2

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches

and dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres,

such as in the presence of ammable liquids, gases, or

dust.Powertoolscreatesparkswhichmayignitethedustor

fumes.

3. Keep bystanders, children, and visitors away while operat-

ing a power tool.Distractionscancauseyoutolosecontrol.

ELECTRICAL SAFETY

1. Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes

and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adaptor plugs.

Check with a qualied electrician if you are in doubt as to

whether the outlet is properly grounded. Ifthetoolsshould

electricallymalfunctionorbreakdown,groundingprovidesalow

resistancepathtocarryelectricityawayfromtheuser.

2. Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. Thereisanincreased

riskofelectricshockifyourbodyisgrounded.

3. Don’t expose power tools to rain or wet conditions. Water

enteringapowertoolwillincreasetheriskofelectricshock.

4. Do not abuse the cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts. Damagedcords

increasetheriskofelectricshock.

5. When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W”.Thesecordsarerated

foroutdooruseandreducetheriskofelectricshock.

6. Use proper extension cords (see chart).Insufcientconduc-

torsizewillcauseexcessivevoltagedrop,lossofpowerand

overheating.

7. Connect the tool to an AC power supply that matches

the name plate specications.Incorrectvoltagesupplycan

causeelectricalshockorburns.

PERSONAL SAFETY

1.Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool while

tired or under the inuence of drugs, alcohol, or medica-

tion. Amomentofinattentionwhileoperatingpowertoolsmay

resultinseriouspersonalinjury.

2. Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing and gloves

away from moving parts. Looseclothes,jewelry,orlonghair

canbecaughtinmovingparts.

3. Avoid accidental starting. Be sure switch is OFF before

plugging in. Carryingtoolswithangerontheswitchorplug-

gingintoolsthathavetheswitchONinvitesaccidents.

4. Remove adjusting keys or wrenches before turning on the

tool. Awrenchorakeythatisleftattachedtoarotatingpartof

thetoolmayresultinpersonalinjury.

5. Do not overreach. Keep proper footing and balance at all

times. Properfootingandbalanceenablesbettercontrolofthe

toolinunexpectedsituations.

6. Use safety equipment. Always wear eye protection. Dust

mask,non-skidsafetyshoes,hardhat,orhearingprotection

mustbeusedforappropriateconditions.

TOOL USE AND CARE

1. Use clamps or other practical methods to secure and sup-

port the workpiece to a stable platform. Holdingtheworkby

handoragainstyourbodyisunstableandmayleadtolossof

control.

2. Do not force the tool. Use the correct tool for your applica-

tion. Thecorrecttoolwilldothejobbetterandsaferattherate

forwhichitisdesigned.

3. Do not use the tool if switch does not turn it ON or OFF.

Anytoolthatcannotbecontrolledwiththeswitchisdangerous

andmustberepaired.

4. Disconnect the plug from the power source before mak-

ing any adjustments, changing accessories, or storing the

tool. Suchpreventivesafetymeasuresreducetheriskofstart-

ingthetoolaccidentally.

5. Store idle tools out of reach of children and other un-

trained persons. Toolsaredangerousinthehandsofun-

trainedusers.

6. Maintain tools with care. Keep cutting tools sharp and

clean. Properlymaintainedtools,withsharpcuttingedgesare

lesslikelytobindandareeasiertocontrol.

7. Check for misalignment or binding of moving parts, break-

age of parts, and any other condition that may affect the

tool’s operation. If damaged, have the tool serviced before

using. Manyaccidentsarecausedbypoorlymaintainedtools.

8. Use only accessories that are recommended by the manu-

facturer for your model. Accessoriesthatmaybesuitablefor

onetoolmaybecomehazardouswhenusedonanothertool.

SERVICE

1. Tool service must be performed only by qualied repair

personnel. Serviceormaintenanceperformedbyunqualied

personnelcouldresultinariskofinjury.

2. When servicing a tool, use only identical replacement

parts. Follow instructions in

the Maintenance section of

this manual. Useofunauthor-

izedpartsorfailuretofollow

MaintenanceInstructionsmay

createariskofelectricshock

orinjury.

SPECIFIC SAFETY RULES

TheOperator’sManualcontains

specicsafetyinformationand

instructionsforyourprotectionagainstseriousinjuriesincluding:

•Lossofngers,hands,armsorotherbodypartsifclothingor

glovesgetcaughtinmovingparts.

•Electricalshockorburnsfromcontactwithwires,motororother

powerdriveparts.

• Impactinjuries,includingbrokenbonesifmachinetipsoveror

workpiecefalls.

• Eyeinjuries,includingbeingblindedbytheworkpieceor

workpiecechips.

Read and follow the safety labels on the machine.

Knowthelocationandfunctionsofallcontrolsbeforeusing

thetool.

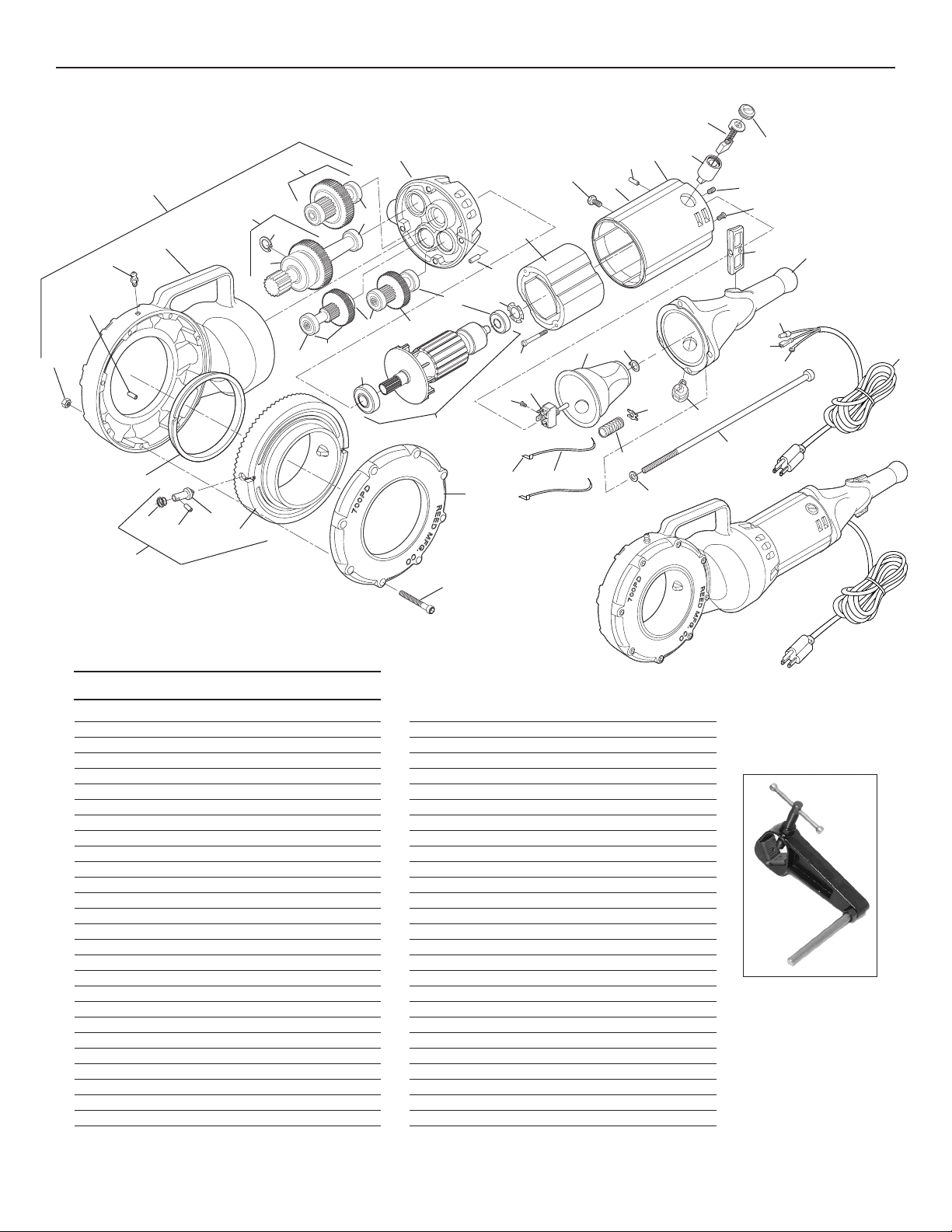

Reed Manufacturing

700PD Power Drive

Minimum Wire Gauge for Cord Set

Nameplate TOTAL LENGTH (IN FEET)

Amps0 - 25 26 - 50 51 - 100

0-6 18AWG 16AWG 16AWG

6-10 18AWG 16AWG 14AWG

10-12 16AWG 16AWG 14AWG

12-16 14AWG 12AWG

NOT

RECOMMENDED

Please submit tool serial number

when requesting service.