EVCOS.p.A.|EV3B33N7VXRX04|Instructionsheetver.1.0|Code1043B33E103DRY|Page1of2|PT27/18

EV3B33N7VXRX04 Controller for refrigerator cycle dryer for compressed air

E ENGLISH

- Power supply 230 VAC or 115 VAC (according to the model).

- Exchanger probe (PTC/NTC).

- Multi-purpose input.

- Compressor relay 30 A res. @ 250 VAC.

- Cooling or heating operation.

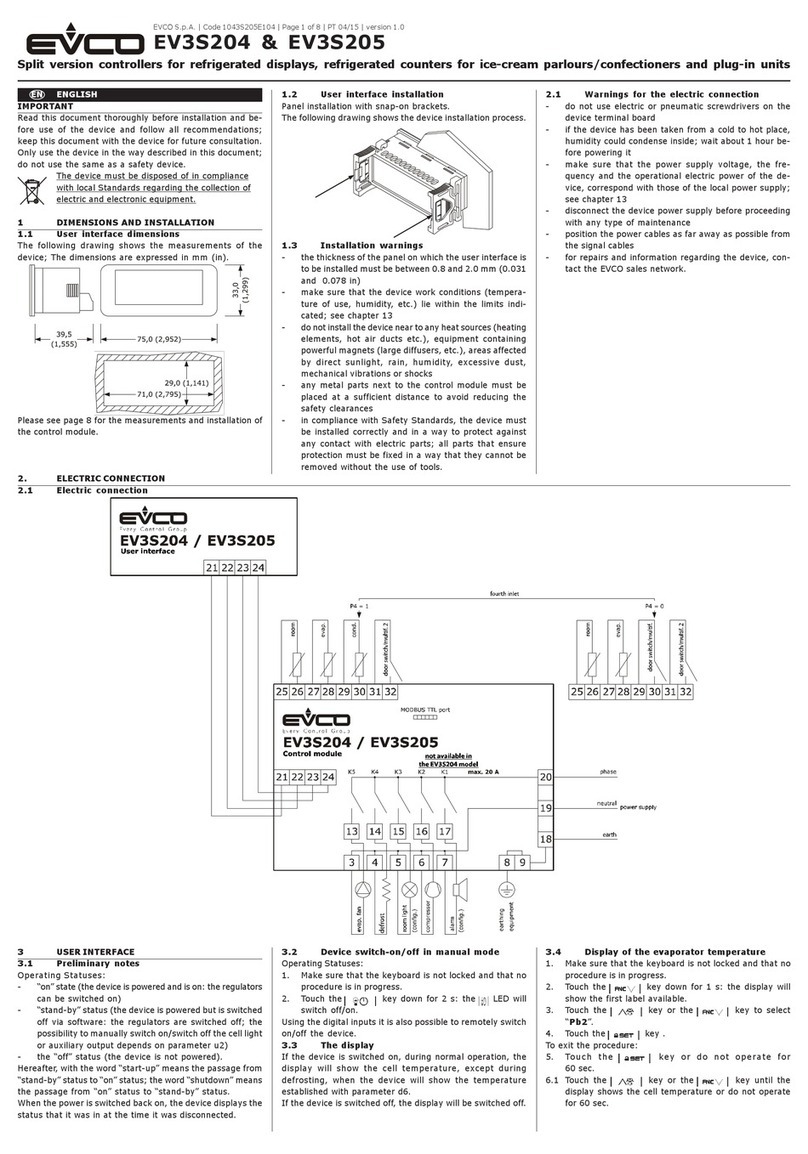

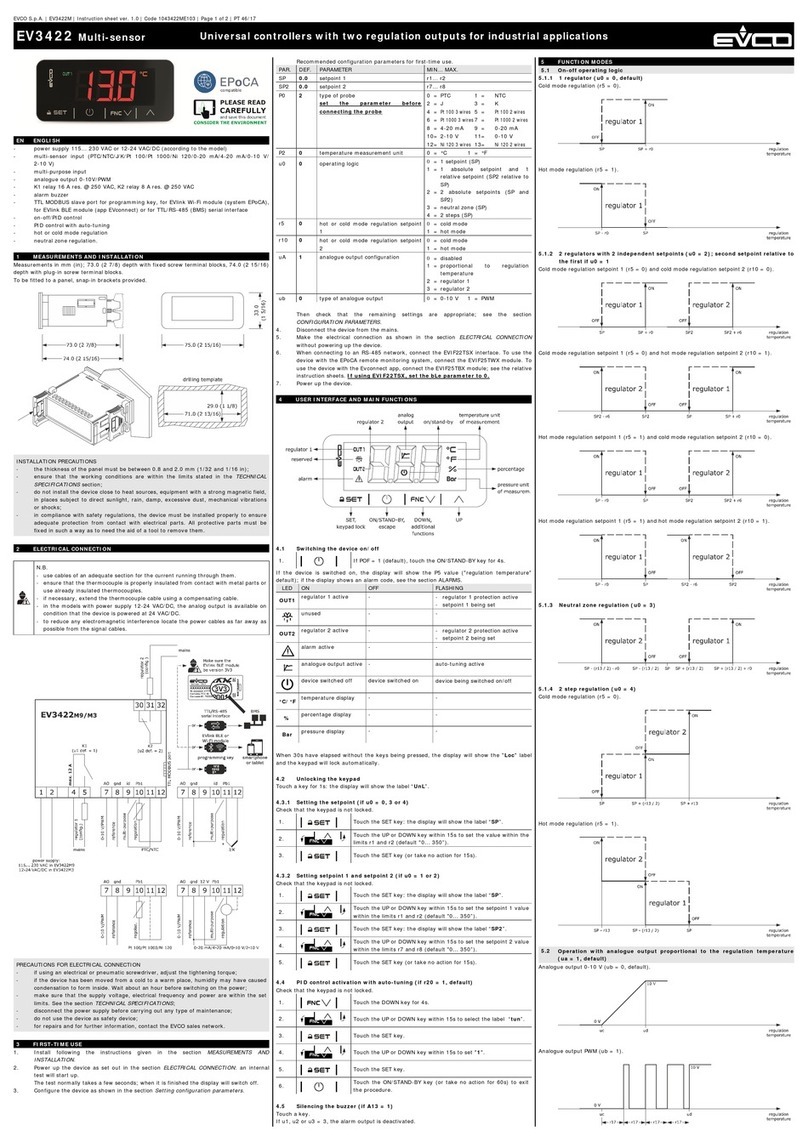

1 MEASUREMENTS AND INSTALLATION

Measurements in mm (inches). To be fitted to a panel, snap-in brackets provided.

INSTALLATION PRECAUTIONS

- The thickness of the panel must be between 0.8 and 2.0 mm (1/32 and 1/16 in)

- Ensure that the working conditions are within the limits stated in the TECHNICAL

SPECIFICATIONS section.

- Do not install the device close to heat sources, equipment with a strong magnetic field,

in places subject to direct sunlight, rain, damp, excessive dust, mechanical vibrations

or shocks.

- In compliance with safety regulations, the device must be installed properly to ensure

adequate protection from contact with electrical parts. All protective parts must be

fixed in such a way as to need the aid of a tool to remove them.

2 ELECTRICAL CONNECTION

N.B.

- Use cables of an adequate section for the current running through them.

- To reduce any electromagnetic interference connect the power cables as far away

as possible from the signal cables.

PRECAUTIONS FOR ELECTRICAL CONNECTION

- If using an electrical or pneumatic screwdriver, adjust the tightening torque.

- If the device has been moved from a cold to a warm place, the humidity may have

caused condensation to form inside. Wait about an hour before switching on the

power.

- Make sure that the supply voltage, electrical frequency and power are within the set

limits. See the section TECHNICAL SPECIFICATIONS.

- Disconnect the power supply before doing any type of maintenance.

- Do not use the device as safety device.

- For repairs and for further information, contact the EVCO sales network.

3 FIRST-TIME

1. Install following the instructions given in the section MEASUREMENTS AND INSTALLA-

TION.

2. Power up the device as shown in the section ELECTRICAL CONNECTION and an internal

test will be run.

The test normally takes a few seconds, when it is finished the display will switch off.

3. Configure the device as shown in the section Setting configuration parameters.

Recommended configuration parameters for first-time use.

PAR. DEF. PARAMETER MIN... MAX.

P0 1 probe type 0 = PTC 1 = NTC

P2 0 temperature unit of measurement 0 = °C 1 = °F

r1

1.0

setpoint compressor off (after time

r3) -99 °C/°F... r2

r2 8.0 setpoint compressor on r1... 99 °C/°F

r3

10

consecutive time exchanger tempera-

ture lower than r1 for compressor off 0... 90 min

hot or cold mode regulation

1 = hot mode

Then check that the remaining settings are appropriate; see the section CONFIGURA-

TION PARAMETERS.

4. Disconnect the device from the mains.

5. Make the electrical connection as shown in the section ELECTRICAL CONNECTION with-

out powering up the device.

6. Power up the device.

4 USER INTERFACE AND MAIN FUNCTIONS

4.1 Switching the device on/off

1. If POF = 1, touch the ON/STAND-BY key for 4 s.

If the device is switched on, the display will show the exchanger temperature; if the display

shows an alarm code, see the section ALARMS.

LED ON OFF FLASHING

compressor on

compressor off

compressor protection active

reserved

-

-

condenser fan on

condenser fan off

-

HACCP

reserved

-

-

- low consumption ac-

tive

- compressor off

-

-

- request for compres-

sor service

- request for device

service

-

-

°C/°F

view temperature

-

-

AUX water pump on

water pump off

-

device off

device on

device on/off active

If 30 s have elapsed without the keys being pressed, the display will show the “Loc” label and

the keypad will lock automatically.

4.2 Unlock keypad

Touch a key for 1 s: the display will show the label “UnL”.

4.3 Switching off the alarm output (if u0 or u1 = 2 and A7 = 1)

Touch a key.

5 ADDITIONAL FUNCTIONS

5.1 View/delete compressor and device functioning hours

Check that the keypad is not locked.

1. Touch the DOWN key for 4 s.

2. Touch the UP or DOWN key within 15 s to select a label.

LAB. DESCRIPTION

hSE view compressor functioning hours

rhS delete compressor functioning hours

hFI view device functioning hours

rhF delete device functioning hours

rFI reset clogged filter alarm

3. Touch the SET key.

4. Touch the UP or DOWN key to set “149” (for selection rhF and

rFI) or “171” (for selection rhS).

5. Touch the SET key.

6. Touch the ON/STAND-BY key (or do not operate for 60 s) to exit

the procedure.

5.2 View the temperature detected by the probes

Check that the keypad is not locked.

1. Touch the DOWN key for 4 s.

2. Touch the UP or DOWN key within 15 s to select a label.

LAB. DESCRIPTION

Pb1 exchanger temperature

Pb2 condenser temperature

3. Touch the SET key.

4. Touch the ON/STAND-BY key (or do not operate for 60 s) to exit

the procedure.

5.3 Evacuation valve test

Check that the keypad is not locked.

1. Touch the UP key for 4 s: the valve will be switched on till the

key release, then it will cyclically work again.

6 SETTINGS

6.1 Setting configuration parameters

1. Touch the SET key for 4 s: the display will show the label “PA”.

2. Touch the SET key.

3. Touch the UP or DOWN key within 15 s to set the PAS value (de-

fault “10”).

4. Touch the SET key (or do not operate for 15 s): the display will

show the label “CA1”.

5. Touch the UP or DOWN key to select a parameter.

6. Touch the SET key.

7. Touch the UP or DOWN key within 15 s to set the value.

8. Touch the SET key (or do not operate for 15 s).

9. Touch the SET key for 4 s (or do not operate for 60 s) to exit the

procedure.

6.2 Restore the factory settings (default) and store customized settings as default

N.B.

- Check that the factory settings are appropriate; see the section CONFIGURATION

PARAMETERS.

- the storing of customized settings overwrites the default.

1. Touch the SET key for 4 s: the display will show the label “PA”.

2. Touch the SET key.

3. Touch the UP or DOWN key within 15 s to set the value.

VAL. DESCRIPTION

149 value to restore the factory settings (default)

161 value to store customized settings as default

4.

Touch the SET key (or do not operate for 15 s): the display will

show the label “dEF” (when value “149” is set) or the label

“MAP” (when value “161” is set).

5. Touch the SET key.

6. Touch the UP or DOWN key within 15 s to set “4”.

7.

Touch the SET key (or do not operate for 15 s): the display will

show for 4 s “- - -“ flashing, then the device will exit the proce-

dure.

8. Interrupt the power supply to the device.

9. Touch the SET key 2 s before action 6. to exit the procedure be-

forehand.

7 CONFIGURATION PARAMETERS

N. PAR. DEF. ANALOGUE INPUTS MIN... MAX.

1 CA1 0.0 exchanger probe offset -25... 25 °C/°F

2 CA2 0.0 condenser probe offset -25... 25 °C/°F

3 P0 1 probe type 0 = PTC 1 = NTC

4 P1 0 enable °C decimal point 0 = no 1 = yes

5

P2

0

temperature unit of measure-

ment 0 = °C 1 = °F

6

P3

0

input Pb1 function

0 = exchanger probe

1 = exchanger probe + high

pressure input (in series,

activation with contact

open)

7 P4 5 display refresh time 0... 250 s : 10

N. PAR. DEF. REGULATION MIN... MAX.

8

r1

1.0

setpoint compressor off (after

time r3)

-99 °C/°F... r2

if r4 = 1, setpoint compressor

on

9

r2

8.0

setpoint compressor on

r1...199°C/°F

if r4 = 1, setpoint compressor

off (after time r3)

10

r3

10

consecutive time exchanger tem-

perature lower than r1 for com-

pressor off

0... 90 min

if r4 = 1, consecutive time

exchanger temperature ower

than r2 for compressor ofm

11

r4

0

cooling or heating operation

0 = cooling

1 = heating

12

r5

0.0

threshold for low temperature

display lock -99... r6 °C/°F

13

r6

5.0

threshold for high temperature

display lock r5... 99 °C/°F

14

r7 1 enable display lock 0 = no 1 = yes

N. PAR. DEF. COMPRESSOR MIN... MAX.

15

C1

1

compressor on delay after pow-

er-on 0... 240 min

16

C2 0 compressor off minimum time 0... 240 min

17

C3 0 compressor on minimum time 0... 240 s

18

C4

0

compressor off time during ex-

changer probe alarm 0... 240 min

19

C5

10

compressor on time during ex-

changer probe alarm 0... 240 min

20

C6

80.0

threshold for high condensation

warning 0... 199 °C/°F

differential A0

21

C7 90.0

threshold for high condensation

alarm 0... 199 °C/°F

22

C8 1 high condensation alarm delay 0... 15 min

23

C9

0

count mode

0 = device hours

1 = compressor hours

24

C10

200

compressor hours for service

0... 999 h x 100

0 = disabled

25

C11 20 suction temperature alarm delay 0... 60 min

N. PAR. DEF. ALLARMS MIN... MAX.

26

A0

1.0

A1, A3, C6 and F1 reset differen-

tial 0.1... 15 °C/°F

27

A1

0.0

threshold for low temperature

alarm -99... A3 °C/°F

28

A2 1 enable low temperature alarm 0 = no 1 = yes

29

A3

15.0

threshold for high temperature

alarm A1... 99 °C/°F

30

A4 1 enable low temperature alarm 0 = no 1 = yes

31

A5

1

high/low temperature alarms de-

lay 0... 240 min

32

A6

2

high/low temperature alarm de-

lay after power-on 0... 99 min x 10

33

A7

0

alarm output mode

0 = with alarm active

1 = with alarm active and

inactive touching a key

34

A8

0

count mode

0 = device hours

1 = compressor hours

35

A9

200

compressor hours for service

0... 999 h x 100

0 = disabled

N. PAR. DEF. FANS MIN... MAX.

36

F0

15.0

threshold for condenser fan on

0... 99 °C/°F

differential A0

37

F1

30

condenser fan off delay after

compressor off for suction tem-

perature alarm

0... 240 s

N. PAR. DEF. DIGITAL INPUTS MIN... MAX.

38

i0

1

multi-purpose 2 input activation

0 = with contact closed

1 = with contact open

39

i1

1

funzione ingresso configurabile

0 = disabled

1 = HP/HPr alarm

2 = FIL alarm

3 = condenser fan on

4 = tSH alarm

5 = device off

6 = condenser probe

40

i2

0

multi-purpose 2 input activation

0 = with contact closed

1 = with contact open

41

i3

0

funzione ingresso multi-purpose

1

0 = disabled

1 = HP/HPr alarm

2 = FIL alarm

3 = condenser fan on

4 = tSH alarm

5 = device off

42

i4 0 high pressure alarm delay 0... 240 s

43

i5 0 clogged filter alarm delay 0... 999 min

44

i6

0

condenser fan on delay from di-

gital input 0... 240 s

45

i7

30

clogged filter alarm delay after

power-on 0... 999 s

N. PAR. DEF. DIGITAL OUTPUTS MIN... MAX.

46

u0

2

configuration auxiliary output 1

0 = disabled

1 = evacuation valve

2 = alarm

3 = condenser fan

4 = water pump

47

u1

1

configuration auxiliary output 2

0 = disabled

1 = evacuation valve

2 = alarm

3 = condenser fan

4 = water pump

48

u2 5 time evacuation valve on 0... 240 s

49

u3 4 time evacuation valve off 0... 240 s

N. PAR. DEF. ENERGY SAVING (if r4 = 0) MIN... MAX.

50

HE1

0

consecutive time without operat-

ing on keys for low consumption 0... 240 min

0 = disabled

51

HE2

3

configuration energy saving LED

(options 0 and 1) and compres-

sor mode during normal opera-

tion (options 2 and 3)

0 = LED energy saving on in

low consumption

1 = LED energy saving on if

compressor off

2 = compressor on, off in

HP, tAL and tAH alarm

3 = compressor on, off in HP

alarm