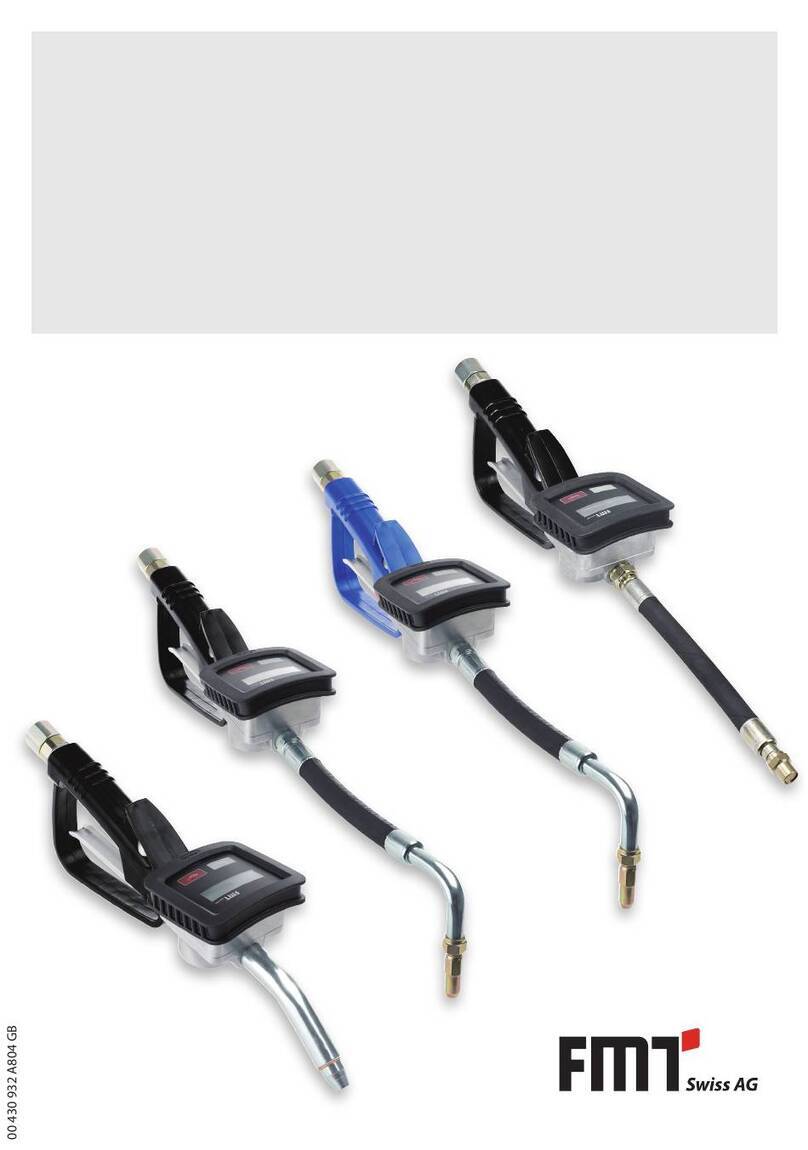

FMT Swiss AG 23295 User manual

83 432 A801 GB

Turbine ow meter

2

GOperating instructions for turbine ow meter

Contents

General details1. ______________________________________________________________________3

Intended use1.1. ________________________________________________________________________3

Design and functional description1.2. ______________________________________________________3

Display LCD1.2.1. _________________________________________________________________________4

User controls1.2.2. ________________________________________________________________________4

Measuring chamber1.2.3. __________________________________________________________________5

Battery compartment1.2.4. _________________________________________________________________5

Technical data1.3. _______________________________________________________________________5

General safety instructions2. ____________________________________________________________6

Information on safety at work2.1. __________________________________________________________6

Signs and symbols used in the safety instructions2.2. __________________________________________6

Hazards when handling the turbine ow meter2.3. ____________________________________________6

Assembly3. ___________________________________________________________________________6

Installation4. _________________________________________________________________________7

Routine operation5. ___________________________________________________________________7

Output of liquid during standard operation (Normal Mode)5.1. __________________________________8

Resetting partial volumes5.1.1. _____________________________________________________________8

Resetting the resettable total volume (RESET TOTAL)5.1.2. ________________________________________9

Output of liquid with display of current ow rate (Flow Rate Mode)5.2. ____________________________9

Resetting partial volumes5.2.1. ____________________________________________________________10

Calibration6. ________________________________________________________________________10

Denition6.1. _________________________________________________________________________10

Why calibrate the meter at all?6.2. ________________________________________________________10

Calibration mode6.3. ___________________________________________________________________11

Displaying the valid calibration factor - resetting the factory calibration factor (if necessary)6.3.1. ______11

Calibration during simulated operation6.3.2. _________________________________________________13

Meter calibration during simulated operation6.3.3. ____________________________________________13

Changing the K FACTOR directly6.3.4. _______________________________________________________15

Conguration of the turbine ow meter7. _________________________________________________17

Service8. ____________________________________________________________________________18

Exchanging batteries8.1. ________________________________________________________________18

Cleaning8.2. __________________________________________________________________________19

Troubleshooting9. ____________________________________________________________________19

Repairs/service10. _____________________________________________________________________20

Manufacturer‘s declaration11. ___________________________________________________________20

Exploded drawingh12. _________________________________________________________________21

3

Operating instructions for turbine ow meter G

1. General details

1.1 Intended use

This turbine ow meter has been designed and built for measuring volumes of various media featuring

dierent viscosities, and for the storage of data so collected.

The turbine ow meter is intended for installation at the end of an output hose, e.g. a hose reeler.

1.2 Design and functional description

The turbine ow meter is a uid meter with electronic counter & memory and digital display.

The medium owing through the meter sets a turbine in rotation. The revolutions of the gears are

converted into electronic pulses and sent to the electronic counter by a Reed switch. The electronics,

nally, uses a certain multiplication factor to convert the pulses into an intelligible volume of liquid

having gone through the device, which is then shown on the LCD display.

The multiplication factor has been pre-set at the factory using an average that has turned out to be

useful in normal operation. However, it can be easily adapted to specic requirements by the user. The

total volume measured is stored and can be called up by pressing the TOTAL button.

Data collection and analysis are being constantly monitored by the electronics. Errors are reported

immediately.

The electronic counter needs a two-phase input signal that‘s being monitored for phase errors. A self

test is being carried out before every RESET. The user needs only two membrane key switches for ope-

ration: RESET and TOTAL (i.e. total volume). The body of the device is made of aluminium.

The electronic components and LCD display sit at the top of the turbine ow meter, far away from and

well insulated against the wet measuring chamber. There is a cover to protect them against the wor-

king environment.

MEASURING CHAMBER

RESET BUTTON

DISPLAY LCD

TOTAL BUTTON

4

GOperating instructions for turbine ow meter

1.2.1 Display LCD

The meter‘s LCD display is equipped with two numeric registers and dierent types of display modes

showing information to the user only when it is actually needed with the operation / function going on

at the moment.

Key:

Register of partial volume (5 digits with oating decimal: 0.000+99999) showing the amount of liquid1.

that has been delivered since the RESET button was last pressed

Battery charge2.

Display of the calibration mode3.

Register of total volume (6 digits with oating decimal 0.0-999999x10/x100) showing two dierent4.

kinds of total volumes:

4.1 Non-resettable total volume (TOTAL)

4.2 Resettable total volume (RESET TOTAL)

Total volume multiplication factor (x10/x100)5.

Type of total volume display (TOTAL / RESET TOTAL)6.

Units for total volume: L = litres, GAL = gallons7.

Flow rate8.

Display of measuring unit for partial volumes:9.

QTS = quarters; PTS = pints; L = litres; GAL = gallons;

The display can be adapted to the direction of ow in 90° steps. To do so, loosen the four screws (item

1). Now you can mount the display unit turned 90°.

Caution!

O-ring (item 10) must be re-mounted correctly.

Do not pinch or excessively twist the cables from the battery compartment (item 11) to the

PCB (item 14).

Then re-insert and tighten the screws (item 1).

1.2.2 User controls

There are two push buttons on the meter (RESET and TOTAL), each controlling two main functions

(pressed individually) and various auxiliary sub-functions (pressed simultaneously).

Main functions:

RESET button: Resetting the partial volume register and the (resettable) total volume register RESET

TOTAL.

TOTAL button: Calling up the calibration mode. Pressed together, the two buttons call up the

conguration mode where you select the unit of measurement.

5

Operating instructions for turbine ow meter G

1.2.3 Measuring chamber

The measuring chamber is located in the centre of the meter.

There is a turbine in the measuring chamber, set in rotation by the ow of liquid. Each revolution will

generate an electrical pulse that is processed by the microprocessor on the control circuit board.

The microprocessor uses a calibration factor (i.e. a‚weighting‘ assigned to each pulse) to convert the

pulses generated by the gears‘ revolutions into an intelligible value representing the volume of liquid

that has passed through. It is then displayed in the unit pre-set before in the corresponding registers of

the LCD display for partial and total volumes, respectively.

All of our turbine ow meters leave the factory with a default calibration factor = 1000 called

„FACTORY K FACTOR“. There is a possibility to calibrate the meter in order to adapt that factor to the

physical properties of dierent liquids.

However, there is always a possibility to return to the manufacturer‘s default setting.

1.2.4 Battery compartment

The meter is powered by two 1.5 V standard batteries (N1).

The battery compartment is inside the body. To replace the batteries, you must remove the cover.

1.3 Technical data

Designation 23295

Measuring system Turbine

Accuracy l/pulse 0,017

Flow rate range l/min 10 - 100

Operating pressure bar 40

Burst pressure bar 80

Storage temperature °C -20 to +70

Storage humidity R.H. 95 %

Max. operating temperature °C 60

Flow rate loss at max.

ow (with diesel oil) bar 0,2

Compatible liquids Heating oil, diesel, hydraulic oils

Viscosity range cSt 2 - 2000

Accuracy

(within ow rate range) ±0,5 %

Repeatability 0,2 %

Weight kg 0,39

Threads at

inlet and outlet 1“

Power supply (batteries) V 2 x 1,5

Lifetime of batteries (est.) h 14.000 - 30.000

Table 1-1: Technical data

6

GOperating instructions for turbine ow meter

2. General safety instructions

2.1 Information on safety at work

The turbine ow meter has been designed and built in compliance with the applicable safety and

health requirements of the relevant EU directives.

However, hazards may result from this product if it is not used for its intended purpose or with the

necessary care.

For all uses of this turbine ow meter, local safety and accident prevention regulations apply, as

well as the safety instructions in these operating instructions.

2.2 Signs and symbols used in the safety instructions

Safety instructions are indicated in this manual with the following keywords and pictograms:

Pictogram Keyword Consequences of failure to comply with the safety

instructions

Caution Possible risk of slight to medium physical injury or material

damage

In addition, a further instruction is used which gives general tips for handling the product.

Pictogram Keyword Meaning

Tip Background information and tips on the right way of using the

product

2.3 Safety instructions concerning hazards that may arise in connection with

the turbine ow meter

Caution!

The turbine ow meter has been designed and is suitable for operation with media of low

ammability, exclusively.

Do not operate this turbine ow meter in areas with potentially explosive atmospheres.

Tip

Be sure to know and respect, in particular, any water management laws that may exist. In

Germany, for instance, § 19g of the German Water Management Act („WHG“) provides that

equipment for lling must be designed, constructed, installed, maintained and operated in such

a way that bodies of water are not aected in any critical ways.

The owner / operator of lling equipment is obliged to permanently check and manage any such

equipment for compliance with the afore-mentioned requirements at the place of installation.

3. Assembly

The turbine ow meter comes fully assembled and ready to go.

There may be accessories that can or must be tted. This depends on the model you chose.

Tip

During assembly, make sure everything is perfectly clean. Take particular care that components

are well aligned and connected and t tightly.

7

Operating instructions for turbine ow meter G

4. Installation

The inlet and outlet of the turbine ow meter are aligned in a straight axis and equipped with 1“ threads.

The meter may be installed in any given position, as a xed unit in a pipeline and/or as a mobile unit on a

spigot.

The turbine ow meter does not have a pre-dened ow direction. Both ends may alternatively serve as

inlet or outlet, as needed. However, it is absolutely important that the side that is used as inlet (where the

pipeline arrives) is equipped with a lter with suitable performance characteristics. Solid particles getting

into the measuring chamber might clog up the turbine.

5. Routine operation

The turbine ow meter comes pre-assembled and ready to go.

Even after periods of prolonged storage, it will be ready for operation without any lengthy preparations.

The only action that may be necessary from time to time during normal operation is to reset the registers

of partial and/or resettable total volumes.

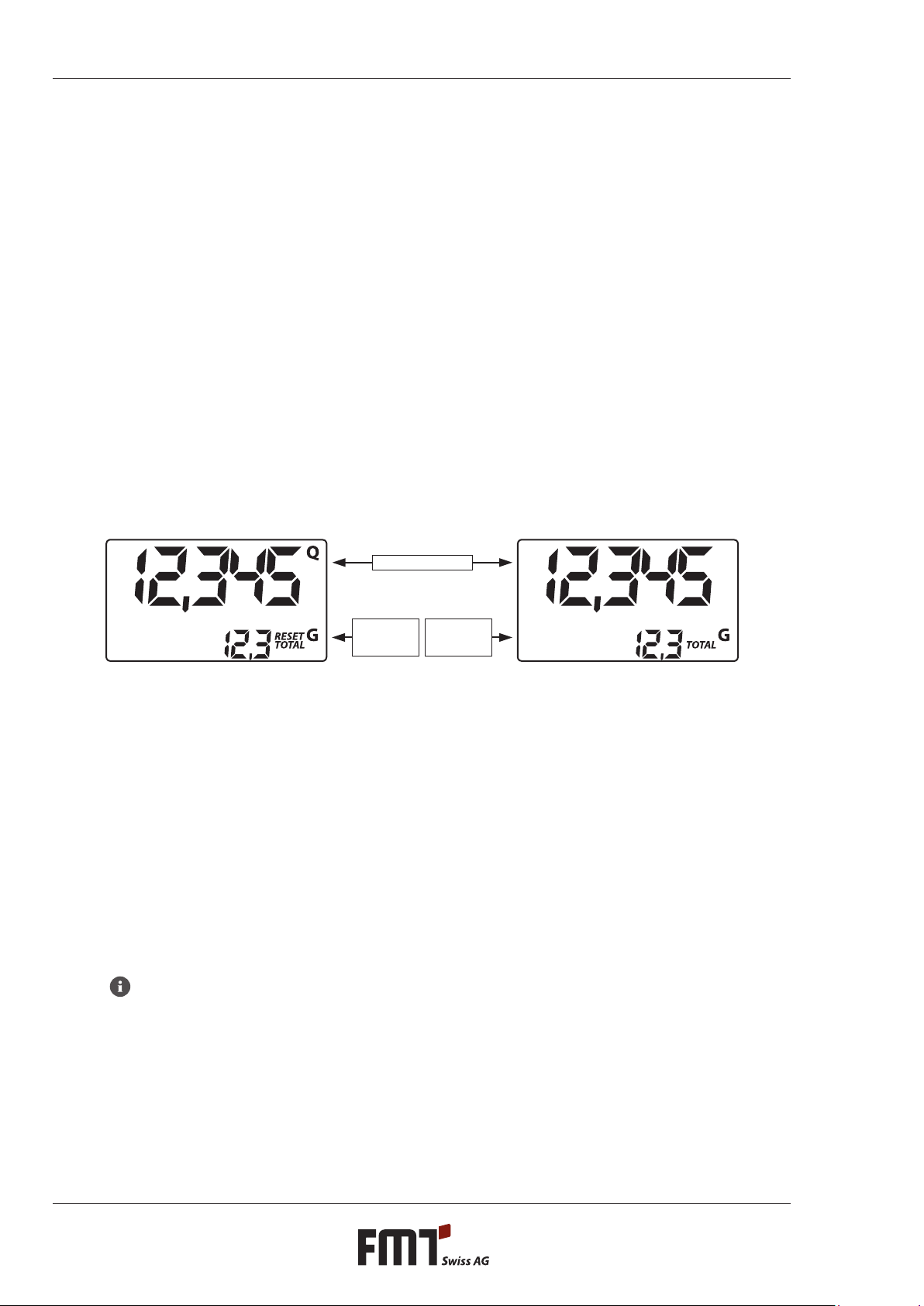

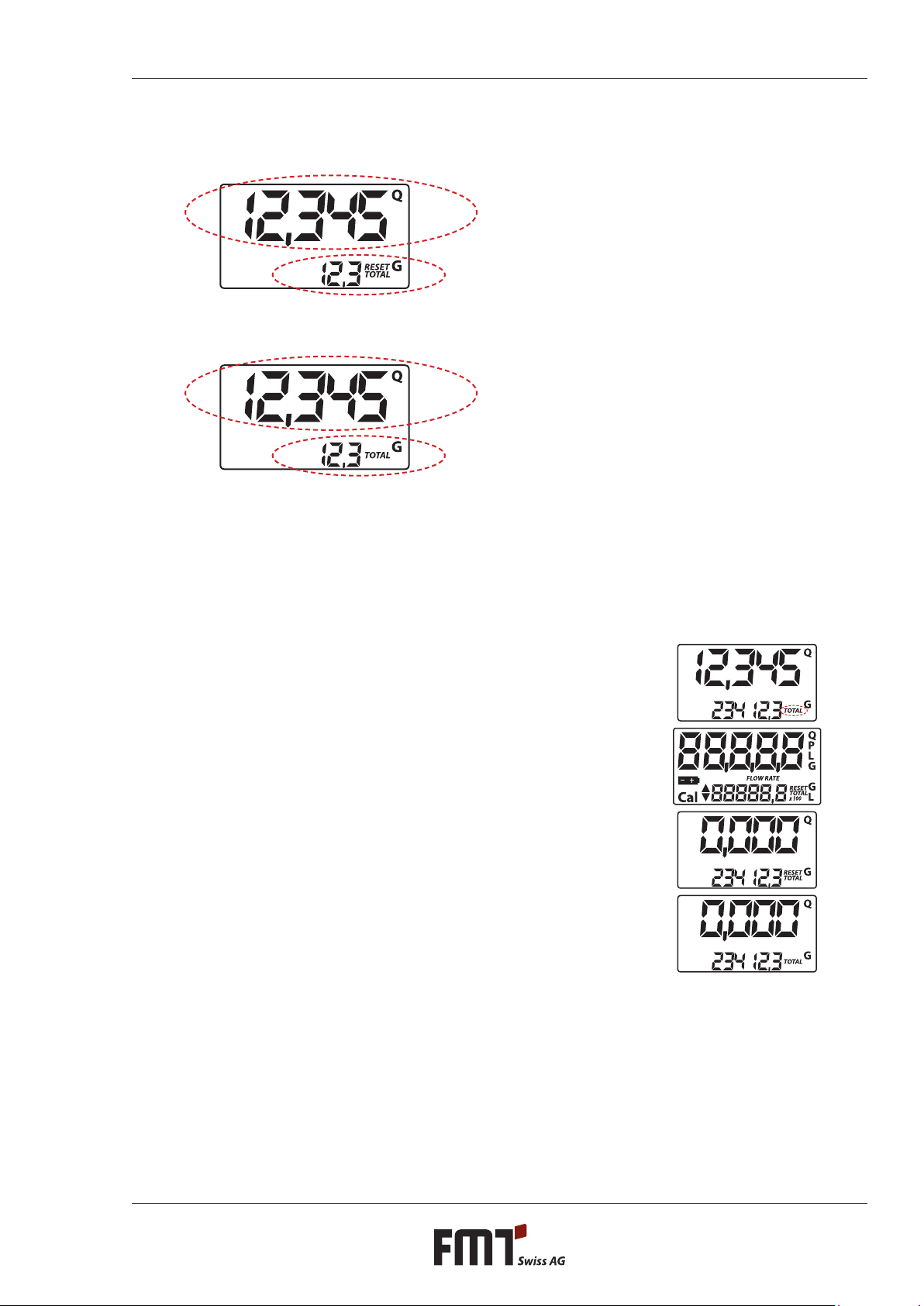

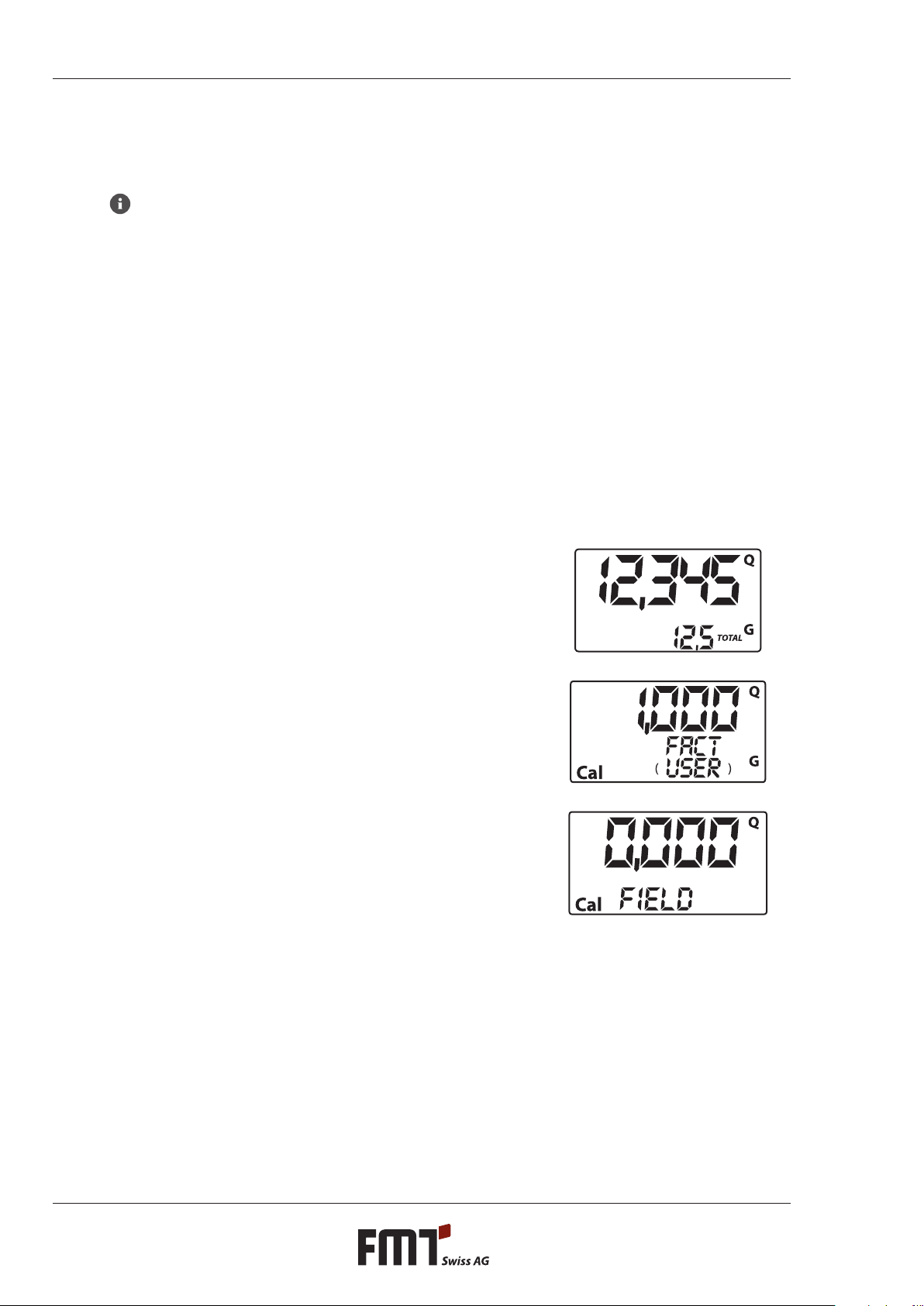

To accomplish that, call up the two displays for normal operation. The rst normal operation display

contains the partial volume and resettable total volume (RESET TOTAL). The other display shows the

partial volume and the non-resettable (absolute) TOTAL volume. The LCD automatically switches between

resettable and absolute total. This has been set at the factory and cannot be inuenced by the user.

Register of

RESETTABLE

TOTAL VOLUME

Register of

ABSOLUTE

TOTAL VOLUME

Register of partial volume

The register of the absolute total (TOTAL) cannot be reset by the user. It will continue counting during the

entire lifetime of the meter. The resettable and non-resettable registers of total volumes (RESET TOTAL and

TOTAL) share the same‚window‘ and the same digits of the LCD display. For that reason, the two numbers

cannot be viewed at the same time.

The turbine ow meter has been programmed so that the one or the other total is visible at certain

moments / in certain modes during operation (never both at a time):

The absolute total volume (TOTAL) is visible in standby mode.

The resettable total (RESET TOTAL) is visible at the following times / in the following modes:

- For a short moment (several seconds) after resetting the (resettable) partial volume.

- During the output of liquid.

A few seconds after output of the liquid this short time span expires and the meter switches to standby

mode. The display of the bottom register shows the absolute total volume.

Tip

For the display of total volumes, there are 6 digits available, plus two icons x10/x100. The

increments are activated in the following sequence:

0,0 ---> 99999,9 ---> 999999 ---> 100000 x10 ---> 999999 x10 ---> 100000 x100 ---> 999999 x100

8

GOperating instructions for turbine ow meter

5.1 Output of liquid during standard operation (Normal Mode)

During standard output of liquid, the meter will count and at the same time display the

volume having gone through the device so far, and the resettable total (RESET TOTAL).

Accidental pressing of the RESET or TOTAL button does not have any eect in this state.

A few seconds after you‘re nished, the display of the lower register will change from resettable total to

absolute total: The word RESET above the word TOTAL will disappear, and the value of the resettable

total will be replaced by the absolute total.

We call this state (or mode)„standby“. It will persist as long as the user does not carry out any more actions

on the meter.

5.1.1 Resetting partial volumes

For resetting the partial volume register: Press the RESET button

while the meter is in standby, i.e. when you see the word TOTAL in

the display.

When you press RESET, the display will rst switch on all the

segments, one after the other, and then switch them all o again.

When the reset is complete, the display will rst show the partial

volume having been reset and then RESET TOTAL.

After a couple of seconds, RESET TOTAL will be replaced by the

NON-resettable total amount (TOTAL).

9

Operating instructions for turbine ow meter G

5.1.2 Resetting the resettable total volume (RESET TOTAL)

You can reset the resettable total only if you have reset the

register of the partial volumes before. To reset the resettable total:

press RESET for several seconds. The display will show the words

RESET TOTAL (see g.):

You must carry out the following steps (in this order):

1. Wait until the display is back to default standby mode (i.e.

showing only TOTAL).

2. Press RESET shortly.

3. The meter will now start resetting the partial volume register.

4. While the display shows all segments, press and release the

reset button.

5. The display will show all the segments again. Only then follows

the phase where all segments are switched o.

Finally, there will be a display showing the total that has been

reset (RESET TOTAL).

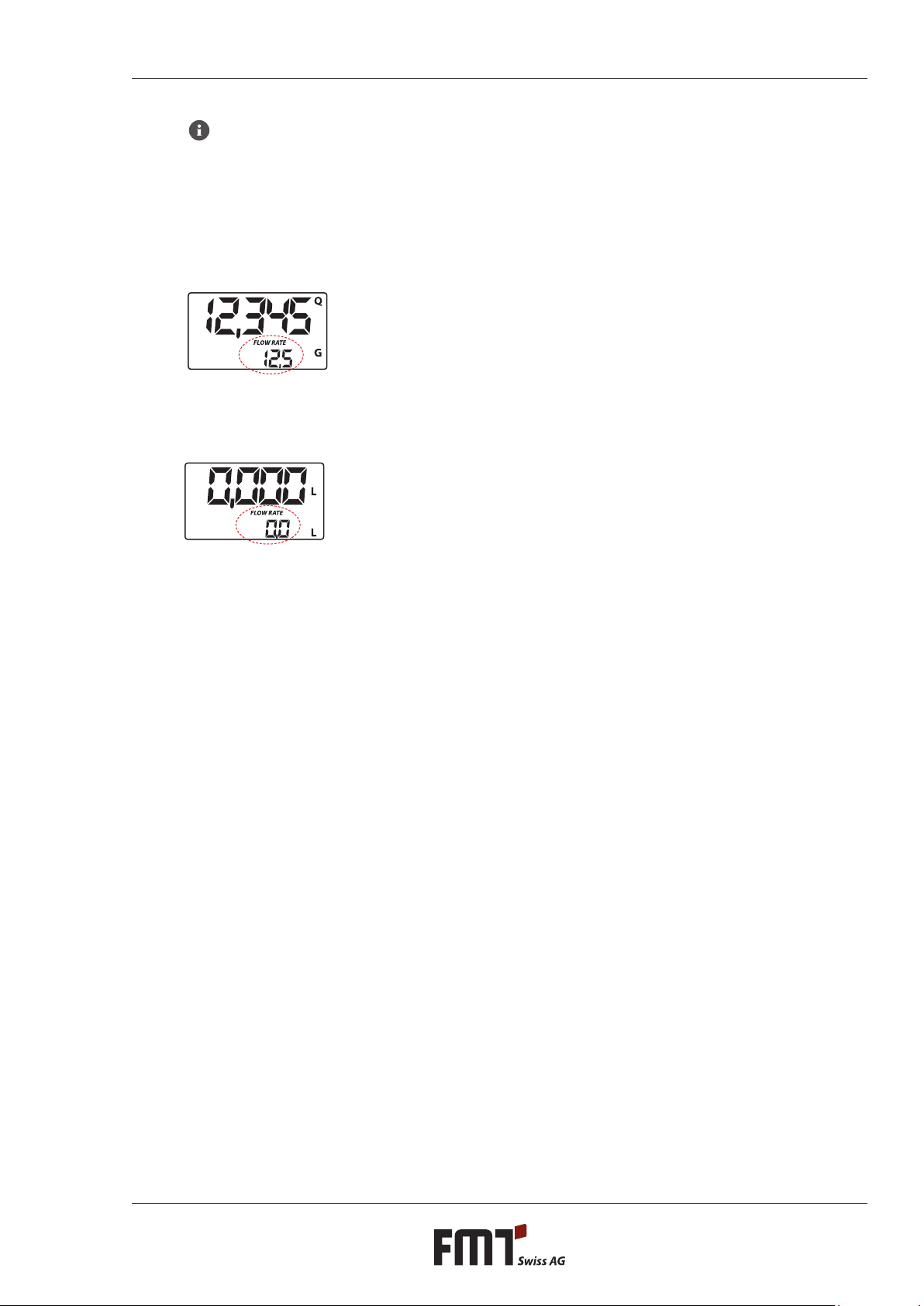

5.2 Output of liquid with display of current ow rate (Flow Rate Mode)

It is possible to output a liquid and have the following displays available:

Partial volumes having been output

Current ow rate (Flow Rate) in [unit of partial volume per min.], as shown below.

This is how you get into this mode:

Wait until the meter is in default standby mode (i.e. the display shows only the total volume).

Press TOTAL shortly.

Start output operation.

The display of the current ow rate will be updated every 0.7 secs. For that reason the display may‚utter‘

somewhat with low ow rates. However, the higher the ow rate, the more stable the display will be.

Tip

The current ow rate will be shown in the unit set for the partial volume register. That means if

partial and total volume have been set to dierent units (as shown in the example below) you

must bear in mind that the ow rate shown is in the unit set for partial volumes. In the example

shown, the ow rate is in QTS./min.

The word GAL next to the ow rate refers to the register of the (resettable and NON-resettable) total

volumes which will be displayed again as soon as you leave the‚current ow rate‘ display mode.

In order to go back to the default standby mode, press the TOTAL button again.

Accidental pressing of the RESET or TOTAL button does not have any eect in this state.

10

GOperating instructions for turbine ow meter

Tip

RESET TOTAL and absolute total (TOTAL) are not shown in this mode. However, the values

nevertheless go up, of course. You can check after you‘re nished. Wait for the default standby

mode and press TOTAL shortly.

5.2.1 Resetting partial volumes

In order to reset the partial volume register, you must rst complete the output of liquid. Wait until the

display shows a ow rate of 0.0 (see g.) and then press RESET shortly

.

The eect is dierent from what you would have if you press Reset in default standby mode. There is no

phase where all the segments are rst switched on and then o again. Instead, the register will display the

reset partial volume immediately.

6. Calibration

6.1 Denition

Calibration factor ->„K FACTOR“:

This is the multiplication factor the system ascribes to the electronic pulses it receives in order to convert

them into a plain unit of measurement.

FACTORY K FACTOR: Calibration (default) factor pre-set at the factory.

Factory K Factor = 1000.

This calibration factor guarantees the highest degree of precision under the following operating

conditions:

Liquid Engine oil type 10W30

Temperature 20 °C

Flow rate 2-20 l/min

You can always return to the original Factory K Factor even after you have changed the value. The

procedure is simple.

USER K FACTOR: This is the calibration factor the user has set to adapt the meter to specic

requirements (i.e. the user has carried out a calibration procedure).

6.2 Why calibrate the meter at all?

The turbine ow meter comes to you with a calibration factor pre-set at the factory that will guarantee the

most precise measurements under most operating conditions.

If calibration is necessary, it should be conducted under the operating conditions in which the meter is

used, such as in the following extreme conditions:

liquids having a viscosity close to the admissible limits (e.g. antifreeze with low viscosity, high-viscosity

oils for gearboxes)

extreme ow rates (i.e. close to upper or lower limits)

11

Operating instructions for turbine ow meter G

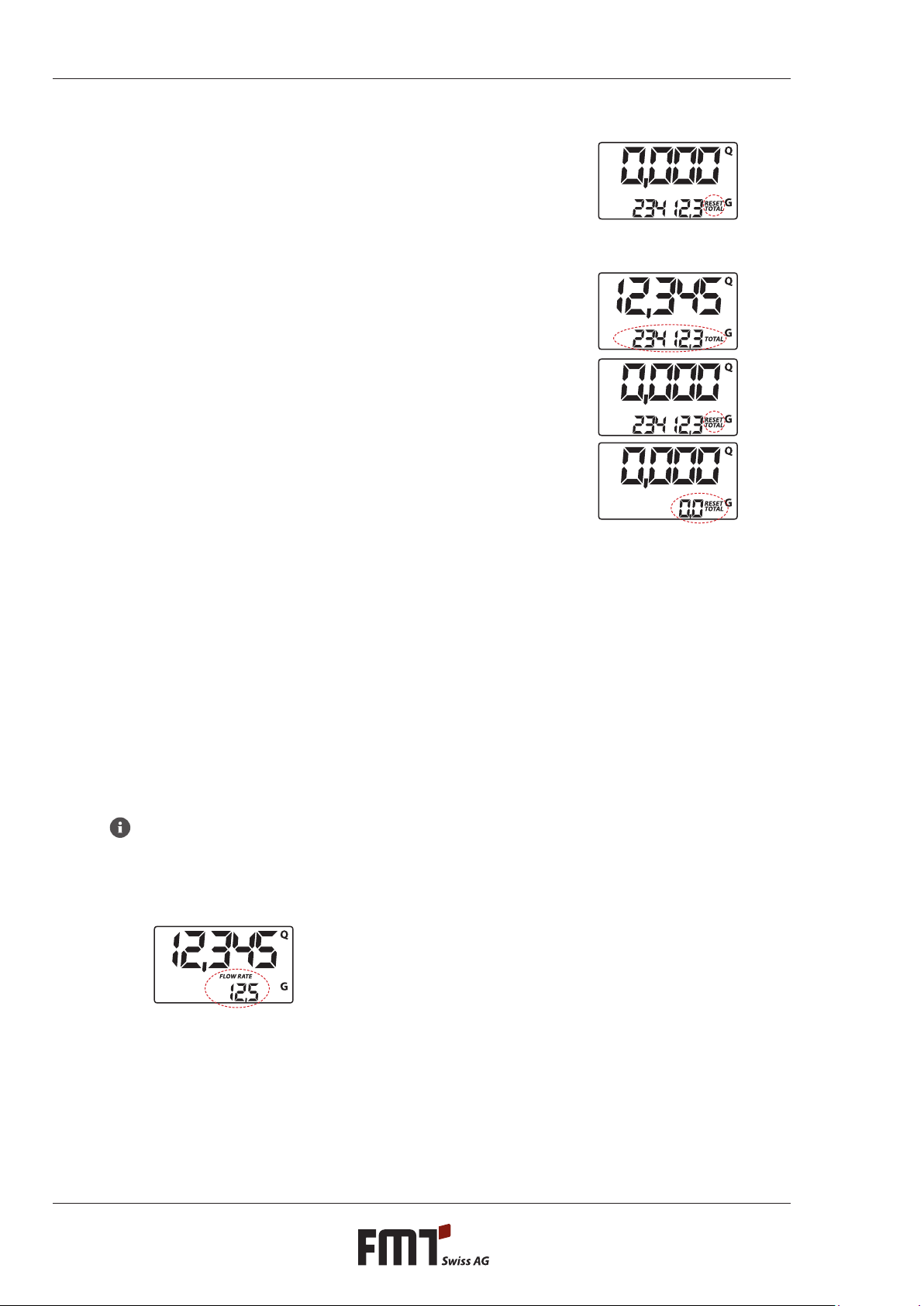

6.3 Calibration mode

The turbine ow meter has a fast and precise electronic calibration mode where you simply change the so-

called calibration factor (K FACTOR).

There are two calibration procedures you may choose from:

Simulated operation + calibration (requiring actual output of liquid to be carried out).

Direct calibration (simply changing the calibration factor).

You may want to call up the calibration procedure for the following reasons (press the TOTAL button for

several seconds):

To display the valid calibration factor

To reset the calibration factor pre-set at the factory (FACTORY K FACTOR) after calibration by the user

To change the calibration factor using one of the two available calibration procedures

During calibration, the registers on the LCD display - that normally show partial and total volumes of liquid

output - will take on new meanings.

During calibration, the meter cannot carry out normal output operation.

During calibration, the count of the absolute total volume of liquid having been output (non-resettable

total) will not increase.

Tip

The turbine ow meter is equipped with a non-volatile memory so that saved calibration data and

the total output amount will be stored for prolonged periods of time - even without power supply.

That means you don‘t have to re-calibrate after you have exchanged the batteries.

6.3.1 Displaying the valid calibration factor - resetting the factory calibration factor (if

necessary)

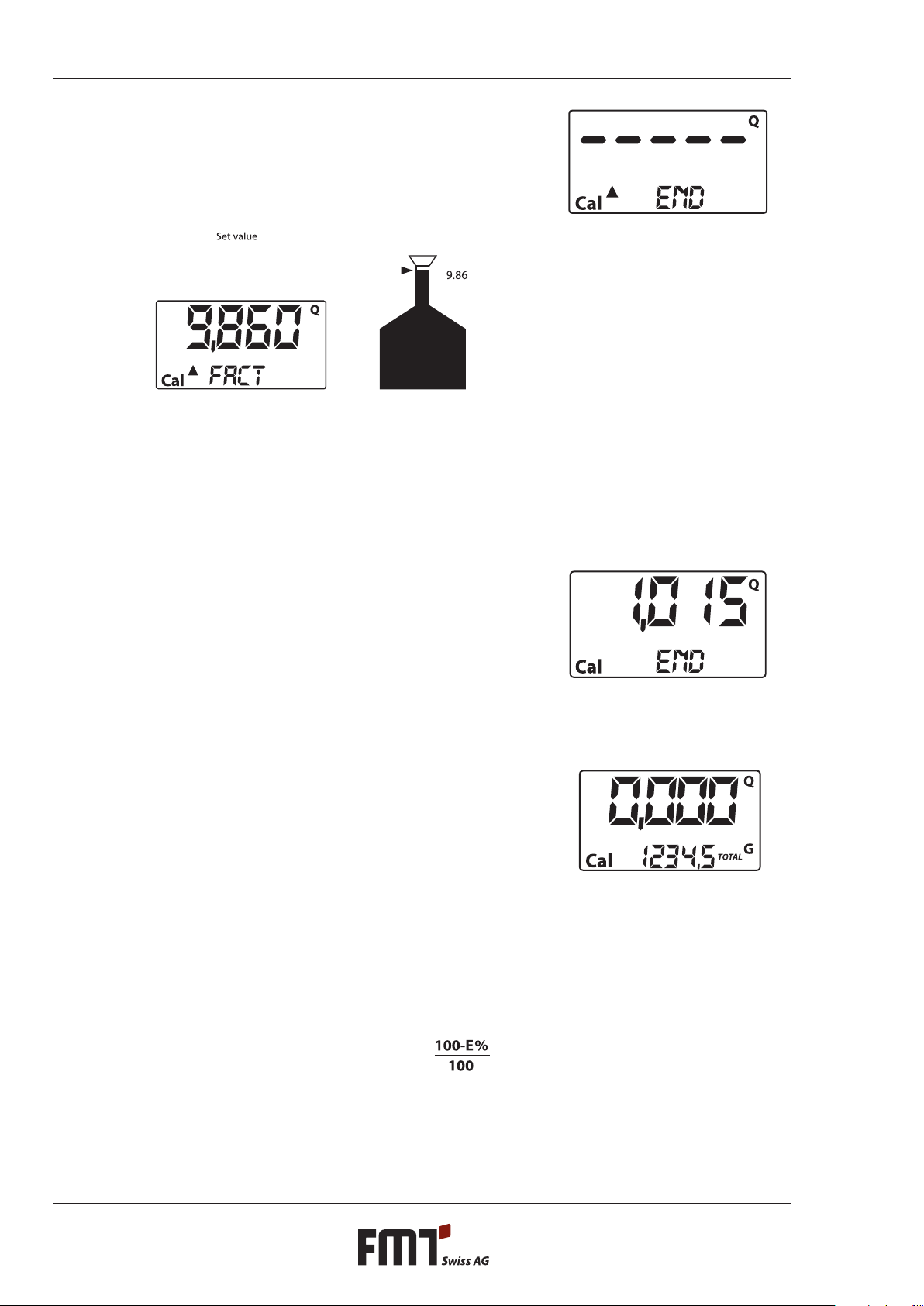

Go to default standby mode. Press the TOTAL button. The display shows the valid calibration factor.

Two situations are possible:

a) User never changed the calibration factor and/or user restored the factory calibration factor after

changing it: the display will show the following:

The word FACT (short for FACTORY) indicates that the valid calibration factor is the factor pre-set at the

factory.

b) If the user has changed the calibration factor, the display will show the new value

(in our example: 0.998)

The word USER indicates that the calibration factor currently used was entered by the user.

12

GOperating instructions for turbine ow meter

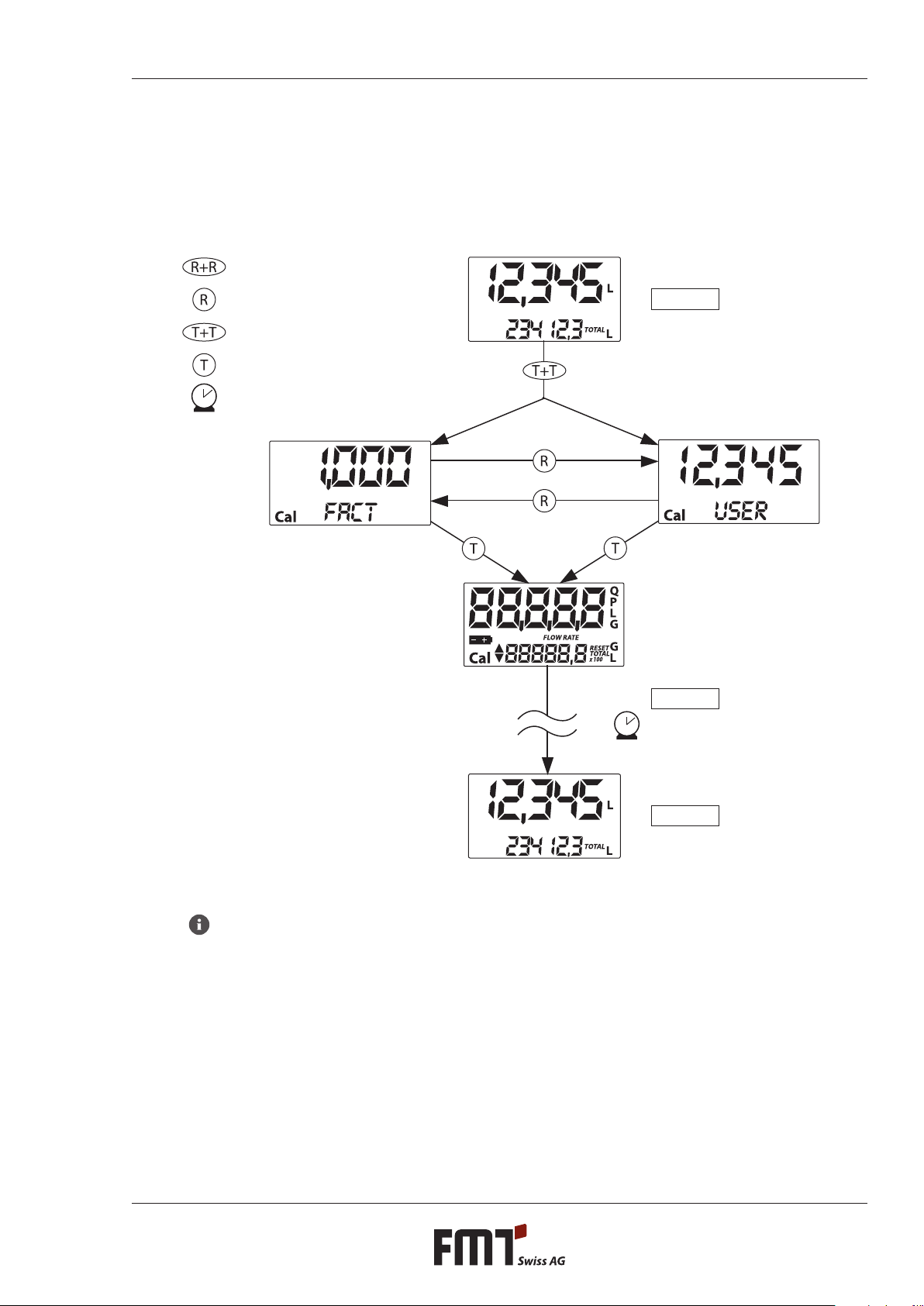

The ow chart below shows the schematics of the display modes the LCD display may go through.

In this mode, the user may press RESET and thus change from the USER to the FACTORY FACTOR .

In order to conrm your choice, shortly press TOTAL while the display shows either USER or FACT.

After re-start, the meter will use the new calibration factor you just conrmed.

Tip

When you conrm restoration of the Factory K Factor, the old user factor will be deleted from

memory.

Standby

Standby

Standby

Reset long

Reset short

Total long

Total short

Time OL 1

Key

13

Operating instructions for turbine ow meter G

6.3.2 Calibration during simulated operation

This procedure is basically a simulated output of liquid into a calibration vessel under actual operating

conditions (ow, rate, viscosity etc.). The procedure must be carried out with utmost care.

Tip

Absolutely bear in mind the following points in order to guarantee proper calibration:

Have your equipment properly vented before calibration.

Use a calibrated vessel holding at least 5 litres with a precise full mark.

For calibration, tap a certain amount of test liquid with a constant ow rate, exactly as you

would do in normal operation. Continue until the vessel is full.

Do not decrease the ow rate when you approach the full mark. Instead, turn the spigot on

and o and ll the vessel in small batches, but make sure the ow rate remains unchanged.

When you‘re nished be sure to wait a few minutes and let air bubbles escape that may still be

in the calibration vessel. Otherwise there is a danger you get a wrong value because the level

in the vessel may still go down.

Be sure to carry out the following procedure correctly.

6.3.3 Meter calibration during simulated operation

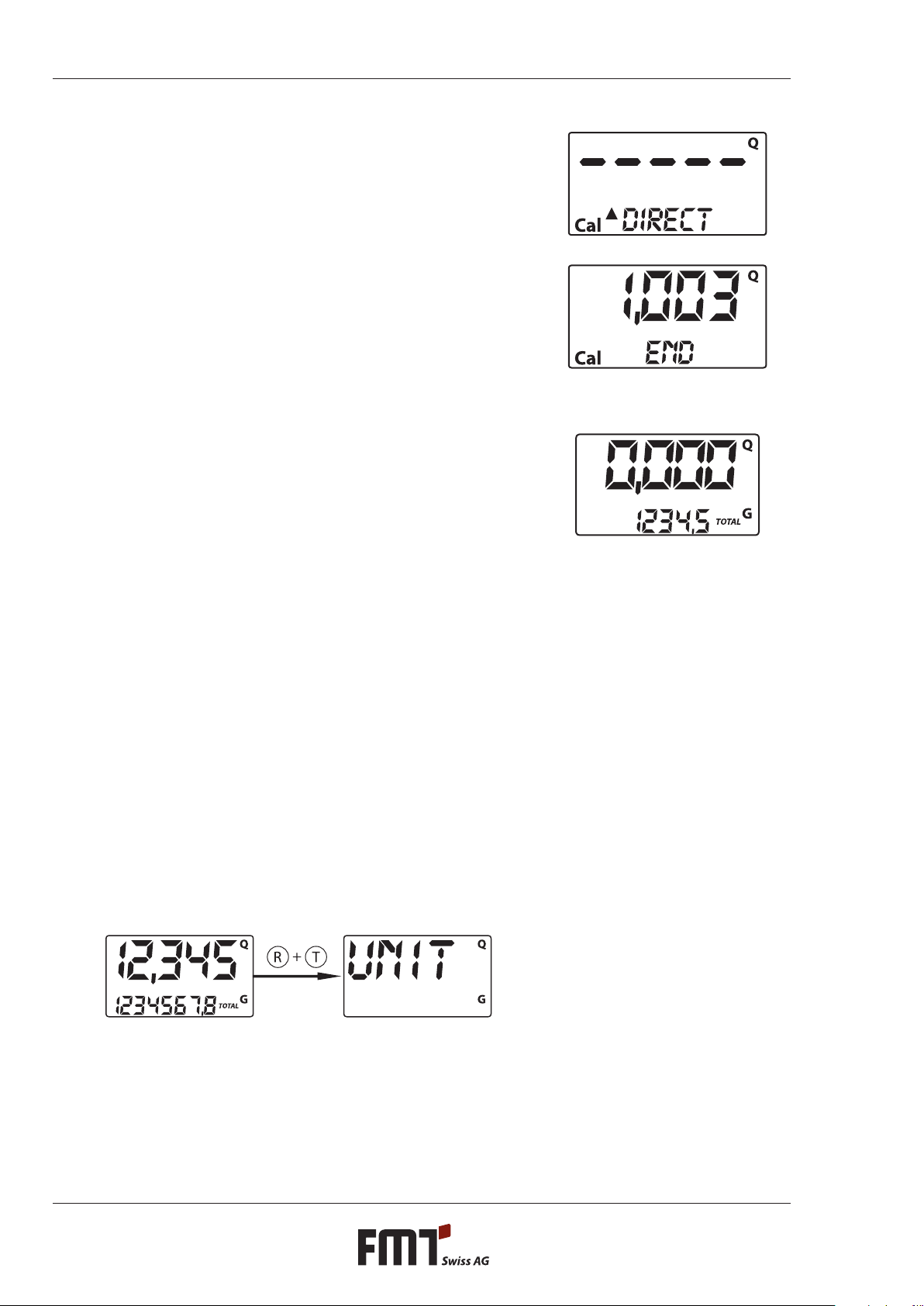

Action DISPLAY

1 NONE

Meter is in default standby mode, not counting

2 PRESS TOTAL SEVERAL SECS

Meter switches to calibration mode, displaying TOTAL.

Display no longer shows total volume, but instead the valid

calibration factor. FACT and USER indicate whether valid

calibration factor is FACTORY K FACTOR or USER K FACTOR .

3 PRESS RESET SEVERAL SECS

Meter shows TOTAL display and the resettable total register

displays zeroes. Meter is now ready for simulated operation

calibration.

14

GOperating instructions for turbine ow meter

4 FILL LIQUID INTO CAL VESSEL

Start simulated operation, but do not press any buttons

yet.

Simulated operation may be interrupted and continued

as necessary. Continue lling the vessel until full mark is

reached. It is not necessary to top out at any specic value.

Set value Actual value

5 PRESS RESET SHORTLY

This is how the meter‚knows‘ that sim op for calibration is

complete. Make sure cal vessel has really been lled up to

full mark before you do this.

For calibration you must correct the count indicated by

the partial volume register (ex.: 9,800), entering the actual

value, i.e. the volume of the cal vessel. An arrow at the

bottom left of the display (pointing up or down) indicates

the direction in which USER K FACTOR is changed. Increase

or decrease when actions 6 or 7 are carried out.

6PRESS RESET SHORTLY

Direction of arrow ips. This may be repeated as often as

necessary.

7PRESS TOTAL SHORTLY / SEVERAL SECS

Value indicated will change as indicated by arrow:

One increment per each time TOTAL is pressed

Continuous if the TOTAL button is held down, the rst 5

increments slow, then fast.

If you overshoot, go back to point 6 and repeat (6).

15

Operating instructions for turbine ow meter G

8PRESS RESET SEVERAL SECS

This is how the meter‚knows‘ that calibration is now

complete.

Before you press the button, be absolutely sure the

display shows the correct value (volume of vessel).

Actual value

The meter will now calculate the new USER K FACTOR: This

may take a couple of secs. depending on the complexity of

the correction. The arrow will disappear during this phase,

but the word TOTAL will remain unchanged.

If you carry out this action right after point 5 the new USER

K FACTOR will be equal to the FACTORY K FACTOR. It will be

ignored, therefore.

9NONE

After completion of the calculation the new USER K

FACTOR will be displayed a few seconds. Next, the meter

will re-start. Finally, the meter will be back in default

standby mode.

PLEASE NOTE: From now on, the new value set will be

used as the new valid K Factor and will remain even

after replacement of batteries!

10 NONE

The meter stores the new K Factor for operation and is now

ready for serious operation using the newly set USER K

FACTOR.

6.3.4 Changing the K FACTOR directly

This procedure is helpful for the correction of a mean error that may occur as a result of many output

operations. In the event you observe a mean percentage error during normal meter operation you may

carry out a correction by changing the valid User K Factor by that percentage. In order to calculate the

correction of the USER K FACTOR, proceed as follows:

New calibration factor = old calibration factor x

16

GOperating instructions for turbine ow meter

Example:

Observed mean percentage error E % -0,9 %

Current K Factor 1.000

New USER K FACTOR 1.000 x 100-(-0,9)÷100=

1.000 x (100+0,9)÷100=

1.009

If the meter displays less than the actual amount of liquid output (negative error), the new K Factor must

be greater than the old one (see example). The opposite is true if the value indicated is greater than the

actual amount (positive error).

Action DISPLAY

1 NONE

Meter is in default standby mode, not counting

2 PRESS TOTAL SEVERAL SECS

Meter changes to calibration mode displaying the valid K

Factor instead of the partial volume. FACT or USER indicates

whether valid calibration factor is Factory K Factor or User

K Factor .

3 PRESS RESET SEVERAL SECS

Meter shows TOTAL display and the resettable total register

displays zeroes. Meter is now ready for simulated operation

calibration.

4 PRESS RESET SEVERAL SECS

Changing valid K Factor directly: The word DIRECT is dis-

played, together with the calibration factor currently in use.

An arrow at the bottom left of the display (pointing up or

down) indicates the direction in which the displayed value

is changed. Increase or decrease when actions 5 or 6 are

carried out.

5 PRESS RESET SHORTLY

Direction of arrow ips. This may be repeated as often as

necessary in order to set the correct direction.

6 PRESS RESET SHORTLY / SEVERAL SECS

Value indicated will change as indicated by arrow.

One increment per each time TOTAL is pressed.

Continuously if TOTAL is held down. Display will‚roll‘

more quickly if button is held permanently.

If you overshoot, go back to point 5 and repeat.

17

Operating instructions for turbine ow meter G

7 PRESS RESET SEVERAL SECS

This is how the meter‚knows‘ that calibration is now com-

plete.

Before you press this button, be absolutely sure the

value indicated is the value you wanted to set.

8 NONE

After the following calculation the new USER K FACTOR will

be displayed a few secs. Next, the meter will re-start. Finally,

the meter will be back in default standby mode.

PLEASE NOTE: From now on, the new value set will be

used as the new valid K Factor and will remain even

after replacement of batteries.

9 NONE

The meter stores the new K Factor for operation and is now

ready for serious operation using the newly set USER K

FACTOR.

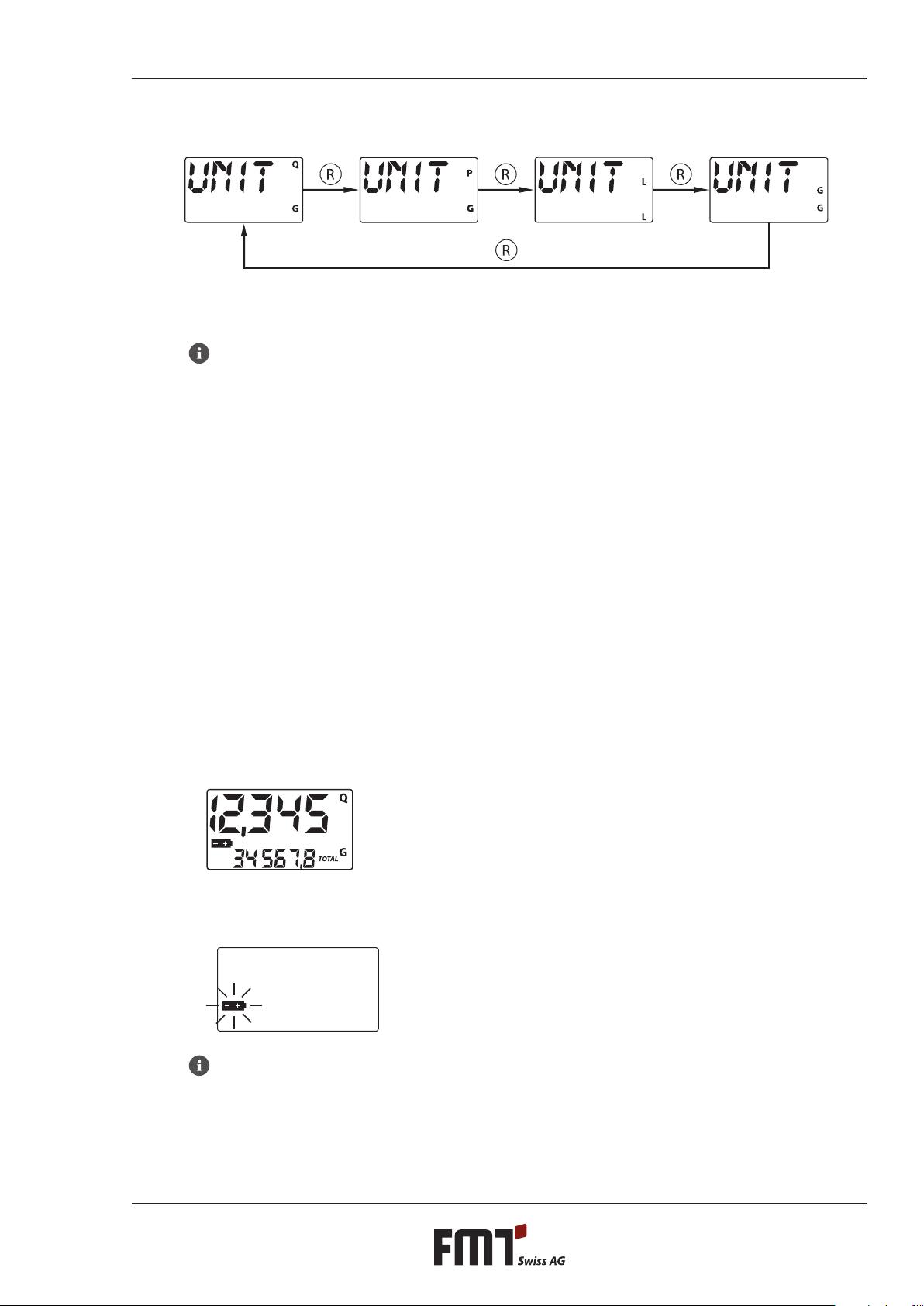

7. Conguration of the turbine ow meter

The turbine ow meter has a menu to assist users in the selection of the main unit of measure: quarters

(QTS), pints (PTS), litres (L), gallons (GAL).

Combining partial-volume and total-volume units is possible as shown in the following table:

Combination no. Unit Register

of partial amounts

Unit Register

of total amounts

1 litres (L) litres (L)

2 gallons (GAL) gallons (GAL)

3 quarters (QTS) gallons (GAL)

4 pints (PTS) gallons (GAL)

This is how you select any of the combinations proposed:

Wait until the meter is in default standby mode. Simultaneously press TOTAL and RESET until the

display shows the word„UNIT“ displaying the valid unit being used at present

(in our example: litres/litres).

18

GOperating instructions for turbine ow meter

Every time you (shortly) press RESET, one of the other combinations of units will be displayed one after the

other (see gs.):

Press TOTAL for several seconds to store the new combination. The meter will re- start and is then ready

for operation using the newly selected combination of units.

Tip

The registers of the resettable and non-resettable totals will automatically switch over to the new

units set.

You do NOT have to re-calibrate after changing the units.

8. Service

This turbine ow meter has been designed for minimum maintenance requirements. What remains to be

done from time to time:

Exchange the batteries when discharged.

Clean the measuring chamber. This may be necessary from time to time depending on the specic

liquid(s) being measured and/or when foreign matter gets into the chamber (inlet lter not sucient).

8.1 Exchanging batteries

The meter is supplied complete with two 1.5 V alkaline batteries (1N).

The meter has a two-step low battery indicator:

1) As soon as the batteries dip below the rst charge level the battery icon in the display will light up.

The meter will continue to operate correctly, but the user is informed that the batteries should be

exchanged as soon as possible.

2) If the batteries are not exchanged, the battery will sooner or later reach the second alarm level. Normal

operation is no longer possible. At this state, the battery icon will ash, being the only thing that is still

visible in the display.

Tip

Do not throw batteries in the dustbin. Be sure to know and respect local regulations concerning

proper disposal.

19

Operating instructions for turbine ow meter G

Proceed as follows (items correspond to spare parts list):

Press RESET in order to update total volume.

Unscrew the battery cover (item 8).

Remove the old batteries.

Insert new batteries. Observe + and - icons on batteries and cap (item 1).

Replace battery cap properly and screw down tightly. Make sure the seal (item 7) and spring (item 9)

are in their correct positions.

The meter will go on automatically and revert to default standby mode. Routine operation may now be

continued.

The values of the resettable and non-resettable totals and partial volume will be the same as before.

Neither will the calibration (K) factor change in the case of power failures and/or exchange of batteries. It is

not necessary to re-calibrate the meter after exchange of batteries.

8.2 Cleaning

The measuring chamber of the turbine ow meter can be cleaned only after disconnecting the meter from

the pipeline or spigot. The inlet and outlet must be fully accessible.

Tip

Always make sure that ALL the liquid has been removed from the device before you start cleaning

it.

The turbine ow meter has no lter that needs to be cleaned. Therefore, it is only possible to determine

at the inlet and outlet whether large particles have gotten caught in the meter. If there are any foreign

objects in the meter, they can be removed with a pointed object, such as a small screwdriver, or needle

nose pliers.

Caution!

Never blow compressed air into the meter, since the resulting high speed of rotation can cause the

magnets to become loose!

After removing larger objects, a suitable liquid can be used to rinse out smaller foreign particles. It is best

to use diesel fuel or heating oil for this.

Be careful not to damage the body of the device and the plastic parts.

9. Troubleshooting

Problem Cause Solution

LCD display: No display Loose battery contact Check batteries for good contact

Accuracy of measurements is

insucient

K FACTOR wrong

Meter operates below admissible

min. ow rate

Check K FACTOR (section 6.3)

Increase ow rate to acceptable

level

Reduced ow rate, no ow at all Turbine blocked Clean measuring chamber

Display ashing„Err 1“ Data stored in electronic memory

are damaged

Sorry, irreparable

Short display of„Err 2“ Limited error reading data (usu-

ally when exchanging batteries)

Control circuit board automa-

tically switches on and o to

restore proper operation

20

GOperating instructions for turbine ow meter

10. Repairs/service

This turbine ow meter has been designed and built in compliance with the highest quality standards.

If a problem should occur despite all quality measures taken, please get in touch with our service

contact partners:

FMT Swiss AG

Tel +49 9462 17-216

Fax +49 9462 1063

11. Manufacturer‘s declaration

We hereby state that the equipment described below, in the model which we have made commercially

available, complies in its design and construction with the applicable requirements. If the equipment is

used other than for its intended purpose, this declaration loses its validity.

Designation of the appliance Turbine ow meter

Complies with EU directive: 89/336/EEC (EMC directive) and pertinent amendments.

Relevant EU standards: EN 61000-6-1

EN 61000-6-3

EN 55014-1-2000

EN 55014-2-97

24.09.2012 FMT Swiss AG

Dipl.-Ing. Rudolf Schlenker

Table of contents

Other FMT Swiss AG Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Extech Instruments

Extech Instruments SDL470 user manual

Rohde & Schwarz

Rohde & Schwarz ZNL4 user manual

HB Ross Manufacturing Co.

HB Ross Manufacturing Co. ACVGD ROSS METER user manual

Polimaster

Polimaster PM1703MO-1 Operation manual

Agilent Technologies

Agilent Technologies U4154A Service guide

Santec

Santec TSL-550 Operation manual