4

F 100

Doc: 101529-GB 1907

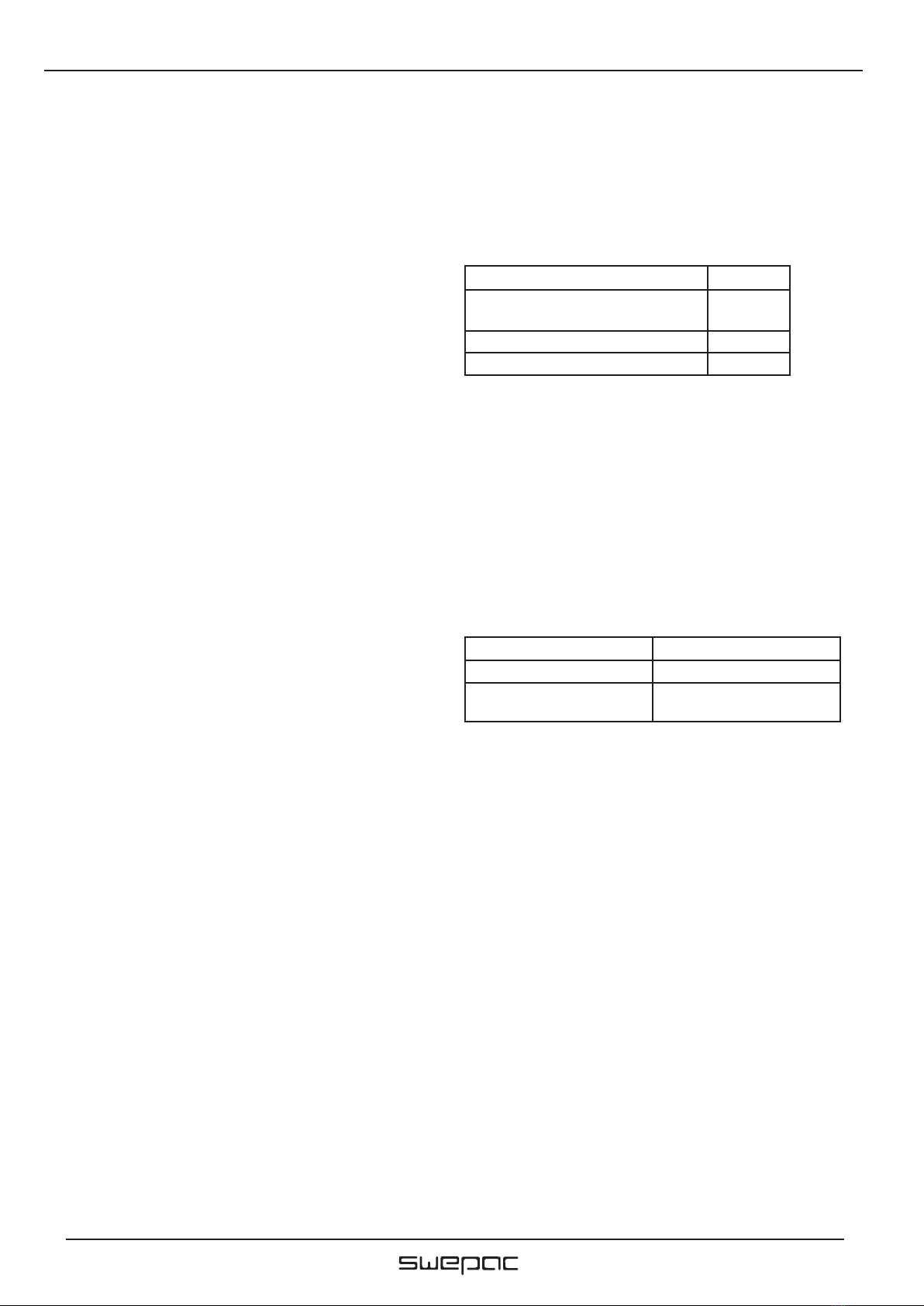

STANDARDS

Noise

Measurement in accordance with the standard EN 500-4 Rev.

1:1998, Annex C:

Measurement uncertainty ± 0.5 dB (A) in 95% of the

measurements.

In accordance with the conditions in Directive 2000/14/EC, An-

nex VI, the following values are reported:

As the sound pressure level at the operator’s ears exceeds 80 dB

(A), ear protectors must be used during operation!

Hand/arm vibrations

The vibration acceleration was measured in accordance with the

ISO 5349 standard during operation on a graveled surface. The

measurement values were translated into the maximum daily

exposure time for regular usage. For additional information about

vibrations, please confer the regulation AFS 2005:15 from the

Swedish Work Environment Authority, eective July 1st 2005.

Measurement uncertainty ± 0.3 m/s2in 95% of the

measurements.

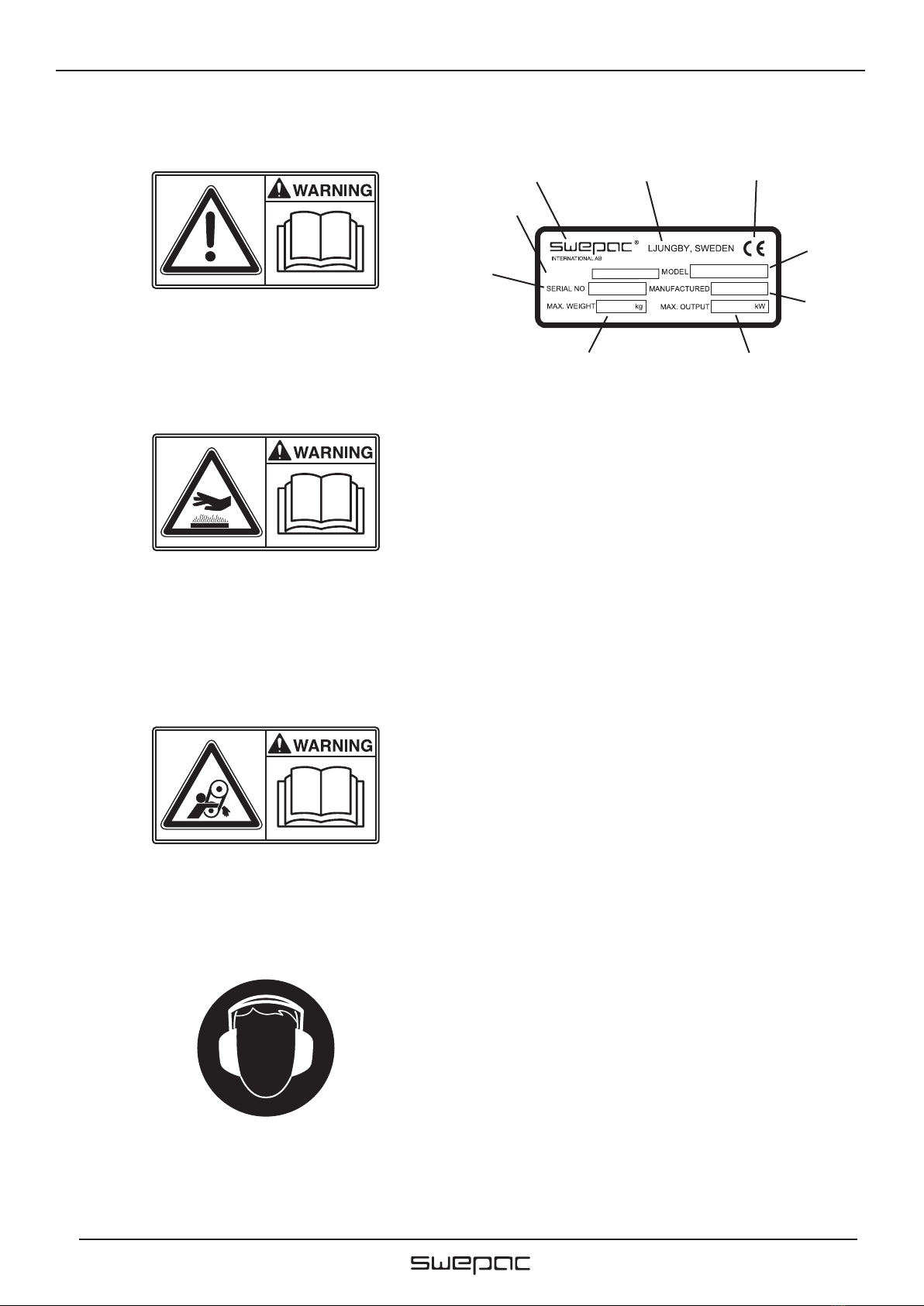

SAFETY INSTRUCTIONS

•Before using the machine, the operator must be informed

of the manufacturer’s safety instructions and instructions

for use.

•The machine may only be used outdoors.

•The machine may not be used if protection and safety

devices are not present or not working.

•The operator may not leave the machine unattended

when the engine is on. When the vibrator is connected,

the operator must be able to control the movement of

the machine using the control handle and the start/stop

controls. The machine may be operated only by a trained

operator.

•During maintenance work or other interventions in the

machine, the engine must always be o.

•Switch the engine o before adding fuel. Avoid fuel

spillage and immediately wipe o any spilled fuel. Add

fuel only in well ventilated areas.

•Avoid touching hot engine parts, for example the

silencer.

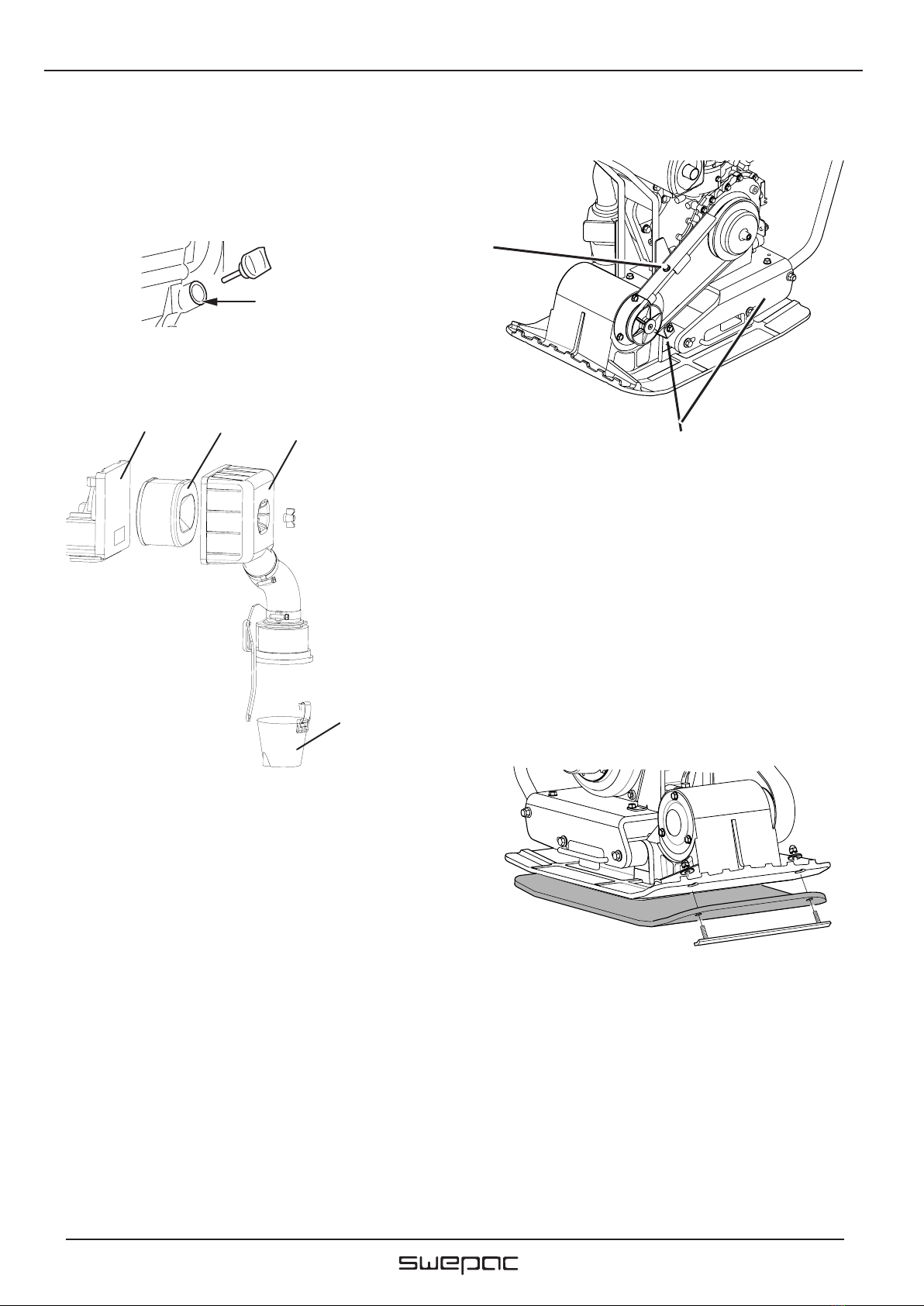

•Before lifting the machine, check that the lifting device

and its mounting are not damaged and that the rubber

dampers on the base plate are undamaged and tightened.

•During transportation and storage, the fuel tank should

be empty and the fuel cock switched o.

•The operator must use ear protectors when working with

the machine.

•The operator must ensure that no unauthorised persons

are in the immediate vicinity of the machine.

•Always wear personal protective equipment as heavy,

non-slip shoes, ear protectors and approved eye

protection.

•The machine may not be used in environments with

potentionell re or explosion danger.

• Never use the machine if you are tired or have

consumed alcohol or are under medication that could

aect your vision, your discretion or your coordination

ability.

• Never use a machine in any way changed from the

original design

Exhaust emissions

F 100 meets the requirements for California ExH, EYP och

EPA PH2

F 100

Sound pressure level at the operator’s

ears, LpA

89 dB (A)

Permitted sound power level, L WA 105 dB (A)

Guaranteed sound power level, L WA 105 dB (A)

F 100

Hand/arm-vibrations, m/s24,5

The maximum daily exposure

time

2,5 h