5307157

Service

Pressure Relief Procedure

WARNING

SKIN INJECTION HAZARD

Fluid under high pressure can be in-

jected through the skin and cause seri-

ous injury. High –pressure fluid from

gun, hose leaks, or ruptured components will

pierce skin. This may look like just a cut, but it is a

serious injury that can result in amputation. Get

immediate surgical treatment. To reduce the risk

of an injury from injection, splashing fluid, or mov-

ing parts, follow the Pressure Relief Procedure

whenever you:

are instructed to relieve the pressure,

stop spraying/dispensing,

check or service any of the system equipment,

or install or clean the spray tips.

1. Engage the spray gun safety latch.

2. Turn off the air to the motor.

3. Close the bleed-type master air valve (required in

your system).

4. Disengage the gun or dispensing valve safety

latch.

5. Hold a metal part of the gun firmly to a grounded

metal waste container, and trigger to relieve the

fluid pressure.

6. Engage the safety latch.

7. Open the pump drain valve (required in your

system), having a container ready to catch the

drainage.

8. Leave the drain valve open until you are ready to

spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, very slowly loosen the

tip guard retaining nut or hose end coupling and relieve

pressure gradually, then loosen completely. Then clear

the tip or hose.

WARNING

A bleed-type master air valve is required in your

system, to reduce the risk of serious injury includ-

ing injury from moving parts if you are adjusting or

repairing the air motor.

The bleed-type master air valve relieves air trapped

between this valve and the motor after the air

regulator is shut off. Trapped air can cause the

motor and pump to cycle unexpectedly. Mount the

valve close to the pump, downstream from the air

regulator.

WARNING

Never operate the pump with the air motor plates

removed. The piston in the air motor, located

behind the air motor plates, moves when air is

supplied to the motor. Moving parts can pinch or

amputate your fingers or other body parts.

Restarting a Stalled Motor

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

CAUTION

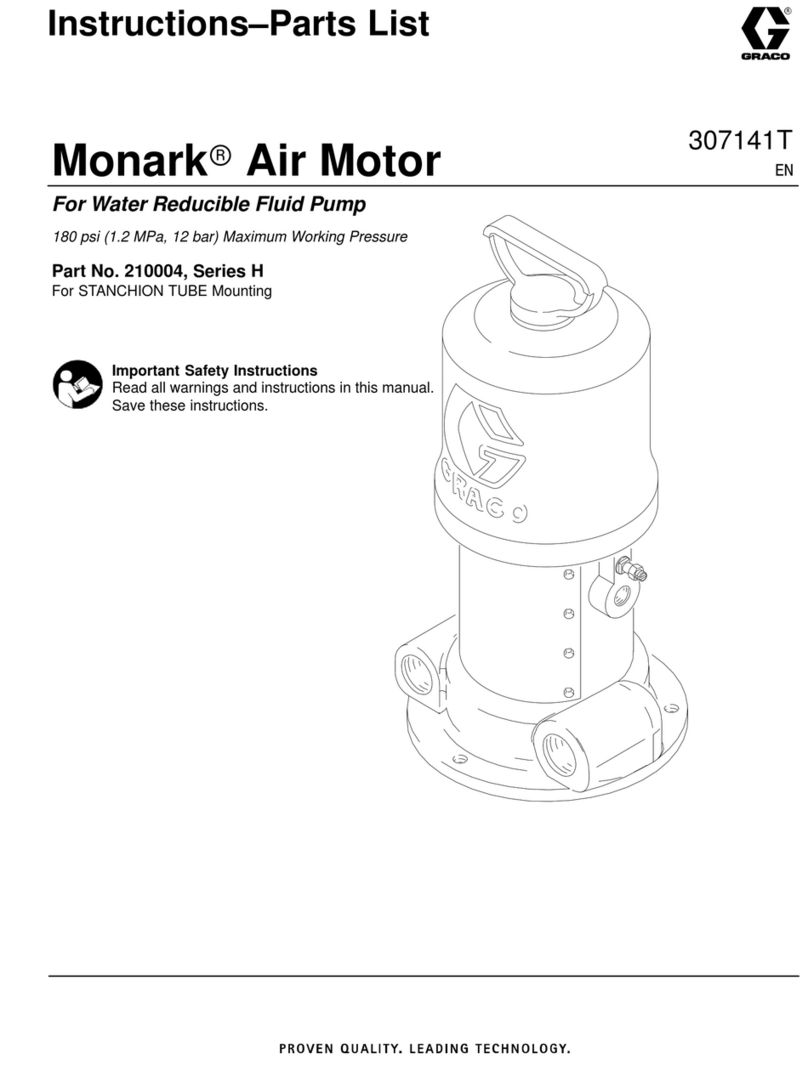

Never exceed 180 psi (12 bar, 1.2 MPa) air supply

pressure to the air motor. Exceeding this pressure

may cause the air motor to stall with the air transfer

valves stuck at mid position, making the air motor

inoperative.

To reseat the air transfer valves and restart a stalled

motor, relieve the air supply pressure to the motor by

closing the bleed-type master air valve. If the air

transfer valves fail to reseat, screw the cap nut (24)

out of the cylinder (22), pull up on the trip rod (30) and

screw the cap nut back into the cylinder. See Fig. 2.

Be sure the air supply pressure is less than 180 psi (12

bar, 1.2 MPa) before opening the bleed-type master air

valve.