1

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

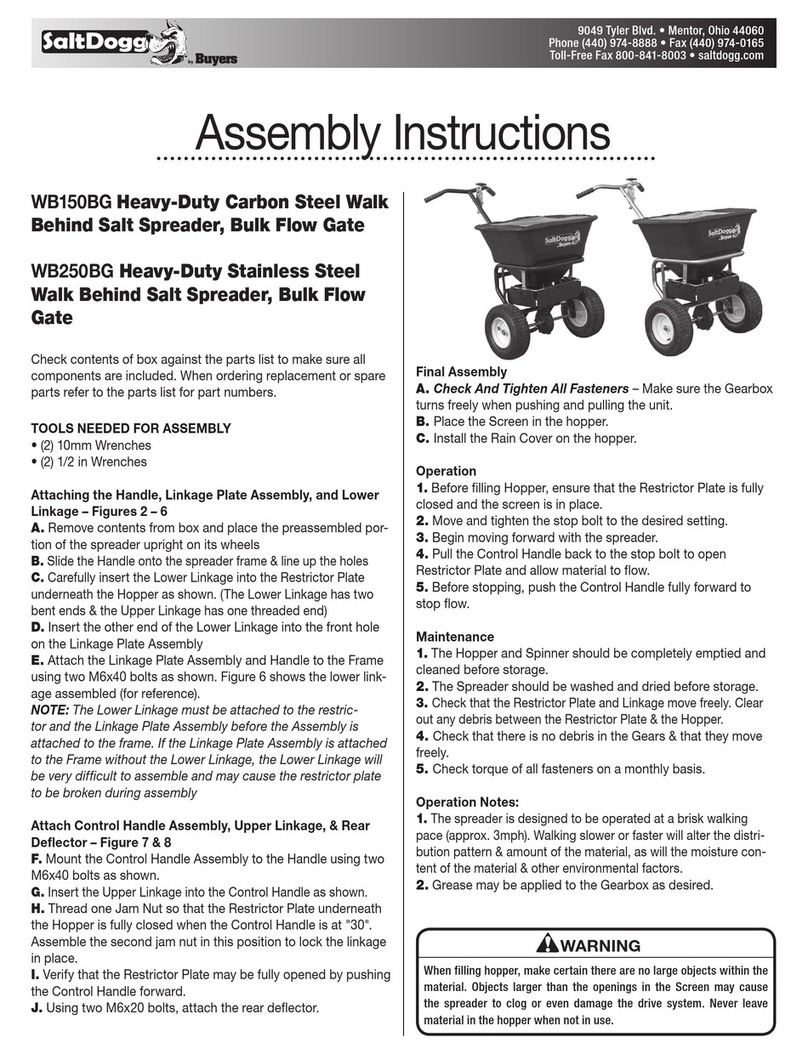

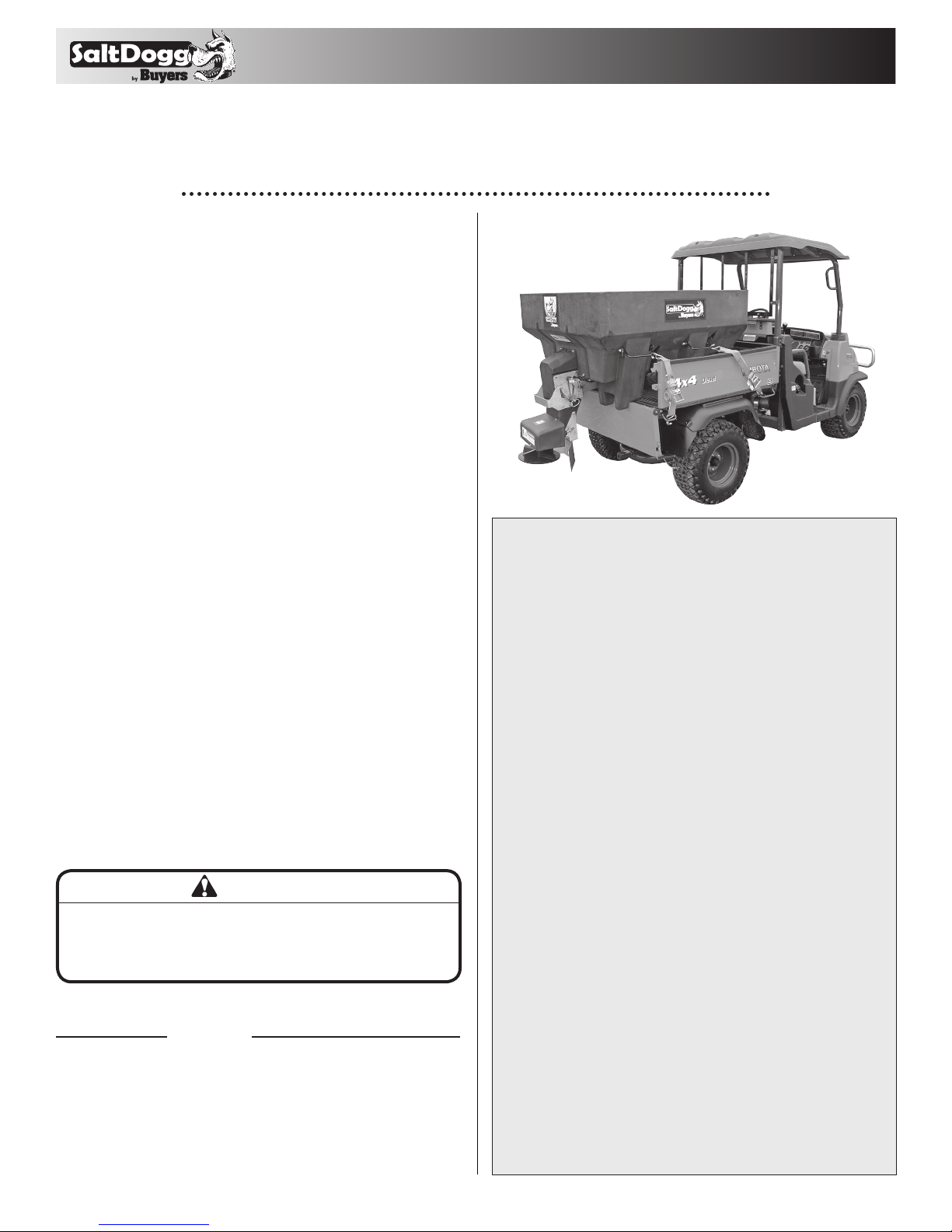

SHPE0750 Series

SaltDogg®Electric Drive

Poly Hopper Spreader

0.65 cubic yards

Serial Number 2300 and higher.

WARNING

Do not overload vehicle beyond the vehicle’s GVWR or GAWR.

Check vehicle's load rating certification sticker for maximum

vehicle capacity.

—continued inside

SPREADER WARRANTY INFORMATION

This warranty replaces all previous warranties and

no employee of this company is authorized to extend

additional warranties, or agreements, or implications

not explicitly covered herein.

Buyers Products Company warrants all parts of the

product to be free from defects in material and work-

manship for a period of one (1) year. Parts must be

properly installed and used under normal conditions.

Normal wear is excluded.

Any part, which has been altered, including modifica-

tions, misuse, accident, or lack of maintenance will not

be considered under this warranty.

The sole responsibility of Buyers Products Company

under this warranty is limited to repairing or replacing

any part(s), which are returned, prepaid, 30 days after

such defect is discovered, and returned part(s) are

found to be defective by Buyers Products Company.

Authorization from Buyers Products Company must

be obtained before returning any part. The following

information must accompany defective parts returned

to Buyers Products Company: RMA #, spreader model,

serial number, date installed, and distributor from

whom purchased.

Buyers Products Company shall not be liable for dam-

age arising out of failure of any unit to operate proper-

ly, or failure, or delay in work, or for any consequential

damages. No charges for transportation or labor

performed on any part will be allowed under

this warranty.

Table of Contents

General Information ...................................................................1

Warranty Information.................................................................1

Safety Precautions .....................................................................2

Installation Instructions .........................................................2-3

Spreader Operation.....................................................................4

Spreader Maintenance ...............................................................5

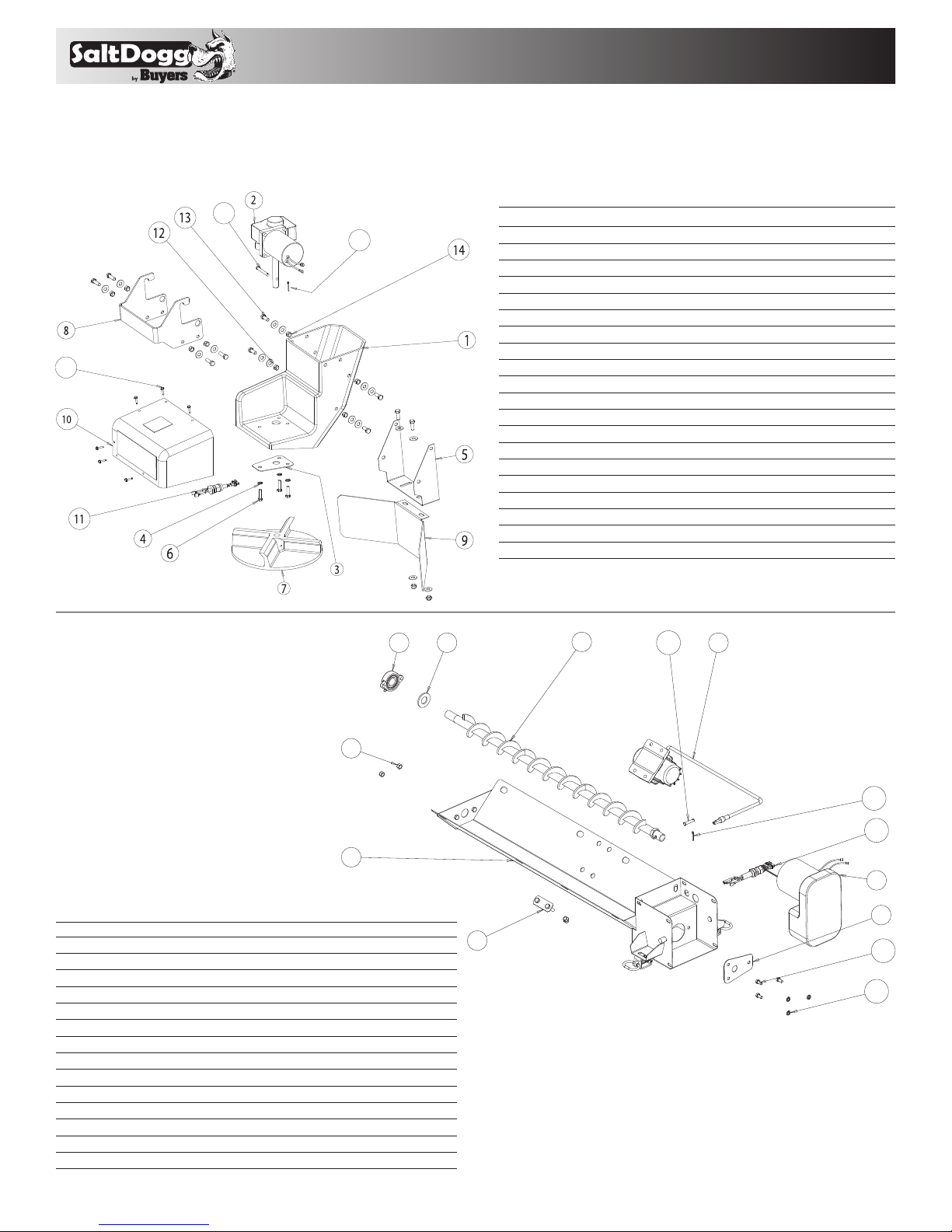

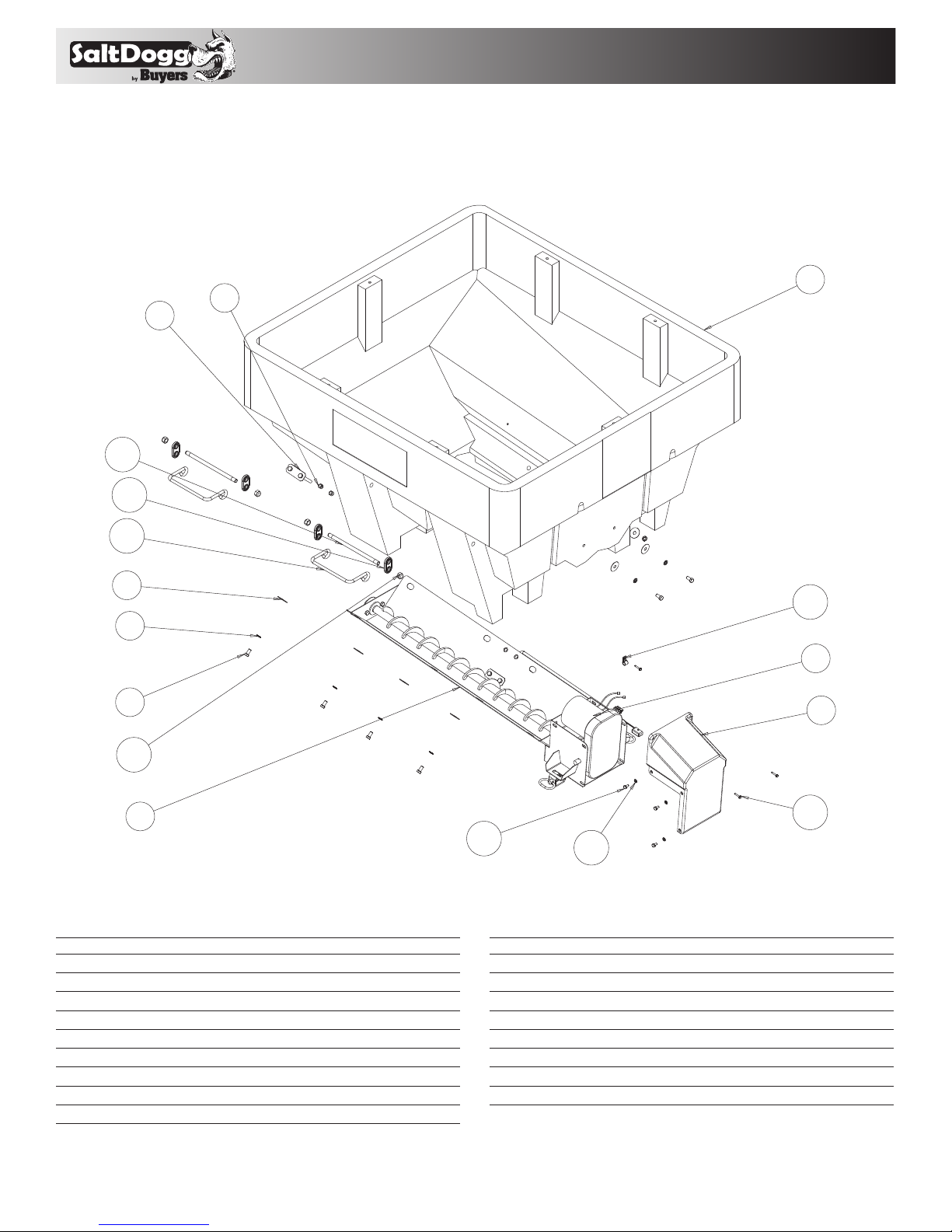

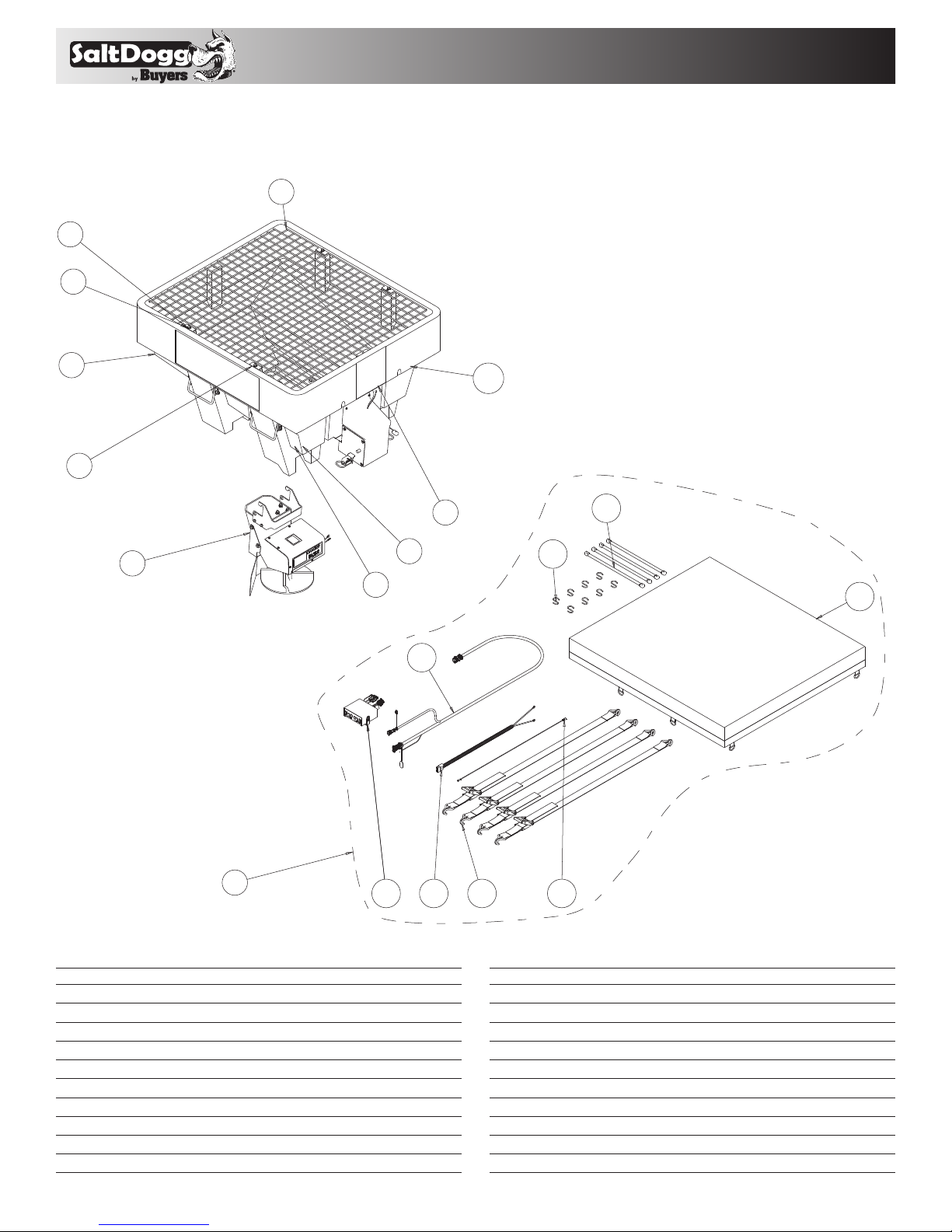

Repair Parts & Drawings ....................................................... 6-8

General Information

SHPE0750- spreader with standard length chute

SHPE0750X- spreader with extended length chute

Overall Length: 55-1/2 inches

Overall Width: 48 inches

Overall Height (installed): 28 inches

SHPE Empty Weight: 205 lbs

SHPEX Empty Weight: 214 lbs

Capacity Struck: .65 cu. yd.

Vehicle Requirements:

½ ton pick-up truck or utility vehicle with 500 lbs. capacity

minimum.

Average Material Weights

Materials to use Weight (pounds per cubic yard)

Fine Salt-Dry 2,250

Coarse Salt-Dry 1,431

Sand/Salt 50/50 Mix-Dry 2,700

Note: To calculate the total spreader weight (including ice

control material), add the empty spreader weight plus the ice

control material and spreader accessories.

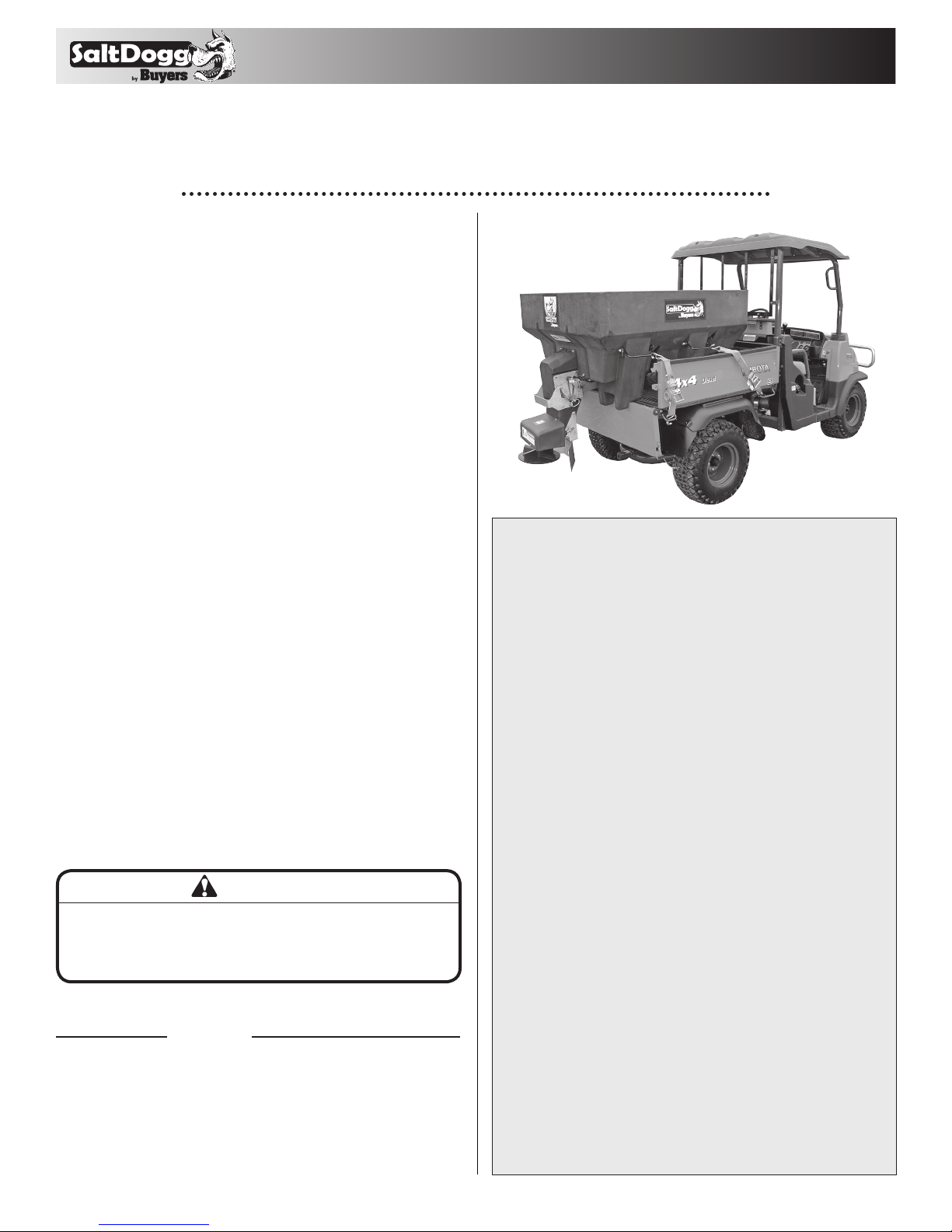

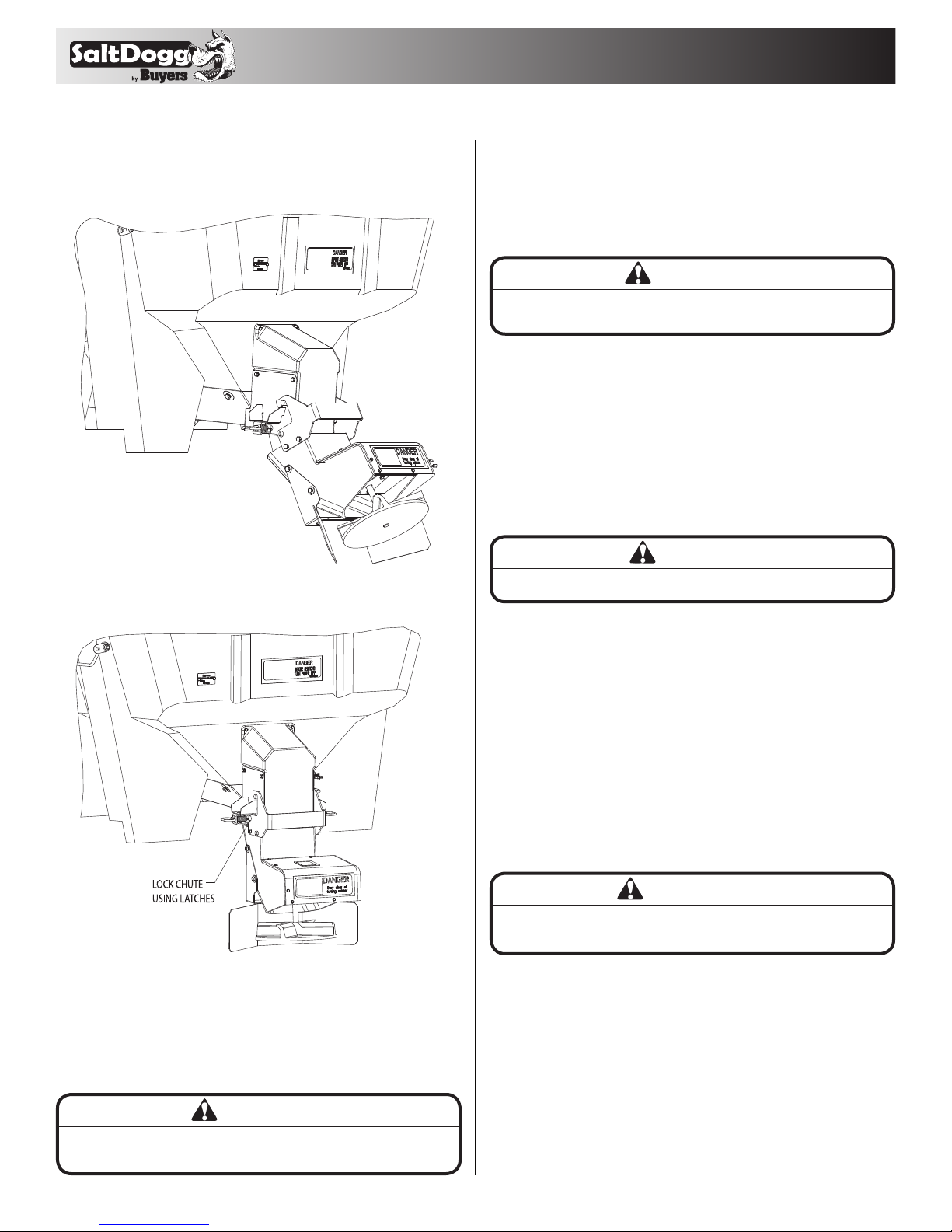

Installation Instructions