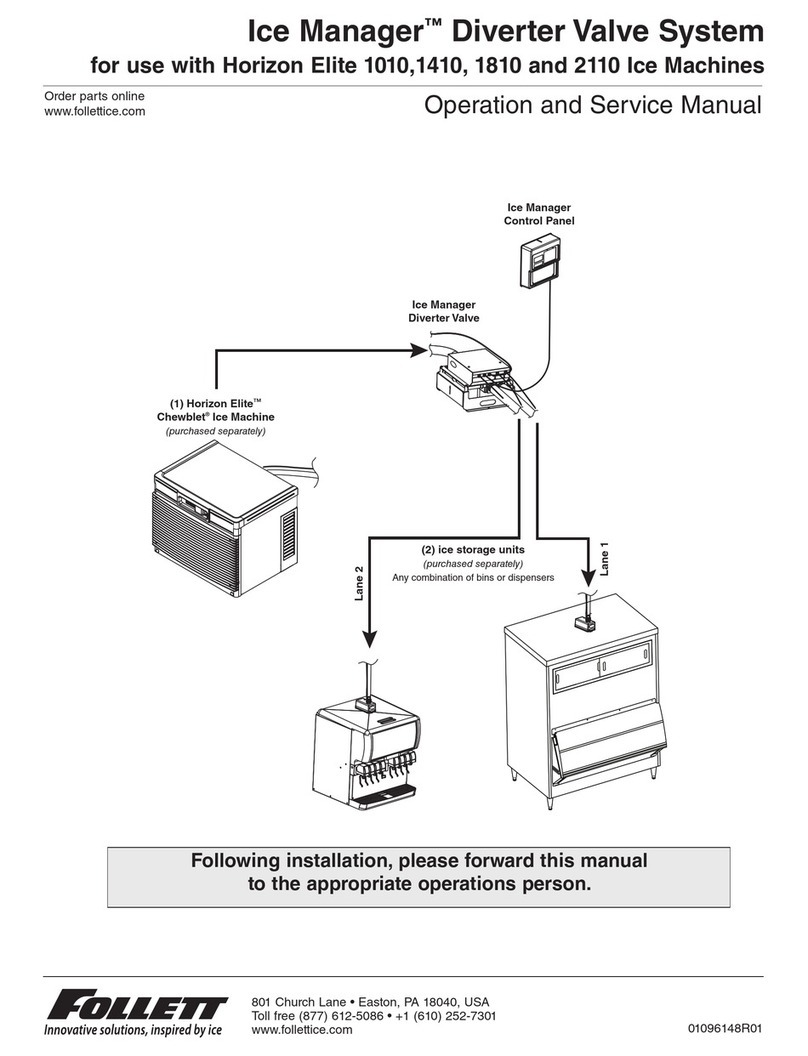

Ice Manager Diverter Valve System Operation and Service Manual 3

Table of contents

Welcome to Follett

Before you begin .......................................................... 4

Specications

Electrical ................................................................ 5

Plumbing ................................................................ 5

Temperature requirements .................................................. 5

Dimensions .............................................................. 5

Operation

General information........................................................ 6

Audible alarm ............................................................ 6

Cleaning and preventive maintenance ......................................... 7

Preventive maintenance .................................................. 7

Weekly exterior care ..................................................... 7

Cleaning and sanitizing................................................... 7

Service

System components ...................................................... 20

System operation ........................................................ 20

Control logic .......................................................... 20

Auto mode............................................................ 20

Manual mode ......................................................... 20

Diverter valve module ..................................................... 21

Control board ......................................................... 21

Divert gearmotor ....................................................... 21

Divert paddle.......................................................... 21

Ice Manager diverter valve wiring diagram ................................... 22

Control panel............................................................ 23

Membrane switch ...................................................... 23

LCD screen ........................................................... 23

Audible alarm ......................................................... 23

Ultrasonic sensor ........................................................ 24

Ice level set points........................................................ 25

To view ice levels ...................................................... 25

To view set points ...................................................... 25

To change set points.................................................... 25

Troubleshooting

Ice shortage with audible alarm ........................................... 26

Ice shortage without audible alarm ......................................... 27

Service Parts

Diverter valve module ..................................................... 28

Control panel............................................................ 29

Sensor distribution unit .................................................... 30

Follett Vision™ VU155 Ice Manager kit ........................................ 31

Follett Vision™ VU300 Ice Manager kit ........................................ 32

Cables ................................................................. 33