electric switching device is no longer needed.

For the supply of residual discharge components with compressed air, can be used a sole-

noid valve [22] (DN8 / actuator spring-to-open) or an optional manually operated ball valve.

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 11

2 General installation instructions

In addition to the following points listed, you also have to follow all relevant regulations such as

VDE 0165 during set-up, operation and maintenance. Only when the following recommendations

are followed we can guarantee long and trouble-free operation.

2.1 Preventive measures

2.1.1 For preventing accidents (caused by ignition of gases)

Explosive protection ordinances are to be followed!

The EPE2-Controller are NOT

suitable for use in explosive areas. However

installation of the device in Zone II is permitted.

2.1.2 To meet the requirements stipulated by standards

•The wiring must be carried out according to the circuit diagrams supplied. The colours of the

wires correspond to DIN 47100. Please follow the colour codes strictly.

•The electrical installation must be carried out according to EN 60079-14; VDE 0165.

•No additional components must be added to the EPE2 housing, since this would void the de-

vice approval.

2.1.3 To ensure trouble-free operation

•Disconnect the power supply during welding on the vehicle.

•Always mount the cable entries facing to the side or downwards, to avoid water from pene-

trating the housing.

•Unused PG screw joints should be sealed on the device using waterproof sealing plugs.

•Protect the terminal- and electronic housings as well as the plugs against direct water spray

(e.g. from the tyres).

•Install all cables so that they cannot get damaged or kinked.

•Fit all wires with end sleeves.

•All electric connections are made using screw clamping technology. The are to be fed into

the housing through the PG-screw joints provided according to their respective cross section.

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

12 Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

If wires have to be trimmed, no cable residues must be allowed to fall into the open unit. This

could cause short circuits on the printed circuit board.

There must never be any connection between the housing/shield and the 0V terminal. Oth-

erwise functional errors can occur.

•Install the solenoid valve upright, i. e. the magnetic coil must point upwards.

2.1.4 To make the job of the service personnel easier

•Install the junction boxes such that they are easily accessible.

•Even the electronic housings should be installed such that they are easily accessible.

•Cables without plug-in connectors may be shortened.

•Slightly lubricate the fixing bolts of the covers prior to installation (e.g. copper paste, graphite

grease). This prevents the screws from corroding and ensures that you can loosen them after

prolonged operation.

2.2 Maintenance

The EPE2-Controller for Meter Draining System are maintenance free. The device must not be

modified mechanically or electronically in any way.

During cleaning with a steam cleaner or with pressurised water, the device should be pro-

tected from the water jet. Never aim the steam jet directly onto the device!

§ We won’t accept liability for any damage caused by water invasion in the equipment caused

by improper cleaning.

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 13

3 Commissioning

The EPE2-Controller is factory set so that no adjustments are required rafter installation. Just the

operating mode, switching logic and the sensor type have to be checked and adapted if necessary.

3.1 Adaptation of the operating mode

•A difference is made between the “Stand-Alone residue discharge“ and “MultiFlow residue

discharge“.

•Both operating modes as well as other settings are made via the DIP switch S1 on the REC-1S

printed circuit board (see also Figure 6 / page 18).

The DIP switch S1 settings are shown in the following table.

DIP switch S1

on the REC-1S board

MultiFlow residue discharge

(from MID version 5.00)

1 = ON – With MultiFlow

2 = OFF – No Tes t

3 = ON – Only channel 2

4 = OFF – Reserved

5 = ON |

6 = OFF | CAN-Bus

7 = ON | address = 5

8 = OFF |

DIP switch S1

on the REC-1S board Stand-Alone

1 = OFF – Stand-Alone

2 = OFF – No Tes t

3 = ON – Only channel 2

4 = OFF – Reserved

5 = x |

6 = x | CAN-Bus

7 = x | address = xx

8 = x |

Table 1: DIP switch S1 settings

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

14 Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

3.1.1 Operating modes

The EPE2-Controller are designed for two operating modes.

•In both operating modes the residue discharge switch or sensor is connected with the sensor

input J3 on the REC-1S control board.

(see also drawing no. 61.351684 / page 43 and 61.351994 / page 44)

•The sensor or switch type has to be adjusted as described in paragraph 3.4 / page 16.

3.1.1.1 “Stand-Alone residue discharge“ mode

REC-1S printed circuit board DIP switch S1-1: OFF

•In this operating mode there are 2 switching outputs available.

•The switching output “2“ controls the solenoid valve in the main air feed.

•The “Power Out“ switching output, switches the supply voltage for the flow computer meter

electronics.

•The flow chart of the residue discharge and an exact functional description can be found in

chapter 0 / page 19.

CAN Bus termination resistors

SVC-2S printed circuit board DIP switch S1-1: OFF (termination resistors ON)

•The switch has no effect on function in this operating mode. The selected switch setting is

thus arbitrary.

3.1.1.2 “MultiFlow residue discharge“ mode

REC-1S printed circuit board DIP switch S1-1: ON

•In this operating mode control of the main air is made via the SeningTM MultiFlow. The meter

electronics needs not to be switched separately.

•The “Power Out“ switching output is not switched in this operating mode and can thus be

used optionally otherwise.

•In this case the DIP switch S1-2 on the power supply printed circuit board SVC-2S is to be

set to the “ON“ position.

CAN Bus termination resistors

If the EPE2-Controller is used together with the MultiFlow in a CAN Bus network and operated as

the last device on the Bus, then the termination resistors are to be switched ON.

SVC-2S printed circuit board DIP switch S1-1: OFF (termination resistors ON)

•To activate the termination resistors the DIP switch S1-1 on the power supply board SVC-2S

is to be placed in the “OFF“ position.

•This is only necessary when the EPE2-Controller is the last device in a CAN Bus network !

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 15

Figure 5: Connection label in the device cover

3.2 Switching outputs in “Stand-Alone residue discharge“ operation

The EPE2-Controller switching device activates the 24 Volt supply of the electronic truck computer.

The level in the metering system is monitored by the attached sensor. An additional solenoid valve

that interrupts the main air supply of the metering system is connected.

3.2.1 Switching output of the solenoid valve for the control air

•The control air is switched off immediately after product shortage is detected.

•The output is designed for the operation of solenoid valves with 12 volt control voltage with a

max. current of 430 mA (order no. MVS1-E11-12).

3.2.2 Power Out switching output for the flow computer

•This output is for controlling the flow computer.

•The deactivation of the output and hence the switching off of the supply voltage of the meter

electronics (flow computer) is time delayed (typically 8 secs ).

•The switching output is designed for a max. switching current of 8 A at 24V supply voltage.

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

16 Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

3.3 Switching outputs for “MultiFlow residue discharge“ operation

During operation of „MultiFlow residue discharge“ none of the EPE2 outputs are switched. The

switching information is transferred via the CAN Bus to the MultiFlow, which then takes over the

control.

When setting the “MultiFlow residue discharge “ the DIP switch S1-

2 on the

power supply board SVC-2S always has to be set into the “ON

“ position. Hence

other optional devices can be powered by the flow computer 24V (out) connec-

tion.

3.4 Setting the sensor type

The EPE2-Controller supports 3 types of sensors. The selected switch or sensor is connected to

the J3 input on the REC-1S control board.

The setting has to be made before commissioning via the jumpers Jp4 and Jp5 on the

REC-1S printed circuit board, listed in the following table.

The 3 sensor types have to be supplied with different voltages. This adjustment is made with the

two jumpers as displayed in the table:

Sensor type

Short circuit

interruption detec-

tion

Jumper

Jp4

Jumper

Jp5

Parame-

ter 2

(via PC or

Laptop)

**

*

1 Sensor with Namur output YES 2-3 inserted 1 ◄

2 optoelectronic sensors (NS2) YES 1-2 removed 2

3 mechanical switch NO 1-2 inserted 3

*: Factory or reset settings.

Table 2: Sensor type settings

The proximity switches are Namur set in the factory.

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 17

3.4.1 Setting the sensor switching logic

REC-1S printed circuit board DIP switch S1-3: ON / OFF

•The switching logic of the connected sensor is defined with this DIP switch (see Figure 6 /

page 18). It can be set whether the switch is an NO contact (in active state switch is closed)

or NC contact (in active state switch is open). The DIP switch is factory set to ON = “0“ ac-

tive.

If an inverted function of the switching signal is required, then the DIP switch S1-3 has to be

placed in the opposite position.

3.5 Further tips for commissioning

•For the commissioning of the residue discharge it may be helpful, if the switching output is

continually switched, independent of the input signals.

•For this the DIP switch S1-2 on the power supply printed circuit board SVC-2S is to be set to

the “ON“ position. The supply voltage (24 volts) is thus always through-connected to the flow

computer connection.

•If the “Stand-Alone residue discharge “ is to be activated, then the DIP switch S1-2 (SVC-

2S) has to be placed in the “OFF“ position. Now the supply voltage for the flow computer

connection is switched according to the input state.

•If a PC or Laptop is available, then the relay can also be switched via the service function.

(see also chapter in DOK-512E).

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

18 Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

3.6 Components overview

3.6.1 Control board REC-1S

Figure 6: Control board REC-1S

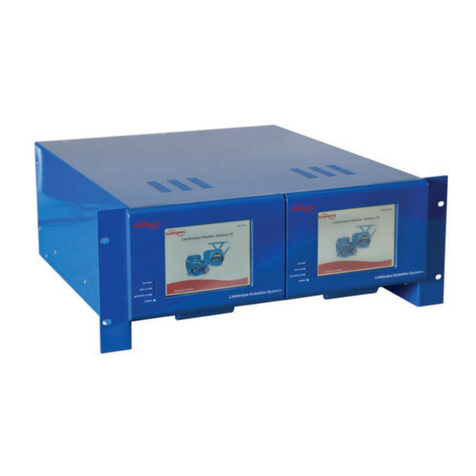

3.6.2 EPE2-Controller Internal overview

SVC-2S power supply board REC-1S control board

SVC-2S

DIP switch S1

SVC-1S

DIP switch S1

JP4

JP5

J1 solenoid valve

connection

J3 sensor connection

J6 PC or Laptop

Figure 7: EPE2-Controller Internal overview

J3 sensor

connection

Sening®

Innovative Tank Truck Systems

EPE2-

Controller for Meter Draining System

EPE2

Installation Manual

MN F08 003 US / DOK-450E Rev. 1.03 / JS / jp / March 2010 19

3.7 Parameters in MultiFflow

No. Name Seal K Factory

Setting Meaning

3.1.6.8

EPE2

(from version 5.00)

3.1.6.8.1

Use of EPE2

M

2

0 (no)

Activation of EPE2 required for optional

residue discharge

3.1.6.8.2

EPE2 node

M

2

5

Node number of EPE2 when activated

3.1.6.8.3

EPE2 interval

M

2

600ms

EPE2 request interval. Used to trigger

EPE2 inactivity monitor.

3.1.8.5

Draining

3.1.8.5.1

Drain control

M

2

0 (no)

(up to version 5.00)

Activates an instruction for residue removal

in the event of product change.

3.1.8.5.2

Receipt draining

M

2

0 (no)

(up to version 5.00)

Parameter currently not in use. In a future

program version will activate printout of a

receipt after residue removal.

3.1.8.5.1

Residue removal

control

M

2

1

(from version 5.00)

1 : Off

2: Stand-alone

Activates an instruction for residue removal

in the event of product change.

3: EPE2 manual

As 2, however the wet leg sensor con-

nected to the EPE2 monitors the residue

removal. No restart of MultiFlow required

after residue removal.

4: EPE2 automatic

As 3, however "Autom. residue removal"

menu item (menu 8) includes the option to

control a pump for the measuring system

residue removal via the EPE2 output.

3.1.8.5.2

Residue removal

timeout

M

2

0 (no)

(from version 5.00)

Timeout for the autom. draining of the

measuring system with the aid of the EPE2

in "EPE2 automatic" mode. Residue re-

moval stops automatically after this period.

3.1.8.5.3

Residue removal

receipt

M

2

0 (no)

(from version 5.00)

Parameter currently not in use. In a future

program version will activate printout of a

receipt after residue removal.

EPE2-Controller for Meter Draining System

EPE2

Installation Manual

Sening®

Innovative Tank Truck Systems

20 Rev. 1.03 / JS / jp / March 2010 MN F08 003 US / DOK-450E

3.7.1 Residue removal control with MultiFlow

The following description is relevant only for program versions from

5.00 (approval according to MID).

The measuring system residue removal message can be switched on and off with Parameter

3.1.8.5.1. In addition Parameter 3.1.8.5.2 has already been implemented which in a future

version will activate the printing out of a document concerning successful residue removal.

If parameter 3.1.8.5.1 (residue removal control)

is set to “2”, this causes the following new oper-

ating sequence:

After entering all the preset values and pressing

the <START> key again, the MultiFlow checks

whether a product change has taken place be-

tween diesel and heating oil / heating oil with ad-

ditives. If this has happened a corresponding

message is shown about the necessary residue

removal:

If residue removal has not been carried out the

driver must press the <F2>k ey.

A corresponding entry is then made in the log-

book and the display shows the following infor-

mation:

The MultiFlow remains in this operating state un-

til it is switched off, i.e. it will not react to key en-

tries (e.g. >START< , >STOP< etc.).

Control resid.

Selection: 31851

1 Off

2 Stand- a lone

3 EPE2- m anua l

4 EPE2- a utomatic

Forward Back ---

Drop pre-set

-------------------

Produkt no: >11<

EL heating oil

Amount: 1000000

Price per 100

with VAT € 87,65

Product change !

Has residue removal

been carried out?

P

no: 11

Yes N o ---

Please

carry out

residue removal

--- --- ---

Table of contents

Other FMC Technologies Controllers manuals

Popular Controllers manuals by other brands

Art Andersen CPH

Art Andersen CPH AACPH-RC1-EU manual

Graco

Graco Series A instructions

Oden Control

Oden Control P30 user guide

Flowserve

Flowserve LMENIM5001-02 Installation and operation maintenance

Resol

Resol DeltaTherm HC MAX Manual for the specialised craftsman

Trox Technik

Trox Technik RN Installation operation & maintenance