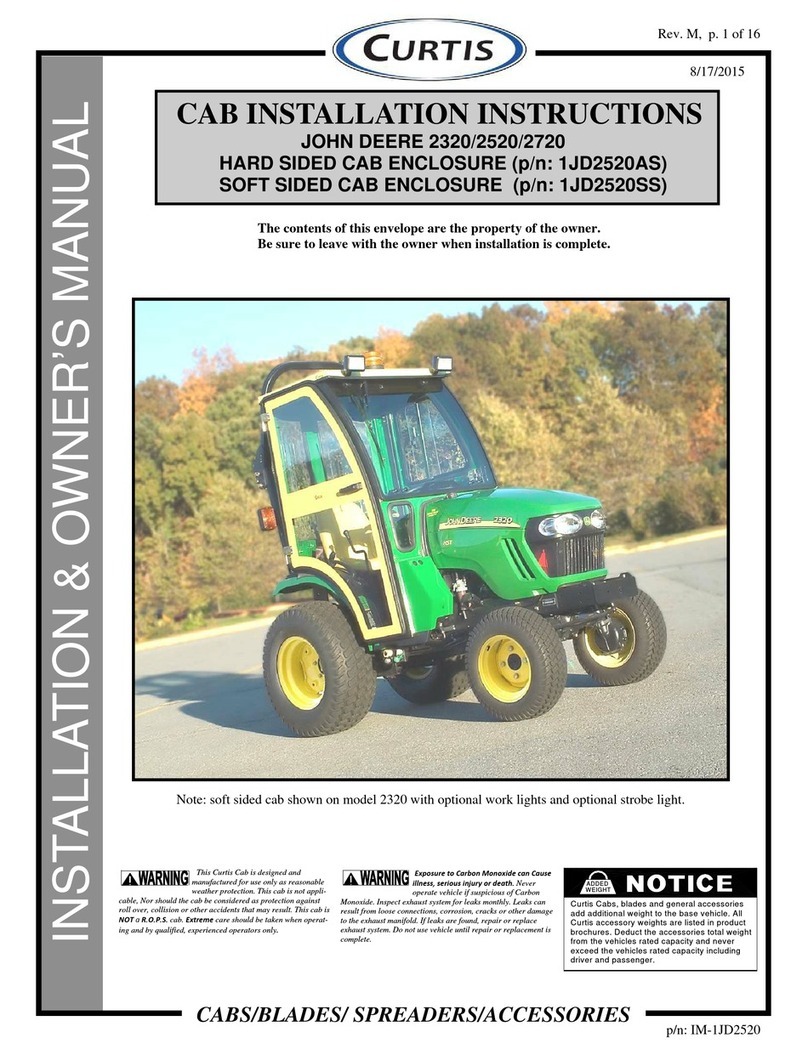

FMC Bolens 18318 Guide

HFWIC

\

Botens

\

SnowThrower

Attachment

38

Inch

Safety

and

Operation

Instructions

Model

18311-03

Thru-05

With

PTO

Attachments

Model

18309-04

Thru-05

Model

18318

.<#»

El—

.-•*!.•.._

FORM

552884-6(3/80)

SUPERSEDES

552884-5

Thank

you

for

purchasing

this

piece

ofFMC

Bolens

equipment-

We

feel

younowownoneofthe

finest

pieces

of

equipment

*

available.

This

isa

safety,

operation

and

general

maintenancemanualwhich

does

not

attempt

to

cover

major

repairs.

FMC

Bolens

equip-

ment

is

carefully

designed,

engineered,

and

manufactured

to

give

goodperformance

if

properly

operated

and

maintained.

Review

this

manual

to

familiarize

yourself

with

the

unit,

its

features

andits

operation.

This

equipment

isa

pfoduct

ofFMC

Corporation,

Outdoor

Power

Equipment

Division,

215

South

Park

Street,PortWashington,

Wisconsin,

53074,

telephone

414-284-5521.

Ifyou

should

have

any

questions

or

encounter

any

problems,which

you

feel

only

the

factory

can

solve,

write

tothe

above

address

or

phone,attention

the

Service

Department.

All

BOLENS

snow

throwers

have

passed

rigid

safety

standards

ofthe

Outdoor

Power

Equipment

Institute

andan

independent

testing

laboratory.

YourWarrantyStatement

is

included,under

separate

cover

with

this

manual.

Please

read

it

carefully.Also,

please

return

the

completed

postpaidowner

registration

card

which

is

included

with

this

manual.

The

purpose

of

thiscard

isto

register

each

unit

and

owner

atthe

factory

for

safety

purposes.

GENERAL

SAFETY

PRECAUTIONS

CAUTION

Preventing

accidents

is

the

responsibility

of

every

equipmentoperator.

The

follow-

ing

general

safetyprecautionsmust

be

fullyunderstood

and

followed

by

every

operator

of

thisequipment.

Review

them

\

frequently

and

never

takechances.

Be

careful

before,

during

and

right

after

use

of

any

poweredequipment.Accidents

*

can

be

prevented.

TRAINING

1.

Read

the

operating

and

service

in-

structionmanual

carefully.

Be

thor-

oughly

familiar

with

the

controls

andthe

proper

useof

thfrequipment.

Know

how

to

stop

the

unit

and

disengage

the

con-

trols

quickly.

2

2.

Never

allow

children

to

operate

the

equipment.

Never

anow

adutts

to

operate

the

equipment

without

properinstruction.

3.

Keep

the

area

of

operation

clear

of

all

persons,

parbajlarty

small

children,

and

pets.

4.

*a

n

n

to

avoid

slipping

or

(aerating

in

re-

PREPA

RATION

1.

Thoroughly

inspect

the

area

where

the

equipment

istobe

used

and

remove

all

doormats,

sleds,

boards,

wire

and

other

foreign

objects.

2.

Disengage

all

clutches

and

shift

into

neutral

beforestarting

the

engine

(motor).

3.Donot

operate

the

equipment

with-

out

wearing

adequate

winter

outer

gar-

ments.

Wear

footwear

which

will

im-

prove

footing

on

slippery

surfaces.

4.

Handle

fuel

with

care;

itis

highly

flammable.

(a)

Usean

approved

fuelcontainer.

(b)

Never

add

fuel

toa

running

engine

or

hot

engine.

(c)

Fill

fuel

tankoutdoors

with

extreme

care.

Never

fill

fueltankindoors.

(d)

Replace

gasoline

cap

securely

and

wipe

up

spilled

fuel.

5.

Adjust

the

collector

housing

height

to

clear

gravel

or

crushed

rock

surfaces.

6.

Never

attempt

to

make

any

adjust-

ments

while

the

engine

(motor)

is

running

(except

where

specifically

recommended

by

manufacturer).

^B

7.Let

engine

(motor)

and

machine

ad-

just

to

outdoor

temperatures

beforestart-

ing

to

clear

snow.

\

•FMC

GENERAL

SAFETY

PRECAUTIONS

(continued)

OPERATION

1.

Donotput

hands

or

feet

near

or

underrotatingparts.Keepclear

ofthe

discharge

opening

atall

times.

2.

Exercise

extremecautionwhenoper-

ating

onor

crossing

gravel

drives,

walks,

or

roads.Stayalert

for

hidden

hazards

or

traffic.

Donot

carry

passengers.

3.

Afterstriking

a

foreignobject,stop

the

engine(motor),

remove

the

wirefrom

the

spark

plug,

thoroughly

inspect

the

snow

thrower

forany

damage,

andre-

pair

the

damagebeforerestarting

andop-

erating

the

snowthrower.

4.Ifthe

unit

shouldstart

to

vibrate

ab-

normally,stop

the

engine

(motor)

and

checkimmediately

forthe

cause.

Vibra-

tion

is

generally

a

warning

of

trouble.

5.

Stop

the

engine(motor)

whenever

you

leave

the

operating

position,

before

unclogging

the

collector/impellerhousing

or

discharge

guide,

and

whenmaking

any

repairs,

adjustments,

or

inspections.

6.

Take

all

possible

precautionswhen

leaving

the

vehicleunattended.

Disengage

the

power

take-off,

lower

the

attachment,

shift

into

neutral,

setthe

parkingbrake,

stop

the

engine,

and

remove

the

key.

make

certain

the

collector/impeller

and

all

moving

parts

have

stopped.Discon-

nect

the

sparkplugwire,

and

keep

the

wire

away

from

the

plug

to

prevent

acci-

dental

starting.

8.Donotrunthe

engineindoors,

ex-

ceptwhenstarting

the

engine

andfor

transporting

the

snow

thrower

inorout

ofthe

building.

Open

the

outsidedoors;

exhaust

fumes

are

dangerous.

9.Donot

clear

snow

across

the

face

of

slopes.

Exercise

extremecautionwhen

changing

direction

on

slopes.

Donotat-

tempt

to

clear

steep

slopes.

10.

Never

operate

the

snowthrower

with-

out

properguards,plates,

or

other

safety

protective

devices

in

place.

11.

Never

operate

the

snowthrower

near

glass

enclosures,

automobiles,

window

wells,

drop-offs,

etc.

without

proper

ad-

justment

ofthe

snow

discharge

angle.

Keep

children

and

petsaway.

12.

Donot

overload

the

machine

capa-

city

by

attempting

to

clear

snow

attoo

fast

a

rate.

13.

Never

operate

the

machine

at

high

transport

speeds

on

slippery

surfaces.

Use

care

whenbacking.

7.

When

clean

ing,repair

ing

or

inspecting,

14.

Never

directdischarge

at

bystanders

or

allowanyone

in

front

ofthe

unit.

15.

Disengage

power

tothe

collector/

impeller

whensnowthrower

is

trans-

ported

ornotin

use.

16.Use

only

attachments

and

accessories

approved

bythe

manufacturer

of

snow

thrower

(such

as

wheelweights,counter-

weights,

etc.)

17.

Never

operate

the

snowthrower

with-

out

goodvisibility

or

light.

MAINTENANCE

AND

STORAGE

1.

Check

shear

bolts,engine

mounting

bolts,

etc.,

at

frequentintervals

for

proper

tightness

tobe

sure

the

equipment

isin

safe

working

condition.

2.

Never

store

the

machine

with

fuel

in

the

fueltankinside

a

buildingwhereopen

flame

or

sparks

are

present.

Allow

theen-

gine

to

coolbeforestoring

inanyen-

closure.

3.

Always

refer

to

owner'sguide

instructions

for

important

details

ifthe

snowthrower

istobe

stored

foranex-

tended

period.

4.Runthe

machine

a few

minutes

after

throwingsnow

to

preventfreeze-up

ofthe

collector/impeller.

IDENTIFICATION

NUMBERS

I

—-

To

ensure

prompt

service

whenrepairs

or

adjustments

are

required,

your

FMC

Bolens

Dealer

must

have

the

following

information.

For

your

own

personal

reference,

fill

inthe

serial

number

spaces

provided

below.

The

Model

Number

and

SerialNumber

are

ona

nameplateattached

tothe

attachments.

ModelNumber

of

Unit

(A}_

Serial

Number

of

Unit

{B)_

Date

of

Purchase

Your

FMC

Bolens

Dealer

has

available

a

Parts

List

for

your

Unit.

Hecan

identify

any

parts

youmay

require

and

furnish

genuine

factoryreplacements.

CAUTION

WE

URGEUSINGONLYGENUINE

FMC

BOLENSFACTORY

REPLACE-

MENTPARTS,WHICHMEET

ALLOF

THE

LATESTSAFETYREQUIRE-

MENTS.REPLACEMENTPARTS

MANUFACTURED

BY

OTHERS

COULDPRESENTSAFETY

HAZARDS

EVENTHOUGHTHEY

MAYFITON

FMC

BOLENSPRODUCTS.

ASSEMBLY

These

attachments

are

shippedcomplete

with

all

parts

and

hardware

necessary

to

installattachments

tothe

tractor.

Before

installingyourSnowThrower

a

Model

18309

or

18318

PTO

attachment

must

be

installed.

Have

your

Bolens

Dealer

order

the

correct

model

that

fits

your

tractor.

ATTACHMENTDRIVE

INSTALLATION

{MODEL

18318)

Remove

rear

nut

(A)

Figure

2

securing

the

left

side

engine

mount.

Positionangle

bracket

(B)

over

the

screw

and

secure

with

thenut

just

removed.

Secure

PTO

casting

to

front

axle

support

using

4

3/8-16

locknutssupplied.

Ifnot

already

in

place,

assemble

lower

drive

sheave

(C).Hookspring

(D)to

angle

bracket.

Fig.

2

"A"

If

lower

sheave

isnotin

line

with

electric

clutch

sheave

remove

the

drivebelt

and

Position

the

drive

belt

up

over

the

electricadjust

thePTO

casting

inthe

mounting

slots

eitherforward

or

backward.

Secure

the

casting

and

reassemble

the

drive

belt.

clutch

sheave.

With

one

hand

relieve

the

tension

onthe

beltidler

and

with

the

otherhand,position

the

belt

around

the

attachmentdrive

sheave

(D).Position

the PTO

cover

between

the

front

axle

arms

and

secure

with

four

clevis

pins

and

springpins(E).

When

the

mower

is

going

tobe

used

and

the

mower

PTO

installedonly

thePTO

guard,

belt

and

drive

sheave

need

be

removed.

•FMC

ASSEMBLY(continued)

ATTACHMENT

DRIVE

INSTALLATION

(MODEL

18309)

Position

round

rod"A"

Figure

2 inthe

inside

ofthe

frame

ifnot

alreay

there.

On

Model

18309-04

turn

handknobs

"B"

with

star

washer

supplied

into

round

rod.

On

18309-05

andup

thread

thehex

head

screw

"B"

with

starwasher

into

the

round

rod.Screw

on

lock

nut

provided

to

keep

eitherhand

knob

or

screw

from

backing out.

Hook

slots

ofPTO

attachmentdriveover

clevis

pins

inthe

front,support.

Position

either

hand

knob

orhex

screw

with

star

washer

into

slot

of

bracket,

see

Figure

2,

and

tighten.

Push

down

onPTO

shaft

while

tightening.

This

will

provideproper

engagement

of

attachment.

Take

a

measurement

from

the

front

crossmember

ofthe

frame

tothe

engine

sheave.

See

Figure

3.

If

this

measurement

is

3/4"

(19

mm),

the

drive

belt

canbe

installed.

Ifitis

more,

remove

one

washer

at

point

(D)for

every1/16"(1-1/2mm).

Ifitis

less

than

3/4"

(19

mm),

addone

or

both

ofthe

extra

washers

included

to

line

upthetwo

sheaves.

To

reach

washers

(D),

loosen

thetwo

locking

collars

on

thePTO

shaft,

and

slide

the

shaftout.

After

final

installation,

thePTO

sheave

should

notbe

able

to

slide

around

onthe

PTO

shaft,

tfso,

reposition

thePTO

shaft.

To

assemble

drive

belt,

loosenscrew

(C)

on

sheave

guard.

Lift

guard

upand

swing

down.

See

Figure

2.

Position

the

drive

belt

up

over

the

electric

clutch

sheave

(D)

Figure

3.

With

one

handrelieve

the

tension

onthe

belt

idler

and

with

the

otherhand,

position

the

belt

around

the

attachmentdrive

sheave

(E)

Figures.

18309-05

and

up

Fig.

2

Reposition

sheave

guard

and

tighten

screw

(C).

SNOW

THROWERASSEMBLY

Position

hitch

into

the

rear

ofthe

rotor

housing

with

the

hitch

brackets

up.See

(A)

Figures

4 and5.

Secure

with

four

3/8-16

x 1

flangelock

capscrews

and

3/8-16

flange

lock

nuts'(B).

Secure

gear

box

support

to

hitch

with

two

3/8-16

x 1"

carriage

bolts,

lock

washers

and

lock

nuts(BB)Figure

5.

Align

keyway

in

universal

joint

(C)

with

woodruff

keyin

gear

case

shaft.

Slide

universal

joint

onto

shaft

of

snow

thrower

gear

box

until

endof

shaft

is

flush

with

inside

of

universalyoke.

Securely

tighten

thetwoset

screws

in

the

universal

joint.

Fig.

3

ASSEMBLY

(continued)

Fig.

4

"B"

Fig.

5

1

•FMC

ASSEMBLY

(continued)

Position

the

hitch

brackets

ofthe

hitch

assembly

into

the

attachment

hitch

bracket

ofthe

tractor.

See(A)

figure

7.

Align

the

mounting

holes

and

secure

with

1/2x

1-1/16

clevis

pinand

spring

cotter.

See

(B)and(C)

figure

7.

Install

universal

joint

(C)

figure

6

onto

universal

drive

shaft

of

snow

thrower.

Depress

lockcollar

(D)

figure

6 of

uni-

versal

joint.

Align

universal

with

splined

shaft

of

attachment

drive.

Slide

universal

joint

onto

shaft

until

collar

locks

in

lock-

ing

groove.

Loosen

locknut

{E}

figures

4 and7 on

lift

tube.

Adjust

lift

tube

toan

approxi-

mate

length

of

26-1/8inch

(N)

figure

5

from

center

of

clevis

pin

hole

to

center

of

clevis

pinat

back

of

slot.

Donot

tighten

locknut

at

thistime.

To

lift

snow

thrower

higher

lengthen

lift

tubelength.

Todig

snow

thrower

deeper

shortentubelength.

Position

slotted

endof

lift

tube

(A)

figure

8

into

tractor

lift

arms

(B)

figure

8.

Align

slot

of

lift

tubewith

upper

hole

in

lift

arms

and

secure

with

1/2

x

2-1/4

clevis

pinand

spring

cotter.

See

{C)

figure

8.

Position

adjustable

end

into

arms

on

rear

of

hitch.

See(F)

figure.4

and7.

Align

holes

and

secure

with

1/2

x

2-1/4

clevis

pinand

spring

cotter

(G)

figures

4 and7.

Securely

block

snow

thrower

upata

height

of6 to9

inches.

(15.2

to

22.8cm)

Itis

best

tousetwo

blocks,

one

under

each

side

of

auger

housing.

Install

spring

anchor

(A}

figure

9

onto

front

of

tractor

frame.Secure

with

two

5/16-18

x 5/8

fiange

hex

head

capscrews

and

5/16-18

locknuts

and

lockwashers.

See

(B)

figure

9.

:

"B

Fig.

7

ASSEMBLY(continued)

Place

short

eye-bolt

(H}

figure

4

into

bracket.Place5/16

flat

washer

onto

eye-

bolt

and

install

5/16-18

hex

locknutonto

eye-bolt.

NOTE

Locknut

must

beruntotheendofthe

thread

onthe

eye-bolt.Make

sure

the

nut

locks

onthe

thread

and

that

some

thread

shows

beyond

the

nut.

Place

threaded

endof

secondeye-bolt

(C)

figure

9

into

thetopofthe

spring

bracket

(D).

Start

5/16-18

hexnut

onto

threaded

endof

eye-bolt(C).Hook

eye

of

eye-boit

(C)

into

springanchor

on

front

of

tractor

frame.Hookspring

(I)

figures

^

and9

into

eye-bolt

(H)

figure

5.

Hookspring

(I)

into

springbracket

(D)

figure

9.

Turn

spring

clockwise

until

nuton

eye-

bolt

(C)

figure

9 istotheendofthe

thread.

For

less

lift

effort

turn

furtherwhich

causes

less

downpressure.

For

more

down

pressure

reducespringlength.

On

tractors

with

a

manual

lift,

fasten

a

5/16-18

x 3/4

bolt

and

locknut

into

the

second

slot

ofthe

lift

quadrant

(A)

figure

10.

Thisstop

forthe

lift

handle

is

needed

to

comply

with

ANSI

safety

code

B71.3

1975.

Remove

the

blocks

fromunder

the

auger

housing

and

lowersnowthrower

tothe

ground.

Place

lift

into

the

lowest

position.

Lift

snowthrowerwith

the

lift

lever

to

its

highestposition.

Measure

fromlowest

point

of

scraper

blade,

see

(J)

figure

5,

tothe

ground.

This

dimension

should

be

a

maximum

of9

inches(22.8cm).

If

adjustment

is

necessary

lowersnow

thrower

tothe

ground.

Remove

clevis

pin

(G)

figures

4 and7.

Turnadjustable

end

into

decrease

andoutto

increase

dimension

at

(J)

figure

5.

After

adjust-

ment

is

achieved,

securely

tighten

nut(E)

figures

4 and7.

\

•FMC

ASSEMBLY

(continued)

Place

one

3/8-16

flange

locknutonto

eye-bolt

(D)

figures

4 and

11

with

the

flange

ofthenut

away

from

the

eye.

Install

eye-bolt

(D)

into

right

side

ofin-

strument

panel

of

tractor,

see

figure

11.

On

hydrostatic

models

usetop

hole

in

panel.

On

gear

drive

use

lowerhole.

Secure

with

second

3/8-16

locknuts

and

lockwashers.

Install

chute

control

crank

(K)

figures

4

and

11

into.eye-bolt

(D).

Place

hooked

end

into

swivel

block

(L)

figures

5 and

11,

and

secure

with

1/8x 3/4

drive

pin.

Slide

chutecontroldirection

disc

with

rubber

grommet

(O)

figure

5,

ontocon-

trol

rod.This

disc

indicates

which

direc-

-

tion

to

turn

control

rodto

operate

chute.

Install

plastic

hand

grip

onto

crank

end

of

chutecontrolrod.

BEFORE

OPERATION

/

The

operatorshouldbecomefamiliar

with

the

BeforeOperation

check

list

in

the

tractorSAFETY

AND

OPERATION

INSTRUCTIONS

and

perform

each

check

prior

to

starting

or

operating

the

FMC

Bolens

tractor

and

snowthrower

attach-

ment.

NOTE

Every

time

that

the

snowthrower

isto

be

used,checkhand

levers

(B)

figure

2.

Make

sure

the

hand

levers

are

tightly

secured.

1.

Visually

check

for

loose

or

missing

nuts,

screws,

and

damagedparts.

Replace

and

tighten

beforestarting.

'

>

2.The

skid

shoes

are

mounted

tothe

lower

side

of

rotor

housing.

The

mount-

ing

holes

inthe

shoes

are

slotted

sothe

snow

thrower

canbe

raised

to

allow

the

scraper

blade

to

clear

most

gravel

or

stone

surfaces

or

lowered

for

cleaning

a

smooth

surface.

These

shoes

are

reversible

for

additional

wear

surface.

Secure

with

3/8-16

x 1

carriage

bolt,flat

washer,

lockwashers

and

locknuts.

.

3.

Adjust

chutedirection

and

deflector

cap

angle

beforestartingsnowthrower.

CAUTION

DONOT

FORCECHUTEBEYOND

ITS

MAXIMUM

TRAVEL

IN

EITHER

DIRECTION.

4.To

helpprevent

snow

from

sticking

spray

the

inside

of

auger-impeller

housing,

discharge

chute,

and

deflector

cap

with

FMC

Bolens

silicone

spray.

NOTE

Itis

recommended

that

a setof

wheel

weights

and

tire

chains

be

installed

for

best

performance.

OPERATION

Read

the

SAFETY

AND

OPERATION

INSTRUCTIONS

for

your

tractor

before

operating

the

snowthrowerattachment.

SNOW

THROWINGTIPS

Check

wind

direction.

Always

throw

the

snow

inthe

same

direction

the

wind

is

blowing.

With

the

wind

blowing

across

your

area

tobe

cleared,startfirst

cutonthe

wind-

ward

side

and

cast

snowdownwind

to

uncleared

area.

In

highwindskeepchute

capsetto

cast

snow

low.

Donot

position

the

discharge

chute

be-

tween

youandthe

wind,

especially

during

turn

arounds.

On

turn

arounds,

turn

with

the

wind.

Adjust

the

chutewhile

turning

to

keep

the

discharge

downwind.

Do

not

direct

the

discharge

into

the

street

or

road.

Itcan

throw

foreign

objects

at

passing

pedestrians

and/or

autos.

Ifthe

snowbank

is

higher

than

the

rotor

housing,move

into

itasfaras

possible,

back

out,knockdown

the

snow

and

blow

itoutonthe

nextapproach.

Before

putting

snowthroweraway,clean

all

the

excess

snow

and

slush

offof

unit

to

prevent

freeze

upof

controls

andthe

chute.

C

10

o

STORAGE

Ifthe

unit

is

stored

in

heatedquarters,

allow

itto

cool

to

outside

temperature

before

operating.This

will

help

to

pre-

ventsnow

from

sticking

tothe

rotor,

rotor

housing,

and

dischargechute.

Be-

forestoring

the

unit

or

allowing

itto

standidle

in

freezingweather,remove

To

helppreventsnow

from.sticking,

snow

from

rotor

as

heavy

icing

could

spray

the

inside.of

the

rotor

housing,

result

in

damagewhen

attempting

tore-

dischargechute

and

deflector

cap

with

start

unit.

Whenstored

fora

long

period

Bolenssiliconespray.

This

silicons

spray

of

time,

coatexposedparts

with

a

light

can

also

be

used

to

lubricate

the

discharge

film

of

grease

to

preventrusting.

chute

pivot.

~

FMC

Bolens

reserves

the

right

to

changespecifications,

add

improvements

or

discontinue

the

manufacture

ofanyofits

equip-

ment

without

notice

or

obligation

to

purchasers

ofits

equipment.

FMC

Bolens'

approval

oftheuseof

attachmentsmanufactured

by

othermanufacturers

is

limited

to

assurance

that

such

use

will

not

void

FMC

Bolenswarranty

ontheFMC

Bolensequipment

to

which

the

alliedmanufacturedattachments

are

adapted.

The

responsibility

forthe

design,performance,

durability,

safety

in

operation,

service

repairavailability,

and

warranty

obligation

re-

main

with

the

alliedmanufacturer.

FMC

Bolensspecificallyexcludes

from

its

warrantyobligation

all

suchalliedmanufactured

attachments.

FMC

Bolenswarranty

will

be

voided

if

unapprovedattachments

are

adapted

touse

with

FMC

Bolens

equipment

andareso

used.

•

_..

w

FMC

Corporation'sobligationunderthiswarranty

is

limited

tothe

repair

or

replacement,

atits

option

byan

authoi

dealer,

ofany

part

found

tobe

defective

in

material

or

workmanship

without

charge

for

parts

and

labor.

In

order

to

obtain

warranty

service,

the

owner

is

responsible

for:

1)

Providingproof

of

purchase

documentation,

ownerregistration

or

copy

of

bill

of

sale.

2)

Informing

any

authorized

Bolens

equipment

dealer

ofthe

defect

and

making,

the

product

available

for

repair.

(Charges

for

pick-up,

delivery

and

service

calls

arenot

covered

by

thiswarranty.)

This

warrantydoes

not

coverdefects,malfunctions

or

failures

caused

by:

1)

Use-of

unauthorized

accessories

or

attachments.

2)

Lack

of

reasonable

and

necessary

maintenance

as

specified

inthe

"Operation

and

Safety

Instructions".

DISCLAIMER

OF

CONSEQUENTIALDAMAGES:

FMC

CORPORATION

DISCLAIMS

ANY

LIABILITY

FOR

CONSEQUENTIALDAM-

AGES

RESULTING

FROM

A

BREACH

OF

THIS

WARRANTY

ORANY

IMPLIED

WARRANTY.

{SOME

EXAMPLES

OF

CONSEQUEN-

TIAL

DAMAGES

ARE,!)

COST

OF

EQUIPMENTRENTAL,

2)

LOSS

OF

INCOME,

AND3)

HIRING

OF

SERVICES

TO

PERFORMTASKS

NORMALLYPERFORMED

BYTHE

EQUIPMENT.}."

LIMITATION

OF

IMPLIEDWARRANTIES:

FMC

CORPORATION

LIMITS

THE

DURATION

OFANY

IMPLIEDWARRANTIES

I'

CLUDING

WITHOUT

LIMITATION,

ANY

IMPLIEDWARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FORA

PARTICULAR

P

POSE

FORA

PERIOD

OFONE

YEAR

(90

DAYS

IF

PRODUCT

IS

PURCHASED

FOR

COMMERCIAL,INSTITUTIONAL,INDUSTRIA1

RENTAL

OR

DEMONSTRATORUSE)

FROM

THE

DATE

OF

SALE.

SOMESTATES

DONOT

ALLOW

THE

EXCLUSION

OR

LIMITATION

OF

CONSEQUENTIALDAMAGES

OR

LIMITATIONS

ONHOW

LONG

AN

IMPLIED

WARRANTYLASTS,

SOTHE

ABOVE

LIMITATIONS

MAYNOT

APPLY

TO

YOU.

Thiswarranty

gives

you

specific

legal

rights,

andyoumay

also

have

otherrightswhich

vary

from

state

to

state.

•FMC

FMC

Corporation

Outdoor

Power

Equipment

Division

Port

Washington,

Wisconsin

53074

,

•

Printed

by

FMC

Corporation

'Outdoor

Power

Equipment

Division

Port

Washington,

Wisconsin

53074

.__—

This manual suits for next models

4

Table of contents