Forbes Marshall Aquacon 4000 User manual

Instruction Manual

Aquacon 4000

Conductivity Controller / Transmitter

01/2004

Preface

This manual serves to explain the use of the Aquacon 4000 Series. The manual functions in two ways,

firstly as a step by step guide to help the user operate the instrument, and secondly as a handy

reference guide. This instruction manual is written to cover as many anticipated applications of the

Aquacon 4000 as possible. If you have any doubts concerning the use of the instrument, please do not

hesitate to contact the nearest office of Forbes Marshall Pvt. Ltd.

The information presented in this manual is subject to change without notice as improvements are made,

and does not represent any commitment whatsoever on the part of Forbes Marshall Pvt. Ltd.

Forbes Marshall Pvt. Ltd. cannot accept any responsibility for damage or malfunction of the unit due to

improper use of the instrument.

Copyright ©2003 All rights reserved.

Forbes Marshall Pvt. Ltd.

01/2004

Safety Information

The Forbes Marshall Controller/ Transmitter shall be installed and operated only in the manner specified

in the Instruction manual. Only skilled, trained or authorized person should carry out installation, setup

and operation of the instrument.

Before powering up the unit, make sure that power source it is connected to, is as specified in the top

label. Failure to do so may result in a permanent damage to the unit.

The unit has live and exposed parts inside. If it has to be opened, make sure that the power to the unit

is off and disconnected.

The unit is Fuse protected. In the event the fuse has to be replaced, use only those as specified in the

manual.

The degree of protection against electric shock will be achieved only by observance of the

corresponding installation rules.

TABLE OF CONTENTS

1INTRODUCTION .......................................................................................................................................... 1

1.1 AT THE VERY BEGINNING......................................................................................................................... 1

1.2 INTENDED USE.......................................................................................................................................... 1

1.3 SAFETY INTSRUCTIONS ............................................................................................................................ 2

1.4 PUTTING OUT OF SERVICE /CORRECT DISPOSAL OF THE UNIT................................................................. 2

2PRODUCT DESCRIPTION.......................................................................................................................... 3

2.1 DESCRIPTION OF UNIT .............................................................................................................................. 3

2.2 MEASUREMENT AND CONTROL SYSTEM .................................................................................................. 4

2.3 UNIT OVERVIEW....................................................................................................................................... 5

2.3.1 Display Overview ............................................................................................................................... 7

2.3.2 Key functions ...................................................................................................................................... 7

2.3.3 LED indicators ................................................................................................................................... 8

2.3.4 Security codes..................................................................................................................................... 8

2.3.5 Menu overview ................................................................................................................................... 9

3ASSEMBLY AND INSTALLATION......................................................................................................... 11

3.1 MOUNTING THE UNIT ............................................................................................................................. 11

3.2 CONNECTION DIAGRAM......................................................................................................................... 13

4NORMAL OPERATION............................................................................................................................. 17

4.1 MEASUREMENT MODE ........................................................................................................................... 17

5CALIBRATION MODE .............................................................................................................................. 18

5.1 ENTERING CALIBRATION MODE............................................................................................................. 18

5.2 CALIBRATION......................................................................................................................................... 19

5.3 VIEW ACTUAL CELL CONSTANT AND CALIBRATION FACTOR................................................................. 20

6SETUP MODE .............................................................................................................................................. 21

6.1 ENTER SETUP MODE............................................................................................................................... 21

6.2 TEMPERATURE COMPENSATION (TC) SUB-FUNCTION ........................................................................... 23

6.3 SETTING TEMPERATURE (SET °C°F) SUB-FUNCTION ............................................................................. 24

6.4 CONTROL RELAY A/RELAY B(SP1/SP2) SUB-FUNCTION ................................................................... 25

6.5 CONTROLLER (CNTR) SUB-FUNCTION.................................................................................................. 27

6.6 CURRENT OUTPUT 1SUB-FUNCTION ..................................................................................................... 30

6.7 CURRENT OUTPUT 2SUB-FUNCTION ..................................................................................................... 31

6.8 WASH RELAY (WASH) SUB-FUNCTION................................................................................................. 32

6.9 MEASURING RANGE SELECTION (RANG) SUB-FUNCTION..................................................................... 33

6.10 CONFIGURATION (CNFG) SUB-FUNCTION............................................................................................. 34

6.11 CALIBRATION (CAL) SUB-FUNCTION .................................................................................................... 35

7RELAY MODES........................................................................................................................................... 36

7.1 VIEW RELAY SET POINTS........................................................................................................................ 36

7.2 MANUAL RELAY MODE .......................................................................................................................... 37

8TECHNICAL SPECIFICATIONS............................................................................................................. 38

8.1 GENERAL SPECIFICATIONS ..................................................................................................................... 38

8.2 SPECIFICATIONS FOR WALL MOUNT VERSION ........................................................................................ 39

8.3 SPECIFICATIONS FOR PANEL MOUNT VERSION....................................................................................... 41

9ACCESSORIES ............................................................................................................................................ 42

9.1 REPLACEMENT UNIT.............................................................................................................................. 42

9.2 ASSEMBLY ACCESSORIES ............................................................... ERROR!BOOKMARK NOT DEFINED.

10 GENERAL INFORMATION...................................................................................................................... 43

10.1 WARRANTY............................................................................................................................................ 43

10.2 PACKAGING /SCOPE OF DELIVERY ........................................................................................................ 43

10.3 RETURN OF GOODS................................................................................................................................. 43

10.4 GUIDELINES FOR RETURNING UNIT FOR REPAIR .................................................................................... 43

10.5 MAINTENANCE AND CLEANING............................................................................................................. 44

11 APPENDICES ............................................................................................................................................... 45

11.1 APPENDIX 1–UNIT FUSE AND JUMPER SETTINGS.................................................................................. 45

11.2 APPENDIX 2–CONDUCTIVITY OF VARIOUS AQUEOUS SOLUTIONS AT 25 °C /77 °F............................. 47

11.3 APPENDIX 3–SIMPLE EXPLANATION ON THE FUNCTION OF HYSTERESIS ............................................. 48

11.4 APPENDIX 4–GENERAL INSTRUCTIONS CONCERNING CONTROLLER SETTING .................................... 49

11.4.1 Control characteristic of Controllers used as limit value switch .............................................. 49

11.4.2 Control characteristic of P-Controllers as proportional controller.......................................... 49

11.4.3 Control characteristic of PI-Controllers as proportional integral controller .......................... 49

11.4.4 Control signal of Pulse length Controllers................................................................................. 50

11.4.5 Control signal of Pulse Frequency Controllers ......................................................................... 51

11.5 APPENDIX 5–ABBREVIATIONS USED IN MENU DISPLAYS ..................................................................... 52

Instruction Manual Aquacon 4000

1

1INTRODUCTION

1.1 At the very beginning

We thank you for having purchased the Forbes Marshall Aquacon 4000

The construction of the Aquacon 4000 employs leading edge technology and complies with

safety regulations currently in force. Notwithstanding this, improper use could lead to hazards

for the user or a third-party, and/or adverse effects on the plant or other equipment. Therefore,

the operating instructions must be read and understood by the persons involved before

work is started with the Aquacon 4000

Forbes Marshall Pvt. Ltd. do not accept any liability for damage that may arise from

neglecting information given in this manual.

This instruction manual identifies safety instructions and additional information by means of

the following symbols:

This symbol draws attention to safety instructions and warnings of potential

danger which, if neglected, could result in injury to persons and/or damage to

property.

This symbol identifies additional information and instructions which, if neglected,

could lead to inefficient operation and possible loss of production.

The instruction manual must always be stored close at hand, in a place accessible to all

people working with the Aquacon 4000.

If you have questions, which are not or insufficiently answered in this instruction manual,

please contact your nearest office of Forbes Marshall Pvt. Ltd. Our engineers will be glad to

assist you.

1.2 Intended use

Forbes Marshall Pvt. Ltd. Aquacon 4000 is intended solely for conductivity and temperature

measurement, as described in this instruction manual.

Any other use, or use not mentioned here, that is incompatible with the technical specifications

is deemed inappropriate. The operator is solely responsible for any damage arising from such

use.

Other prerequisites for appropriate use include:

−observing the instructions, notes and requirements set out in this instruction manual.

−observing all local safety regulations concerning safety at work.

−observing all information and warnings in the documentation dealing with the products

used together with the transmitter (housings, sensors, etc.).

−observing the prescribed environmental and operational conditions.

Instruction Manual Aquacon 4000

2

1.3 Safety intsructions

The Aquacon 4000 should be installed and operated only by personnel familiar with

the transmitter and who are qualified for such work.

A defective transmitter must neither be installed nor put into service.

The Aquacon 4000 must only be operated under the specified operating conditions

(see section 8).

The Aquacon 4000 must not be repaired by the customer.

The Aquacon 4000 must only be opened to replace the unit fuse or to set the jumper

for Pt100/Pt1000 temperature sensor. This work must be carried out only by

personnel familiar with the transmitter and who are qualified for such work. Make sure

the mains cable is separated from the power supply before opening the unit.

No modifications to the Aquacon 4000 are allowed. The manufacturer/supplier

accepts no responsibility for damage caused by unauthorised modifications. The risk

is borne entirely by the user.

1.4 Putting out of service / Correct disposal of the unit

Putting out of service

•First disconnect the unit from the mains, then undo all electrical connections.

•Remove the unit from the wall / panel.

Correct disposal of the unit

When the transmitter is finally taken out of service, observe the local environmental

regulations for correct disposal or send the transmitter to your local office of the Forbes

Marshall Pvt. Ltd., they will take care of proper disposal.

Instruction Manual Aquacon 4000

3

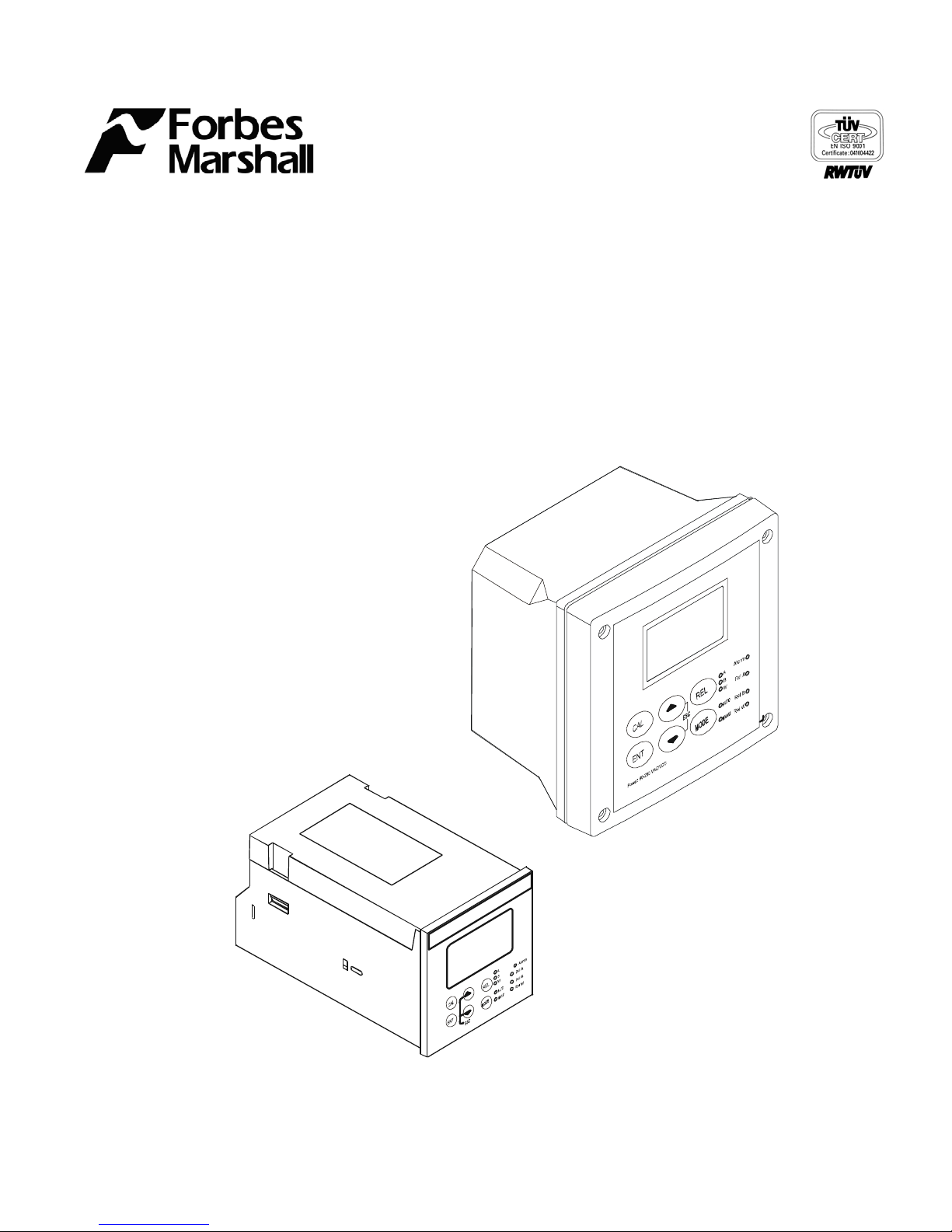

2PRODUCT DESCRIPTION

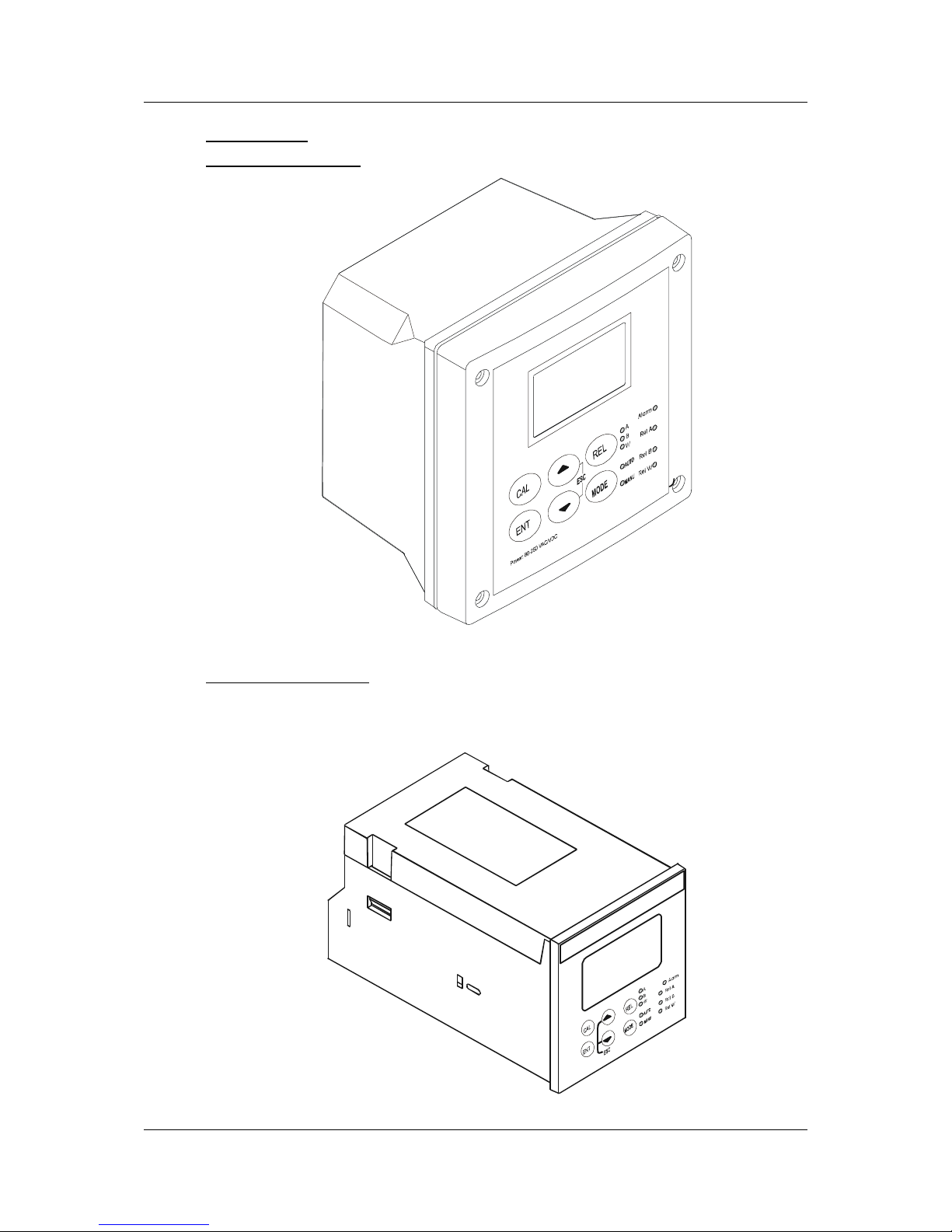

2.1 Description of unit

The Forbes Marshall Aquacon 4000 is used for measuring conductivity and temperature

values. The conductivity values can be measured using limit or P/PI control. The transmitter is

available in two versions, one for panel mounting and one for wall mounting in a enclosure.

The transmitter can be used for applications such as water treatment and monitoring,

galvanic-decontamination, chemical processing, food processing, clean or wastewater control

and neutralization processes.

This transmitter has many user-friendly and safety features which include:

•Menu-driven program that simplifies set-up.

•Built-in non-volatile memory to ensure that calibration and other information are not

erased if power supply fails.

•Push-button for calibration and sensor offset adjustment from the keypad.

•Automatic temperature compensation (ATC).

•Manual temperature compensation setting without the ATC probe, with independent

setting for calibration and process temperature.

•Two galvanically isolated current outputs 0/4...20mA.

•0 to 2000 seconds time delay adjustment on all relays – minimizes false alarms.

•Separately adjustable high and low set-point hysteresis (dead bands) prevent chattering

of relays around the set points.

•Three control modes: limit controller, P controller and PI controller (P/PI controller as

pulse length or pulse frequency).

•Large dual display LCD for easy reading with clear multiple annunciators, alarm status,

operational and error messages.

•Two switching contacts as set-point relays.

•Separate alarm relay alerting you to set point limits exceeded for a certain time and if the

Pt100/Pt1000 wires are broken or disconnected during the ATC function.

•Wash relay.

•Hold function to freeze output current (0/4...20mA) and release control relays.

•LED indicators signal control activities to visually monitor transmitter status from a

distance.

•Protection against electromagnetic interference. ( Available for panel mount only)

•Back lit and UV light protected LC display.

Instruction Manual Aquacon 4000

4

2.2 Measurement and control system

A typical measurement system consists of:

•A conductivity process transmitter

•A conductivity sensor with integrated or separate temperature sensor Pt100/Pt1000.

•An appropriate measurement cable

•An immersion, flow or process assembly

•A final control element such as pump or valve

•A chart recorder

Power Mains

(80 - 250 VAC)

0/4 - 20 mA

Measurement Cable

Housing and

Sensors

Chart Recorder

A

quacon 4000 Transmitter

Instruction Manual Aquacon 4000

5

2.3 Unit overview

Wall mounting version

Panel mounting version

Instruction Manual Aquacon 4000

6

Instruction Manual Aquacon 4000

7

2.3.1 Display Overview

The LC display shows two alpha-numerical fields for parameters and measured values as well

as various mode and status indicators.

MEAS

SETUP

CAL

HOLD

°C °F

4

ERR

ATC

mS

µS

Mode indicators:

MEAS: measurement mode

SETUP: Set-up mode

CAL: Calibration mode

Status indicator:

HOLD: Unit in “HOLD” mode

ATC: Visible in ATC (Automatic Temperature

Compensation) mode. Not visible in the Manual

Temperature Compensation mode. “ATC”

flashes if the temperature probe is faulty in its

ATC mode

ERR: Error indicator

4: Measurement range number

2.3.2 Key functions

Key Description

Enter Calibration mode (requires access code)

Enter Set-up mode (requires access code)

Access sub functions (parameters) within a function group of Set-up mode

Confirm (store) set-up parameters and numerical values

Start/Confirm calibration in Calibration mode.

Select function group in the Set-up mode.

Set parameters and numerical values (if key is pressed continuously, the setting speed

increases).

Control the relays in MANUAL relay operation.

Returns to “Measurement mode” when both keys are pressed simultaneously.

Display limit values for SP1 and SP2 and settings for wash contact in AUTO relay

operation.

Toggle between RELAY A, RELAY B or Wash relay in MANUAL relay operation

Switch from AUTO to MANUAL relay operation (requires access code)

Instruction Manual Aquacon 4000

8

2.3.3 LED indicators

Relay indicators

If REL key is pressed the LED (A, B or W) indicates to which Relay (A, B or

Wash) the displayed limit values refer.

Relay mode indicators

Auto LED lights if relay operation is set to automatic mode. Manu LED lights

if relay operation is set to manual mode.

Relay status indicators

This LED lights if limit value is exceeded or the ATC probe fails.

This LED lights green if measured value is within the limit for Relay A or

lights red if measured value exceeds limit.

This LED lights green if measured value is within the limit for Relay B or

lights red if measured value exceeds limit.

This LED lights if cleaning cycle is on.

2.3.4 Security codes

The access to Calibration mode, Setup mode and Manual relay operation mode is protected

with security codes. The security codes are set at the factory and cannot be changed by the

user. The following security codes are used:

Security code Mode Description

000 View only mode to view actual settings

11 Calibration mode to start calibration

22 Setup mode to configure parameters

22 Manual relay operation to switch relay operation mode from

automatic to manual

Instruction Manual Aquacon 4000

9

2.3.5 Menu overview

CCD “000” = Check calibration parameters

(

View onl

y

mode

)

CCD “11” = Calibration mode

SCD “000” = Check setup parameters (View only mode)

SCD “22” = Setup mode

MEAS

SETUP

SETUP

SETUP

SETUP

SETUP

SETUP

SETUP

SETUP

SETUP

SETUP

HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

µS

4

4

4

4

4

4

4

4

4

4

4

°C

Temperature settings

see section 6.3

Relay A (set point 1) settings

see section 6.4

Relay B (set point 2) settings

see section 6.4

Controller settings

see section 6.5

Current output 1 settings

see section 6.6

Current output 2 settings

see section 6.7

Wash contact settings

see section 6.8

Unit settings

see section 6.10

Calibration

see section 5

CAL

ENT

ENTER

ENT

ENT

ENTER

ENTER

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

CAL

SETUP

HOLD

4

Range settings

see section 6.9

ENT

1

1

2

2

Instruction Manual Aquacon 4000

10

Instruction Manual Aquacon 4000

11

3ASSEMBLY AND INSTALLATION

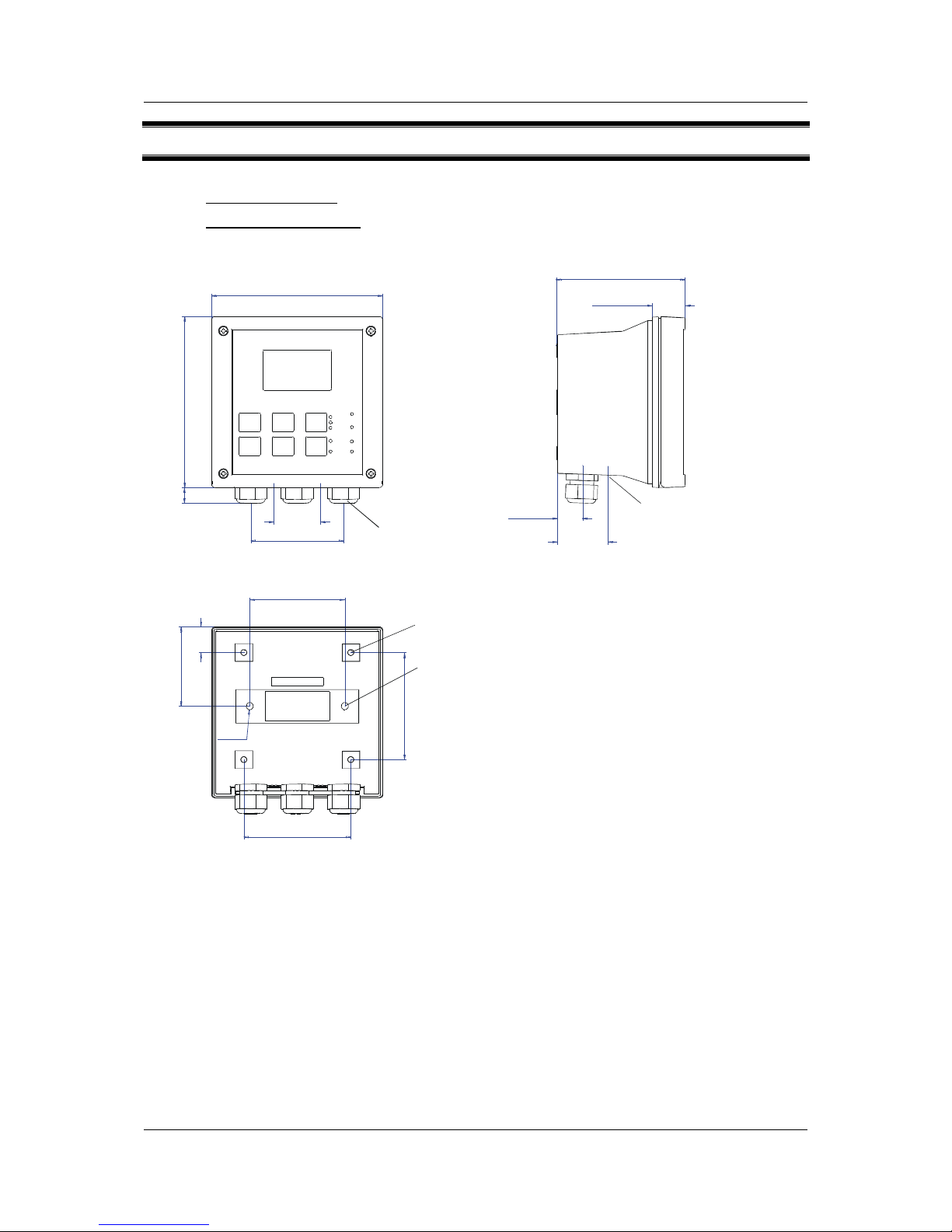

3.1 Mounting the unit

Wall mounting version

approx. 14 [.55]

39 [1.54]

Holes for wall

mounting (2X)

21.5 [.85]

6 [.24]

144 [5.67]

144 [5.67]

78 [3.07]

111.50 [4.39]

27.5 [1.08]

24 [.94]

66.5 [2.62]

80 [3.15]

90 [3.54]

57.8[2.28]

90 [3.54]

Pg13.5 (3 pcs.)

Holes for post

mounting (4X)

For P

g

13.5 cable

g

lands

Unit:

MM [INCH]

Transmitter housing for wall mounting: protection class IP 65

Instruction Manual Aquacon 4000

12

Panel mounting version

Flat gasket 1mm [.04]

(to be inserted by customer)

Panel cut out

UNIT: MM [INCH]

Transmitter housing for panel mounting: protection class IP 54 (front), IP 40 (housing)

Instruction Manual Aquacon 4000

13

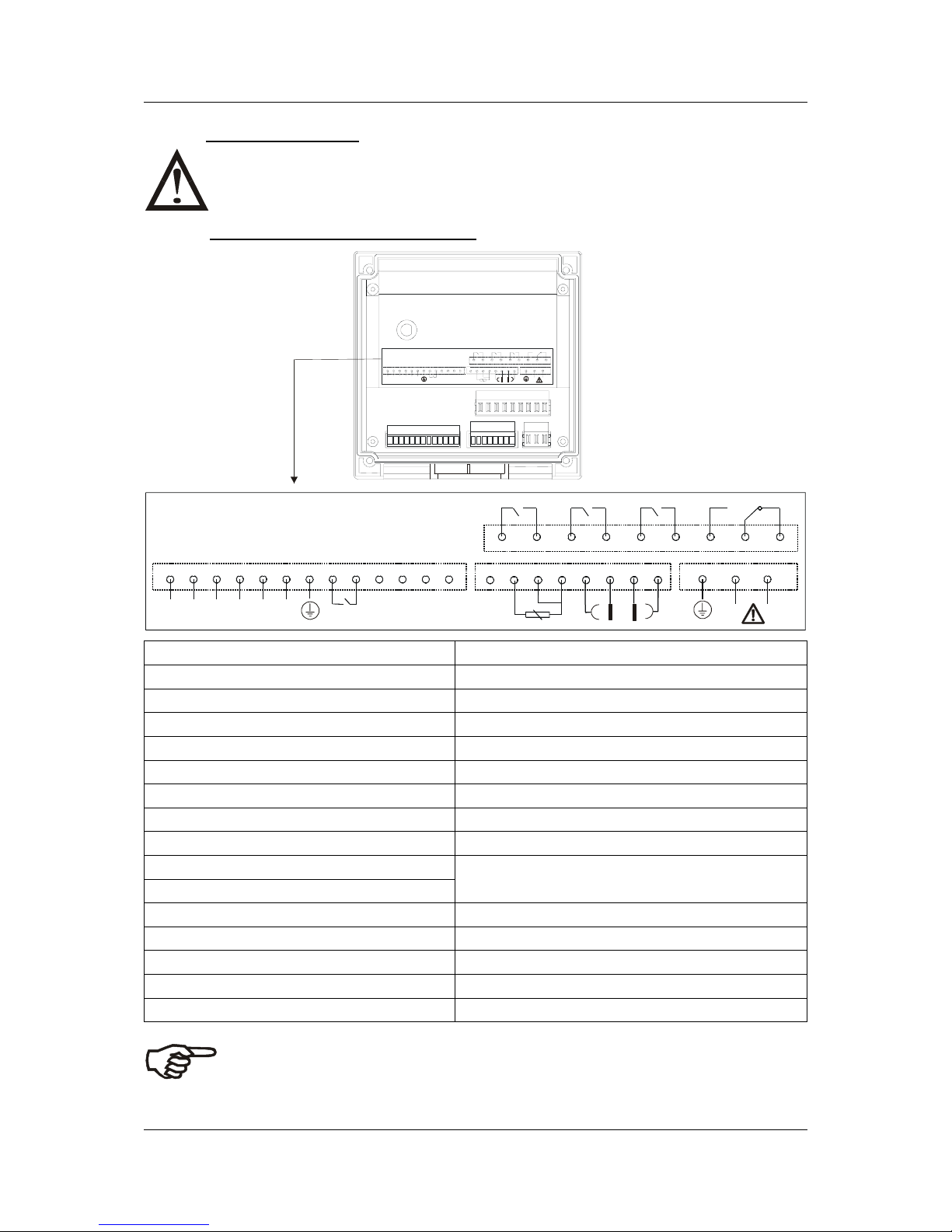

3.2 Connection Diagram

Caution: Ensure electrical mains are disconnected before proceeding.

Connections for wall mounting version

RELA RELB WASH RELAY ALARM RELAY

-+

Current

OP 2

29 28 19

GND+12V

-+

Current

OP1

3031 20 22

PT100/

PT1000

2524 26

HOLD

14 13

47

65 89

N L

3

12

21

11 10

15 16 17 18

RE LA RELB WAS H RE LAY A LAR M RE LAY

-+

Current

OP 2

29 28 19

GND+12V

-+

Current

OP1

3031 20 22

PT10 0/

PT10 00

2524 26

HOLD

14 13

476589

N L

3

12

21

11 10

15 16 17 18

1. AC mains live wire 17. 4 Cell / 2 Cell type Conductivity Input

2. AC mains neutral wire 18. 4 Cell type Conductivity Input

3. AC mains protective earth wire 19. 12V Power supply

4. Relay A (SP 1) 20. 12V ground

5. Relay A (SP 1) 21. no connection

6. Relay B (SP 2) 22. Earth ground

7. Relay B (SP 2) 23. no connection

8. Wash relay 24. Temperature ground

9. Wash relay 25. Temperature input

10. Alarm relay (NC) 26. Temperature sense (short to

11. Alarm relay common terminal 25 if using 2- wire RTD)

12. Alarm relay (NO) 27. no connection

13. Hold function 28. 4-20 mA temperature output, -ve terminal

14. Hold function 29. 4-20 mA temperature output, +ve terminal

15. 4 Cell type Conductivity Input 30. 4-20 mA Conductivity output, -ve terminal

16. 4 Cell / 2 Cell type Conductivity Input 31. 4-20 mA Conductivity output, +ve terminal

IMPORTANT: The Alarm relay functions as an “Active Low” device i.e. it switches

OFF under Alarm condition. Therefore the Alarm display device should be connected

to the ‘NC’ contacts of the relay (10 & 11).

Instruction Manual Aquacon 4000

14

When using 2 Cell type Conductivity electrode, terminal 15 should be shorted to

terminal 16 and terminal 18 should be shorted to terminal 17.

NOTE:

a) Switch or circuit breaker shall included in the building installation.

b) It shall be in close proximity to the equipment and within easy reach of the

operator.

c) It shall be marked as the disconnecting device for the equipment.

Instruction Manual Aquacon 4000

15

Connections for panel mounting version

1. AC mains live wire 17. 2 Cell type Conductivity Input

2. AC mains neutral wire 18. 4 Cell type Conductivity Input

3. AC mains protective earth wire 19. 12V Power supply

4. Relay A (SP 1) 20. 12V ground

5. Relay A (SP 1) 21. no connection

6. Relay B (SP 2) 22. Earth ground

7. Relay B (SP 2) 23. no connection

8. Wash relay 24. Temperature ground

9. Wash relay 25. Temperature input

10. Alarm relay (NC) 26. Temperature sense (short to

11. Alarm relay common terminal 25 if using 2- wire RTD)

12. Alarm relay (NO) 27. no connection

13. Hold function 28. 4-20 mA temperature output, -ve terminal

14. Hold function 29. 4-20 mA temperature output, +ve terminal

15. 4 Cell type Conductivity Input 30. 4-20 mA Conductivity output, -ve terminal

16. 2 Cell type Conductivity Input 31. 4-20 mA Conductivity output, +ve terminal

IMPORTANT: The Alarm relay functions as an “Active Low” device i.e. it switches

OFF under Alarm condition. Therefore the Alarm display device should be connected

to the ‘NC’ contacts of the relay (10 & 11).

When using 2 Cell type Conductivity electrode, terminal 15 should be shorted to

terminal 16 and terminal 18 should be shorted to terminal 17.

Table of contents

Popular Controllers manuals by other brands

PIETRO FIORENTINI

PIETRO FIORENTINI APERFLUX 851 Technical manual

MidNite Solar

MidNite Solar Classic 150 owner's manual

Ransburg

Ransburg 9060 Service manual

SLV

SLV 470810 Quick installation guide

Neptronic

Neptronic BT100S Specification & installation instructions

SMC Networks

SMC Networks MXQ6 Series Operation manual