Force America SSC3100 Use and care manual

SSC3100 Operation

and

Calibration Manual

SSC3100 Operation & Calibration Manual

Welcome and Table of Contents

i

Welcome

Congratulations on your purchase of a FORCE America®, Inc. SSC3100 Spreader Control. This

manual will guide you through the process of using your new spreader control.

Table of Contents

Welcome ...........................................................................................................i

Table of Contents.............................................................................................i

Hardware..........................................................................................................1

Powering up the SSC3100..............................................................................2

Normal Operation Mode..................................................................................3

Applying Material.................................................................................................................. 4

Blast ....................................................................................................................................... 6

Unload..............................................................................................................7

Calibration........................................................................................................9

Description of Calibration Values................................................................10

Spreader Min Duty Cycle.................................................................................................... 10

Spreader Max Duty Cycle................................................................................................... 10

Spinner Min Duty Cycle...................................................................................................... 11

Spinner Max Duty Cycle..................................................................................................... 11

Liquid Min Duty Cycle ........................................................................................................ 11

Liquid Max Duty Cycle........................................................................................................ 12

Blast Time............................................................................................................................ 12

Speedometer Configuration .............................................................................................. 13

Liquid Mode......................................................................................................................... 13

Restore Defaults ................................................................................................................. 14

Firmware Version................................................................................................................ 14

Troubleshooting and Error Conditions .......................................................15

FORCE America Contact Information..........................................................18

SSC3100 Operation & Calibration Manual

Hardware

1

Hardware

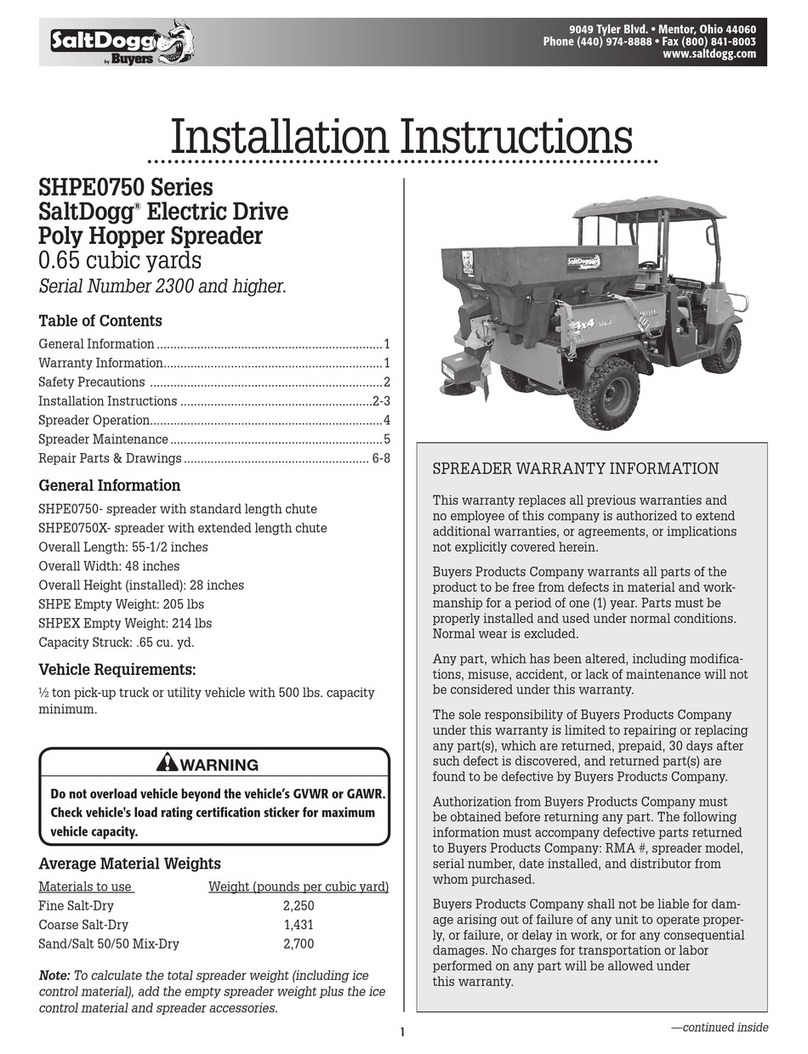

The SSC3100 is a self-contained spreader system. It has three rotary adjustment knobs with

pushbuttons.

Figure 1: The SSC3100

SSC3100 Operation & Calibration Manual

Power Up the SSC3100

2

Powering up the SSC3100

Upon applying 12V DC dashkey power to the SSC3100, the system will perform a panel test by

illuminating the LEDs around the dials as well as the ACTIVE and BLAST LEDs. During this test

the outputs will remain inactive. The system will also perform a test on the various system inputs.

If the system detects any errors on startup the ACTIVE LED and BLAST LED will alternately flash

RED to indicate that an error was detected. The error code will be displayed using the Spreader

and Spinner dial indicators. If no errors are detected on startup the system will enter normal

operation mode in standby.

SSC3100 Operation & Calibration Manual

Normal Operation

3

Normal Operation Mode

When the spreader control is in normal operation mode the output set rates are indicated by the

illuminated number next to the corresponding dial from zero to the active rate. The output rates

represent the percentage of output between the min and max calibration settings.

The numbers around the liquid dial will be illuminated when the liquid system is active. When the

liquid system is turned off all the numbers around the dial will be off. Pressing the liquid knob will

turn on and off the liquid application, if it is enabled. The liquid output operation will also follow

the standby state of the spreader control, if enabled.

SSC3100 Operation & Calibration Manual

Applying Material

4

Applying Material

When your SSC3100 system starts up, it will always be in standby with all outputs inactive. You

will need to remove your system from standby before it will apply material.

The spreader can apply granular material only (Dry Granular Application), apply a prewet liquid to

the granular material while spreading (Prewetted Granular Application) or apply liquid only (Direct

Liquid Application).

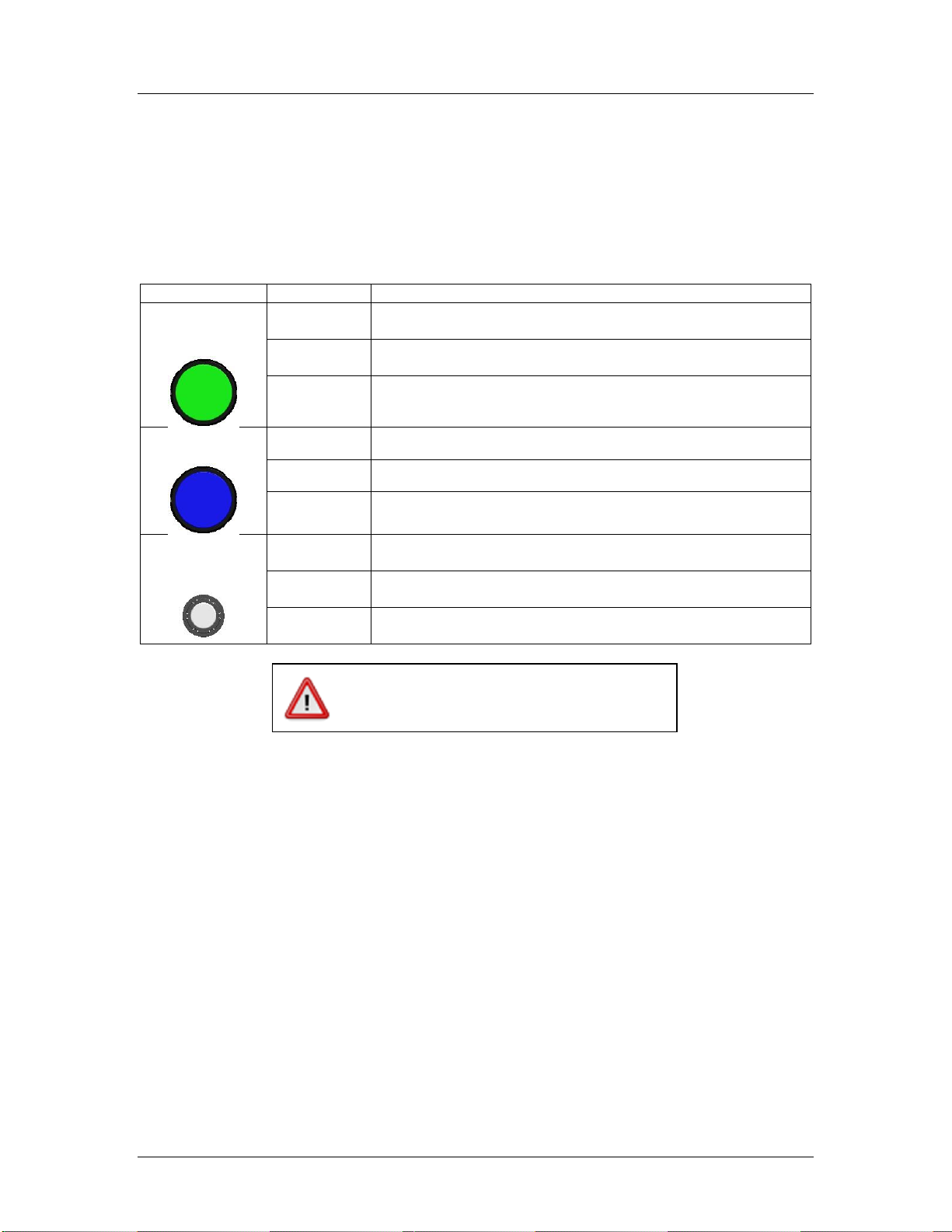

Each rotary adjustment knob on the Operator Interface performs a different function when

applying material. See the table below.

Input

Input

Function

Green

SPREADER

Knob

Twist Left

Decrease the granular set rate.

Twist Right

Increase the granular set rate.

Pushbutton

Place the system in standby.

Remove the system from standby.

Blue SPINNER

Knob

Twist Left

Decrease the spinner set rate.

Twist Right

Increase the spinner set rate.

Pushbutton

Blast the active material(s).

Cancel Blast.

Gray LIQUID

Knob

Twist Left

Decrease the liquid set rate, if enabled.

Twist Right

Increase the liquid set rate, if enabled.

Pushbutton

Turn on or off the liquid application, if enabled.

To spread granular material:

STEP 1: Twist the SPREADER knob to adjust your granular output percentage.

STEP 2: Twist the SPINNER knob to adjust your spinner set rate.

STEP 3: Press the SPREADER knob to remove the spreader control from standby.

Granular material will spread depending on the state of the ground speed

interrupt calibration setting and if the vehicle is detecting ground speed.

STEP 4: Press the SPREADER knob to place the spreader control back in standby and

stop the outputs.

To reduce the risk of death or injury, ensure

that all personnel are clear from moving

machinery before activating outputs.

SSC3100 Operation & Calibration Manual

Applying Material

5

To spread granular and prewet material:

STEP 1: Press the gray LIQUID knob to activate the prewet application. This will

illuminate the selected prewet application percentage next to the LIQUID dial.

STEP 2: Twist the SPREADER knob to adjust your granular output percentage.

STEP 3: Twist the SPINNER knob to adjust your spinner set rate.

STEP 4: Twist the LIQUID knob to adjust the prewet output percentage.

STEP 5: Press the SPREADER knob to remove the spreader control from standby.

Granular and prewet material will spread depending on the state of the ground

speed interrupt calibration setting and if the vehicle is detecting ground speed.

STEP 6: Press the SPREADER knob to place the spreader control back in standby and

stop the outputs.

To spread direct liquid material:

STEP 1: Turn the SPREADER and SPINNER dials to 0.

STEP 2: Press the gray LIQUID knob to activate the liquid application. This will illuminate

the selected liquid application percentage next to the LIQUID dial.

STEP 3: Twist the LIQUID knob to adjust the direct output percentage.

STEP 4: Press the SPREADER knob to remove the spreader control from standby. The

liquid material will spread depending on the state of the ground speed interrupt

calibration setting and if the vehicle is detecting ground speed.

STEP 5: Press the SPREADER knob to place the spreader control back in standby and

stop the outputs.

To reduce the risk of death or injury, ensure

that all personnel are clear from moving

machinery before activating outputs.

This application mode is only applicable when

the liquid mode is set to one of the three prewet

related modes in calibration.

This application mode is only applicable when

the liquid mode is set to one of the two direct

liquid related modes in calibration.

SSC6100 Operation Manual

Applying Material - Blast

6

Blast

Blast is a spreader feature that runs the applicable output at the maximum percentage for a set

amount of time. By default, Blast is set to spread for ten seconds.

When Blast is activated, the BLAST LED will illuminate RED.

To activate Blast:

STEP 1: Press the Blue SPINNER Knob on the Operator Interface. The system will blast

for its configured amount of time. The Blast feature works whether or not the

system is in standby or the vehicle is moving.

To deactivate Blast before it automatically shuts off:

STEP 1: While the system is Blasting, press the Blue SPINNER Knob on the Operator

Interface. The Blast feature will shut off and return to its previous operation

(spreading or standby).

To reduce the risk of death or injury, ensure

that all personnel are clear from moving

machinery before activating outputs.

When blast mode is activated, blast rates will

only be applied to outputs with application rates

currently not set to zero.

NOTE: Blast mode does not affect the spinner

output.

SSC3100 Operation & Calibration Manual

Unload

7

Unload

The Unload mode allows you to unload materials from the vehicle. This mode is only necessary if

the system is setup to have the ground speed interrupt enabled. The mode is cancelled by

placing the system into standby.

Each rotary adjustment knob on the Operator Interface performs a different function when

unloading material. See the table below.

Input

Action

Function

Green

SPREADER

Knob

Twist Left

Decrease the granular output percentage.

Twist Right

Increase the granular output percentage.

Pushbutton

Stop unloading material.

Blue SPINNER

Knob

Twist Left

Decrease the spinner output percentage. (If available)

Twist Right

Increase the spinner output percentage. (If available)

Pushbutton

None

Gray LIQUID

Knob

Twist Left

Decrease the liquid output percentage.

Twist Right

Increase the liquid output percentage

Pushbutton

Turn on or off the liquid output.

When unload mode is active the ACTIVE LED and BLAST LED will illuminate red. The output

rates for the granular, spinner or liquid will be reflected by the illuminated numbers around the

corresponding dials.

To unload granular material:

STEP 1: Ensure that the system is in standby and the vehicle is not moving.

STEP 2: Turn off the liquid output if it is active by pressing the liquid button.

STEP 3: Press and hold the blue SPINNER knob.

STEP 4: Press the green SPREADER knob, the ACTIVE LED and the BLAST LED will

change to red, you can then release the blue SPINNER knob and the green

SPREADER knob.

STEP 5: Use the green SPREADER knob to adjust the granular output percentage, it will

start out at the maximum rate.

STEP 6: Use the blue SPINNER knob to adjust the spinner output percentage.

STEP 7: Press the green SPREADER knob to finish unloading granular material.

To reduce the risk of death or injury, ensure

that all personnel are clear from moving

machinery before activating outputs.

SSC3100 Operation & Calibration Manual

Unload

8

To unload liquid material:

STEP 1: Ensure that the system is in standby and the vehicle is not moving.

STEP 2: Turn the SPREADER and SPINNER dials to 0.

STEP 3: Turn on the liquid output if it is not already on.

STEP 4: Press and hold the blue SPINNER knob.

STEP 5: Press the green SPREADER knob, the ACTIVE LED and the BLAST LED will

change to red, you can then release the blue SPINNER knob and the green

SPREADER knob.

STEP 6: Use the gray LIQUID knob to adjust the liquid output percentage, it will start out

at the maximum rate.

STEP 7: Press the green SPREADER knob to stop unloading liquid material.

SSC3100 Operation & Calibration Manual

Calibration

9

Calibration

The Calibration feature is used to setup your FORCE America SS3100 for your system and

application requirements. When the calibration feature is active the blast indicator on the front of

the unit will be illuminated green.

To activate the Calibration Feature:

1. Set the SPREADER and SPINNER set rates to 0.

2. While the system is in Standby, press and hold the liquid button for three seconds.

3. Once the system activates the calibration feature indicated by the blast indicator on the

front panel turning green, release the liquid button.

To exit the Calibration Feature:

1. Press and hold the liquid button for three seconds.

When the calibration feature is active, the buttons have the following functions:

Input

Input

Function

Green

SPREADER

Knob

Twist Left

Adjust the value for the active calibration setting.

Twist Right

Adjust the value for the active calibration setting.

Pushbutton

Place the system in standby.

Remove the system from standby.

Blue

SPINNER

Knob

Twist Left

Decreases the value for the active calibration setting when

setting the min or max duty cycle.

Twist Right

Increases the value for the active calibration setting when setting

the min or max duty cycle.

Pushbutton

None.

Gray

LIQUID

Knob

Twist Left

Select the previous calibration setting for adjustment.

Twist Right

Select the next calibration setting for adjustment

Pushbutton

Exits the calibration menu when held for 3 seconds when the

system is in standby.

The particular calibration setting being modified along with its current value will be indicated through

the various illuminated LEDs on the panel which is explained in the following section, Description

of Calibration Values.

SSC3100 Operation & Calibration Manual

Description of Calibration Values

10

Description of Calibration Values

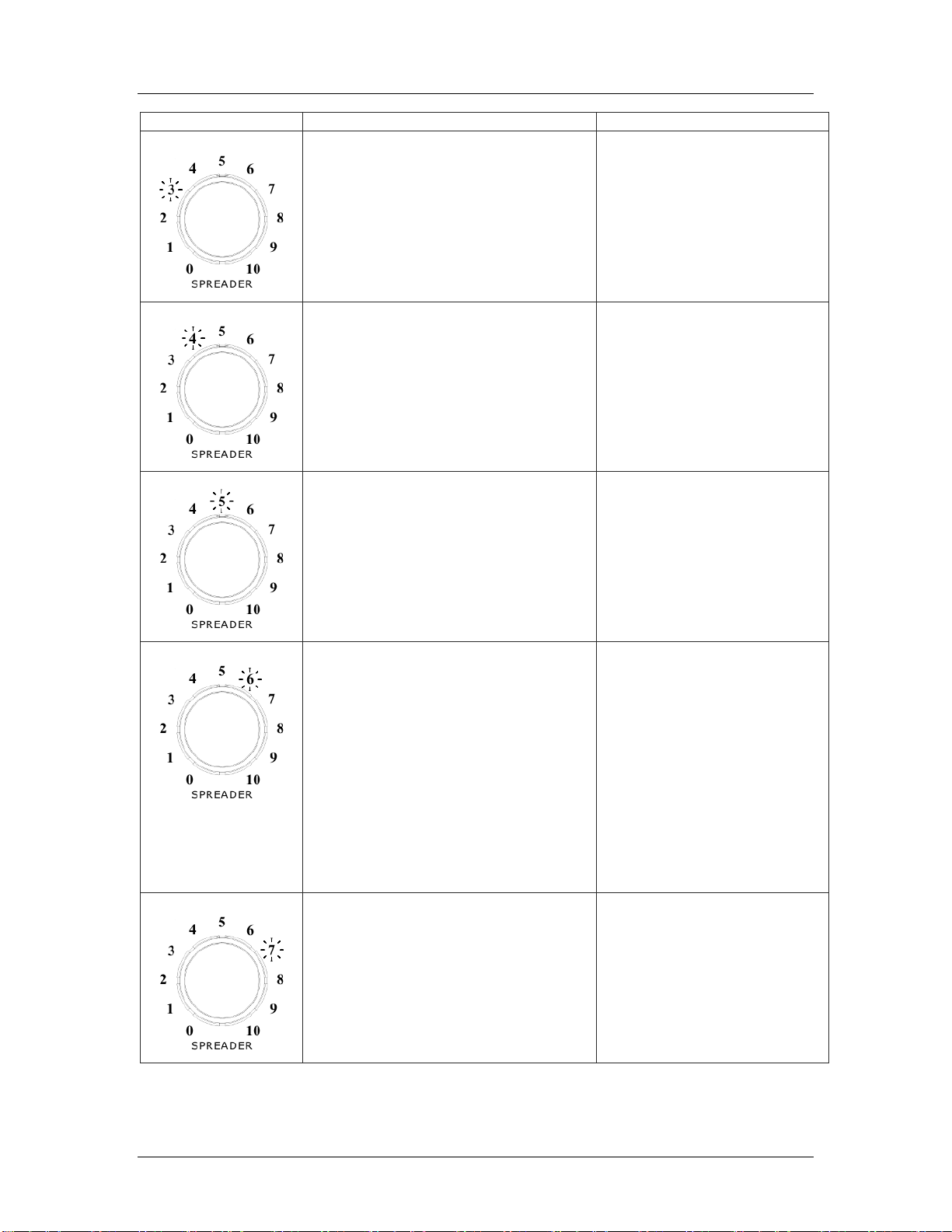

The numbers located around the liquid dial will be used to indicate which calibration setting is active

and the numbers located around the spreader and spinner dials will indicate the selected value for

that setting. Rotating the liquid dial will adjust which calibration setting is currently being displayed

and changed. Rotating the spreader dial will adjust the setting for the selected calibration item.

The calibration settings will follow the order listed below. The initial value upon entering calibration

will be the spreader min output.

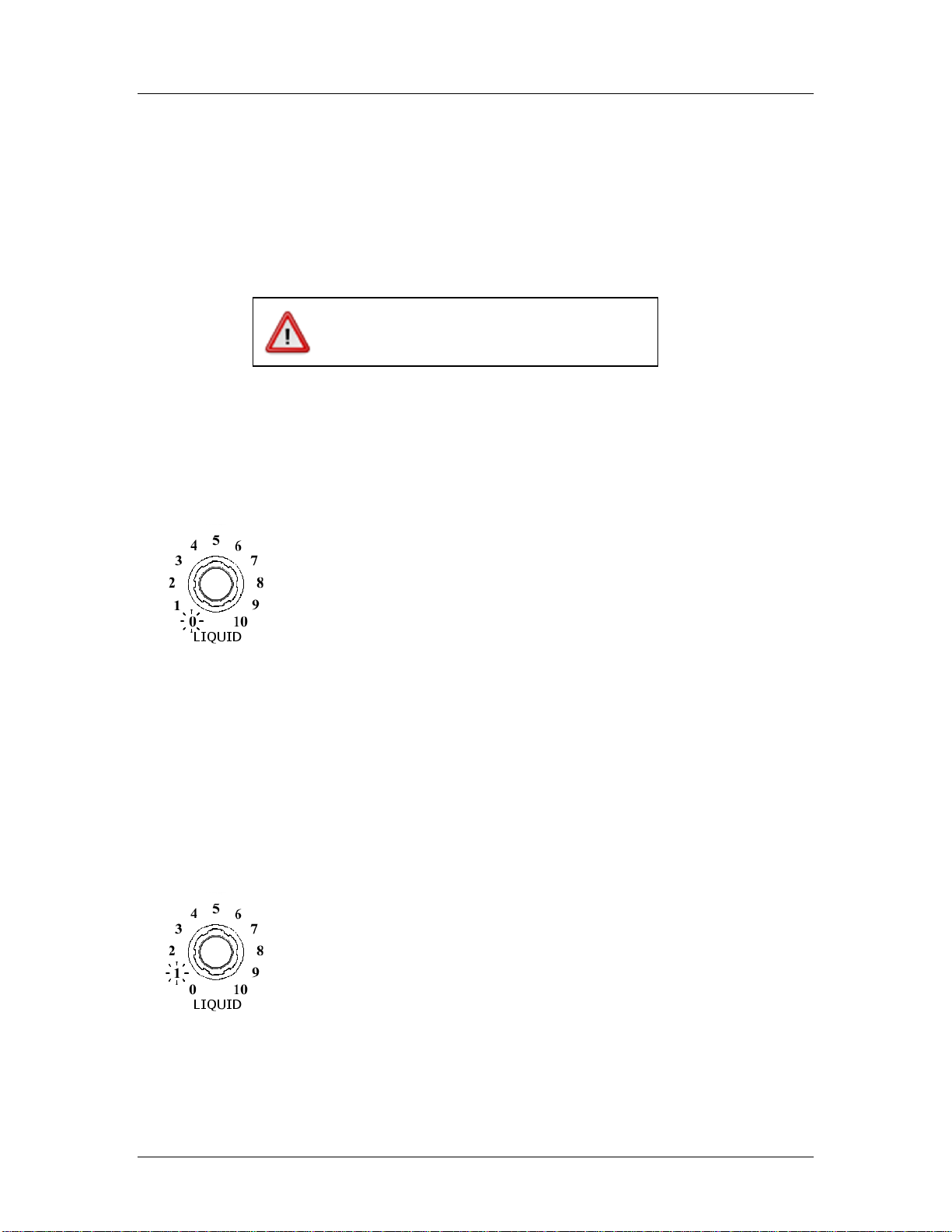

Spreader Min Output

The Spreader Min Output item sets the duty cycle required to turn the auger

at its slowest rate. The setting is indicated by having the LIQUID dial

illuminated at 0. The value is indicated by illuminating the numbers around

the SPREADER and SPINNER dials. The highest number illuminated

around the SPREADER dial indicates the tens position for the duty cycle

and the highest number illuminated around the SPINNER dial indicates the

ones position. The default value is 20% and is represented by having the

0, 1, and 2 numbers illuminated around the SPREADER dial and the 0

number illuminated around the SPINNER dial.

Use the green SPREADER knob to activate/deactivate the output to test

the auger speed when adjusting the Min Output value. The ACTIVE LED

will illuminate green when the spreader control is out of standby and

running the output. Rotating the SPREADER knob will increase/decrease

the duty cycle by 10% and using the SPINNER knob will increase/decrease

the duty cycle by 1%.

Spreader Max Output

The Spreader Max Output item sets the duty cycle required to turn the

auger at its fastest rate. The setting is indicated by having the LIQUID dial

illuminated at 1. The value is indicated by illuminating the numbers around

the SPREADER and SPINNER dials. The highest number illuminated

around the SPREADER dial indicates the tens position for the duty cycle

and the highest number illuminated around the SPINNER dial indicates the

ones position. The default value is 75% and is represented by having the

numbers 0 thru 7 illuminated around the SPREADER dial and the numbers

0 thru 5 illuminated around the SPINNER dial.

Use the green SPREADER knob to activate/deactivate the output to test

the auger speed when adjusting the Max Output value. The ACTIVE LED

will illuminate green when the spreader control is out of standby and

running the output. Rotating the SPREADER knob will increase/decrease

the duty cycle by 10% and using the SPINNER knob will increase/decrease

the duty cycle by 1%.

To reduce the risk of death or injury, ensure

that all personnel are clear from moving

machinery before activating outputs.

SSC3100 Operation & Calibration Manual

Description of Calibration Values

11

Spinner Min Output

The Spinner Min Output item sets the duty cycle required to turn the spinner

at its slowest rate. The setting is indicated by having the LIQUID dial

illuminated at 2. The value is indicated illuminating the numbers around

the SPREADER and SPINNER dials. The highest number illuminated

around the SPREADER dial indicates the tens position for the duty cycle

and the highest number illuminated around the SPINNER dial indicates the

ones position. The default value is 20% and is represented by having the

0, 1, and 2 numbers illuminated around the SPREADER dial and the 0

number illuminated around the SPINNER dial.

Use the green SPREADER knob to activate/deactivate the output to test

the spinner speed when adjusting the Min Output value. The ACTIVE LED

will illuminate green when the spreader control is out of standby and

running the output. Rotating the SPREADER knob will increase/decrease

the duty cycle by 10% and using the SPINNER knob will increase/decrease

the duty cycle by 1%.

Spinner Max Output

The Spinner Max Output item sets the duty cycle required to turn the

spinner at its fastest rate. The setting is indicated by having the LIQUID dial

illuminated at 3. The value is indicated by illuminating the numbers around

the SPREADER and SPINNER dials. The highest number illuminated

around the SPREADER dial indicates the tens position for the duty cycle

and the highest number illuminated around the SPINNER dial indicates the

ones position. The default value is 75% and is represented by having the

numbers 0 thru 7 illuminated around the SPREADER dial and the numbers

0 thru 5 illuminated around the SPINNER dial.

Use the green SPREADER knob to activate/deactivate the output to test

the spinner speed when adjusting the Max Output value. The ACTIVE LED

will illuminate green when the spreader control is out of standby and

running the output. Rotating the SPREADER knob will increase/decrease

the duty cycle by 10% and using the SPINNER knob will increase/decrease

the duty cycle by 1%.

Liquid Min Output

The Liquid Min Output item sets the duty cycle required to turn the liquid

pump at its slowest rate. The setting is indicated by having the LIQUID dial

illuminated at 4. The value is indicated illuminating the numbers around

the SPREADER and SPINNER dials. The highest number illuminated

around the SPREADER dial indicates the tens position for the duty cycle

and the highest number illuminated around the SPINNER dial indicates the

ones position. The default value is 20% and is represented by having the

0, 1, and 2 numbers illuminated around the SPREADER dial and the 0

number illuminated around the SPINNER dial.

SSC3100 Operation & Calibration Manual

Description of Calibration Values

12

Use the green SPREADER knob to activate/deactivate the output to test

the liquid pump speed when adjusting the Min Output value. The ACTIVE

LED will illuminate green when the spreader control is out of standby and

running the output. Rotating the SPREADER knob will increase/decrease

the duty cycle by 10% and using the SPINNER knob will increase/decrease

the duty cycle by 1%.

Liquid Max Duty Cycle

The Liquid Max Output item sets the duty cycle required to turn the liquid

pump at its fastest rate. The setting is indicated by having the LIQUID dial

illuminated at 5. The value is indicated by illuminating the numbers around

the SPREADER and SPINNER dials. The highest number illuminated

around the SPREADER dial indicates the tens position for the duty cycle

and the highest number illuminated around the SPINNER dial indicates the

ones position. The default value is 75% and is represented by having the

numbers 0 thru 7 illuminated around the SPREADER dial and the numbers

0 thru 5 illuminated around the SPINNER dial.

Use the green SPREADER knob to activate/deactivate the output to test

the liquid pump speed when adjusting the Max Output value. The ACTIVE

LED will illuminate green when the spreader control is out of standby and

running the output. Rotating the SPREADER knob will increase/decrease

the duty cycle by 10% and using the SPINNER knob will increase/decrease

the duty cycle by 1%.

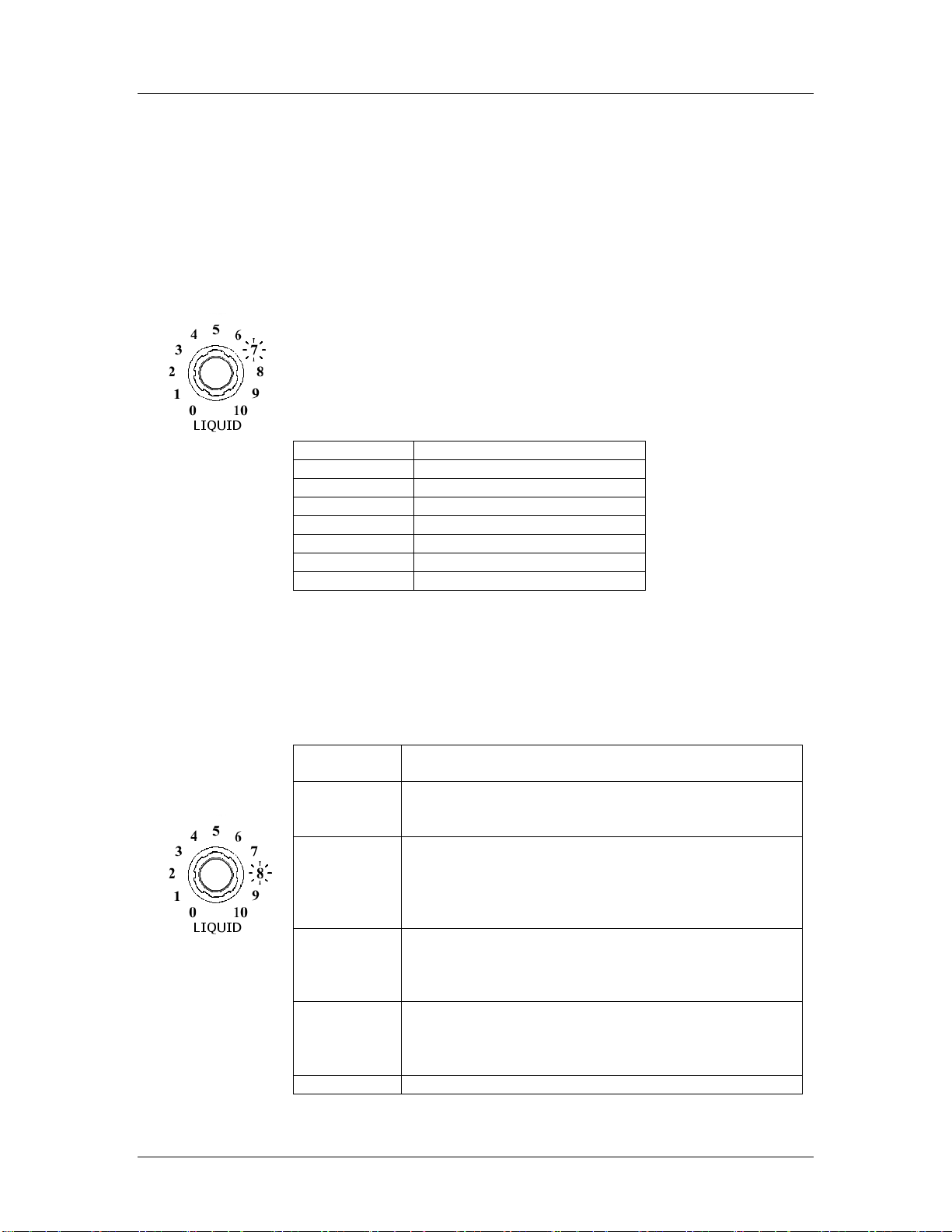

Blast Time

The Blast Time item sets the amount of time in seconds that the blast mode

will run once the blue Blast Knob has been pressed and released. The

setting is indicated by having the liquid dial illuminated at 6. The value is

indicated by the numbers around the spreader dial and the table below.

The default value is 10 seconds.

Spreader

Dial

Time Setting

0

Momentary

1

1 Second

2

2 Seconds

3

3 Seconds

4

4 Seconds

5

5 Seconds

6

6 Seconds

7

7 Seconds

8

8 Seconds

9

9 Seconds

10

10 Seconds

SSC3100 Operation & Calibration Manual

Description of Calibration Values

13

Speedometer Configuration

The speedometer configuration item is used to enable the ground speed

interrupt. When the ground speed interrupt is enabled, the system will stop

spreading material when the vehicle is not moving. If ground speed

interrupt is to be enabled the proper speedometer signal type and input

pulse range needs to be selected. The system supports an electronic or

mechanical signal with a low pulse rate or high pulse rate. If the vehicles

pulses per mile is higher than 20,000 (pulses per kilometer is higher than

12,500) select the high pulse rate otherwise select the low pulse rate. The

setting is indicated by having the liquid dial illuminated at 7. The value is

indicated by the numbers around the spreader dial and the table below.

The default value is Disabled.

*When this calibration item is active, spreader dial position 10 will illuminate

in addition to the setting value when the system is detecting a speedometer

signal.

Spreader Dial

State

0

Disabled

1

Electronic –Low Pulse Rate

2

Electronic –High Pulse Rate

3

Mechanical –Low Pulse Rate

4

Mechanical –High Pulse Rate

*10

Signal Present

Liquid Mode

The liquid mode item determines how the liquid output on the controller will

operate. The setting is indicated by having the liquid dial illuminated at 8.

The value is indicated by the number around the spreader dial and the table

below. The default value is Disabled.

Spreader

Dial

Description

0

Disabled

The liquid output will not run regardless of the

system state

1

Gravity Prewet

The liquid output will function as an on/off output

used to operate a ball valve. The output will

only be active when the granular output is

active.

2

Prewet (No Liquid Blast)

The liquid output will only operate when the

granular output is active and the output rate will

not change when the blast feature is active.

3

Prewet (Liquid Output Blasts)

The liquid output will only operate when the

granular output is active and the output rate will

increase to the max setting when blast is active.

4

Direct (No Liquid Blast)

SSC3100 Operation & Calibration Manual

Description of Calibration Values

14

The liquid output will run independent of the

granular output allowing the liquid to be active

when the granular rate is 0. In this mode the

liquid output will not change when the blast

feature is active.

5

Direct (Liquid Output Blasts)

The liquid output will run independent of the

granular output allowing the liquid to be active

when the granular rate is 0. In this mode the

liquid output will increase to the max setting

when blast is active.

Aux Output Configuration

The Aux Output Configuration will determine the operation of the output

associated with the loose wire labeled AUX in the harness. The setting is

indicated by having the liquid dial illuminated at 9. The value is indicated

by the numbers around the spreader dial and the table below. The default

value is None.

Spreader

Dial

Description

0

None/Off

The aux output does nothing and will be off.

1

Auger On

The aux output will be on when the auger is

running.

2

Liquid On

The aux output will be on when the liquid output

is active.

Restore Defaults

The Restore Defaults item allows for the resetting of all calibration settings

to factory default settings. The setting is indicated by having the 0 and 10

illuminated around the liquid dial.

To restore the calibration settings, press and release the spreader dial then

press and release the spinner dial.

Firmware Version

The firmware version item allows for the determination of the systems

firmware (software) version. The setting is indicated by having the 1 and

10 illuminated around the liquid dial.

The number indicated by the spreader dial indicates the major number and

the number indicated by the spinner dial indicates the minor number.

(Version = Major Number.Minor Number)

SSC3100 Operation & Calibration Manual

Troubleshooting and Error Conditions

15

Troubleshooting and Error Conditions

When the system encounters an error condition the ACTIVE LED and BLAST LED will alternately

flash RED to indicate that an error was detected. The information related to the error will be

indicated using the numbers around the SPREADER dial by illuminating the number of the error.

The following table can be used to determine the active error, what conditions caused it to occur

and any recommended actions that can be taken to resolve the error.

Pressing the liquid dial will acknowledge the error condition and either advance the indicator to

the next error condition or if no more errors are active place the system into normal operation

mode. Stuck input errors and the valve power error cannot be acknowledged and will remain

active until resolved.

System Status

Condition

Recommended Action

Unstable Voltage Detected

The system is detecting an unstable

voltage input on the constant power

wire during startup.

Verify that the voltage input for

the constant power connection

is stable and above 8 volts.

Stuck Spreader Knob

The green SPREADER knob was

pressed during startup.

Verify that the green

SPREADER knob is not

pressed. This error condition

cannot be acknowledged and

will remain active until cleared.

Stuck Spinner Knob

The blue SPINNER knob was pressed

during startup.

Verify that the blue SPINNER

knob is not pressed. This error

condition cannot be

acknowledged and will remain

active until cleared.

Stuck Liquid Knob

The gray LIQUID knob was pressed

during startup.

Verify that the gray LIQUID

knob is not pressed. This error

condition cannot be

acknowledged and will remain

active until cleared.

SSC3100 Operation & Calibration Manual

Troubleshooting and Error Conditions

16

System Status

Condition

Recommended Action

Fused Power Missing

The system is not detecting power on

the fused circuit which is used to run the

valve outputs.

Verify that the fuse is not

blown, if it is blown replace

with a 10 Amp

Stuck Remote Standby

The remote standby input was active

during startup.

Verify that the remote standby

input is not grounded.

Stuck Remote Blast

The remote blast input was active

during startup.

Verify that the remote blast

input is not grounded.

Improper Shutdown

The system detected an improper

shutdown caused by losing constant

power before the system completed its

shutdown process.

Verify that the dashkey wire is

properly connected to a

dashkey signal.

Verify that the constant power

wire is properly connected to a

voltage source that receives

constant power.

Verify that the voltage input for

the constant power connection

is stable and above 8 volts.

Corrupt calibration settings

The system detected an issue with the

stored calibration data. The calibration

data has been reset to the factory

defaults.

When calibrating the system

make sure to exit the

calibration menu before turning

off the spreader control.

Table of contents