Force Flow SOLO 1000 Guide

INSTALLATION&OPERATION

electroniccylinderscale

1-or2-channelindicator

factorycalibrated

s/n__________________

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723Fax:925-686-6713

www.forceflow.com/Info@forceflow.com

Version:PRO96LCD

REF:T4\O&M\CYLSOLO\CVRCYLSO.tcw(O00a.pdf)

SOLO1000

FORCEFLOW

SOLO 1000

CHLOR-SCALE150

AMMONIA-SCALE

CYLINDER-SCALE

SOLO1000

7

INDICATOR:

ALLCYLINDERS

SCALE:

NET#1=175

NET#2=225

SOLO1000

NET=175

1-CHANNEL2-CHANNEL

7

J

J

INCLUDESMODELS:

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

WWW.FORCEFLOW.COM/INFO@FORCEFLOW.COM

REF:T4\O&M\CYLSOLO\MODELNO.tcw(OOAa.pdf)

ELECTRONICfor

ALLCYLINDERS

SINGLEORDUALCYLINDER

withSOLO1000DIGITAL

1-AND2-CHANNELINDICATOR

FORCAPACITIES:

CHLOR-SCAL1150

150lbCYLINDERSforCHLORINE&SULFURDIOXIDE

400lbAMMONIACYLINDERS

&200lbLIQUEFIEDGASCYLINDERS

SingleCylinder

withSolo1000(SingleChannelIndicator)

DualCylinder

withSolo1000-2(DualChannelIndicator)

SR150

SR150-2

(Metric:SR68K68kg)

(Metric:SR68K-268kg)

AMMONIA-SCALESingleCylinder

withSolo1000(SingleChannelIndicator)

DualCylinder

withSolo1000-2(DualChannelIndicator)

SR400-AS

SR400-2AS

(Metric:SR200K-AS200kg)

(Metric:SR200K-2AS200kg)

CYLINDER-SCALESingleCylinder

withSolo1000(SingleChannelIndicator)

DualCylinder

withSolo1000-2(DualChannelIndicator)

SR200

SR200-2

(Metric:SR100K100kg)

(Metric:SR100K-2100kg)

FORCEFLOW

FORCEFLOW

HELPHOTLINE

1-800-893-6723

www.forceflow.com

info@forceflow.com

NOTES:

S.1.000

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

REF:T4\O&M\INDEX\Y44.tcwetc(Y44.pdfetc)

SECTION

INSTALLATIONDRAWINGS

S.1.101-1.1

S.1.101-1.2

S.1.101-2.1

S.1.101-2.2

S.1.101-3.1

S.1.101-3.2

S.2.000SCALEOPERATION:

S.2.101ScaleOperation(Use"Portable"Applications)

S.3.000

SOLO1000IndicatorwithALLCYLINDERSCALES

INDEX

INSTALLATIONCHECKLISTS

S.1.301

S.1.305

1-CHANNEL:IndicatorWiring&PlumbingDrawing

2-CHANNEL:IndicatorWiringetc.

1-CHANNEL:Instructions:Power;LoadCell&TareAdjust;4-20mA

2-CHANNEL:Instructions:Poweretc.

1-CHANNEL:Instructions:SetPoint;Surge&StaticProtection

2-CHANNEL:Instructions:SetPointetc.

INDICATORINSTALLATION

S.1.201-1

S.1.201-2

S.1.202-1

S.1.202-2

S.1.203-1

S.1.203-2

InstallationCheckList

Start-UpCheckList

OPTIONALALARMSETPOINT:

S.2.301-1

S.2.301-2

1-CHANNELAlarmSetPointConfiguration

2-CHANNELAlarmSetPointConfiguration

MISCELLANEOUS:

S.3.105

S.3.401

Calibration(SlottedPlatformsONLY)

PartsList

YOU

ARE

HERE!

InstallationnDrawing

InstallationIntroduction

InstallationSteps1thru2

InstallationSteps3thru6a

InstallationSteps6bthru6f

InstallationSteps6gthru7

INSTALLATIONINSTRUCTIONS

S.1.102

S.1.103

S.1.104

S.1.105

S.1.106

S.1.107

Single200#(100kg)Cyl.Scale,SingleChannelDrawing

Dual200#(100kg)Cyl.Scale,DualChannelDrawing

Single400#(200kg)Cyl.Scale,SingleChannelDrawing

Dual400#(200kg)Cyl.Scale,DualChannelDrawing

Single150#(68kg)Cyl.Scale,SingleChannelDrawing

Dual150#(68kg)Cyl.Scale,DualChannelDrawing

FORCEFLOW

NET=150

CylinderBackstop

PlatformMountedLevel

15/8"(41mm)

SOLO1000

1-Channel

Indicator

39"to40"

(990mm-1016mm)

10"

(254mm)

Platform

SafetyChain

WallMounted

Chaining

Bracket

SpringLoaded

SnapHook

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

Drawnby:SLP

Date:01/02/94

Revised:04/09/01

Scale:NONE

DrawingNumber

File:T4\O&M\CYLSOLO\150SOLO1.tcw(O01-1a.pdf)(WEB:150#SOL1.pdf)

30333

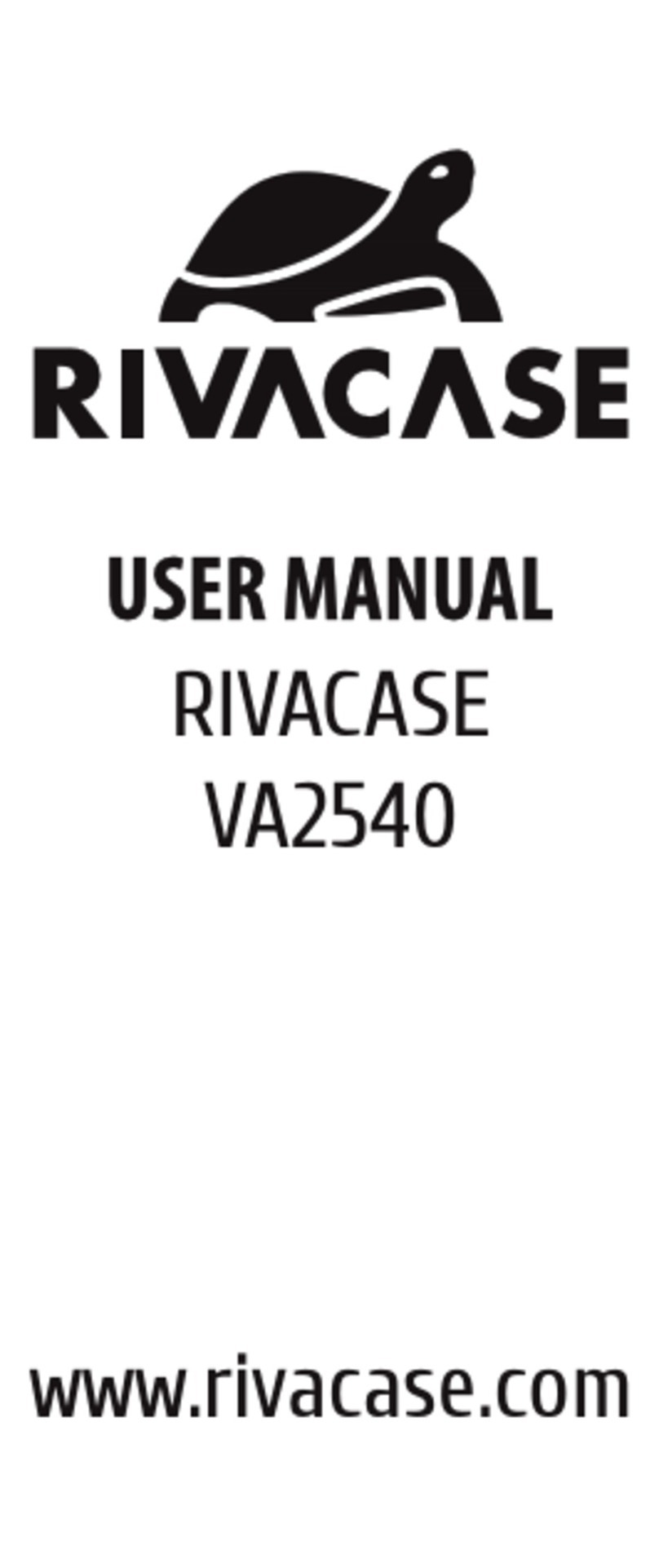

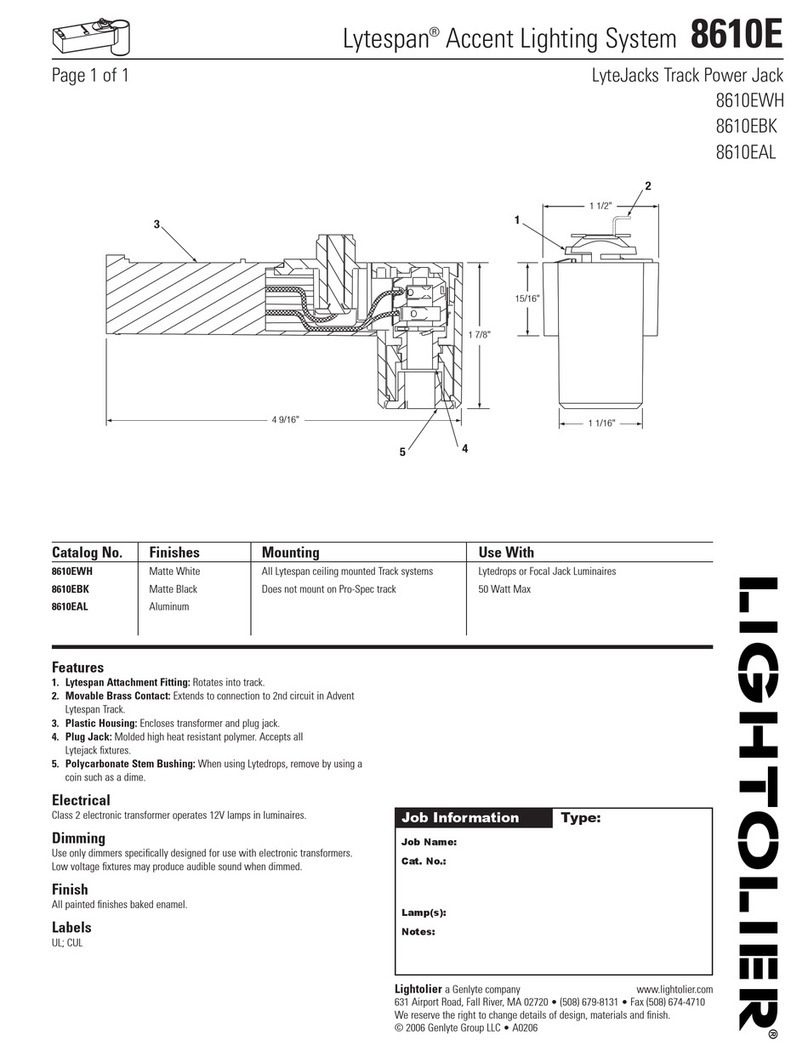

ELECTRONICCHLOR-SCALE150

WITHSOLO1000INDICATOR

FOR150#CYLINDERS

4-20mA

Output

131/2"

(343mm)

161/2"

(419mm)

181/2"

(470mm)

SOLO1000

S.1.101-1.1

SINGLECYLINDERSCALEwith

1-CHANNELINDICATOR

FORCEFLOW

FORCEFLOW

150LB.(68KG)CYLINDERS

NET=150

CylinderBackstop

PlatformMountedLevel

15/8"(41mm)

SOLO1000

1-Channel

Indicator

39"to40"

(990mm-1016mm)

10"

(254mm)

Platform

SafetyChain

WallMounted

Chaining

Bracket

SpringLoaded

SnapHook

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

Drawnby:SLP

Date:01/15/96

Revised:08/16/02

Scale:NONE

DrawingNumber

File:T4\O&M\CYLSOLO\AMMSOLO1.tcw(O01-2a.pdf)

30448

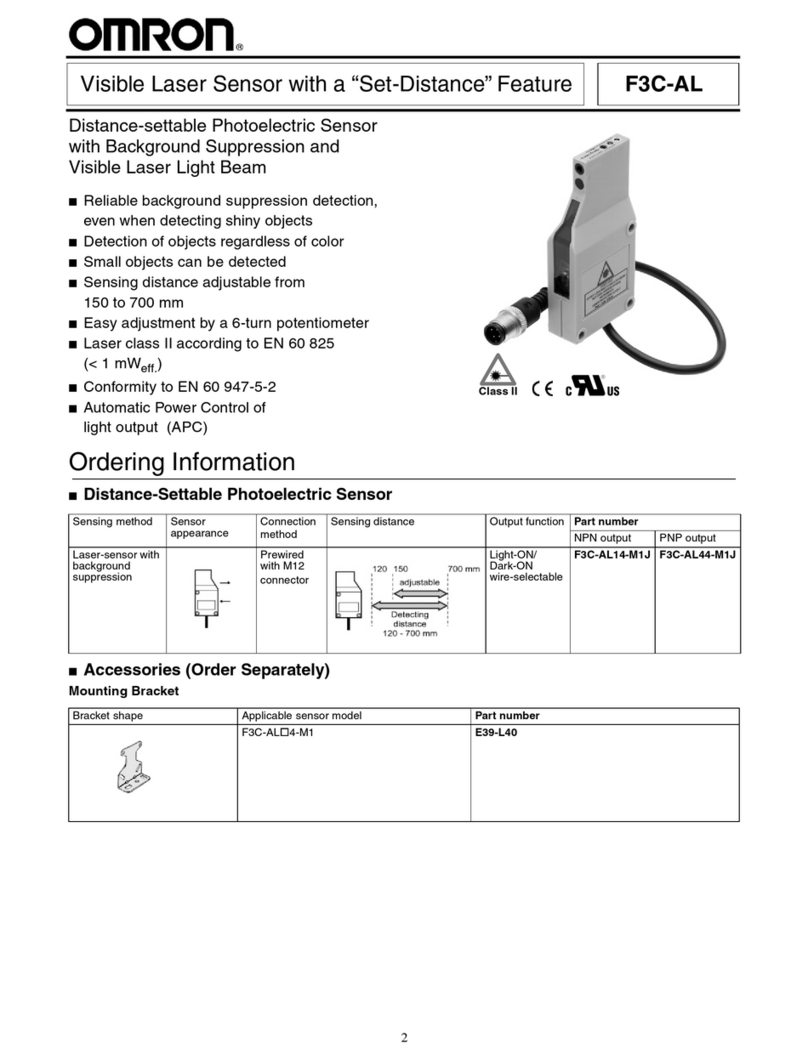

ELECTRONICAMMONIA-CYLINDER

WITHSOLO1000INDICATOR

FOR400LB(200kg)CYLINDERS

4-20mA

Output

SOLO1000

S.1.101-2.1

SINGLECYLINDERSCALEwith

1-CHANNELINDICATOR

FORCEFLOW

FORCEFLOW

211/2"

(546mm)

183/4"

(476mm)

153/4"

(400mm)

CALIBRATION

RING

400LB.(200KG)AMMONIACYLINDERS

NET1=150

NET2=125

CylinderBackstop

PlatformMountedLevel

15/8"(41mm)

Electrical

Cable

SOLO1000

2-Channel

Indicator

39"to40"

(990mm-1016mm)

10"

(254mm)

Platform

SafetyChain

Wall

Mounted

Chaining

Bracket

SpringLoaded

SnapHook

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

Drawnby:SLP

Date:01/02/94

Revised:04/09/01

Scale:NONE

DrawingNumber

File:T4\O&M\CYLSOLO\150SOLO2.tcw(O01-1b.pdf)(WEB:150#SO2.pdf)

30330

ELECTRONICCHLOR-SCALE150

WITHSOLO1000-2DUALCHANNELINDICATOR

FOR150#CYLINDERS

Scale2

Scale1

Channel2

Channel1

4-20mAOutput

(Channel1)

4-20mAOutput

(Channel2)

131/2"

(343mm)

161/2"

(419mm)

181/2"

(470mm)

FLOQUIPFORCEFLOWEQUIPMENT

SOLO1000

S.1.101-1.2

DUALCYLINDERSCALEwith

2-CHANNELINDICATOR

FORCEFLOW

FORCEFLOW

150LB.(68KG)CYLINDERS

NET1=150

NET2=125

CylinderBackstop

PlatformMountedLevel

15/8"(41mm)

Electrical

Cable

SOLO1000

2-Channel

Indicator

39"to40"

(990mm-1016mm)

10"

(254mm)

Platform

SafetyChain

Wall

Mounted

Chaining

Bracket

SpringLoaded

SnapHook

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

Drawnby:SLP

Date:01/02/94

Revised:08/16/02

Scale:NONE

DrawingNumber

File:T4\O&M\CYLSOLO\150SOLO2.tcw(O01-2b.pdf)(WEB:AMM#SO2.pdf)

30449

ELECTRONICAMMONIA-SCALE

WITHSOLO1000-2DUALCHANNELINDICATOR

FOR400#(200kg)CYLINDERS

Scale2

Scale1

Channel2

Channel1

4-20mAOutput

(Channel1)

4-20mAOutput

(Channel2)

FLOQUIPFORCEFLOWEQUIPMENT

SOLO1000

S.1.101-2.2

DUALCYLINDERSCALEwith

2-CHANNELINDICATOR

FORCEFLOW

FORCEFLOW

400LB.(200KG)CYLINDERS

211/2"

(546mm)

183/4"

(476mm)

153/4"

(400mm)

CALIBRATION

RING

NET=150

CylinderBackstop

PlatformMountedLevel

15/8"(41mm)

SOLO1000

1-Channel

Indicator

39"to40"

(990mm-1016mm)

10"

(254mm)

Platform

SafetyChain

WallMounted

Chaining

Bracket

SpringLoaded

SnapHook

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

Drawnby:SLP

Date:08/17/02

Revised:

Scale:NONE

DrawingNumber

File:T4\O&M\CYLSOLO\CYLSOLO1.tcw(O01-3a.pdf)

30450

ELECTRONICCYLINDERSCALE

WITHSOLO1000INDICATOR

FOR200LB(100kg)CYLINDERS

4-20mA

Output

SOLO1000

S.1.101-3.1

SINGLECYLINDERSCALEwith

1-CHANNELINDICATOR

FORCEFLOW

FORCEFLOW

200LB.(100K)CYLINDERS

131/2"

(343mm)

161/2"

(419mm)

181/2"

(470mm)

NET1=150

NET2=125

CylinderBackstop

PlatformMountedLevel

15/8"(41mm)

Electrical

Cable

SOLO1000

2-Channel

Indicator

39"to40"

(990mm-1016mm)

10"

(254mm)

Platform

SafetyChain

Wall

Mounted

Chaining

Bracket

SpringLoaded

SnapHook

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

Drawnby:SLP

Date:01/02/94

Revised:08/16/02

Scale:NONE

DrawingNumber

File:T4\O&M\CYLSOLO\200SOLO2.tcw(O01-3b.pdf)(WEB:AMM#SO2.pdf)

30451

ELECTRONICCYLINDERSCALE

WITHSOLO1000-2DUALCHANNELINDICATOR

FOR200#(100kg)CYLINDERS

Scale2

Scale1

Channel2

Channel1

4-20mAOutput

(Channel1)

4-20mAOutput

(Channel2)

FLOQUIPFORCEFLOWEQUIPMENT

SOLO1000

S.1.101-3.2

DUALCYLINDERSCALEwith

2-CHANNELINDICATOR

FORCEFLOW

FORCEFLOW

200LB.(100KG)CYLINDERS

131/2"

(343mm)

161/2"

(419mm)

181/2"

(470mm)

FORCEFLOW

HELPHOTLINE

1-800-893-6723

www.forceflow.com

info@forceflow.com

NOTES:

S.1.000

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

REF:T4\O&M\INDEX\Y44.tcwetc(Y44.pdfetc)

SECTION

INSTALLATIONDRAWINGS

S.1.101-1.1

S.1.101-1.2

S.1.101-2.1

S.1.101-2.2

S.1.101-3.1

S.1.101-3.2

S.2.000SCALEOPERATION:

S.2.101ScaleOperation(Use"Portable"Applications)

S.3.000

SOLO1000IndicatorwithALLCYLINDERSCALES

INDEX

INSTALLATIONCHECKLISTS

S.1.301

S.1.305

1-CHANNEL:IndicatorWiring&PlumbingDrawing

2-CHANNEL:IndicatorWiringetc.

1-CHANNEL:Instructions:Power;LoadCell&TareAdjust;4-20mA

2-CHANNEL:Instructions:Poweretc.

1-CHANNEL:Instructions:SetPoint;Surge&StaticProtection

2-CHANNEL:Instructions:SetPointetc.

INDICATORINSTALLATION

S.1.201-1

S.1.201-2

S.1.202-1

S.1.202-2

S.1.203-1

S.1.203-2

InstallationCheckList

Start-UpCheckList

OPTIONALALARMSETPOINT:

S.2.301-1

S.2.301-2

1-CHANNELAlarmSetPointConfiguration

2-CHANNELAlarmSetPointConfiguration

MISCELLANEOUS:

S.3.105

S.3.401

Calibration(SlottedPlatformsONLY)

PartsList

YOU

ARE

HERE!

InstallationnDrawing

InstallationIntroduction

InstallationSteps1thru2

InstallationSteps3thru6a

InstallationSteps6bthru6f

InstallationSteps6gthru7

INSTALLATIONINSTRUCTIONS

S.1.102

S.1.103

S.1.104

S.1.105

S.1.106

S.1.107

Single200#(100kg)Cyl.Scale,SingleChannelDrawing

Dual200#(100kg)Cyl.Scale,DualChannelDrawing

Single400#(200kg)Cyl.Scale,SingleChannelDrawing

Dual400#(200kg)Cyl.Scale,DualChannelDrawing

Single150#(68kg)Cyl.Scale,SingleChannelDrawing

Dual150#(68kg)Cyl.Scale,DualChannelDrawing

FORCEFLOW

IMPORTANT:ReadInstallation

Instructionsthoroughlybefore

installing.

5

1

6

4

3

7

2

1"(25mm)

to2"(51mm)

29966

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

Drawnby:SLP

Date:02/15/93

Revised:04/24/97

Scale:NONE

DrawingNumber

File:T4\O&M\CYLWIZ\150WIZ1.tcw(K02.pdf)

CHLOR-SCALE150

For150lb.Chlorine&SO2Cylinders

ElectronicScales

FORCEFLOW

W.1.102

S.1.102

2

WIZARDorSOLO1000Indicators

AllCYLINDERApplications

INSTALLATION.OPERATION.MAINTENANCE

Two(2)AdjustableWrenches

ScrewDriverandTapeMeasure

Hammer(forpoundinginanchorbolts)

Cylinder(foraligningplatform)

CylinderChange-OutToolHooks

Topreventpossiblepersonalinjuryordamagetotheequipment

throughmisuse,thisequipmentshouldbeinstalled,operatedand

servicedonlybytrained,qualifiedpersonnelwhoarethoroughlyfamiliarwiththe

entirecontentsofthisInstructionManual,whichshouldbethoroughlyreviewedand

understoodpriortoinstallingandoperatingtheequipment.

havebeenaddedtotheChainingBracket

tokeepfrequentlyusedtools

neededto

change

cylinders.

PowerDrillandDrillBits

HammerDrillandMasonryBit(5/16")

Two(2)1/4"DiameterAnchors(forplatform)

Two(2)properlychosenAnchors(ChainingBracket)

Four(4)properlychosenAnchors(WizardorSolo)

YourElectronicCYLINDERScaleconsistsof

3basicassemblies:

1.LoadCellSystem(LoadCell,Cableand

WizardorSoloIndicator)

2.PVCPlatform(Backstop,Platform

withHingeandlevelingshims)

3.ChainingDevice(BracketwithEquipment

Hooks,ChainandSpringLoadedBoltSnap)

ITEMSREQUIREDFORINSTALLATION:

WARNING:

COMMENTS:

ElectronicScaleALLCYLINDERSwithSOLOINDICATOR

Ifyouhaveanyquestionsregardingtheinstallation,operationormaintenanceonyour

CYLINDERScaleorpleasedonothesitatetocallour....HELPHOTLINE1-800-893-6723.

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

File:T4\O&M\CYLELE\150WIZA.tcw(K03.pdf)

FORCEFLOW

W.1.103

S.1.103

(B)

A)Placetheplatformonthefloorwiththebackstopsideoftheplatformatthewall.

NOTE:Allowatleast1"clearancebetweenwallandplatform.

DONOTANCHORPLATFORMTOFLOORUNTILSTEP4.

(A)Thechainingbracketshouldbeatapproximately

3/4theheightofthecylinder.

STEP2:ALIGNINGANDMOUNTINGTHECHAININGBRACKET

NOTE:IftheFootofyourwallprotrudes,itmaybenecessary

toputaspacerbetweenthewallandthechainingbracketto

assurenomorethan1"to2"spacebetweencylinderand

frontedgeofchainingbracket.(SeeInstallationDrawing

Step3and4).

CAUTION:Forproperoperationandtoavoidpossibledamagetothescaleorinjurytoyourself,youMUST

installtheseitemsinthefollowingStep-by-Stepmanner.ThestandardElectronicCHLOR-SCALE150is

meanttobeinstalledincloseproximitytoawallorotheruprightstructure.Ifthisisnotpossible,please

consultfactoryforproperinstallation.Eachofthesescalesisdesignedtoaccomodateaspecificcylinder

only(consultfactoryifyouareindoubt).SeedrawingsinSections1.101.1thru1.101.3.Removeallitems

frombox.Theloadcellsystemiswiredandcalibratedatthefactory.

INSTALLATIONNOTES:

(B)Toalignthechainingbracketwiththeplatform,adjustbracket

untilthehangingchainalignswiththeright-handsideofthe

backstop.Besurethebracketislevel,markholesandanchor

thebrackettothewall.Makesureyouranchorboltsare

properlysizedandarecompatiblewithyourwallmaterial!!

3/4oftheCylinderHeight

(A)

STEP1:PLACEPLATFORMONFLOOR

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

File:T4\O&M\CYLWIZ\WIZ150B.tcw(K04.pdf)1/24/02BD

FORCEFLOW

W.1.104

S.1.104

1"CLEARANCEBETWEEN

PLATFORMANDWALL

PLATFORM

WALL

PLATFORM

(B)

B)FORALLIGNMENTPURPOSESONLY:

(A)

TEMPORARILY

UPSIDEDOWN

LOADCELL

TemporarilyplaceLoadCellUPSIDEDOWN

withstudthroughholeofplatform.

1"to2"

Adjusttheplatformdistancesothatwitha150lb.

cylinderagainsttheplatformbackstop,thecylinder

isapproximately1"to2"fromthefrontedgeofthe

chainingbracket.

CylinderMUSTNOTtouchchainingbracket

orscalewillnotoperateproperly.

Platformmustnottouchwallorscalewillnotfunction

properly.Markmountingholesonthefloor.Drillholes

with5/16"bitandboltscaletothefloorusingtwo(2)1/4"

diameteranchorbolts.Makesureyouranchorbolts

areproperlysizedandcompatiblewithyourfloormaterial!!

STEP3:ADJUSTINGCYLINDERDISTANCEFROMCHAININGBRACKET

Toavoidinjurycausedbytippingcylinder,DONOT

useuntilplatformisboltedtofloor.

STEP5:ANCHORINGTHELOADCELL

STEP4:ANCHORINGTHEPLATFORM

CAUTION:

(A)REMOVELOADCELL.UsingHOLEIN

PLATFORMastemplate,markfloorthrough

holetodrillLoadCellanchoringhole.

Usingthishole

tomarkfloorfor

loadcellanchoring.

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

File:T4\O&M\CYLEWIZ\WIZ150C.tcw(K05.pdf)01/24/02BD

W.1.105

S.1.105

(B)Aftermarkisestablishedonthefloor,pivotPlatformoutoftheway.Centerpunchthe

marktoensureaccurateholelocation.Drilla5/16"holeusinganappropriatebit.

Drilltheholeapproximately1inchdeep.

Drill5/16"diameter

hole,1inchdeep.

FORCEFLOW

(C)Slidelevelingwasher(s)ifneededontostud,

sothatplatformislevelfronttorear.

(D)1.InsertLoadCellStudintohole

inthefloor.

2.BecertainthattheLoad

Cellisseated"flush"onthefloor.

3.PositionLoadCellsothatthecable

runsstraightouttoeithersideofthe

Platform.

Cabletoexitstraight

outoneithersideof

Platform.

(E)PivotPlatformbackintoplace.Sitethroughthe

mountingholeontheplatformtoensurethatthe

"BLACKDOT"ontheLoadCellbuttonis

centeredintheholeontheplatform.

Correct

Incorrect

(E)

(D3)

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

File:T4\O&M\CYLWIZ\WIZ150D.tcw(K06.pdf)1/24/02BD

W.1.106

S.1.106

STEP5:ANCHORINGTHELOADCELLcont...

(D2)

(D1)

FORCEFLOW

To mount additional scales side-by-side, be sure

to allow for the frame hinge when determining the

distance between platforms (if minimizing floor

area) and repeat Step 1 - 7.

(F) If the "BLACK DOT" on the Load

Cell Button is not centered in the hole

on the platform loosen the floor anchor

bolts slightly and adjust platform as

needed. Once proper alignment is

achieved, tighten the anchor bolts.

Adjust platform for

proper alignment.

Loosen

"BLACK DOT" on

Load Cell should

be centered in hole

on platform.

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

File: T4\O&M\CYLWIZ\WIZ150E.tcw (K07.pdf) 1/24/02 BD

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.107

S.1.107

Check the platform-mounted level to assure that the

scale is level from FRONT to REAR. If the platform

is not level, either:

(A) RAISE REAR of platform by placing shim(s)

UNDERNEATH the LOAD CELL,

or (B) RAISE FRONT by placing shim(s)

UNDERNEATH the HINGE on the

ANCHOR BOLTS (shims provided with scale). (B)

LOAD CELL

FRONT

MOUNTING FOOT

PLATFORM

REAR

(A)

STEP 6: LEVEL PLATFORM

LEVELING

SHIMS

(if needed)

LEVELING

SHIMS

(if needed)

STEP 5: ANCHLORING LOAD CELL cont...

STEP 7: MOUNTING ADDITIONAL SCALES

FORCEFLOW

HELPHOTLINE

1-800-893-6723

www.forceflow.com

info@forceflow.com

NOTES:

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

S.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX\Y44.tcw etc (Y44.pdf etc)

SECTION

INSTALLATION DRAWINGS

S.1.101-1

S.1.101-2 Single Cylinder Scale, Single Channel Drawing

Dual Cylinder Scale, Dual Channel Drawing

S.2.000 SCALE OPERATION:

S.2.101 Scale Operation (Use "Portable" Applications)

S.3.000

SOLO 1000 Indicator with CHLOR-SCALE 150

INDEX

INSTALLATION CHECK LISTS

S.1.301

S.1.305

1-CHANNEL: Indicator Wiring & Plumbing Drawing

2-CHANNEL: Indicator Wiring etc.

1-CHANNEL: Instructions: Power; Load Cell & Tare Adjust; 4-20mA

2-CHANNEL: Instructions: Power etc.

1-CHANNEL: Instructions: Set Point; Surge & Static Protection

2-CHANNEL: Instructions: Set Point etc.

INDICATOR INSTALLATION

S.1.201-1

S.1.201-2

S.1.202-1

S.1.202-2

S.1.203-1

S.1.203-2

Installation Check List

Start-Up Check List

OPTIONAL ALARM SET POINT:

S.2.301-1

S.2.301-2 1-CHANNEL Alarm Set Point Configuration

2-CHANNEL Alarm Set Point Configuration

PARTS LIST:

S.3.401 Parts List

YOU

ARE

HERE !

Installationn Drawing

Installation Introduction

Installation Steps 1 thru 2

Installation Steps 3 thru 6a

Installation Steps 6b thru 6f

Installation Steps 6g thru 7

INSTALLATION INSTRUCTIONS

S.1.102

S.1.103

S.1.104

S.1.105

S.1.106

S.1.107

Other Force Flow Accessories manuals