Focal Point POLARIS User manual

Other manuals for POLARIS

1

Table of contents

Other Focal Point Indoor Fireplace manuals

Focal Point

Focal Point L23 CHESHIRE Guide

Focal Point

Focal Point versailles Guide

Focal Point

Focal Point AMERSHAM LED ELECTRIC SUITE Assembly Instructions

Focal Point

Focal Point vesailles User guide

Focal Point

Focal Point EVOKE LED ELECTRIC Assembly Instructions

Focal Point

Focal Point EF11-36 PASADENA Assembly Instructions

Focal Point

Focal Point AVONBURY CUBE LED ELECTRIC COMPLETE SUITE... Assembly Instructions

Focal Point

Focal Point GRANGE MULTIFLUE Assembly Instructions

Focal Point

Focal Point eko 3040 Guide

Focal Point

Focal Point EF461L-E Assembly Instructions

Focal Point

Focal Point REFLECTION Guide

Focal Point

Focal Point COLUMBUS EF12-36 Assembly Instructions

Focal Point

Focal Point ATHERSTONE SLATE ELECTRIC SUITE Assembly Instructions

Focal Point

Focal Point NOIR L23 Assembly Instructions

Focal Point

Focal Point Wickes User manual

Focal Point

Focal Point blenhein multiflue Assembly Instructions

Focal Point

Focal Point MULTIFLUE GAS FIRE RANGE Guide

Focal Point

Focal Point OBLIQUE Guide

Focal Point

Focal Point BLENHEIM Assembly Instructions

Focal Point

Focal Point L27G Guide

Popular Indoor Fireplace manuals by other brands

Astra

Astra H8295 Installation and operation instructions

Dovre

Dovre 2000CBGL Installation and operating manual

STRAXGAS

STRAXGAS Theme 22 Installation and servicing instructions

Amantii

Amantii BLT-IN-5124 Installation and operating instructions

Hearth Technologies

Hearth Technologies HEAT-N-GLO 6000XLT-AU Installation and operation instruction

Riello

Riello RS 45/M BLU Installation, use and maintenance instructions

Temp-Cast

Temp-Cast 2000 installation manual

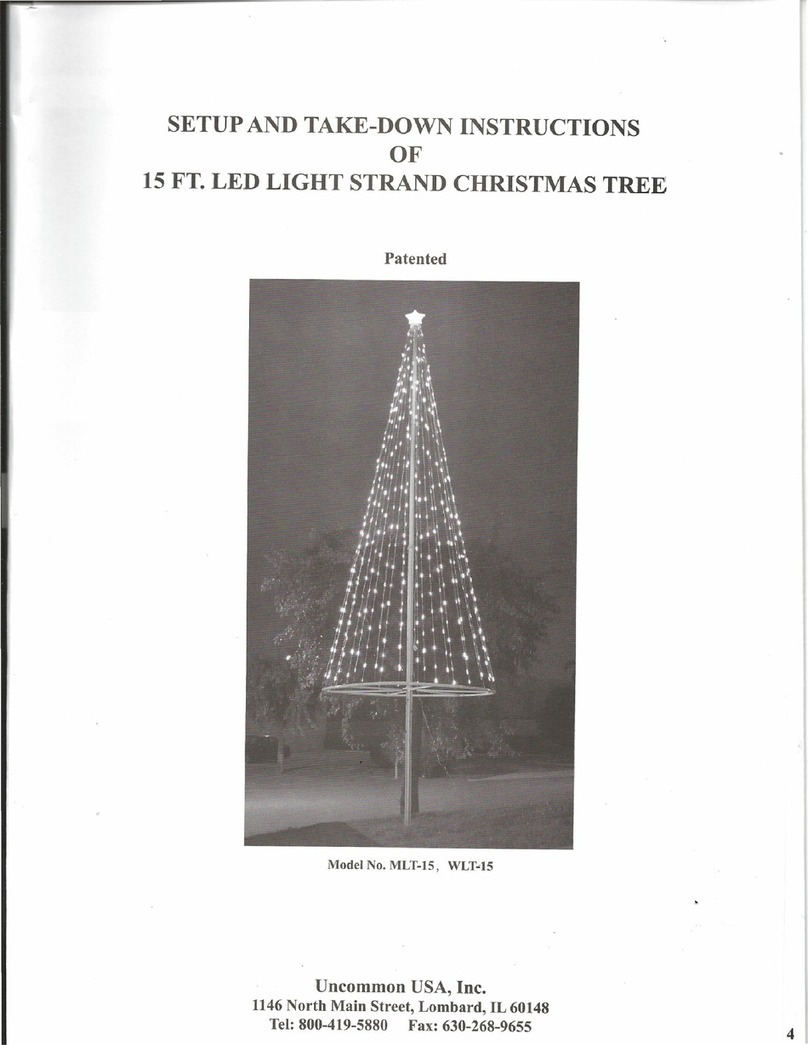

Uncommon USA

Uncommon USA MLT-15 SetUp and Take Down Instructions

Hearth & Home

Hearth & Home Majestic SB100 owner's manual

MHSC

MHSC WEF26 Homeowner's installation and operating instructions

Napoleon

Napoleon GDS60-N Installation and operation instructions

Lennox

Lennox VILLA VISTA 850028M Installation and operation instructions