molex 63811-1500 User manual

Other molex Crimping Tools manuals

molex

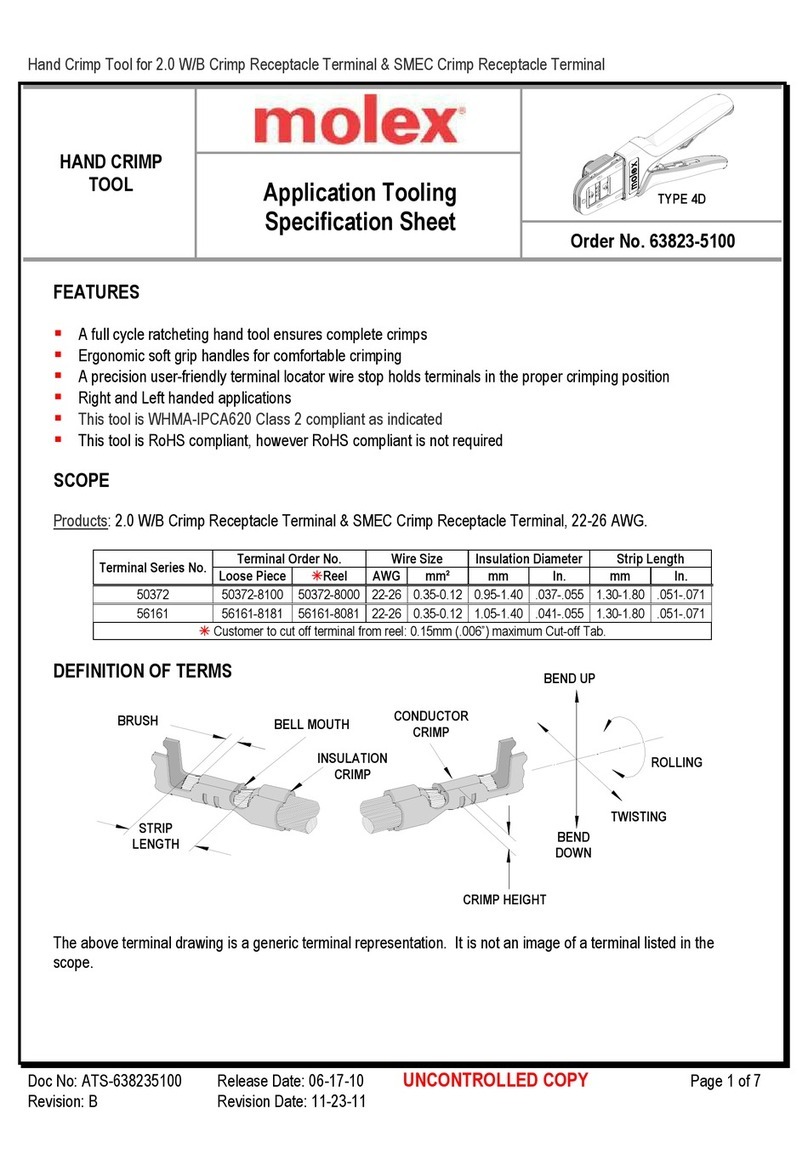

molex 63823-5100 User guide

molex

molex 207129 Series User manual

molex

molex 63811-7000 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63811-1200 User manual

molex

molex 207128 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

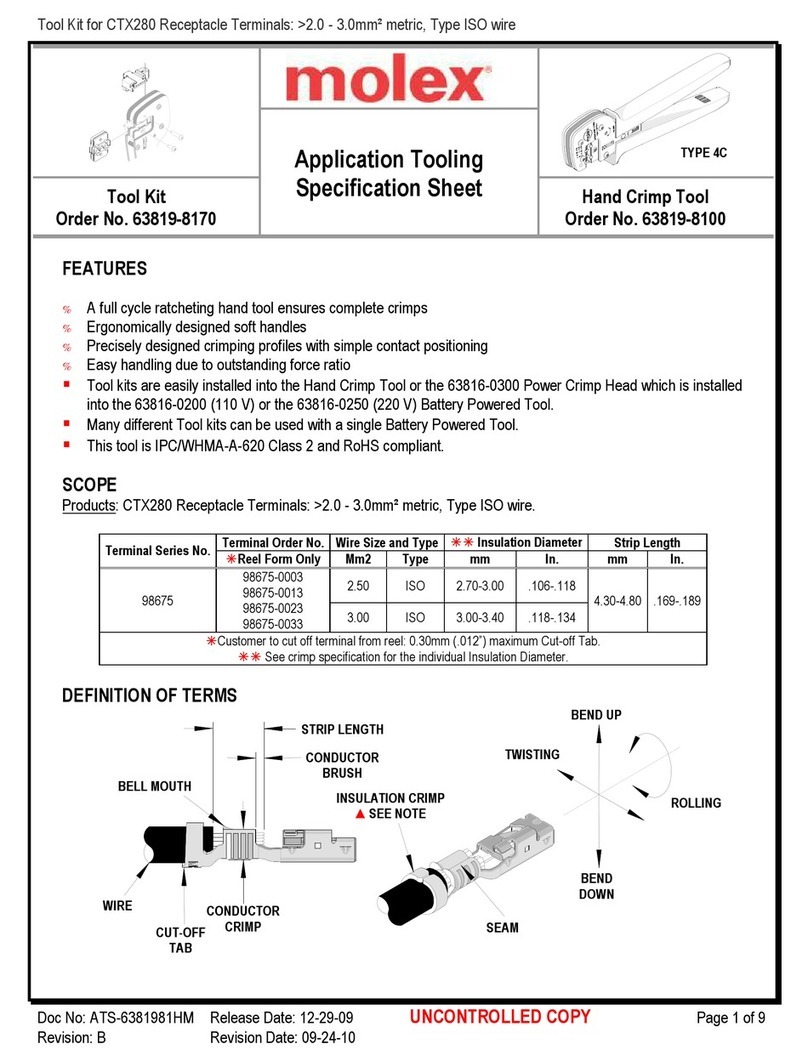

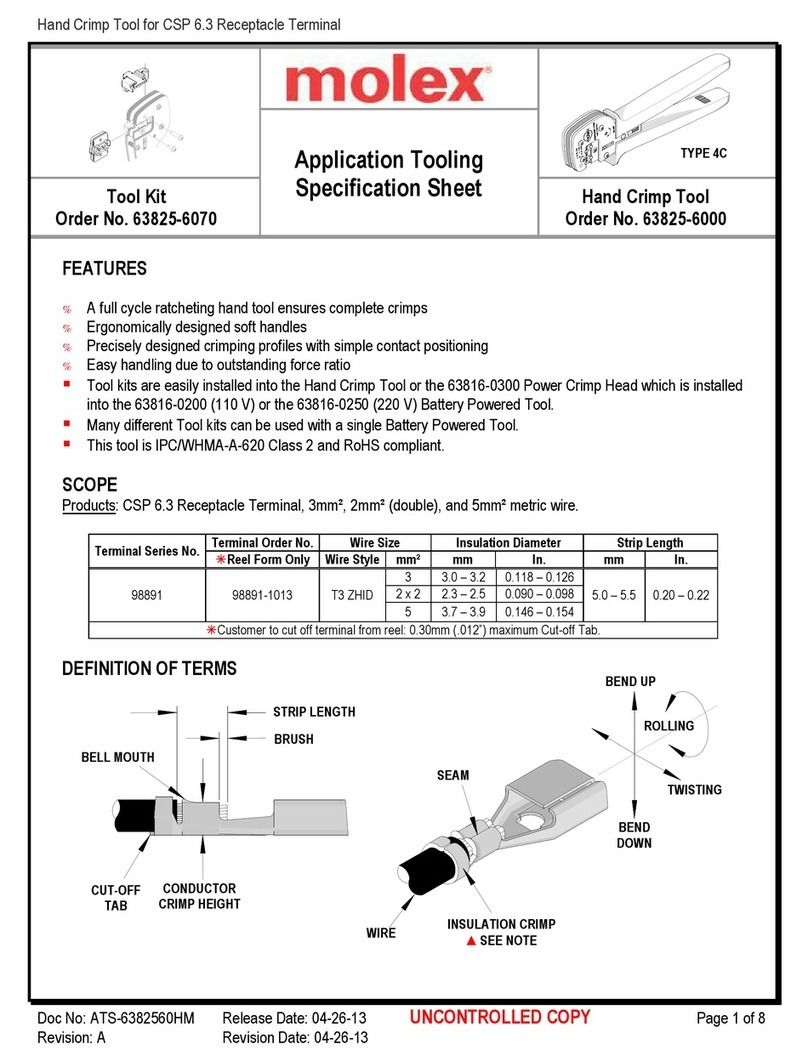

molex 63825-6070 User manual

molex

molex 35768 Series User manual

molex

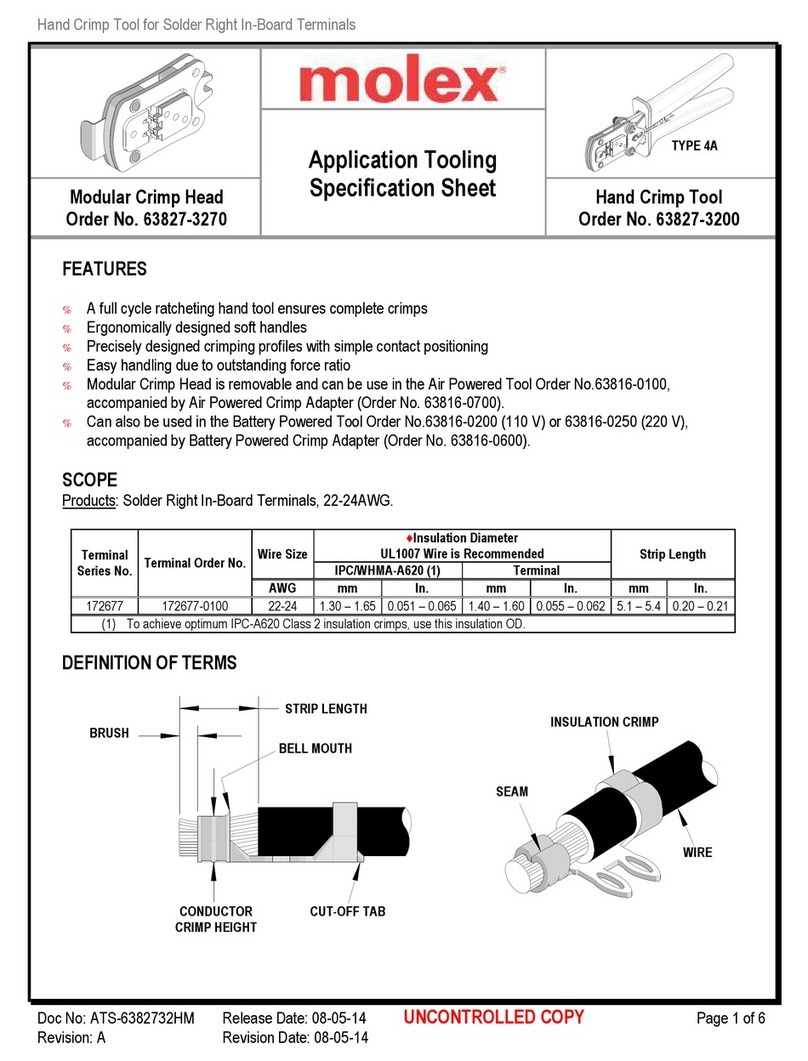

molex 63827-3200 User manual

molex

molex CR60670B User manual

molex

molex 63823-5200 User manual

molex

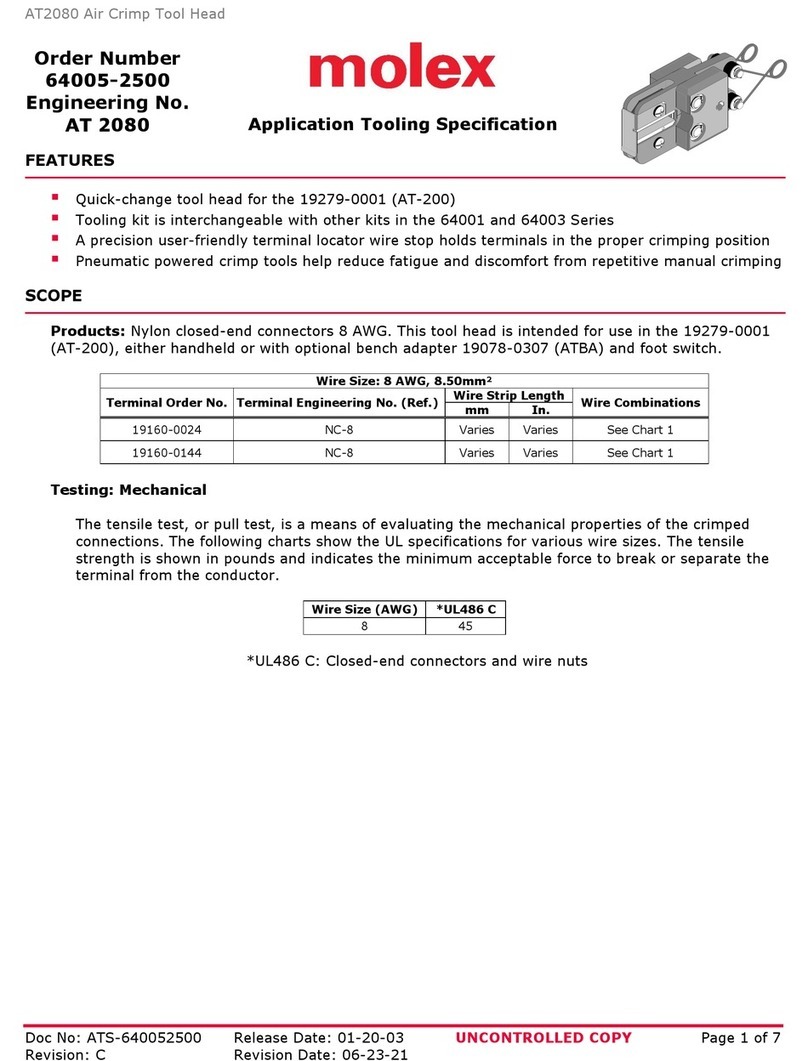

molex AT 2080 User guide

molex

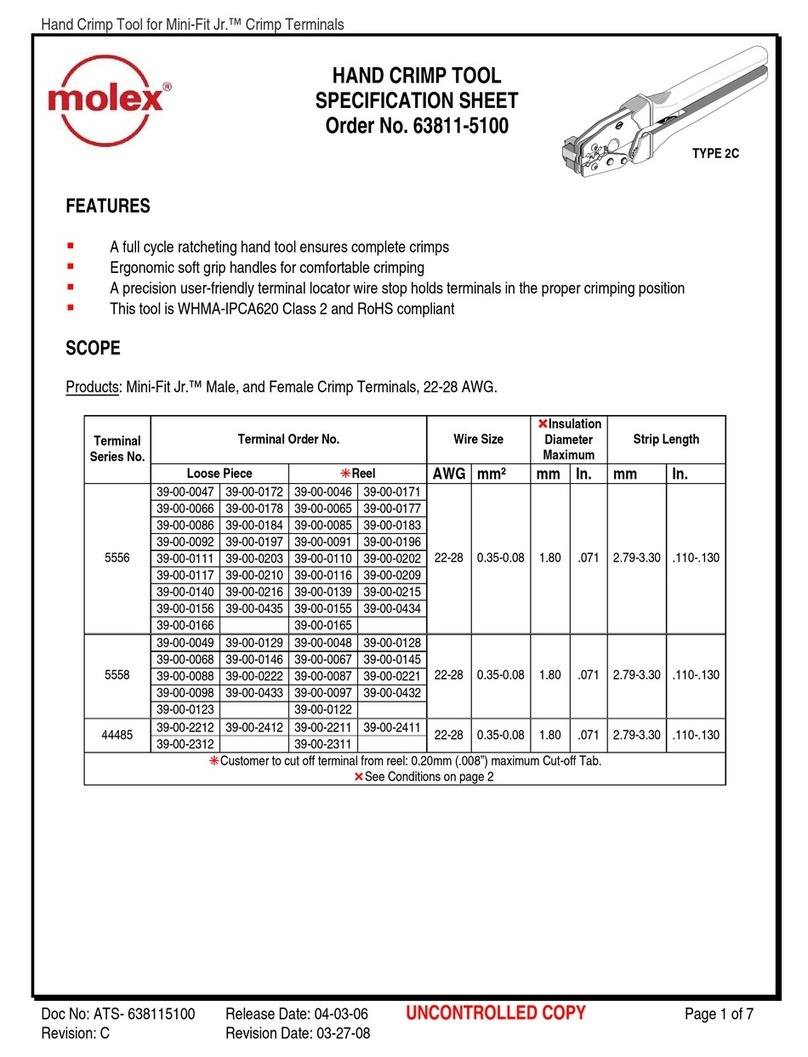

molex 63811-5100 User manual

molex

molex 63816-0200 User manual

molex

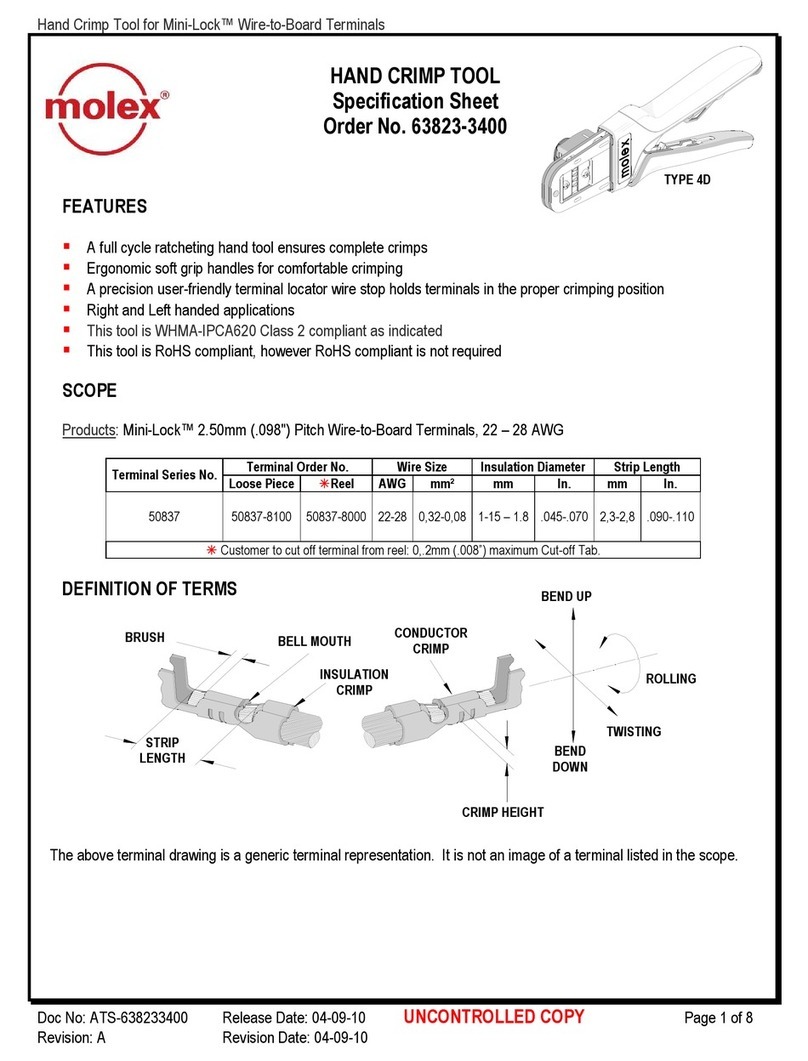

molex 50837 User manual

molex

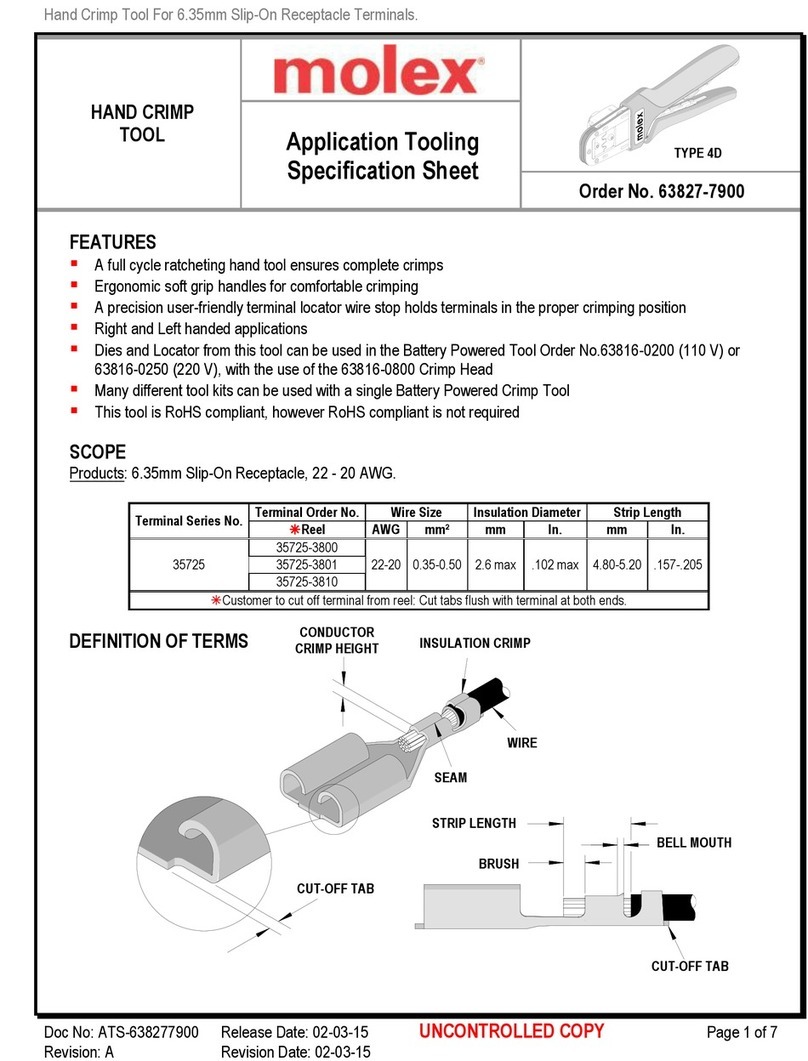

molex 63827-7900 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet