HB Ross Manufacturing Co. ACVGD ROSS METER User manual

2

THE ACVGD®ROSS METER®

USER MANUAL

Published by the H.B. ROSS MANUFACTURING COMPANY, LLC.

in Richmond, Virginia. U.S.A.

© 2017 H.B. ROSS MANUFACTURING COMPANY. All Rights Reserved.

ACVGD® and Ross Meter® are registered trademarks of the

HB ROSS MANUFACTURING COMPANY, LLC.

- Since 1975 -

3

TABLE OF CONTENTS

1.0 DIRECTIONS FOR USING THE ACVGD®…………………………………………………………...4

1.1 Background….……………………………………………………………………………………..4

1.2 On the Job Site…………………………………………………………………………………....4

1.3 Taking Readings…………………………………………………………………………………..4

1.4 The Zero Reading Point…………………………………………………………………………..5

1.5 Other Reading Techniques……………………………………………………………………….6

1.5.1 The Triangulation Technique……………………………………………………………6

1.5.2 The Cable Path Technique……………………………………………………………...6

1.6 Typical Users Actual Practice…………………………………………………………………….7

2.0 GENERAL INFORMATION ABOUT THE ACVGD® ……….…………………………………………9

2.1 Warranty……………………………………………………………………………………………9

2.2 Battery Replacement……………………………………………………………………………...9

2.3 Probe Construction………………………………………………………………………………..9

2.4 Product Redesign Notice……………………………………………………………………..…10

2.5 Disclaimer…………………………………………………………………………………………10

FIGURE 1 and FIGURE 2………………………………………………………………………………….11

FIGURE 3…………………………………………………………………………………………………….12

WHAT’S INCLUDED WITH THE ACVGD®………………………………………………………….......13

MANUFACTURER CONTACT INFORMATION…………………………………………………………14

INSTANT JUMP TO MANUFACTURER WEBSITE (QR CODE)……………………………………...14

4

1.0 DIRECTIONS FOR USING THE ACVGD®

1.1 BACKGROUND –The alphabetic characters of the

trademark, ACVGD®, form an abbreviation, a symbol, for our

use to more simply name the instrument which was orginially

known as the 60 Hz A.C. Voltage Gradient Detector. The

ACVGD®ROSS METER®is an instrument designed to locate

the point along an underground cable path where a "fault to

the surrounding earth" is occurring. The ACVGD®makes use

of the existing 60 hertz A.C. voltage that is still energizing the

faulted cable. The ACVGD®does not require that any

secondary voltage service cables be disconnected in order to

use it. The operator merely walks out to where the cable is

buried and begins to probe along the path of the cable as

described below. Since the instrument does not put a signal onto the faulted cable the instrument is

“Passive in Nature” both in its design and in its use in locating the fault. Because of this passive nature

the instrument does not introduce any additional risk to the job site nor to the operator/user than was

present prior to arrival at the job location.

1.2 ON THE JOB SITE –The ACVGD®is easy to use and its

application to the job of locating the precise location of the

fault can be mastered in just a few times of use. The following

discussion explains the techniques used to locate secondary

voltage (less than 600 VAC) service cable faults with the

ACVGD®. Please refer to the attached drawings throughout

this discussion on the use of the ACVGD®.Figure 1 shows a

typical layout of facilities in a customer's yard. There is a chain

link fence, underground water pipes, and the underground secondary service. There is an earth ground at

the customer's meter base and there is another at the pad-mount transformer. These grounds may be

solidly (electrically) connected to the underground pipes and possibly even to the chain link fence.

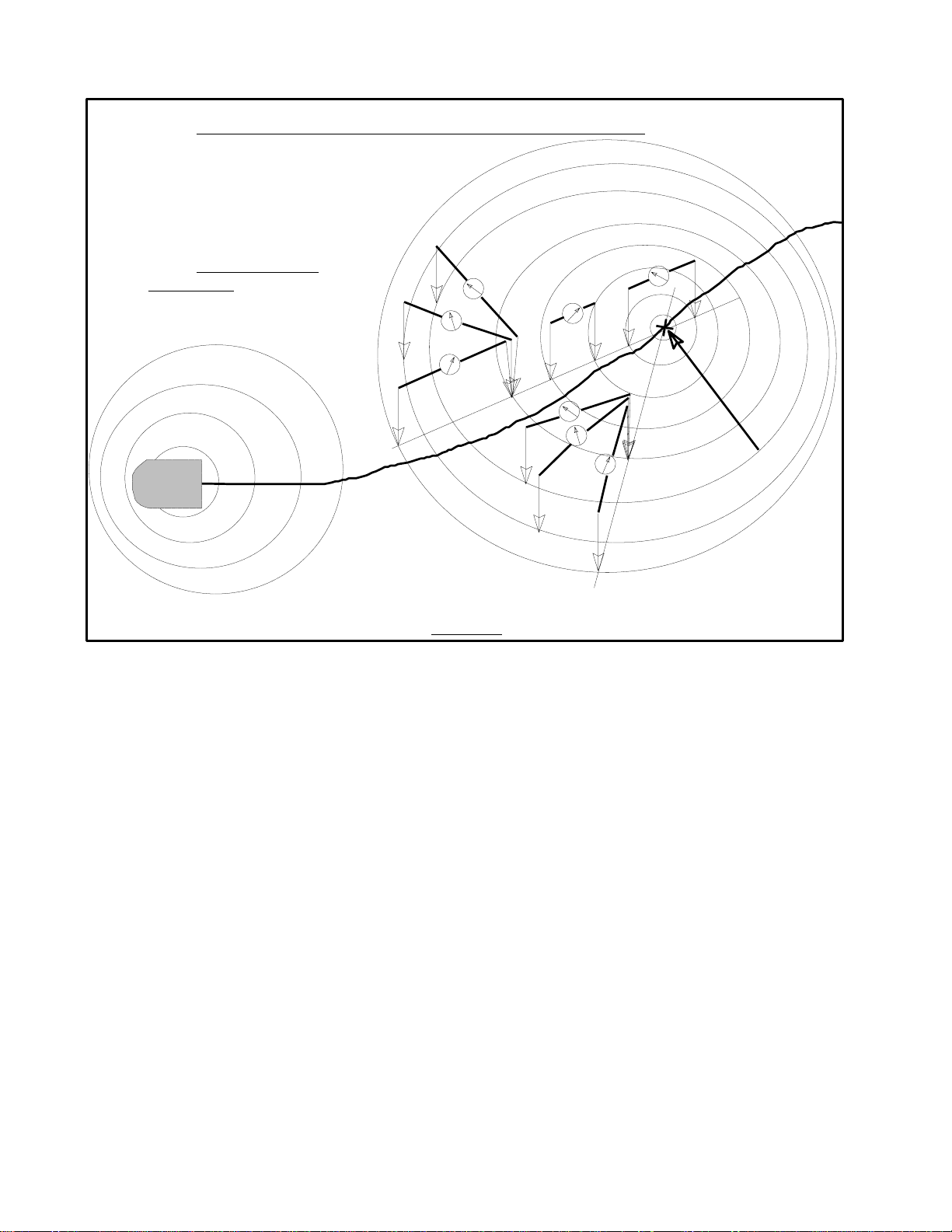

1.3 TAKING READINGS –Let's look at Figure 2 for the basic method of taking readings with the

instrument. Here the readings are represented as circular shapes, each being a specific voltage's pattern

that is generated at the surface of the ground. You also see there is an area that is labeled the

transformer zone on the left and the fault zone to the right. Of course, you cannot know immediately

where the fault zone is, but you do know where the source transformer is and where the customer's

meter base or street light is. With this in mind the following rule was developed (by user experience in

the field) as a time saving approach to finding the point of the fault.

THE 2/3's RULE

Observe the relative locations of the metered service point (that is

experiencing problems) and the source transformer. Walk to a

position that is approximately 2/3's of the way from the transformer

toward the metered service point. Position yourself along what

you would consider the probable path of the underground service.

This is where you should begin to take readings with the ACVGD®.

With the SCALE ADJUST knob turned fully Clock Wise (CW; ie, ⟳) place the probes at a comfortable

distance from your sides and push them into the ground enough to establish a firm contact with the soil. It

is not necessary to try to stick the probe tips deep into the soil in order for the instrument to detect the

presence of an A.C. voltage in the soil. However, it is important to try and maintain a similar amount of

depression into the soil, and a consistent distance between the probes, from one reading to the next.

This will help you to make the "comparisons" of the readings (from one sample reading to the next) more

meaningful. In other words, if the probes will easily penetrate two inches into the soil then try to take all

5

the readings by sticking them into the soil about two or three inches deep. If you go five or six inches

deep, after taking readings at two inches deep, the A.C. voltage, at the deeper point, will likely provide a

significantly higher reading, which could temporarily mislead you into thinking the fault point is closer than

it actually is. Also, when you hold the probes 'comfortably' at your sides if they are about 3 to 3.5 feet from

each other then you should try to maintain about that same distance between them as you probe for the

voltage reading.

Let's assume that the first location of your probes is represented by position

#1 as shown in Figure 2. Assuming that there is sufficient A.C. voltage signal

from the fault to cause the instrument's meter to give an up-scale indication,

you can make a mental note of how high the reading is at that position. Leave

one of the probes in place and move the other one about 45 degrees Counter

Clock Wise (CCW; ie, ⟲) around from its original position. This brings you

into position #2 and you can see a higher reading than you had in position #1.

Successive readings, moving the one probe CCW (⟲) will bring you to

the point of "highest" relative reading. This "highest" reading position

establishes the 'general direction' of the fault. This is the path indicated

by the dashed line that is drawn between the probe tip positions on the

ground. Next, you will have to determine which way you should move

along the dashed line shown in Figure 2. Move along the line in either

direction you choose. If the reading you get after moving is higher than

the previous then continue to move along the line in that direction. If the

reading is lower than the first then go the other direction along the line

and follow that procedure until you approach the point of the fault.

1.4 –THE ZERO READING POINT –As you

move closer to the fault, you will have to turn the

SCALE ADJUST knob counterclockwise (CCW;

⟲) in order to keep the indicating needle of the

panel meter from staying pegged solidly at the

right side of the scale. Again, what you will

observe is a pattern of increasing readings as

you move toward the fault. Then as you pass

one probe just beyond the point where the fault

actually is you will notice a decline in the relative

reading. Moving the probes in football chain

fashion in the same direction will again result in a

lower relative reading. If you go too far the

readings will rise sharply at first; but, as you

continue moving in that direction the readings will

become lower and lower. However, you can find

a point shown as position #5 in Figure 2 where

the reading is essentially ZERO. At this point you

will be standing directly above the fault. Why does a ZERO reading indicate the point of the fault?

Realizing that the voltage patterns in the soil are in the shape of concentric circles around the point of the

fault, note the diagram of dashed lines in Figure 2. Thus, when you have both probes on the same

"voltage pattern circle" there is no difference for the instrument to read, hence it will indicate ZERO. It is

this ZERO reading position that you are looking for.

6

1.5 –OTHER READING TECHNIQUES

Two other techniques you may choose to use in locating the point of the fault are:

1.5.1 -THE TRIANGULATION TECHNIQUE

Now let's look at Figure 3. You will notice that it is essentially the same as Figure 2 but another set of

readings is shown. Here you see that the 'general direction' indicated by position #C establishes a

second line of direction and this second line intersects the one that was established in Figure 2. It is

at this point of intersection that you would expect to find the fault. This is referred to as the

triangulation technique for locating the point of the fault. You probably see already how to achieve this

but let's run through it briefly;

(1) Take your first set of readings as shown in position #1 through #3 and note the 'general

direction' line the probes establish;

(2) Next, pick another position about 12 to 15 feet to the side (along the 90 degree line) of position

#3;

(3) Determine the 'general direction' as shown in position #C. Observe the indicated point of inter-

section of the two 'general direction' lines.

(4) Probe along this second line in football chain fashion in the direction of the intersection point.

The closer to the fault that these initial indications are found the

better the accuracy of determining the intersection point. If you

appear to be 15 to 20 feet from the intersection point you should

take several more readings along both of the direction lines

established above. When you work the readings of both

direction lines to within 4 to 6 feet of the intersection point you

can "literally" draw two lines in the soil for the direction lines you

have been following and the point where they cross will be very

close to the point of the fault. It is recommended, however, that

you confirm the actual point by finding the ZERO reading point

(described previously) along both direction lines. If the ZERO

reading points, as determined along both direction lines,

coincide then you can be confident that there is A.C. voltage present from some source at that point

in the soil.

Some users prefer to begin their probing with the ACVGD®after they assure themselves of the exact

path of the underground service cables, because (for them) this adds an element of certainty that they

are probing in the correct area(s). This technique we shall refer to as:

1.5.2 -THE CABLE-PATH TECHNIQUE

With this approach you would simply use any "path finding" equipment, that you may already have,

that can sense the presence of the electromagnetic field emitted by the energized service wires.

After marking or mentally noting the path of the conductors, you would then go to the location (along

this path) about 2/3's of the distance from the pad-mount transformer toward the metered service

point. There you would begin to take readings in football chain fashion (in your choice of direction)

along the actual path of the conductors. Depending upon where the fault is from this initial point, you

may find;

(1) that you have no readings even at the full clockwise (CW; ie, ⟳) setting of the SCALE

ADJUST knob, in which case you have to decide which direction to move along the cable path

7

to continue taking readings. If you go far from the starting location without getting any readings

you probably should go back to the 2/3's point, to start again, and probe in the other direction.

Remember that as you get close to the source

transformer (into the transformer zone) you will

begin to get readings due to the a.c. current flowing

back to the transformer's grounding rod. As was

pointed out in the opening discussion, the voltage

patterns will make a more concentrated pattern at

both the point of the fault and at the pad-mount

transformer's ground rod. You need to be mindful

of this since you will almost always find strong

readings within 6 to 8 feet of the pad-mount

transformer,or near the ground rod at the base of the overhead transformer pole, that serves

underground secondary service conductors. Of course there are times when the fault is within

the area of the transformer and the hunt for the exact spot of the fault is more difficult,but still

possible.

(2) that you have readings and so you move the probes in football chain fashion, in either direction

you choose, to get your next comparison reading. Then if the next reading is higher you can be

reasonably confident that you should continue moving along the cable's path in that direction.

However, if the readings seem to be getting lower then you should go in the opposite direction.

Once you have determined the direction that produces higher readings you simply continue, in

football chain fashion, along the cable's path until the readings drop off sharply and you can find the

ZERO point as described in the ZERO POINT paragraph above.

The technique that you may use is a personal choice, it depends on what you feel comfortable with. In

either approach it may be of some help if you take a sample reading about 8 feet from the source

transformer (within the "transformer zone") to determine how high the reading may actually be when you

begin to come close to the point of the fault (within the fault zone).

1.6 –TYPICAL USERS ACTUAL PRACTICE

The football chain technique of probe

movement described in the previous

paragraph(s) is what you can use once you

come near to the fault location. However, the

real-world user technique (as reported by

users) for getting into the general area of the

fault is a bit more “swashbuckling” than has

been described thus far. Football chain

movement is rather clumsy and it is more

comfortable to be able to walk straight ahead

as one is probing for the fault. Whenever the

"seasoned user" begins to probe at a new job

site; instead of initially moving the probes in

football chain fashion, the operator positions

himself/herself such that they have the probes stuck in the ground, one at each side of their body, and

they are facing in the direction they wish to walk to begin the probing process. Then the operator keeps

one probe in the ground (we will call it probe “A”) as he/she steps forward one step moving the other probe

(probe “B”) ahead of probe “A” and then sticks probe “B” into the ground. At this position the operator

looks to see whether there is any change in the panel meter reading, either higher or lower, from the

previous position where probes “A” and “B” were both stuck in the ground. If there is an increased reading

then the operator keeps probe “B” in the ground and then steps forward again but this time moving probe

“A” ahead of probe “B” by one step and sticks probe “A” in the ground to see if the reading increases

8

again. Repeating this process until the panel meter reading reaches a maximum value and then begins

to decline will bring the operator within range of the fault point. This technique allows the user to move

along the cable path by walking in a straight ahead manner while moving the probes alongside their body.

Once the operator observes the PEAK reading and then sees a declining value on the ACVGD®panel

meter he/she can then utilize the football chain technique to move the probes to locate the exact point of

the fault by determining the ZERO reading point as described above.

9

2.0 GENERAL INFORMATION ABOUT THE ACVGD®

2.1 –WARRANTY

The ACVGD®instrument, and the probes, are guaranteed to be free from material and manufacturing

defects for a period of one (1) year from the date of shipment to buyer. The probe tips are not

warranted against normal wear and tear.

The ACVGD®instrument is guaranteed self-protected for 60HZ A.C. voltages up to 300 Volts-

RMS. Application of voltages higher than 300 Volts-RMS may result in failure of the circuit's

electronics and in such event the warranty is void.

The instrument storage box (either orange or white in color) is guaranteed for ninety (90) days.

Batteries are not guaranteed.

Modification of the Instrument, or the Probes, by anyone other than the Manufacturer will VOID the

Warranty.

2.2 –BATTERY REPLACEMENT

It is recommended that you use alkaline

type, 9 volt batteries of a type similar to

the Duracell Plus Power DuraLock

MN1604 or the UltraLife U9VL-BP

Lithium batteries. NOTE: For very cold

weather conditions (which cause most

batteries to loose their charge more

rapidly, especially when stored

outdoors) lithium batteries, such as the

UltraLife U9VL-BP, will hold their charge

longer and maintain their output closer

to the 9 volt level better than any other

type of battery currently available;

however, they are more expensive than

the Alkaline batteries.

There are two batteries in the instrument and you must replace both at the same time, otherwise the

instrument will soon begin erratic operation. If this happens, the first items to check are the batteries.

Since the BATT-TEST push-button on the face of the instrument takes the reading from only one

battery,you will have to swap the two batteries in order to read the condition of the second battery.

Remember, when in doubt, remove both batteries and check them with a voltmeter. You should replace

them whenever they read less than 7.5 volts.

To replace the batteries you must first remove the four screws that secure the faceplate to the box. Then

you can lift the faceplate up until you see the batteries inside. Use your finger to lift each battery out of the

metal clip. Set the faceplate and the two batteries next to the top edge of the instrument. Now you simply

unsnap the old batteries from their connectors and then reverse the process to install the new batteries.

2.3 –PROBE CONSTRUCTION

The probe body is made of industrial quality Isophthalic Polyester Resin, reinforced with fiberglass, that

has excellent electrical, thermal, and mechanical properties for this application. It is similar to the “hot-

sticks” used by electric utility crews. The probe wiring is 18 AWG test probe wire rated at 5,000 volts d.c.

When the banana jack plugs are plugged flush into the terminals of the instrument no electrical contact

10

points exist anywhere along the length of these wires. This is a safety feature that is designed into the

probes.

The probe tips are made of stainless steel (1/4 inch solid rod) for added strength and durability. One end

of the rod is threaded using a 1/4-20 NC die. The wire is secured to the end of the probe tip, within the

probe's handle, by two 1/4-20 NC finished (zinc coated) hex nuts.

2.4 –PRODUCT REDESIGN NOTICE

Your ACVGD®unit may come equipped with probes that were recently redesigned. Our previous design

included stainless steel hose clamps that held the stainless steel probe tips inside the probe. The new

design replaces the clamps with one or two piece oxide steel shaft collar clamps. These clamps are far

superior in many ways to the worm gear type of clamps that we used in the past. We’d like to hear your

feedback on this new design –both positive and negative. Most importantly, if you find any problems with

this new design, we’d like to know. Send us a quick note via email to troy@hbrossmfg.co.

Former Design

New Design

2.5 –DISCLAIMER

Working with electricity can be dangerous. Responsibility lies with

you, the user of the ACVGD®, to act safely when using this device.

Inspect the instrument before use. Be sure that the probe wires are

not damaged, exposing any conductor. The instrument must be

used in accordance with the manufacturer’s user manual and only

for the purpose which it was designed. The manufacturer and

distributor(s) of this product shall neither assume nor accept any

liability or responsibility for consequential damages or injury

resulting from the use or misuse of this product or any of its

component parts. In using this product, the user of the ACVGD®

assumes the responsibilities of ownership, use and operation and

the user agrees to hold harmless the manufacturer and its

distributors, partners and employees for any incident or action

involving the use of this product.

11

TYPICAL LAYOUT OF FACILITIES

Figure 1

GROUND

HOUSEHOLD

METER BASE

CHAIN LINK FENCE

U.G. WATER DISTRIBUTION PIPES

PADMOUNT

TRANSFORMER

GROUND

ROD

x x x x x x x x x

#1

#2

#3

#4

#5

TYPICAL PATTERN OF VOLTAGE CIRCLES NEAR THE SURFACE

FAULT ZONETRANSFORMER ZONE

EACH DASHED CIRCULAR SHAPE

REPRESENTS A SPECIFIC VOLTAGE

AND ITS PATTERN WITHIN THE SOIL

POINT OF

THE FAULT

Figure 2

UNDERGROUND SERVICE CABLE

12

#1

#2

#3

#4

#5

TRIANGULATION METHOD OF LOCATING THE FAULT POINT

FAULT ZONETRANSFORMER ZONE

EACH DASHED CIRCULAR SHAPE

REPRESENTS A SPECIFIC VOLTAGE

AND ITS PATTERN WITHIN THE SOIL

POINT OF

THE FAULT

Figure 3

#A

#B

#C

13

WHAT IS INCLUDED WITH THE ACVGD®ROSS METER®?

1. Utility Dry Box –(Outside Width: 7.75", Length: 15", Height: 6.5", Volume: 5.6 Liters) Orange in

color. Extra-thick co-polymer construction wall will not warp from sun, cold, or rough handling.

Hand-laid lid gasket seals the inside from moisture to protect the ACVGD®from damage. Strong

reinforced steel pin hinge system. Heavy-duty steel bar latch system with locking feature keeps

the ACVGD®safe and secure. A padlock (not included) may also be used, if desired.

2. The ACVGD® device includes two 9 volt batteries already installed in the unit. Its case is made of

thermoplastic ABS which is mar and scratch resistant, chemical resistant and heat resistant to

475 degrees. The handy neckstrap is made of light weight nylon webbing which is military spec

and has a breaking strength of 1200 pounds.

3. Two probes which are constructed of Isophthalic Polyester Resin reinforced with fiberglass. Each

probe includes the 18 AWG wiring which is rated at 5,000 volts D.C.Banana jack plugs are also

included which are used to connect the probes to the ACVGD® . The probe tips are made of

stainless steel T304 and are ¼” diameter (standard specification ASTM A276, QQS-763,

T304/304L).

4. One User Manual (physical form) and digital (available online via computer or smartphone).

Table of contents

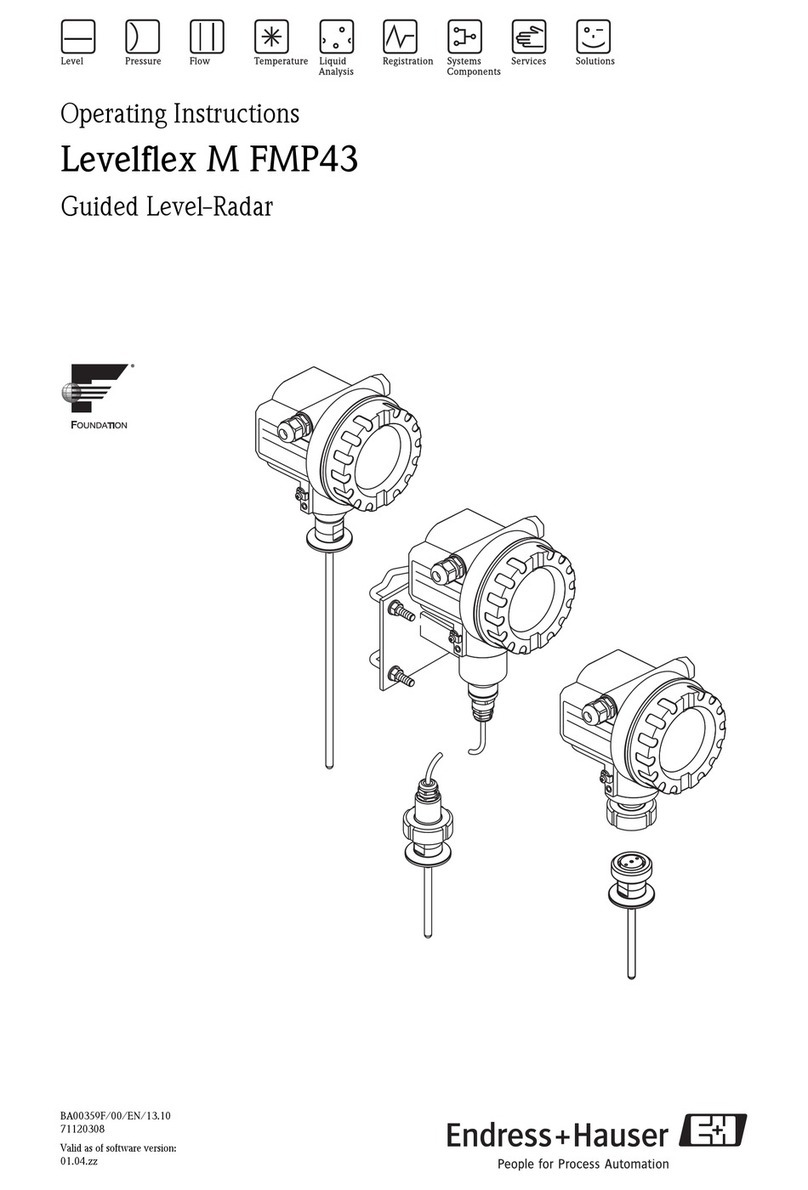

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Memosens CFS51 operating instructions

DeFelsko

DeFelsko PosiTector SHD instruction manual

Endress+Hauser

Endress+Hauser Levelflex M FMP43 operating instructions

amc VIBRO

amc VIBRO AV CONDITIONER 1000 user manual

EMCIS

EMCIS EA-300 Operation manual

PASCO

PASCO PS-3234 Product guide