EVCO S.p.A. EVDRIVE03 | User manual ver. 3.7 | Code 144EPDE374

Pa e 3 of 76

Index

1

INTRODUCTION ................................................................................................................................... 5

1.1

Introduction ........................................................................................................................................ 5

1.2

Summarizin table of the main features and available models ................................................................... 6

2

DESCRIPTION ...................................................................................................................................... 8

2.1

Description .......................................................................................................................................... 8

3

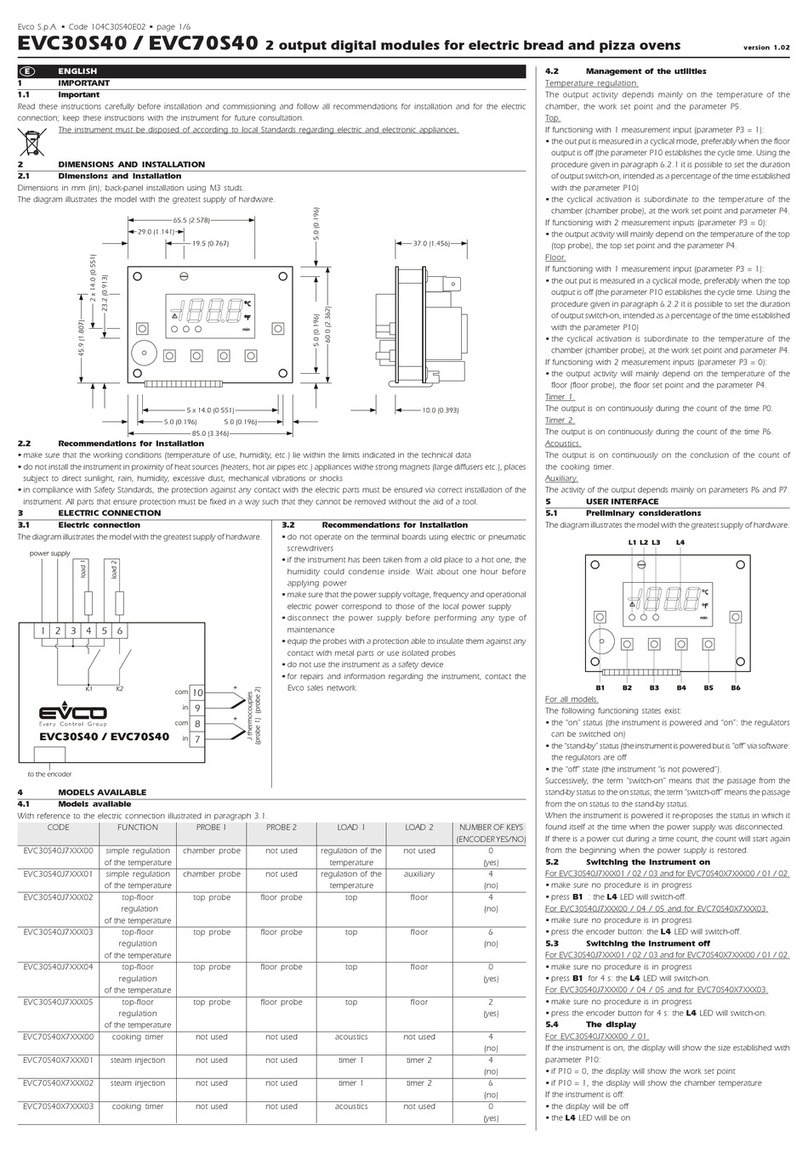

SIZE AND INSTALLATION ...................................................................................................................... 9

3.1

Size .................................................................................................................................................... 9

3.2

Installation ........................................................................................................................................ 10

3.3

Additional information for the installation .............................................................................................. 10

4

ELECTRICAL CONNECTION .................................................................................................................. 11

4.1

Meanin of the connectors .................................................................................................................. 11

4.2

Example of electrical connection .......................................................................................................... 15

4.3

Additional information for electrical connection ...................................................................................... 16

5

USER INTERFACE ............................................................................................................................... 17

5.1

Preliminary information ....................................................................................................................... 17

5.2

Keyboard (not available in the blind versions) ........................................................................................ 17

5.3

Si nallin LEDs .................................................................................................................................. 17

6

OPERATION ....................................................................................................................................... 19

6.1

Switch on and resynchronization .......................................................................................................... 19

6.2

Operatin mode ................................................................................................................................. 21

6.2.1

Preliminary information ............................................................................................................... 21

6.3

Stand-by and operation mode selection ................................................................................................ 21

6.4

Enablin EVDRIVE03 .......................................................................................................................... 22

6.5

Analo positioner control ..................................................................................................................... 22

6.6

Al orithm start-up .............................................................................................................................. 23

6.7

Manual mode ..................................................................................................................................... 23

6.8

Debu in mode ................................................................................................................................ 24

6.9

Superheat control al orithm ................................................................................................................ 24

7

CONFIGURATION ............................................................................................................................... 26

7.1

Unit of measurements ........................................................................................................................ 26

7.2

Confi urin a built-in version ............................................................................................................... 26

7.3

Confi urin a blind version .................................................................................................................. 31

7.4

Confi urin the device throu h the pro rammin key EVKEY10 ............................................................... 32

7.5

Connectin the device throu h the set-up software system Parameters Mana er ....................................... 33

7.6

Main menu ........................................................................................................................................ 33

7.7

Backup and restore ............................................................................................................................ 34

7.8

List of confi uration parameters ........................................................................................................... 35

8

SERIAL COMMUNICATION ................................................................................................................... 53

8.1

Preliminary information ....................................................................................................................... 53

8.2

CANBUS serial communication ............................................................................................................. 53

8.3

MODBUS serial communication ............................................................................................................ 55

9

ALARMS AND ERRORS ........................................................................................................................ 56

9.1

Alarms and errors .............................................................................................................................. 56

9.2

Memory error .................................................................................................................................... 56

9.3

Confi uration error ............................................................................................................................. 56

9.4

Communication error .......................................................................................................................... 57

9.5

Probe error ........................................................................................................................................ 58