Force America SSC6100 CAN ULTRA Use and care manual

SSC6100

Spreader Control

Calibration Manual

Firmware Version

0.57

SSC6100 CAN Ultra Calibration Manual

i

Table of Contents

Operator Interface..................................................................................................................... 1

Calibration Menu ....................................................................................................................... 3

Entering the Calibration Menu ................................................................................................ 3

The Calibration Menu Items..................................................................................................... 4

Descriptions of Calibration Values.......................................................................................... 5

Configuration ............................................................................................................................ 5

Ground Speed........................................................................................................................... 7

Granular Materials .................................................................................................................... 8

Prewet Materials ..................................................................................................................... 10

Direct Materials....................................................................................................................... 11

Dust Control Materials ........................................................................................................... 12

Herbicide Materials................................................................................................................. 13

Truck / Tow Plow .................................................................................................................... 13

Inputs....................................................................................................................................... 20

Outputs.................................................................................................................................... 21

Event Logging......................................................................................................................... 23

Alarms...................................................................................................................................... 24

Systems Management............................................................................................................ 28

Auto Calibration ...................................................................................................................... 32

AutoCalibration of Axle Pulses............................................................................................. 32

AutoCalibration of Granular Material Displacements......................................................... 32

AutoCalibration of Liquid Material Displacements ............................................................. 33

Joystick Normalization........................................................................................................... 34

Appendix A –Default Settings and Import/Export Types ................................................... 35

Appendix B –Sample Exported Calibration Text File......................................................... 48

SSC6100 CAN Ultra Calibration Manual

1

Operator Interface

The Operator Interface lets you enter the Calibration Menu, select and edit settings, and run

outputs.

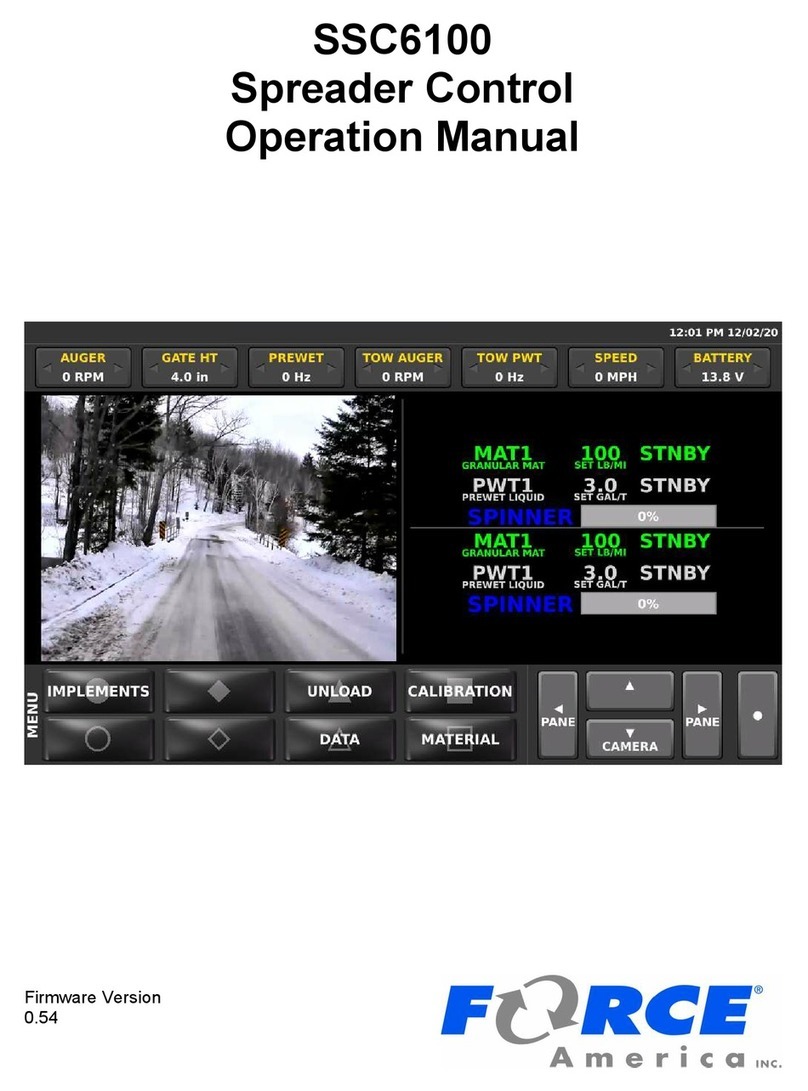

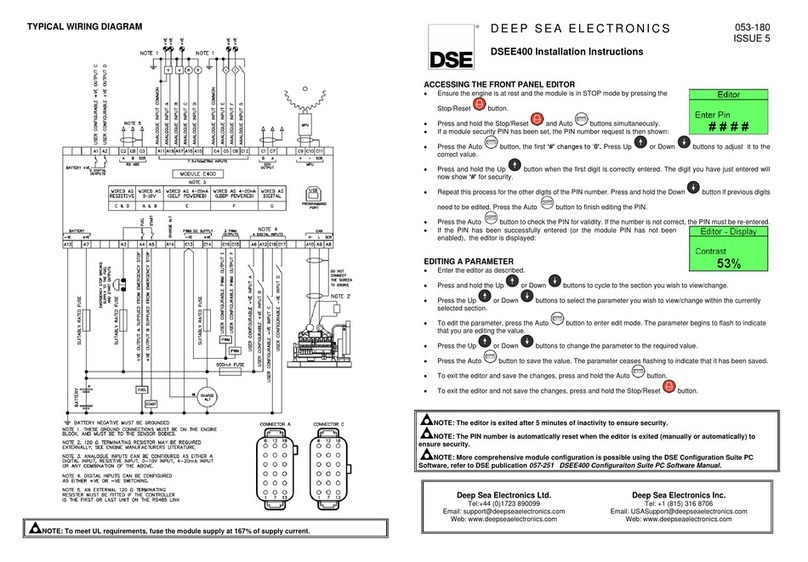

Figure 1: Operator Interface

Input

Action

Function

Green Knob

Twist Left

Decrease the auger set rate.

Twist Right

Increase the auger set rate.

Pushbutton

Run outputs, Stop outputs.

Blue Knob

Twist Left

Decrease the spinner set rate.

Twist Right

Increase the spinner set rate.

Pushbutton

Blast.

Gray Nav Stick

Twist Left

Decrease digit by 1, Select previous calibration value.

Twist Right

Increase digit by 1, Select next calibration value.

Up

Highlight previous menu item, Increase digit by 1,

Select previous calibration value.

Down

Highlight next menu item, Decrease digit by 1,

Select next calibration value.

Left

Return to previous submenu, Select previous digit,

Exit Calibration Menu.

Right

Enter Submenu, Edit Calibration Item, Select next

digit.

Pushbutton

Enter Submenu, Edit Calibration Item, Save

Calibration Item.

SSC6100 CAN Ultra Calibration Manual

2

Input

Action

Function

Soft Switches

8 Individual

Pushbuttons

Correspond to the 8 functions shown in the soft switch

panes on the lower left portion of the screen. Shapes

on each button allow matching to the functions on the

screen.

SSC6100 CAN Ultra Calibration Manual

3

Calibration Menu

Entering the Calibration Menu

The Calibration Menu is entered using the Calibration Button on the Menu Soft Switch Pane on

the Operation Screen. In order to enter the Calibration Menu, the vehicle must be in Standby.

Unlike the Data Menu or the Unload Menu, the Calibration Menu requires the entry of an Access

Code before it will appear.

To enter Calibration:

1. Move the Operator Interface’s Gray Navigation Joystick, or Nav Stick left or right until the

MENU soft switch pane is displayed.

2. Press the CALIBRATION soft switch to open the Calibration Menu. The Access Code

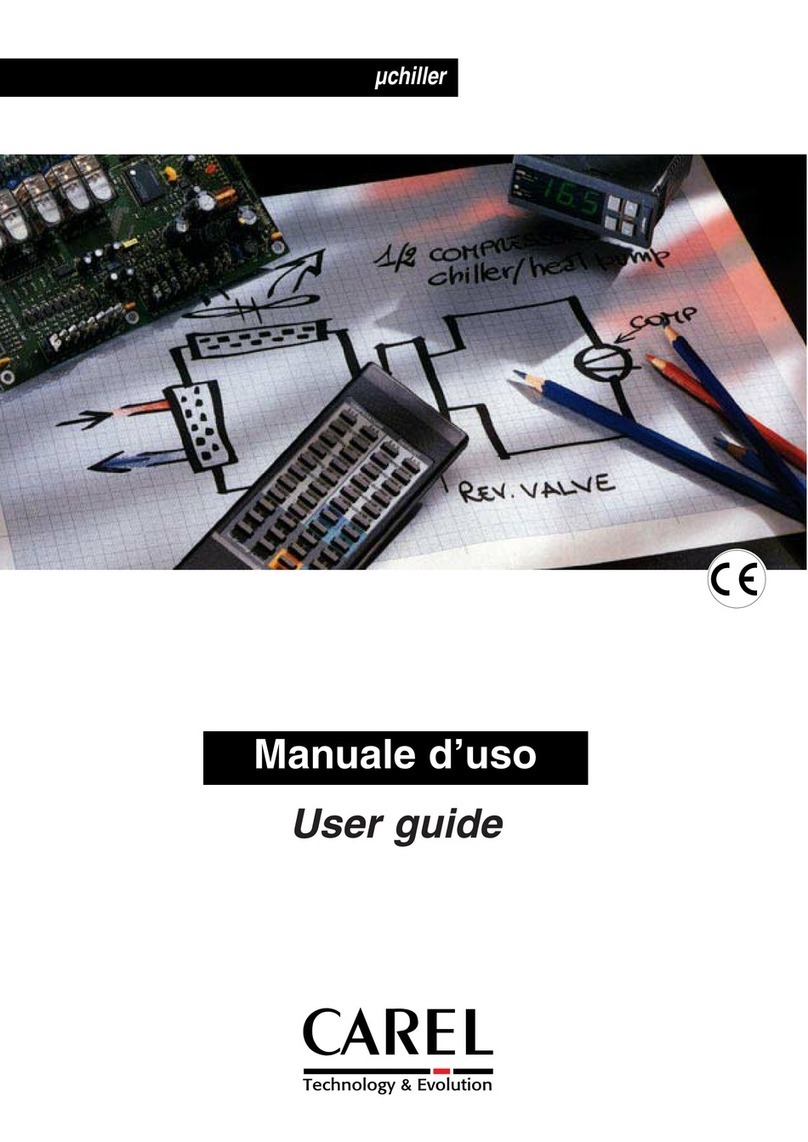

window will appear, as shown in Figure 2.

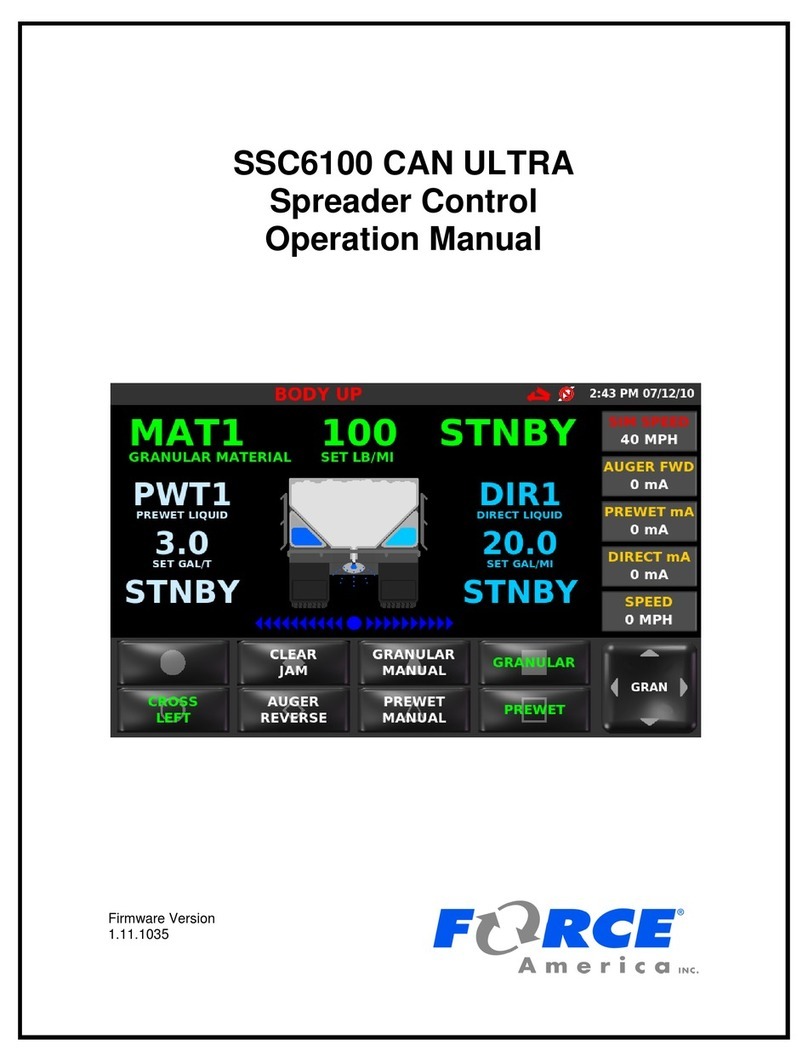

Figure 2: Access Code Window

3. Enter the access code using one of the following two methods:

a. Connect the Supervisor USB Key.

b. Use the Nav Stick to enter the Access Code.

The default access code is 000000. For

information on changing the Access Code,

see page 5.

SSC6100 CAN Ultra Calibration Manual

4

The Calibration Menu Items

The Calibration Menu contains all of the settings required to operate an SSC6100 system.

Settings within the Calibration Menu are broken up into two categories: Fleet-Wide Settings and

Vehicle Specific Settings.

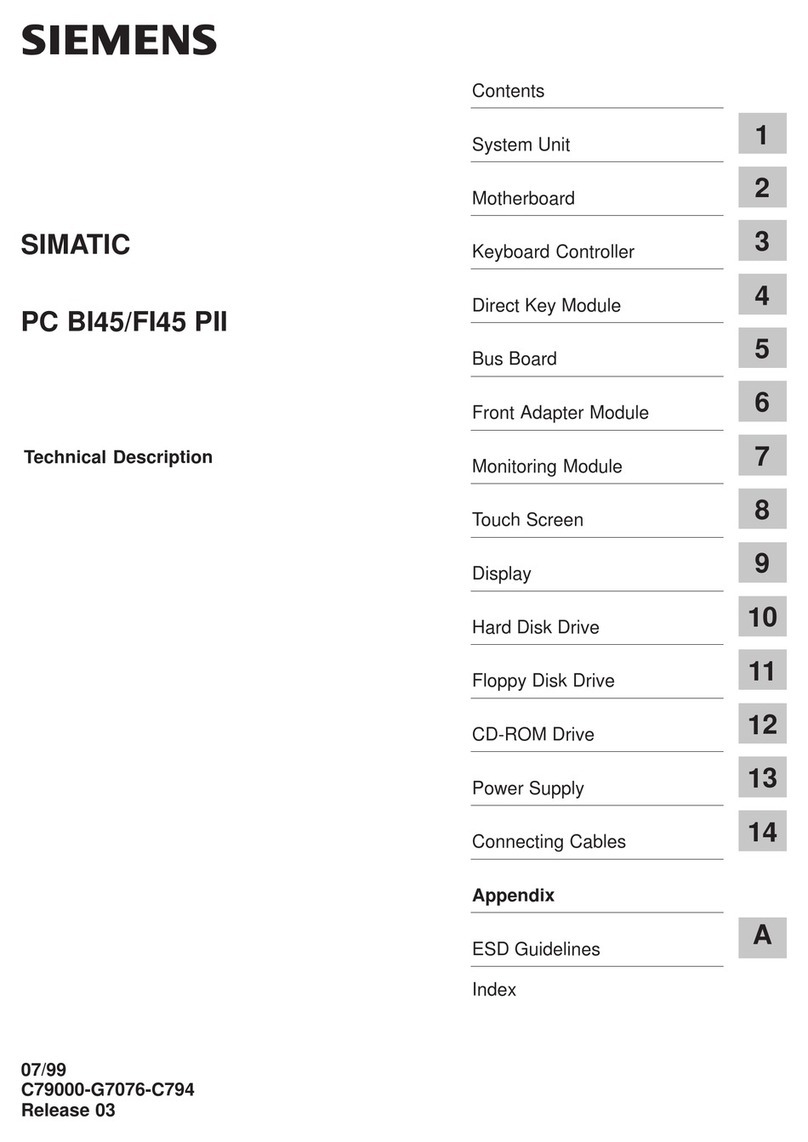

The Calibration Menu uses a “NeverLost” menu system to ensure that navigating the settings is

easy and quick. The Calibration Menu has four subsections: the Trackback Pane, Submenus,

Menu Items, and the Soft Switches, as shown in Figure 3.

Figure 3: Calibration Menu

Trackback

Pane

Submenu

Menu

Item

Main

Window

Soft

Switches

SSC6100 CAN Ultra Calibration Manual

5

Descriptions of Calibration Values

This section will describe each calibration value in the Calibration Menu in detail. For a complete

list of default settings, see Appendix A –Default Settings and Import/Export Types on page

Error! Bookmark not defined..

Configuration

Vehicle-wide settings, such as the supervisor access and clear codes, the vehicle's name, and

enabled options.

Access Code

Changes the supervisor code required to enter the Calibration Menu or clear season data

totals. It consists of 6 numbers and/or underscores which are set individually. The default

value is 000000.

Vehicle Name

Changes the descriptive name given to the vehicle. This name is displayed on reports

and as part of filenames when exporting. It can be set to 8 alphanumeric characters.

Measurement Units

Change the type of measurement system the vehicle uses for inputs and outputs.

Enabled Options

System-wide settings that can be enabled or disabled.

Sim Speed

Shows the SimSpeed data item and the SimSpeed soft switches in the UTIL2

soft switch pane and allow the user to simulate a ground speed without having to

physically move the vehicle.

Distance Measure

Allows the user to measure and reset distances travelled by the vehicle using

soft switches on the UTIL2 soft switch pane.

When SimSpeed is in use, the SSC6100 will disable the distance measure soft

switches and distance data item.

Aux Power

Allows the use of the auger valve to run auxiliary functions. In order to operate

the Aux Power feature the base truck or attached truck implement needs to

contain a granular output.

Event Logging (Serial)

Selects the format of event logging that is transmitted to an external PreCise®

MRM or 3rd party AVL device using the RS-232 connection on the Hub.

Event Logging (OTA)

Enables the built-in cellular data modem to transfer event data to the PreCise®

MRM system in near real-time. OTA event logging requires a PreCise® MRM

subscription.

Driver ID

Enables material usage and tracking per driver by requiring them to log in before

running the spreader. Several log-in methods are available.

SSC6100 CAN Ultra Calibration Manual

6

Momentary Spreading

Causes the standby button to operate in a momentary mode, requiring that it be

continuously held down to spread material.

Diagnostics

Adds a diagnostic button in the UTIL2 pane which is useful for observing live

system values that can be used to help in troubleshooting. This setting resets to

disabled each time the spreader is power-cycled.

Cameras

Settings to enable and control the behavior of the optional camera inputs.

Dual Camera Mode

Allows for up to two cameras to be displayed on the screen at the same time.

Camera 1, Camera 2, & Camera 3 (Full Screen)

Orientation

Configures the screen image to account for various mounting scenarios

including rear-facing and upside down mounted cameras.

Manual Select

Allows the user to select the active camera by pressing the Nav-Stick

down function.

Trigger

Allows a custom configurable trigger signal to bring up the camera. See

your FORCE America representative for options to setup these custom

trigger options.

Triggered Shutoff Delay

Causes a triggered camera to remain on the screen for a set amount of

time after the trigger signal has stopped.

Temperature Sensor

Sensor type and wireless sensor specific options.

Sensor Type

Selects the kind of temperature sensor attached to the 6100 whether wired or

wireless. For wireless sensors also see Wireless Settings for options to pair the

sensor to the SSC6100.

Temp Comp

Enables or disables material rate compensation based on real-time road surface

temperature. Compensation profiles are setup under the Granular Materials and

Prewet Materials menus.

T-Comp Averaging

Sets the number of temperature readings used to determine the average road

temperature for T-Comp operation.

Wireless Settings

Pairs the wireless sensor to the 6100 and set various options that control when

the sensor wakes up.

SSC6100 CAN Ultra Calibration Manual

7

Sensor ID

Shows the currently selected sensor in green text or pairs a new one.

Note that the sensor may need to be physically tapped to wake it up and

ready it for pairing.

Report Interval

Adjusts how often the sensor reports a new reading. Increasing the

reporting interval will conserve the sensor’s battery power.

Wake Interval

Adjusts how often the sensor wakes up and tries to connect to the 6100

spreader control. Increasing the wake interval will conserve the sensor’s

battery power.

Acceleration Threshold

Adjusts how much vibration is required to wake up the sensor.

Increasing the threshold can help reduce battery consumption in cases

where wind or other environmental vibrations can cause the sensor to

wake up while the vehicle is not in use.

X, Y, Z Acceleration Readings

Shows the actual peak and current acceleration values as a reference to

help choose appropriate acceleration threshold values.

Aux Power Ramp Time

Sets how quickly the Aux Power output will ramp up to the set speed.

Protect Current Data

Enables a password screen when clearing “Current Data” from the Data menu. This

password can be set differently than the supervisor access code.

Current Clear Code

Changes the code required to clear the current data from the Data menu. If Protect

Current Data is Disabled, this code does nothing. The default value is 314159.

Create Driver ID

Programs a standard USB FLASH drive to become a custom driver key. For the menu to

become available, the Driver ID key option has to be selected in the Enabled Options,

Driver ID section and a USB FLASH drive needs to be plugged into one of the USB ports

on the 6100.

Ground Speed

Vehicle speedometer input configuration settings.

Speedometer Type

Selects the speedometer input type to match the vehicle.

J1939 Baud Rate

Selects the CAN baud rate for the J1939 harness connection.

Pickup Sensitivity

Selects how sensitive the speedometer input is. Use a Low setting to help filter out noise

and false readings. Custom trip points can also be set for specific applications.

SSC6100 CAN Ultra Calibration Manual

8

Low Trip Point

Sets the voltage that the speedometer signal must drop below in order to register a pulse.

It is only adjustable for the Custom Pickup Sensitivity type and can be adjusted by a

passenger while the vehicle is moving to help determine the correct setting required to

pick up a ground speed signal.

High Trip Point

Sets the voltage that the speedometer signal must climb above in order to register a

pulse. It is only adjustable for the Custom Pickup Sensitivity type and can be adjusted by

a passenger while the vehicle is moving to help determine the correct setting required to

pick up a ground speed signal.

Axle Pulses

Defines how many pulses from the speedometer input are expected in 1 mile or

kilometer. Pressing the AUTOCAL softswitch launches a step by step wizard that sets

the pulses by driving a fixed distance.

The Axle Pulses can also be manually set. While the vehicle is moving, have a

passenger adjust the Axle Pulses up or down until the speed displayed on the screen

matches the vehicle’s speedometer.

Jump Start Speed

Stabilizes the spreader outputs at low ground speeds by simulating an artificially higher

than actual ground speed until the truck is moving fast enough. At speeds above zero,

the system immediately starts spreading at the set jump start speed until that speed is

exceeded.

Overspeed Alarm

Alerts the driver when he is exceeding the maximum allowed speed. If enabled, it can be

set to always be active or only when spreading.

Overspeed Speed

Sets the speed that the vehicle must exceed for the system to display the Overspeed

Warning. It is only available if the Overspeed Alarm setting is enabled.

Granular Materials

Settings used for general granular material application and for the individual granular materials.

Enabled Options

General granular application settings that apply to the truck and tow plow application

systems.

Manual Mode

Enables the Granular Manual soft switch on the GRAN and/or TOW PLOW

softswitch panes.

Unload Mode

Enables unload mode in the Unload menu.

AutoVerify Mode

Enables the AutoVerify softswitch in the Material menu which runs a step by step

wizard that can be used to verify the calibration of each material.

Blast Mode

Sets Blast to operate for either a set Time or a set Distance each time the Blast

button is pressed.

SSC6100 CAN Ultra Calibration Manual

9

Blast Time

Sets the amount of seconds blast will run when it is activated in Blast Time mode.

Blast Distance

Sets the distance that blast will run when it is activated in Blast Distance mode.

Skip Mode

Enables the Skip Mode soft switch on the GRAN pane, which activates an on/off

spread pattern for granular materials.

Skip On Distance

Sets the amount of distance the auger / conveyor and spinner will be actively

spreading before switching off when Skip Mode is active.

Skip Off Distance

Sets the amount of distance the auger / conveyor and spinner will be off before

switching back on when Skip Mode is active.

Loop Mode

Sets the control output into either Closed Loop or Open Loop Mode.

Materials Enabled

Sets how many materials will be available to the user.

Materials

Settings for each of the enabled granular materials.

Material 1, Material 2, Material 3, etc.

Custom settings for each particular granular material.

Material Name

Sets a custom name for the material. This name appears on the

spreader operating screen and in the material select menu.

# of Set Rates

Sets how many set rates will be available to the user during operation.

Set Rates

Adjusts custom set rates available to the user for each material.

Set Rate 1, Set Rate 2, Set Rate 3, etc.

Sets the material rate for each setting.

Blast Rate

Sets the output rate when operating in Blast mode.

Temperature Compensation

Settings related to the granular Temperature Compensation mode.

Profile 1, Profile 2, Profile 3, etc.

Adjusts the individual temperature compensation values for each temperature

profile.

SSC6100 CAN Ultra Calibration Manual

10

Compensation at X, Compensation at Y, Compensation at Z, etc.

Adjusts the material compensation percentage for each given

temperature point.

Prewet Materials

Settings used for general Prewet material application and for the individual prewet materials.

Enabled Options

General prewet application settings that can apply to the truck and tow plow application

systems.

Manual Mode

Enables the Prewet Manual soft switch on the GRAN and/or TOW PLOW

softswitch panes.

Unload Mode

Enables unload mode in the Unload menu.

AutoVerify Mode

Enables the AutoVerify softswitch in the Material menu which runs a step by step

wizard that can be used to verify the calibration of each material.

Loop Mode

Sets the control output to either Closed Loop, Open Loop, On/Off, or Manual operation.

Materials Enabled

Sets how many Prewet materials will be available to user.

Materials

Settings for each of the enabled Prewet materials.

Material 1, Material 2, Material 3, etc.

Settings available for each enabled Prewet material.

Material Name

Sets a custom name for the Prewet material.

# of Set Rates

Sets how many rates will be available to the user during operation.

Set Rates

Custom set rates for Prewet materials.

Set Rate 1, Set Rate 2, Set Rate 3, etc.

Sets the Prewet rate for each setting.

# of Spray Bar Set Rates

Sets how many rates will be available to the user during operation.

Spray Bar Set Rates

Custom set rates for Prewet Spray Bar materials.

Set Rate 1, Set Rate 2, Set Rate 3, etc.

Sets the Prewet Spray Bar rate for each setting.

SSC6100 CAN Ultra Calibration Manual

11

Temperature Compensation

Settings related to the Prewet Temperature Compensation mode.

Profile 1, Profile 2, Profile 3, etc.

Adjusts the individual temperature compensation values for each temperature

profile.

Compensation at X, Compensation at Y, Compensation at Z, etc.

Adjusts the material compensation percentage for each given

temperature point.

Direct Materials

Settings used for general direct liquid application and for the individual direct liquid materials.

Enabled Options

General direct liquid application settings that can apply to the truck and tow plow

application systems.

Manual Mode

Enables the Direct Manual soft switch on the DIRECT and/or TOW PLOW

softswitch panes.

Unload Mode

Enables unload mode in the Unload menu.

AutoVerify Mode

Enables the AutoVerify softswitch in the Material menu which runs a step by step

wizard that can be used to verify the calibration of each material.

Blast Mode

Sets Blast to operate for either a set Time or a set Distance each time the Blast

button is pressed.

Blast Time

Sets the amount of seconds blast will run when it is activated in Blast Time mode.

If simultaneous application is active, Direct Liquid’s Blast Time will have no effect

and the Granular Blast Time will be used.

Blast Distance

Sets the distance that blast will run when it is activated in Blast Distance mode.

If simultaneous application is active, Direct Liquid’s Blast Distance will have no

effect and the Granular Blast Distance will be used.

Loop Mode

Sets the control output into either Closed Loop or Open Loop Mode.

Materials Enabled

Sets how many materials will be available to the user.

Materials

Settings for each of the enabled Direct materials.

Material 1, Material 2, Material 3, etc.

Settings available for each enabled direct liquid material.

SSC6100 CAN Ultra Calibration Manual

12

Material Name

Sets a custom name for the direct liquid material. This name appears on

the spreader operating screen and in the material select menu.

# of Set Rates

Sets how many rates will be available to the user during operation.

Set Rates

Custom set rates for Direct materials.

Set Rate 1, Set Rate 2, Set Rate 3, etc.

Sets the Direct rate for each setting.

Blast Rate

Sets the output rate when operating in Blast mode.

Dust Control Materials

Settings used for dust control liquid application.

Enabled Options

General dust control application settings that can apply to the truck application systems.

Manual Mode

Enables the Dust Manual soft switch on the DUST softswitch pane.

Unload Mode

Enables unload mode in the Unload menu.

AutoVerify Mode

Enables the AutoVerify softswitch in the Material menu which runs a step by step

wizard that can be used to verify the calibration of the material.

Loop Mode

Sets the control output into either Closed Loop or Open Loop Mode.

Left Boom, Center Boom, Right Boom Width

Sets the actual width of each control boom. This is used in calculation of the material

rate.

Materials

Settings related to the dust control material.

Material 1

Settings available for the dust control material.

Material Name

Sets a custom name for the material. This name appears on the

spreader operating screen and in the material select menu.

# of Set Rates

Sets how many rates will be available to the user during operation.

Set Rates

Adjusts custom set rates available for each material.

SSC6100 CAN Ultra Calibration Manual

13

Set Rate 1, Set Rate 2, Set Rate 3, etc.

Sets the material rate for each setting.

Blast Rate

Sets the output rate when operating in Blast mode.

Herbicide Materials

Settings used for herbicide application.

Enabled Options

General herbicide settings that can apply to the truck application systems.

Manual Mode

Enables the Herbicide Manual soft switch on the HERBICIDE softswitch pane.

Unload Mode

Enables unload mode in the Unload menu.

AutoVerify Mode

Enables the AutoVerify softswitch in the Material menu which runs a step by step

wizard that can be used to verify the calibration of the material.

Loop Mode

Sets the control output into either Closed Loop or Open Loop Mode.

Left Boom, Center Boom, Right Boom Width

Sets the actual width of each control boom. This is used in calculation of the material

application rate.

Materials

Settings related to the herbicide material.

Material 1

Settings available for the herbicide material.

Material Name

Sets a custom name for the herbicide material. This name appears on

the spreader operating screen and in the material select menu.

# of Set Rates

Sets how many rates will be available to the user during operation.

Set Rates

Custom set rates for the herbicide application.

Set Rate 1, Set Rate 2, Set Rate 3, etc.

Sets the rate for each setting.

Truck / Tow Plow

Settings related to both the truck mounted and tow plow systems including generic operating

modes and material-specific options. Note that the actual settings available in this section of the

Calibration menu will vary depending on the specific configuration of the system and will likely not

have all of these settings and options.

SSC6100 CAN Ultra Calibration Manual

14

Auger / Conveyor

Settings for the Truck and/or Tow Plow granular system.

Enabled Options

Auger and conveyor settings that can be enabled or disabled.

Auger Reverse

Enables the Auger Reverse soft switch on the GRAN softswitch pane.

Clear Jam

Enables the Clear Jam Soft Switch on the GRAN softswitch pane.

Calib/Unload Auger

Defines the direction the Auger runs when in Calibration or Unload Mode.

Calib/Unload Cross

Defines the direction of the Cross Auger when in Calibration or Unload

Mode.

Pulses per Revolution

Sets how many pulses the auger sensor produces in 1 revolution of the auger.

Valve Outputs - Auger Forward, Auger Reverse, Cross Augers 1-4, Tow

Auger

Settings for optimizing system response by calibrating the valve drive Min and

Max settings.

The actual number of outputs and the specific names for each of the outputs is

dependent on how your system is configured. The process of calibrating the Min

and Max settings should be repeated for each output.

Min DC

Raise this setting up to a point where the function is moving slowly and

then reduce it until it just comes to a stop.

Max DC

Start with a high value and slowly reduce it until the function begins to

slow down, then raise it back up until it just reaches full speed.

Note: If your system uses Implements,

make sure the associated Implement and

material type you wish to calibrate is

selected in the Implements menu before

attempting to run outputs and calibrate the

material. If your system contains multiple

Implements with different material types

and/or valve outputs, you will need to exit

Calibration, select another implement, and

re-enter calibration to set those up.

SSC6100 CAN Ultra Calibration Manual

15

Maximum RPM (Forward, Reverse & Tow Augers)

Optimizes performance and accuracy by telling the system what the highest RPM

that the function can achieve when running at maximum duty cycle.

Closed Loop Gain

Adjusts the responsiveness of the system in closed loop mode. Decrease this

value to stabilize a hunting system, or increase this value to speed up a sluggish

system.

Gate Mode (Truck only)

Selects the type of gate used by a conveyor style granular system. Two position

requires sensors on the gate. Adjustable requires the operator to manually

match the gate setting on the controller to the actual gate height on the spreader.

Material Settings

Configures the enabled granular materials that are specific to the application

system.

Material X, Material Y, Material Z, etc.

Custom settings available for each granular material. The material

names in this menu are defined in the Granular Materials – Materials

menu section.

Calib Gate Height (Truck only)

Sets the gate height that is used when calibrating a given

material. If this value is changed, it will require re-calibrating of

the auger displacement.

Two Position Gate (Truck only)

Sets the expected gate position (high or low) to be used for each

material.

Displacement

Sets the amount of material dispensed by the auger in one

revolution of the auger sensor.

Pressing the AUTOCAL softswitch launches a step by step

wizard that assists with determining the displacement setting.

Enabled Spinners (Tow Plow only)

Allows configuration of what spinners are enabled when the Tow Plow implement

is activated

Spinner

Settings for the Truck and/or Tow Plow spinner(s).

Spinner Reverse (Truck only)

Enables the ability to reverse the rotational direction of the spinner.

Calib/Unload Spinner

Defines which Spinner will run when in Calibration or Unload mode.

Pulses per Revolution (Truck only)

Configures how many pulses from the spinner sensor are expected in 1

revolution of the spinner. Used to display the spinner RPM on one of the

operation screen data items.

SSC6100 CAN Ultra Calibration Manual

16

Separate Spread Width (Tow Plow Only)

Enables the ability to control the truck spinner’s and tow plow spinner’s spread

width independently.

Spinner 1 - 4

Settings for optimizing system response by calibrating the valve drive Min and

Max settings.

The actual number of outputs and the specific names for each of the outputs is

dependent on how your system is configured. The process of calibrating the Min

and Max settings should be repeated for each output.

If your system uses Implements, make sure the associated Implement is selected

in the Implements menu to make them available for calibration.

Min DC

Raise this setting up to a point where the function is moving slowly and

then reduce it until it just comes to a stop.

Max DC

Start with a high value and slowly reduce it until the function begins to

slow down, then raise it back up until it just reaches full speed.

Actuator Min

Sets the minimum valid voltage for the spinner position sensor. Only visible if the

system is configured to use a Directional Spinner.

Actuator Max

Sets the maximum valid voltage for the spinner position sensor. Only visible if

the system is configured to use a Directional Spinner.

Five Second Run On (Truck only)

Enables a mode that keeps the spinner running for 5 seconds after the spreader

stops to keep the spinner disk clear of material.

Spinner Skip (Truck only)

Determines if the spinner stops during the Skip Off interval.

Prewet

Settings for the Truck and/or Tow Plow Prewet system.

Drive Type (Truck only)

Configures the Prewet drive method.

“Standard” uses a proportional valve on the valve stack. “Exhaust” uses a valve

on the auger to send a portion of the oil flow to the prewet motor.

Pulses per Revolution

Configures how many pulses are expected in 1 revolution of the prewet

flowmeter.

SSC6100 CAN Ultra Calibration Manual

17

Prewet Output

Settings for optimizing system response by calibrating the valve drive Min and

Max settings. The specific name of the output is dependent on how your system

is configured.

If your system uses Implements, make sure the associated Implement is selected

in the Implements menu to make them available for calibration.

Min DC

Raise this setting up to a point where the function is moving slowly and

then reduce it until it just comes to a stop.

Max DC

Start with a high value and slowly reduce it until the function begins to

slow down, then raise it back up until it just reaches full speed.

Maximum RPM

Optimizes performance and accuracy by telling the system what the highest RPM

that the function can achieve when running at maximum duty cycle.

Closed Loop Gain

Adjusts the responsiveness of the system in closed loop mode. Decrease this

value to stabilize a hunting system, or increase this value to speed up a sluggish

system.

Material Countdown

Sets up the material countdown functions that show the amount of liquid

remaining in the tank

Material Countdown

Enables the material countdown function.

Tank Size

Sets the size of the liquid tank as a starting point for material countdown.

Low Liquid Level

Sets the percentage of remaining liquid that triggers the Low Liquid

indication.

Material Settings

Configures the enabled Prewet materials that are specific to the application

system.

Material X, Material Y, Material Z, etc.

Custom settings available for each particular prewet material. The

material names in this menu are defined in the Prewet Materials –

Materials menu.

Displacement

Sets the amount of material dispensed in one revolution of the

prewet flowmeter.

Pressing the AUTOCAL softswitch launches a step by step

wizard that assists with determining the displacement setting.

Direct Liquid

Settings for the Truck and/or Tow Plow Direct Liquid system.

SSC6100 CAN Ultra Calibration Manual

18

Pulses per Revolution

Configures how many pulses are expected in 1 revolution of the direct liquid

flowmeter.

Direct Output

Settings for optimizing system response by calibrating the valve drive Min and

Max settings. The specific name of the output is dependent on how your system

is configured.

Min DC

Raise this setting up to a point where the function is moving slowly and

then reduce it until it just comes to a stop.

Max DC

Start with a high value and slowly reduce it until the function begins to

slow down, then raise it back up until it just reaches full speed.

Maximum RPM

Optimizes performance and accuracy by telling the system what the highest RPM

the function can achieve when running at maximum duty cycle.

Closed Loop Gain

Adjusts the responsiveness of the system in closed loop mode. Decrease this

value to stabilize a hunting system, or increase this value to speed up a sluggish

system.

High Boom

Sets the flow rate that determines when the flow should be redirected from the

low boom to the high boom.

High/Low Boom

Sets the flow rate that determines when both the high and low booms will be

used simultaneously to apply the direct liquid material.

Material Countdown

Sets up the material countdown functions that show the amount of liquid

remaining in the tank

Material Countdown

Enables the material countdown function.

Tank Size

Sets the size of the liquid tank as a starting point for material countdown.

Low Liquid Level

Sets the percentage of remaining liquid that triggers the Low Liquid

indication.

Material Settings

Configures the enabled Direct materials that are specific to the application

system.

Other manuals for SSC6100 CAN ULTRA

4

Table of contents

Other Force America Control System manuals