Force America SSC6100 CAN ULTRA User manual

SSC6100 CAN ULTRA

Spreader Control

Operation Manual

Firmware Version

1.11.1035

SSC6100 Operation Manual

Welcome and Table of Contents

i

Welcome

Congratulations on your purchase of a FORCE America®, Inc. SSC6100 Spreader Control. This

manual will guide you through the process of using your new spreader control.

Table of Contents

Welcome ...........................................................................................................i

Table of Contents.............................................................................................i

Hardware..........................................................................................................1

Core Module (PN: 1104694).................................................................................................. 4

Operator Interface (PN: 1104696)........................................................................................ 6

20 Port Valve Module (PN: 1018887)................................................................................... 7

10 Port Valve Module (PN: 1101182)................................................................................... 9

7-Inch LCD Display (PN: 1104695) .................................................................................... 11

6100 Event Logging Authentication Module (PN: 1016063) ........................................... 12

Direct Liquid Application Module (PN: 1018830)............................................................. 13

Powering up the SSC6100............................................................................15

System Operation..........................................................................................18

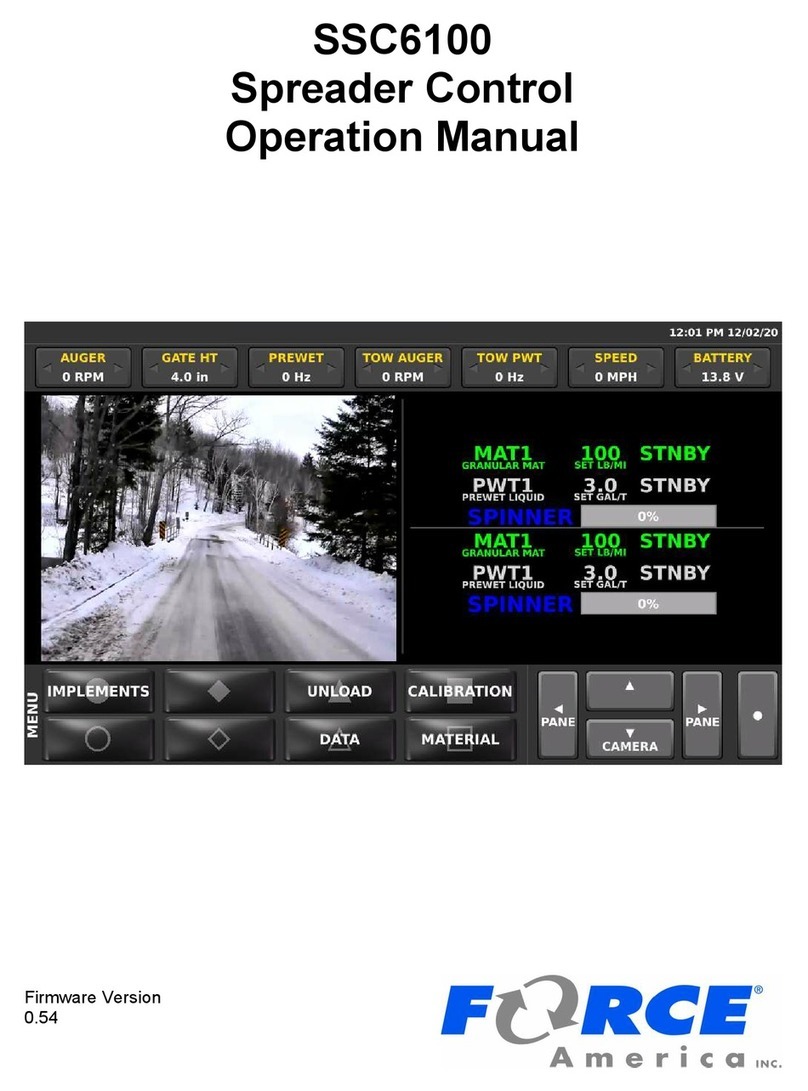

The Spreader Power Off Screen........................................................................................ 18

The Operation Screen......................................................................................................... 19

Monitoring System Status.................................................................................................. 74

Entering Menus................................................................................................................... 75

Implements Menu..........................................................................................76

Material Selection Menu ...............................................................................78

Data Menu......................................................................................................81

Viewing a Report................................................................................................................. 85

Summary Report................................................................................................................. 86

Detailed Report ................................................................................................................... 87

Error Log.............................................................................................................................. 88

Unload Menu..................................................................................................89

Granular Unload.................................................................................................................. 90

Tow Granular Unload.......................................................................................................... 93

Prewet Unload..................................................................................................................... 96

Tow Prewet Unload............................................................................................................. 99

Direct Unload..................................................................................................................... 102

Setting Sim Speed.......................................................................................108

Distance Measure........................................................................................109

Joysticks......................................................................................................111

Switches.......................................................................................................113

SSC6100 Operation Manual

Welcome and Table of Contents

ii

Automatic Recall of Joystick Functions......................................................................... 113

Enable or Disable a Joystick ........................................................................................... 113

Change a Joystick to an Alternate Function.................................................................. 114

Run a Low Current Function ........................................................................................... 114

Powering Down the SSC6100.....................................................................115

Troubleshooting and Error Conditions .....................................................116

Header Bar Warnings ....................................................................................................... 116

Error Windows .................................................................................................................. 120

In-Line Errors .................................................................................................................... 127

The Emergency Stop Warning Screen............................................................................ 133

Joystick Error Codes........................................................................................................ 134

Licensing and Source Code Availability ...................................................135

FORCE America Contact Information........................................................135

Appendix A –GNU General Public License, Version 2............................136

SSC6100 Operation Manual

Hardware

1

Hardware

Every SSC6100 comes with at least 4 components:

Core Module

(PN: 1104694)

Operator Interface

(PN: 1104696)

7-Inch LCD Display

(PN: 1104695)

SSC6100 Operation Manual

Hardware

2

20 Port Valve Module

(PN: 1018887)

or

10 Port Valve Module

(PN: 1101182)

SSC6100 Operation Manual

Hardware

3

In addition, your spreader control may ship with one or more of the following optional

components:

6100 Event Logging Authentication

Module, 6100-ELA-Module

(PN: 1016063)

Direct Liquid Application Module

(PN: 1018830)

For more information on hardware pinouts and

connections, refer to Schematic 3388, included

in the SSC6100 Binder.

SSC6100 Operation Manual

Hardware

4

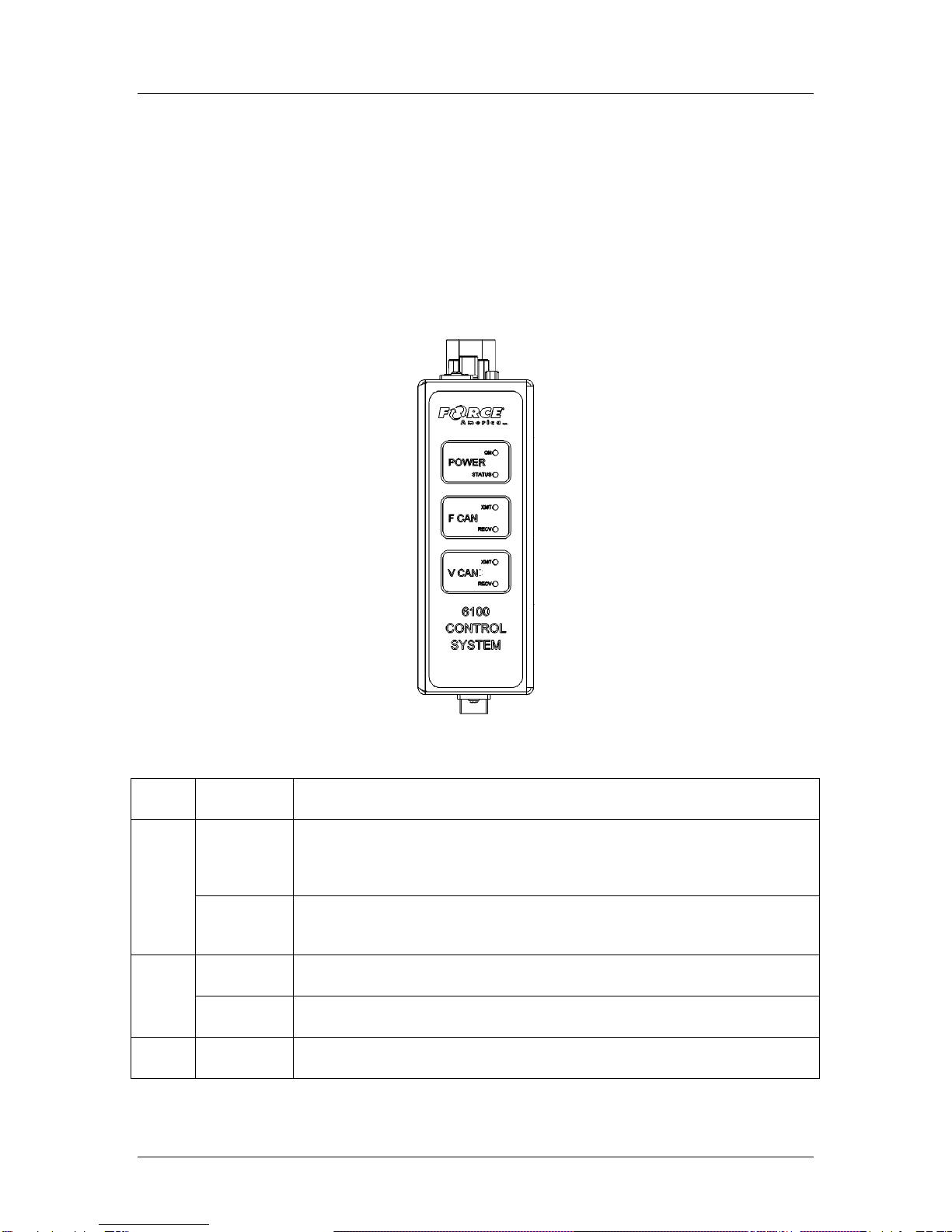

Core Module (PN: 1104694)

The Core Module is the heart of the SSC6100 system. It acts as the central point of

communication for all CAN devices, processing all the inputs and redirecting them to the

appropriate outputs.

The Core Module is mounted vertically on the floor of the vehicle. Its LEDs face up towards the

driver to present status information.

The top of the Core Module has 6 status LEDs, as shown in Figure 1:

Figure 1: Top of the Core Module

Label

LED

Function

Power

On

This LED displays the presence of the vehicle’s ignition switch. This LED

is lit when the vehicle’s ignition switch is in the powered position and is

unlit when it is off.

Status

This LED confirms the operating status of the SSC6100 hardware. This

light should blink if the SSC6100 hardware initialized successfully.

FCAN

XMT

This LED blinks when the Core Module transmits data on the CAN bus.

RECV

This LED blinks when the Core Module receives data from the CAN bus.

VCAN

XMT

This LED blinks when the Core Module transmits data on the CAN bus.

SSC6100 Operation Manual

Hardware

5

Label

LED

Function

RECV

This LED blinks when the Core Module receives data from the CAN bus.

The front of the Core Module has a single USB port, which can be used to import and export

calibration files or material usage reports. The ports on the back of the core module are used as

connectors to the Operator Interface, 20 Port Valve Module, 10 Port Valve Module, LCD Display,

and temperature sensor.

Do not attempt to connect the DVI connector

on the Core Module to any other device

besides a Force America 7 Inch LCD Display.

You may damage your equipment.

For more information on the ports on the back

of the Core Module, refer to the installation

drawing included in the SSC6100 Binder.

SSC6100 Operation Manual

Hardware

6

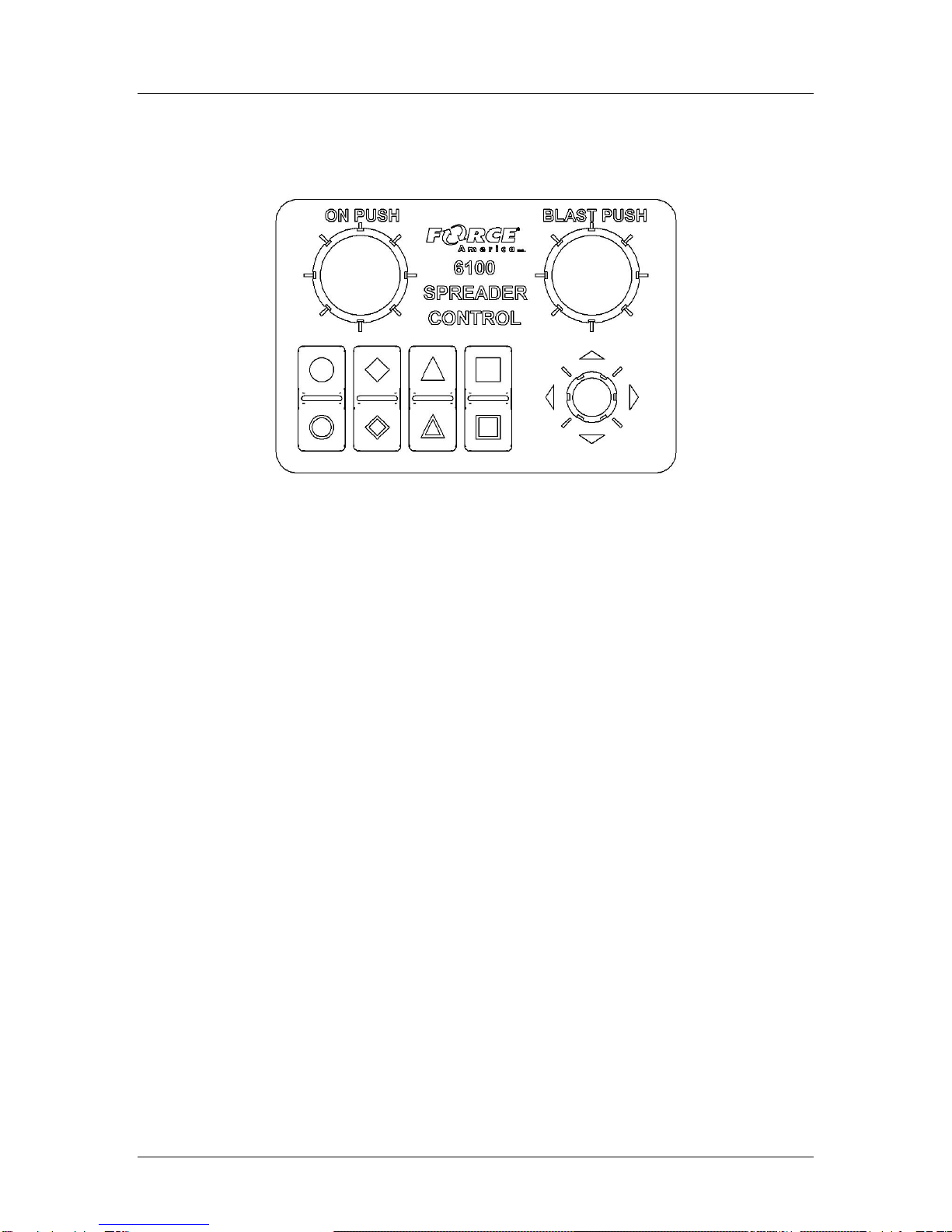

Operator Interface (PN: 1104696)

The Operator Interface lets you control all the aspects of the SSC6100.

Figure 2: Operator Interface

The Operator Interface has two single-axis encoders, one triple-axis encoder, and eight “soft

switches” that act as pushbuttons for SSC6100 functions. The functions that they control change

depending on what portion of the SSC6100 system is active. See System Operation on page 18.

SSC6100 Operation Manual

Hardware

7

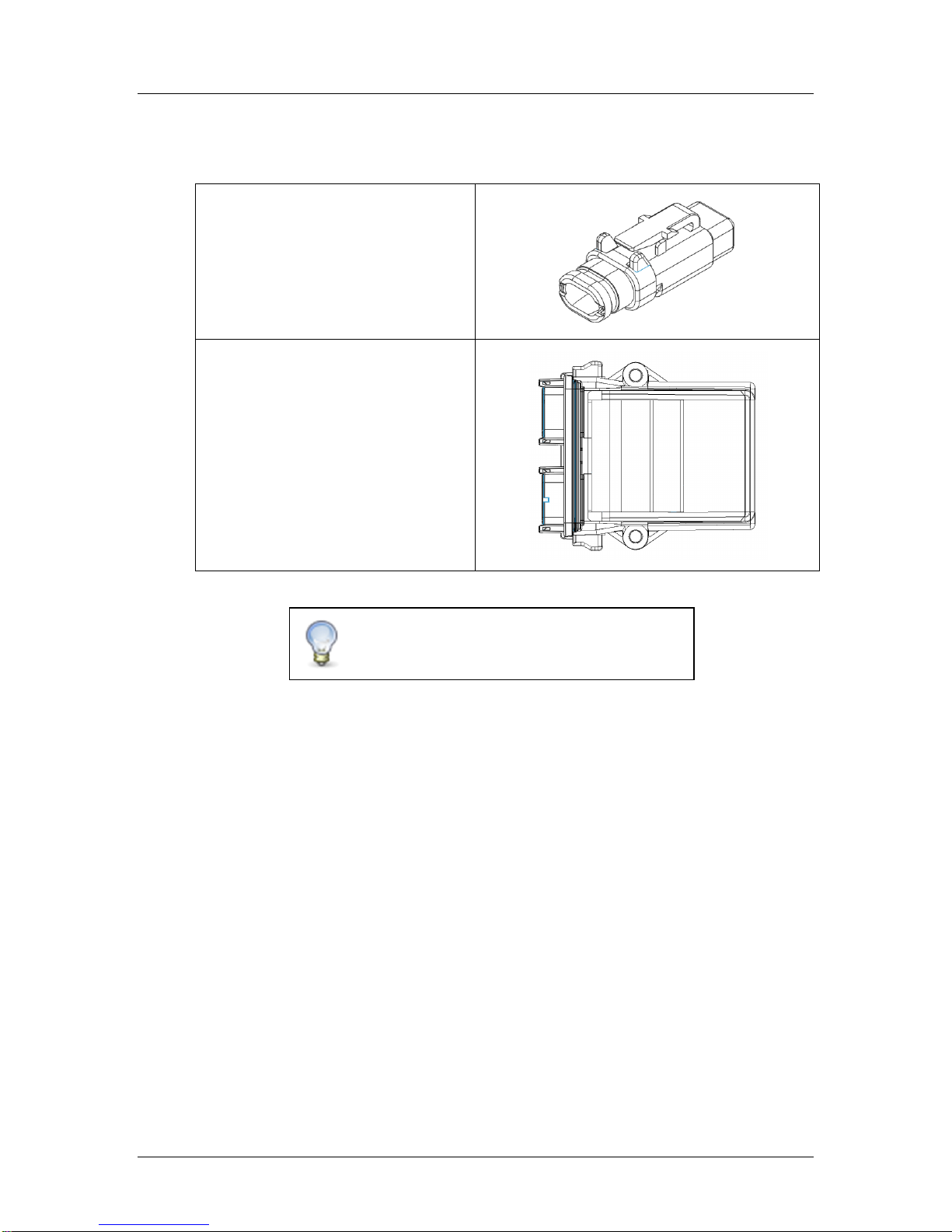

20 Port Valve Module (PN: 1018887)

The 20 Port Valve Module acts as the primary driver of outputs for an SSC6100 system. It

contains a 50 pin Deutsch connector with a harness for feedback inputs to the Core Module, as

well as LEDs to inform you of the Valve Module’s operational status.

Figure 3: 20 Port Valve Module

LED

Function

STATUS

This LED displays the presence of CAN power to the valve module. This LED

blinks when the valve module is powered and is unlit when it is not.

TX

This LED blinks when the Valve Module transmits data on the CAN bus.

RX

This LED blinks when the Valve Module receives data from the CAN bus.

SSC6100 Operation Manual

Hardware

8

LED

Function

INPUT 1

The INPUT 1 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to a Low Filter

Bypass sensor.

INPUT 2

The INPUT 2 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to a High Filter

Bypass sensor.

INPUT 3

The INPUT 3 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to an Oil Level

sensor.

INPUT 4

The INPUT 4 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to an Oil

Temperature sensor.

INPUT 5

The INPUT 5 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to a Body Up

sensor.

INPUT 6

The INPUT 6 LED will light when the valve module detects a sourcing signal from

a connected sensor.

FDBK 1

The FDBK 1 LED will flash when the Valve Module receives pulses from a

connected feedback sensor. In many systems, this feedback input is connected to

Auger / Conveyor Feedback.

FDBK 2

The FDBK 2 LED will flash when the Valve Module receives pulses from a

connected feedback sensor. In many systems, this feedback input is connected to

Prewet Feedback.

FDBK 3

The FDBK 3 LED will flash when the Valve Module receives pulses from a

connected feedback sensor. In many systems, this feedback input is connected to

Direct or Spinner Feedback.

SSC6100 Operation Manual

Hardware

9

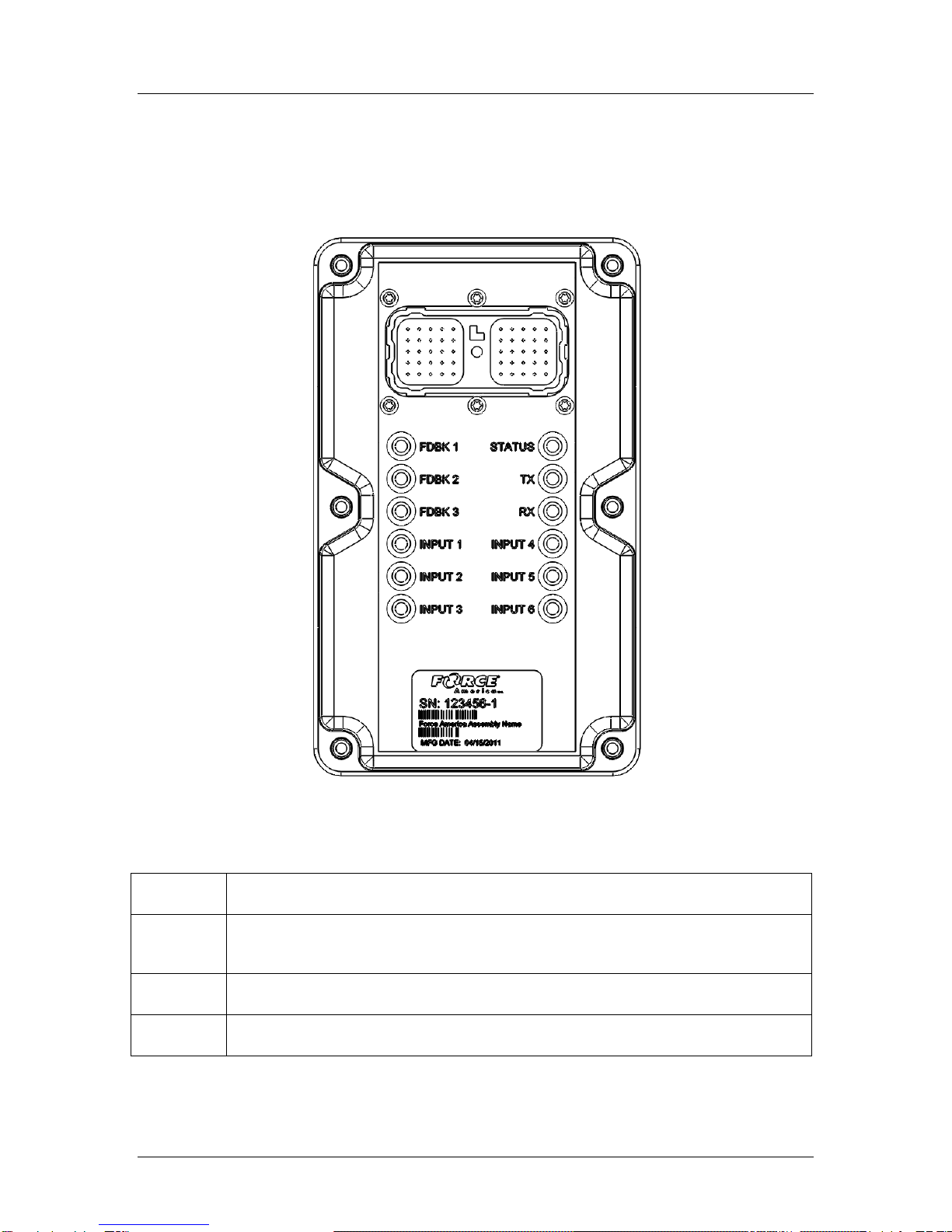

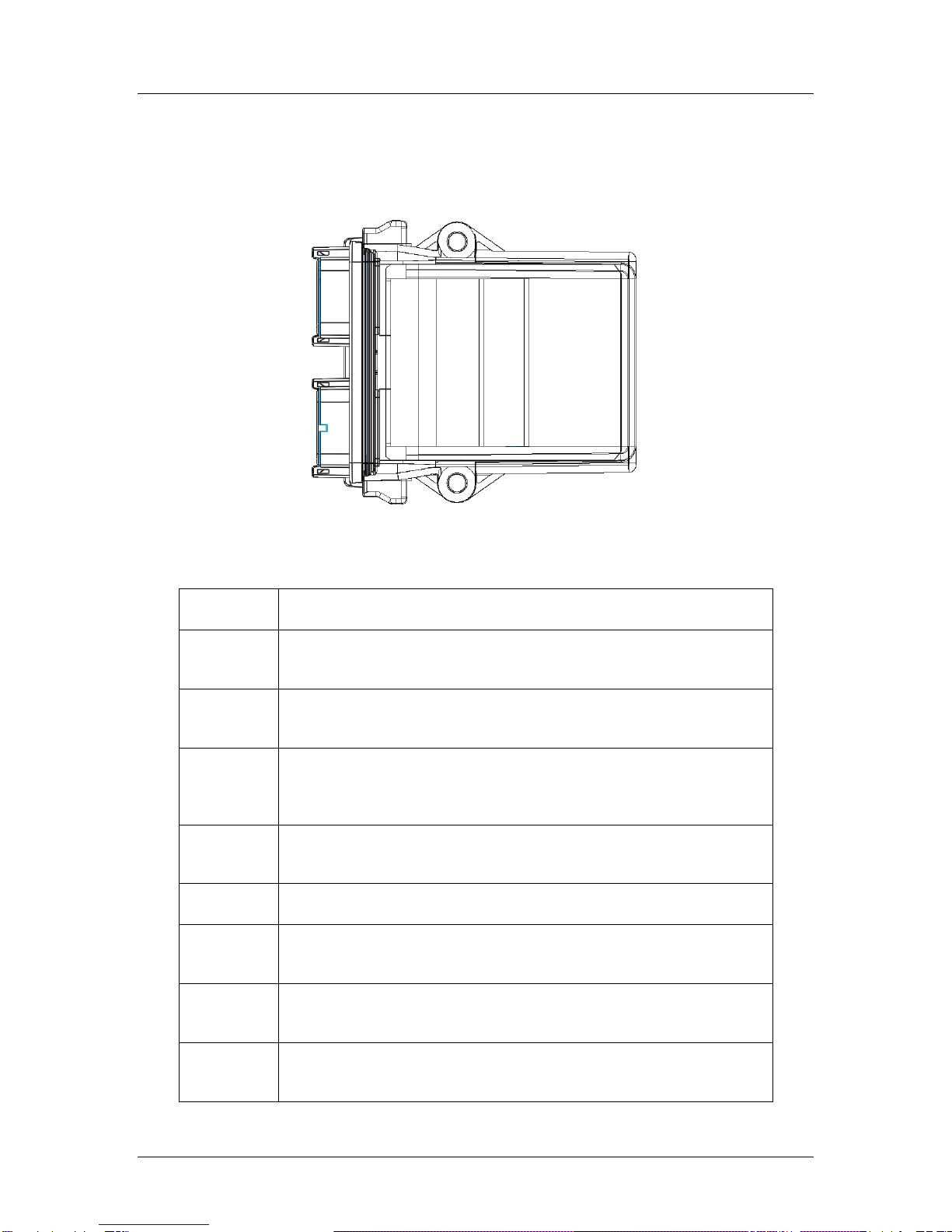

10 Port Valve Module (PN: 1101182)

The 10 Port Valve Module acts as the primary driver of outputs for an SSC6100 system. It

contains a 50 pin Deutsch connector with a harness for feedback inputs to the Core Module, as

well as LEDs to inform you of the Valve Module’s operational status.

Figure 4: 10 Port Valve Module

LED

Function

STATUS

This LED displays the presence of CAN power to the valve module. This LED

blinks when the valve module is powered and is unlit when it is not.

TX

This LED blinks when the Valve Module transmits data on the CAN bus.

RX

This LED blinks when the Valve Module receives data from the CAN bus.

SSC6100 Operation Manual

Hardware

10

LED

Function

INPUT 1

The INPUT 1 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to a Low Filter

Bypass sensor.

INPUT 2

The INPUT 2 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to a High Filter

Bypass sensor.

INPUT 3

The INPUT 3 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to an Oil Level

sensor.

INPUT 4

The INPUT 4 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to an Oil

Temperature sensor.

INPUT 5

The INPUT 5 LED will light when the valve module detects a grounding signal

from a connected sensor. In many systems, this is connected to a Body Up

sensor.

INPUT 6

The INPUT 6 LED will light when the valve module detects a sourcing signal from

a connected sensor.

FDBK 1

The FDBK 1 LED will flash when the Valve Module receives pulses from a

connected feedback sensor. In many systems, this feedback input is connected to

Auger / Conveyor Feedback.

FDBK 2

The FDBK 2 LED will flash when the Valve Module receives pulses from a

connected feedback sensor. In many systems, this feedback input is connected to

Prewet Feedback.

FDBK 3

The FDBK 3 LED will flash when the Valve Module receives pulses from a

connected feedback sensor. In many systems, this feedback input is connected to

Direct or Spinner Feedback.

SSC6100 Operation Manual

Hardware

11

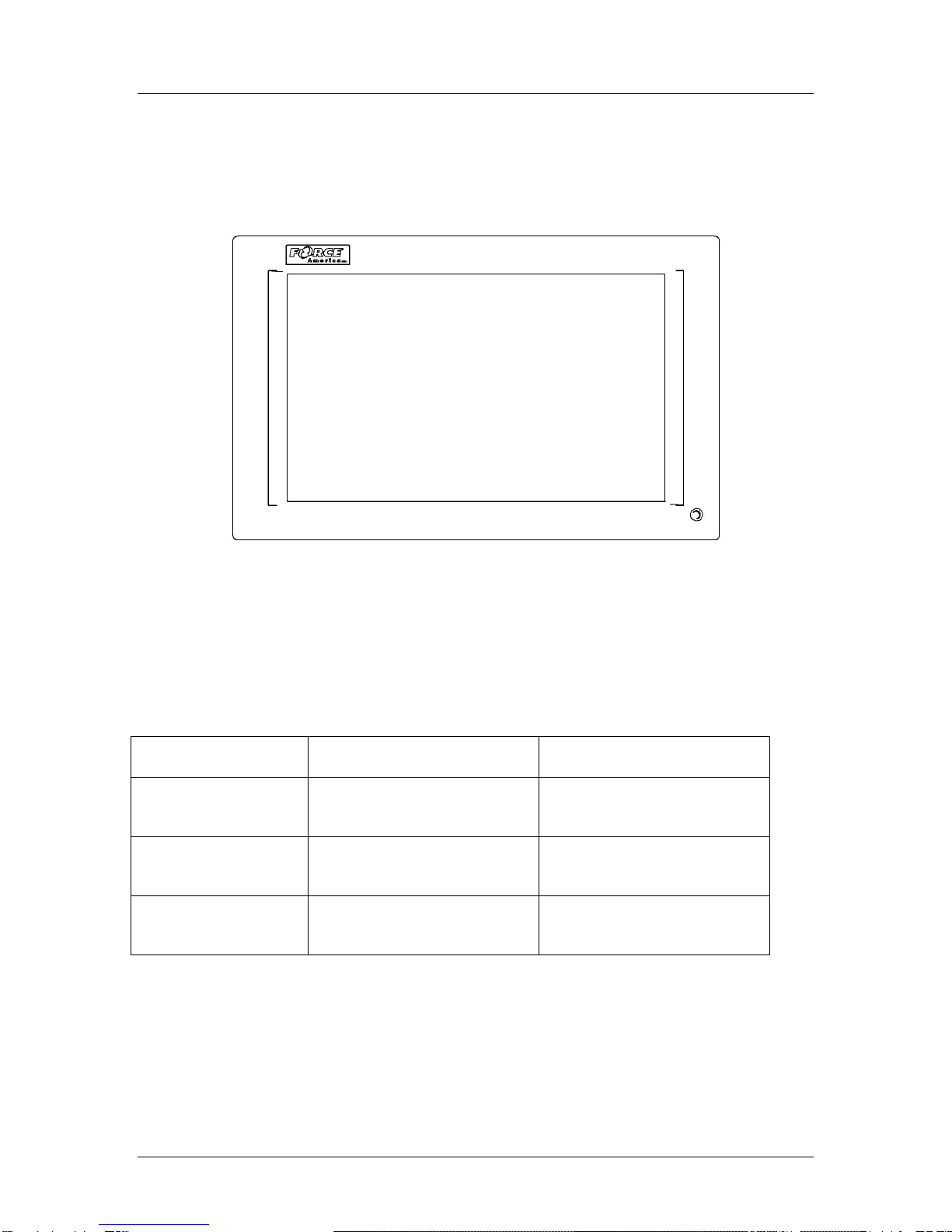

7-Inch LCD Display (PN: 1104695)

The LCD Display shows all of the interactive content, including operation status, configuration

options, material usage reports, and error codes.

Figure 5: LCD Display

The LCD has a bi-color LED which can light up green or red. It also has a buzzer to signal system

startup, system shutdown, or an operational error.

The following table describes the LED and buzzer states during startup, shutdown, and while the

system is running.

Status

During Startup & Shutdown

System Running

LED: Solid Green

Buzzer: Silent

--

Normal Operation

LED: Blinking Red

Buzzer: Beeps Once

Normal Operation

CAN Communication Error

LED: Off

Buzzer: Silent

No Power to LCD

No Power to LCD

SSC6100 Operation Manual

Hardware

12

6100 Event Logging Authentication Module (PN: 1016063)

The 6100 Event Logging Authentication Module, 6100 ELA Module, is an optional component for

the SSC6100 that configures the system to use AVL Event Logging. It provides security

information and your unique group ID to the spreader control so that it can communicate with the

AVL module.

Figure 6: 6100 Event Logging Authentication Module

If Event Logging is set to AVL in Calibration, you will see the DGID item in the Version Menu. It

will display your Digital Group ID code, a unique identifier for your operation and AVL provider,

which can be used to re-order 6100 ELA Modules.

If the 6100 ELA module is disconnected but is required by the system, an Event Logging

Authentication Module Communication Error will appear. See Troubleshooting and Error

Conditions on page 116 for more information.

SSC6100 Operation Manual

Hardware

13

Direct Liquid Application Module (PN: 1018830)

The Direct Liquid Application (DLA) Module runs the main direct liquid pump and lane ball valves,

and receives feedback from direct sensors.

Figure 7: Direct Liquid Application Module

The DLA Module has LEDs to inform you of the input and output states.

LED Label

Function

TX

The TX LED blinks when the DLA Module transmits data on the CAN

bus.

RX

The RX LED blinks when the DLA Module receives data from the

CAN bus.

Status

The Status LED confirms the operating status of the DLA Module.

This light should blink regularly if the DLA Module initialized

successfully.

Input 1

The Input 1 LED will blink when the DLA Module receives pulses

from a connected feedback sensor.

Input 2

The Input 2 LED is reserved for future use.

Input 3

The Input 3 LED will be lit when the DLA Module receives a low

liquid warning from a low liquid sensor.

Out 1

The Out 1 LED will be lit when the DLA Module is running the main

direct valve via PWM.

Out 2

The Out 2 LED will be lit when the DLA Module is running the left

lane.

SSC6100 Operation Manual

Hardware

14

LED Label

Function

Out 3

The Out 3 LED will be lit when the DLA Module is running the center

lane.

Out 4

The Out 4 LED will be lit when the DLA Module is running the right

lane.

Out 5

The Out 5 LED is reserved for future use.

SSC6100 Operation Manual

Powering up the SSC6100

15

Powering up the SSC6100

Upon applying either remote or dashkey power to the SSC6100, the 1104695 LCD Display will

beep once and its status LED will illuminate orange or blink red. On the 1104694 Core Module,

the Power On and Power Status lights will be lit.

As the system boots, it will display the SSC6100 logo on-screen with a blue-on-gray progress bar

at the bottom. The progress bar will scroll from left to right as the system starts up. See Figure 8.

Figure 8: SSC6100 Boot Screen

After booting, the SSC6100 shall test the ESTOP wiring for faults. You will see the Testing

ESTOP… screen, shown in Figure 9.

Figure 9: Testing ESTOP… Window

After the ESTOP test, if no errors occurred, the system will return to normal operation. Joysticks

will be activated after the ESTOP test is complete.

If an ESTOP Miswired Error or a CAN Device ESTOP Miswired Error occurs, shut down the

vehicle and the spreader control, then follow the steps outlined in Troubleshooting and Error

Conditions on page 116.

When the SSC6100 has completed booting and testing ESTOP, it will display either the Spreader

Power Off Screen or the Operation Screen, depending on the status of the spreader power

switch. The status LED on the 1104695 LCD Display should be lit solid green.

If this system is configured to require a Driver ID, you may see this message on startup:

SSC6100 Operation Manual

Powering up the SSC6100

16

Figure 10: Driver ID Required Notice

Place the black Driver Key on the security port to login to the spreader control. Upon a

successful login a welcome message similar to the following message will be displayed. The

logged in Driver ID will replace the SAMPLE text.

Figure 11: Driver Logged In Notice

Press the Navigation Stick to acknowledge the login. The Driver ID will then be reported with all

event strings, if enabled, from the spreader control. If an unsuccessful attempt was made to

login to the spreader control an error message will appear on the screen. See Troubleshooting

and Error Conditions on page 116 for more information.

If this system is configured with an Adjustable Gate, you may see this message on startup:

Figure 12: Check Gate Setting Warning

Other manuals for SSC6100 CAN ULTRA

4

Table of contents

Other Force America Control System manuals