Force Flow WIZARD 4000 Manual

2430 Stanwell Dr, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

www.forceflow.com / info@forceflow.com

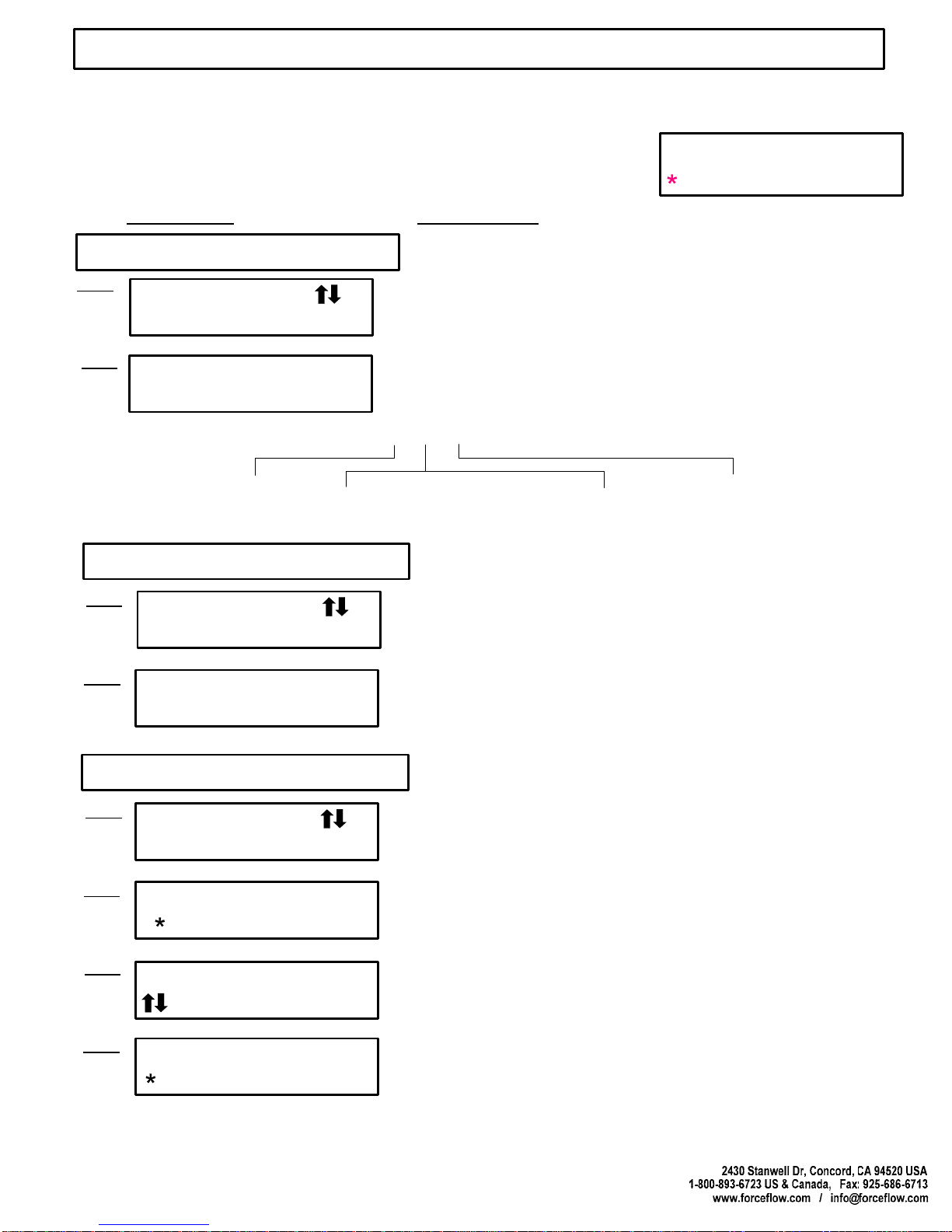

WIZARD 4000

DIGITAL WEIGHT INDICATOR

1 to 4 Channels

#3 NET 57.11 GL

#3 BULK 0.0 GL

PRESS REPEATEDLY TO VIEW:

NET WEIGHT

FEED RATE

DAILY USAGE

DAYS UNTIL EMPTY

TOTAL USAGE

PERCENT FULL

BASE UNITS

BULK TANK SUPPLY

BAR GRAPH

PRESS BEFORE STARTING TANK CHANGES OR REFILLS TO

MAINTAIN ACCURATE USAGE DATA.

ACCESS "USER" AND "SETUP" MENUS. "USER" MENU LISTED

BELOW (SEE O&M MANUAL FOR "SETUP" MENU).

1 ALARM HISTORY

2 DATE LAST CLEARED

3 CLEAR AMOUNT USED

4 VIEW TOTAL

5 SET TIME & DATE

6 VIEW BULK SUPPLY

7 VIEW TARE

8 DISPLAY UNITS

9 SET ZER

INSTALLATION, OPERATION

& MAINTENANCE

2430 Stanwell Dr, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\WIZ INDEX 2007.tcw

03/21/08 MT

SECTION II - WIZARD 4000 WEIGHT INDICATOR

INDEX

W.1

W.2

W.3

W.4

W.5

W.6

W.7

W.8

W.9

W.10

INDEX

INSTALLATION CHECKLIST

START-UP CHECKLIST

KEYBOARD QUICK REFERENCE GUIDE (Drawing 30835)

ELECTRONIC INDICATOR SPECS (Drawing 30831)

KEYPAD FUNCTIONS

TANK LOAD PROCEDURE (Drawing 30774)

HAZARDOUS LOCATION INSTALLATION (Drawing 29893)

WIRING INSTRUCTIONS (Drawing 29892)

MOTHERBOARD COMPONENT LAYOUT

W.11

W.12 POWER, LOAD CELL, 4-20mA SIGNALS

MODBUS, RELAYS, DISPLAY VIEW ANGLE

INSTALLATION & WIRING

W.13

W.14

W.15

1 ALARM HISTORY / 2 DATE LAST CLEARED / 3 CLEAR AMOUNT USED

4 VIEW TOTAL / 5 SET TIME & DATE / 6 SET BULK SUPPLY / 7 VIEW TARE

8 SET ZERO

USER MENU

W.16

W.17

W.18

W.19

W.20

W.21

W.22

W.23A

W.23B

1 DISPLAY FORMAT / 2 CHANNEL ID / 3 100 PERCENT

4 AUTO LOAD / 5 FILTER BAND / 6 MOTION BAND

7 SYSTEM TIME BASE

8 CONFIG. 4-20mA / 9 BULK SUPPLY / 10 AUTO REFILL

10 AUTO REFILL cont. / 11 SET ALARM VALUES / 12 ASSIGN RELAYS

12 ASSIGN RELAYS cont. / 13 USER PRIVILEGES / 14 DIAGNOSTICS

14 DIAGNOSTICS cont. / 15 FIELD CALIBRATION

15 FIELD CALIBRATION cont.

16 CONFIG TOTAL / 17 TANK SET UP

SETUP MENU

W.24

W.25

W.26

QUICK START GUIDE, DESCRIPTION, WIRING

SET VALUES, OVERFILL PROTECT., ARC CYCLE, PAUSE & PROJECT

AUTO REFILL CONTROL WIRING (Drawing 31172)

AUTO REFILL CONTROL (OPTIONAL)

W.27

W.28

W.29

CONFIGURATION, COMM., SET-UP, DEVICE ADDRESS

REGISTER MAP

SAMPLE DATA STRINGS

MODBUS SERIAL COMMUNICATIONS (OPTIONAL)

M.1 FACTORY WARRANTY & PERFORMANCE GUARANTEE

WARRANTY

W.1

W.30

W.31 RELAY WIRING FOR 1 TO 8 RELAYS (Drawing 31272)

RELAY WIRING FOR 9 TO 12 RELAYS (Drawing 31273)

RELAY WIRING

INSTALLATION CHECKLIST

QUESTIONS ? Help Hotline: 1-800-893-6723

W.2

File: T4\O&M\WIZ MSTR\WIZ PR328 INSTALL CHKLST.tcw

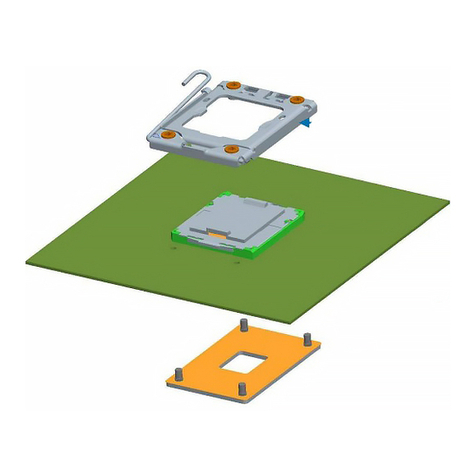

INSTALL SCALE PLATFORM(S), PROCELL(S) or ECHO-SCALE(S) in accordance with supplied

Operation & Maintenance Manual.

WIZARD 4000 INDICATOR

MOUNT INDICATOR

WIRE INDICATOR

FORMAT INDICATOR (See Pages W.4 through WA-16)

Check all current settings in USER and SETUP Menus.. Make changes

as needed for your specific application.

SEAL ENCLOSURE

Tighten all six (6) door screws to seal and maintain NEMA 4X rating. Check

all cord connectors and conduit connectors for tight seal.

7

7

J

POWER-UP:

Apply weight (press on platform or tank) and verify indicator NET WT responds.

START-UP CHECKLIST

QUESTIONS ? Help Hotline: 1-800-893-6723

W.3

File: T4\O&M\WIZ MSTR\WIZ NEW PR328 CHKOFF.tcw

03/21/08 MT

WIZARD 4000 INDICATOR

7

Scale display should read NET WT or NET REMAINING. Press DISPLAY SELECT

key as needed until display reads NET WT or NET REMAINING.

SCALE APPLICATIONS:

ULTRASONIC SENSOR (ECHO-SCALE) APPLICATIONS ONLY:

Enter tank diameter in SETUP MENU "17 TANK SETUP". See Page W.23B for details.

SET ZERO:

Enter USER MENU "8 SET ZERO" and follow prompts. See page W.15 for details.

(Indicator typically zero'd with empty tank and all other appurtenances installed.

For gas cylinders and ton containers, zero scale with empty platform).

CLEAR AMOUNT USED:

Enter USER MENU "3 CLEAR AMOUNT USED" and follow prompts. See page W.13 for details.

REVIEW TANK LOAD PROCEDURE:

See page W.7 for details.

AUTO REFILL WARNING!

If using AUTO REFILL OPTION (ARC), thoroughly review pages W.24 through W.26 to protect

against chemical spills!

REVIEW ALL MENU ITEMS:

Review all USER MENU and SETUP MENU items and change as required for your application.

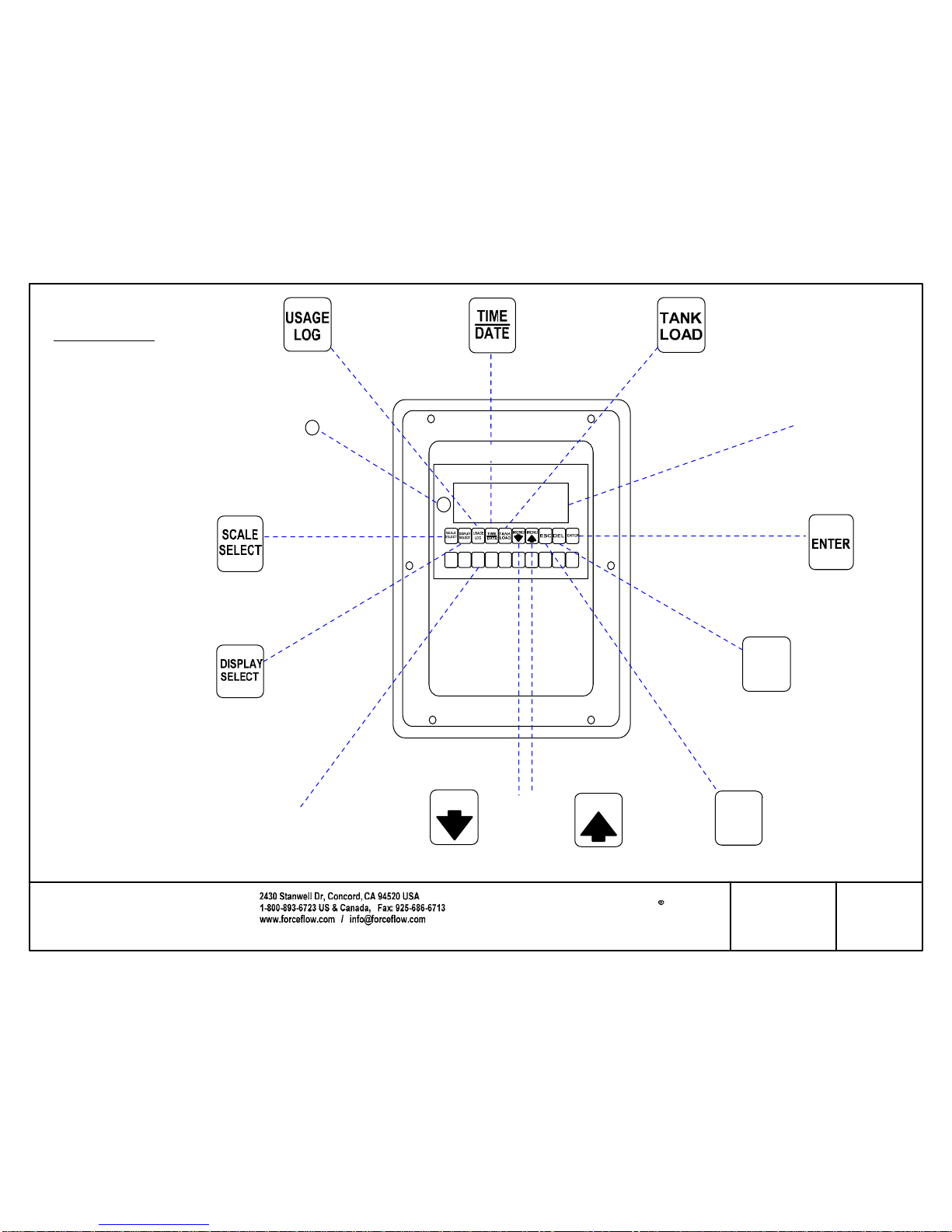

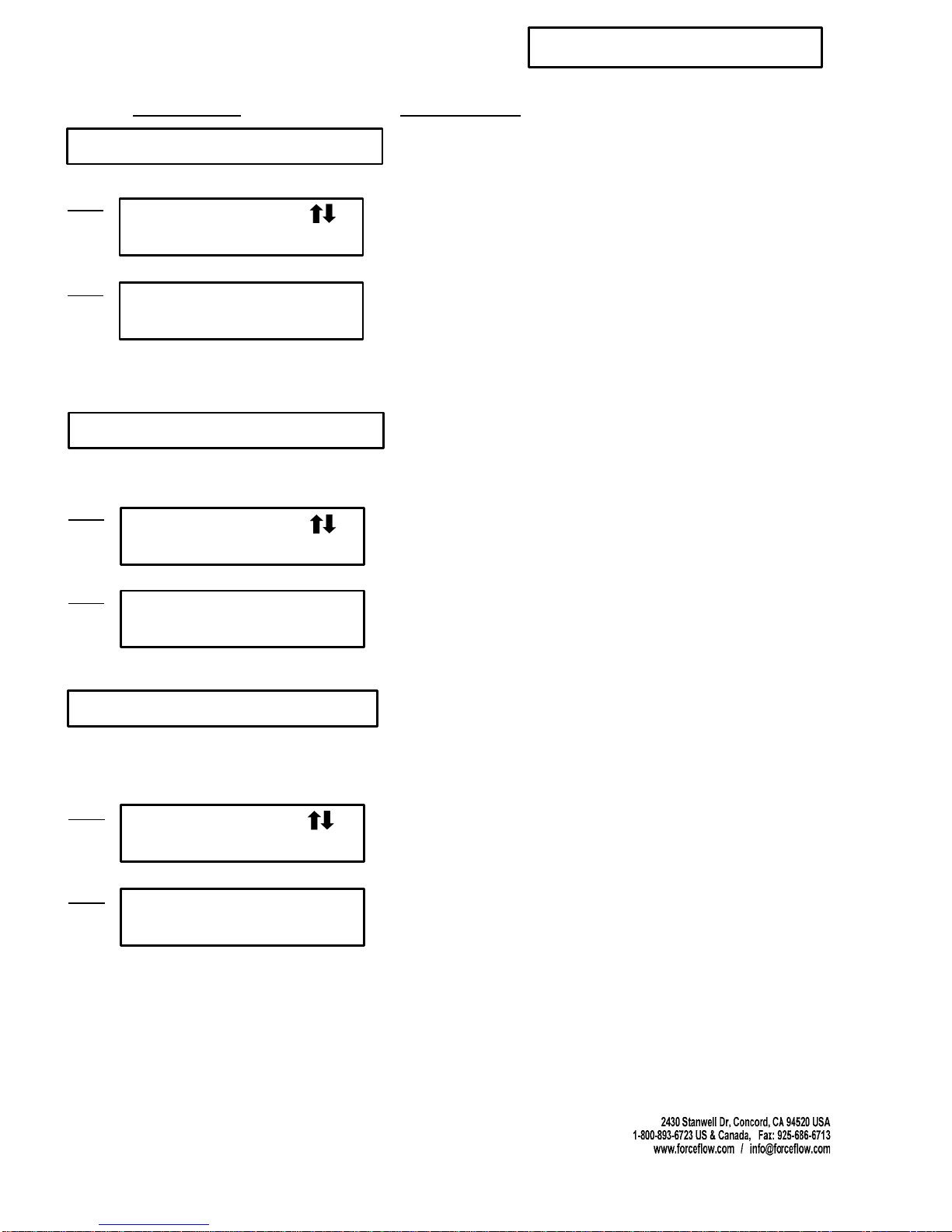

KEYBOARD

QUICK REFERENCE GUIDE

QUESTIONS ? Help Hotline: 1-800-893-6723

W.4

File: T4\_NEW O&M WIZ\W4 WIZ NEW KEYBD PR328.tcw

03/21/08 MT

Scrolls forward through individual scales.SCALE SELECT

Toggles through a multi-function display for each scale in the

following decending order:

DISPLAY SELECT

1 NET REMAINING............

2 BAR GRAPH ..................

3 AVERAGE FEED RATE.

4 DAILY USAGE................

5 DAYS UNTIL EMPTY.....

6 AMOUNT USED ............

7 PERCENT FULL ............

8 BASE UNITS .................

Chemical remaining in tank or cylinder (default screen)

Analog bar graph. 0-100%

Chemical feed rate displayed as weight/volume per hour or day.

Amount of chemical fed so far today.

Days until empty at the current feed rate

A running total of net chemical used since last reset.

Numeric display of 0-100%.

Units of measure that Wizard was calibrated in.

Daily usages of most recent 31 days.

USAGE LOG:

Time and Date

TIME DATE

Loading new tanks or chemicals and entering tank tare weights.

TANK LOAD

ESCAPE key returns you to main display

ESC

These are the functions that are used on a day-to-day basis.

Access to USER and SETUP Menus. Allows

you to scroll through each of these Menus from

beginning to end.

MENU UP/DOWN

DELETE key backspaces or previous screen.

DEL

Data Entry or Advance to Next Screen.

ENTER

2430 Stanwell Dr, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

www.forceflow.com / info@forceflow.com

Drawn by: SLJ/MT

Date: 09/01/95

Revised: 04/08/08 MT

Scale: NONE

Drawing Number

File: T4\O&M\_NEW O&M 2007\W5 WIZ NEW PR328 WIZARD.tcw

CHANNELS:

INPUTS:

INCREMENTS:

DISPLAY UNITS:

RANGE:

RESOLUTION:

DISPLAY:

KEYBOARD:

OPERATING TEMP:

POWER:

CONNECTORS:

ENCLOSURE:

PERFORMANCE:

4-20mA OUTPUT SIGNALS (Model WMA420):

Up to 8 separate output signals (NET, RATE, DAILY, BULK or TOTALS)

1000 ohms max per output.

RELAYS (Models W5ASP-OD, W5AP-CD, W5ASP-OS & W5ASP-CS):

A maximum of 12 solid state or dry contact relays, NO/NC

latching/non-latching.

COMMUNICATIONS (Models WRS232 & WRS485):

RS232 Serial Port or RS485 Serial Network Port (MODBUS ASCII protocol).

SPECIFICATIONS

OPTIONS:

WIZARD 4000

ELECTRONIC INDICATOR

4000-1 (1-Channel)

4000-2 (2-Channel)

4000-3 (3-Channel)

4000-4 (4-Channel)

W.5

OPTIONS:

Qty Model Description

SUBMITTAL DATA: Wizard 4000 Model No.___________________

No. of Channels _____________

INPUTS

No. of Sourcing 4-20mA Outputs ________________________

No. of Relays: ____________________

____________________

Other Options ______________________________________________________________

__________________________________________________________________________

Dry Contact / Solid State

N.O. / N.C.

1 to 4 independent channels

Up to 4 electronic load cells or 1 Ultrasonic sensor

per channel

1, 2, 5, 10, 20, 50

LB, KG, GAL, LITER, IN, CM

0.01 TO 2,000,000

UP TO 20,000

2 lines, 16 characters per line, alphanumeric LCD

display backlighting, 0.4" characters

10 function keys, 10 numeric keys with tactile feedback

32 to 122 degrees F (0-50 degrees C)

110, 220 or 240 VAC, 50/60 Hz, 1/4 AMP Max.

Power and input/output - 1/2" nylon conduit connectors

Load Cells - 1/2" nylon cord connectors

Nema 4X, UL listed structural foam molded enclosure

Overall System Accuracy: 0.1 to 0.25% F.S.

Non-Linearity: <0.03% F.S.

Hysteresis: <0.02% F.S.

Non-Repeatability: <0.01% F.S.

Thermal Stability: <0.002% degrees F, zero and span

MODELS:

JOB REFERENCE: _______________________________________/s/___________

Dry Contact / Solid State

N.O. / N.C.

#3 NET 57.11 GL

#3 BULK 0.0 GL

6 5/8" (168mm)

10 1/2"

(266mm)

13"

(330mm)

Centerline

Mounting Brackets (4)

3" (76mm)

6" (152mm)

8 1/2" (216mm)

3/8" (9mm)

PRESS REPEATEDLY TO VIEW:

NET WEIGHT

FEED RATE

DAILY USAGE

DAYS UNTIL EMPTY

TOTAL USAGE

PERCENT FULL

BASE UNITS

BULK TANK SUPPLY

BAR GRAPH

PRESS BEFORE STARTING TANKCHANGES OR REFILLS TO

MAINTAIN ACCURATE USAGE DATA.

ACCESS "USER" AND "SETUP" MENUS. "USER" MENU LISTED

BELOW (SEE O&M MANUAL FOR "SETUP" MENU).

1 ALARM HISTORY

2 DATE LAST CLEARED

3 CLEAR AMOUNT USED

4 VIEW TOTAL

5 SET TIME & DATE

6 VIEW BULK SUPPLY

7 VIEW TARE

8 DISPLAY UNITS

9 SET ZERO

MOUNTING BRACKET (TYP 4 PLCS)

WIZARD 4000 +

0123456789

MENU

MENU

DEL

Toggles through a

multi-function display

for each scale.

Displays Daily Usage

for past 31 days

Toggles

Between

Individual

Scales

Return to Main

Default Screen

Backspace

or Back to Previous

Screen

Data Entry

and Advance

to Next Screen

Time and

Date

"NET WEIGHT"

"YES * NO"

ENTER SCALE #

Single or Dual

Display (16

Characters

per Line Screen)

Net Weight

Bar Graph

Feed Rate

Daly Use

Days Until Empty

Total Use

% Full

Base Units

Bulk

Scrolls Forward

and Backward

Through the Menu

Loading

New Tanks

or Chemicals

Numeric

Data Entry

Key Pad

Drawn by: SLP/MN

Date: 11/03/05 MN

Revised:

Scale: NONE

Drawing Number

File: T4\NEW O&M 2007\W6 WIZ NEW PRO328 BUTTONS.tcw

03/21/08 MT

30831

WIZARD 4000

KEYPAD FUNCTIONS

W.6

#3 NET 57.11 GL

Checked by: MN

ESC

#3 BULK 0.0 GL

*TO USE RESET BUTTON

*Reset Button &

Displays Software

Version

1. Push and hold "DEL" key.

2. While holding "DEL" key, push

and hold "RESET" button for 2

seconds.

3. After 2 seconds release ONLY the

"RESET" button, but continue to hold

down the "DEL" key until the display

reads one of the following:

Release "DEL" key.

Press "MENU" arrow keys to choose "NO"

Press "MENU" arrow keys to choose different

number than you did before.

WARNING ! DO NOT UNLOAD or LOAD tanks until "CHANGE TANKS NOW, THEN

PRESS ENTER" appears on the display. If you load or unload tanks

before reaching this step, the "AMOUNT USED" and "DAILY USAGE"

displays will be incorrect.

It also allows you to enter the tare weight(s) of your tanks if you choose "Manual" tank load mode, or load the

net weight of a cylinder if you chose the "Auto" tank load mode.

'TANK LOAD" key allows you to load new tanks without adversly

affecting the "AMOUNT USED" and "DAILY USAGE" displays.

Press "TANK LOAD" key to enter the tank load mode.

Remove empty tanks and place new tank(s) onto the scale

then press "ENTER" key to continue.

#2 TANK #1 TARE

#1 NET = 0 LB

#2 NET = 1950 LB

ARE YOU SURE

....If you chose "AUTO" the WIZARD automatically loads the

net weight and goes into the weighing mode (skip Step 6).

CHANGE TANKS NOW

THEN PRESS ENTER

WAIT

TANK TARE

*AUTO MANUAL

Verify you would like to continue tank load procedure.

Press "MENU" arrow keys to select which method, then press "ENTER".

MANUAL Mode: Requires that you enter tare weight of EACH tank on

EACH scale. (Example: Scale #2, tare weight of TANK #1is 1234 lbs.,

then TANK #2, etc). After entering the tare weights of all your tanks, the

WIZARD 4000 automatically adds them up and subtracts them from

the gross weight.

Step 6

Digital Display Action Required - Press "ENTER" after completing each step.

Step 2

Step 4

Step 5

Step 3

Step 1

....If you chose "MANUAL" you will manually enter tank

tare weight in Step 6.

....If MANUAL chosen above in Step 3...

Use "MANUAL" for PARTIALLY FULL containers.

Use "AUTO" for FULL containers.

TANK LOAD MODE

Fill your tank with chemicals, then press "ENTER" key to continue.

FILL TANK NOW

THEN PRESS ENTER

Step 7

"PORTABLE" Tank Applications (follow Steps 1 thru 6 only), such as

Ton Containers, Drums and Cylinders.

"PERMANENT" Tank Applications (follow Steps 1, 2 and 7 only), such as

Chem-Scale, Hoppers, Procells and Ultrasonic

Skip to STEP 7 in "PERMANENT" Tank Applications.

QUESTIONS ? Help Hotline: 1-800-893-6723 W.7

File: T4\NEW O&M 2007\W7 WIZ NEW DAY1C.tcw

NO *YES

LBS = 1234

SELECT CHANNEL Use "MENU" arrow keys, to choose channel, press "ENTER"

to accept the channel you want to load/unload tanks. This

"freezes" or "holds" the AMOUNT USED and DAILY USAGE

displays until tank load procedure finishes.

Step 2 , enter CH# 1

WIZARD 4000 TANK LOAD PROCEDURE:

2430 Stanwell Dr, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawing Number

File: T4\NEW O&M 2007\W8 WIZ NEW INTRINSIC WIZ SOLO.tcw 30774

HAZARDOUS LOCATIONS

NON-HAZARDOUS LOCATION

CONDUIT MUST BE

SEALED PER

ELECTRICAL CODE

ELECTRONIC

LOAD CELL

WALL

LOAD CELL

CABLE

Allows refilling of tanks. To maintain accur ate usage data,

DO NOT fill tanks unt il STEP 3.

PressTANK LOAD button

Press 1 2 3 or 4 to select which scale,then press ENTER .

Fillyour tanksnow ! Then press ENTER

Togglesthroughdisplay options:

NetRemaining,AmountUsed,Average

Feed Rate , DaysUn til Empty, Daily Usage

Togglesthroughdisplay forthe totals

ofall scales

1

2

3

SAFETY BARRIER

(IF REQUIRED)

FOR HAZARDOUS LOCATIONS, VERIFY ELECTRONIC LOAD CELL(S)

FURNISHED WITH YOUR SCALE HAVE THE FOLLOWING LABEL TO

MEET SAFETY REQUIREMENTS:

FOR FURTHER TECHNICAL INFORMATION OR FOR APPLICATIONS

ENGINEERING ASSISTANCE, PLEASE CONTACT FORCE FLOW

1-800-893-6723.

HAZARDOUS LOCATION

INDICATOR IS NOT APPROVED FOR USE IN HAZARDOUS LOCATIONS.

IF YOUR INSTALLATION CONSTITUTES AN EXPLOSIVE OR COMBUSTIBLE

ENVIRONMENT, PLEASE CONSULT FACTORY FOR SAFETY PRECAUTIONS.

W.8

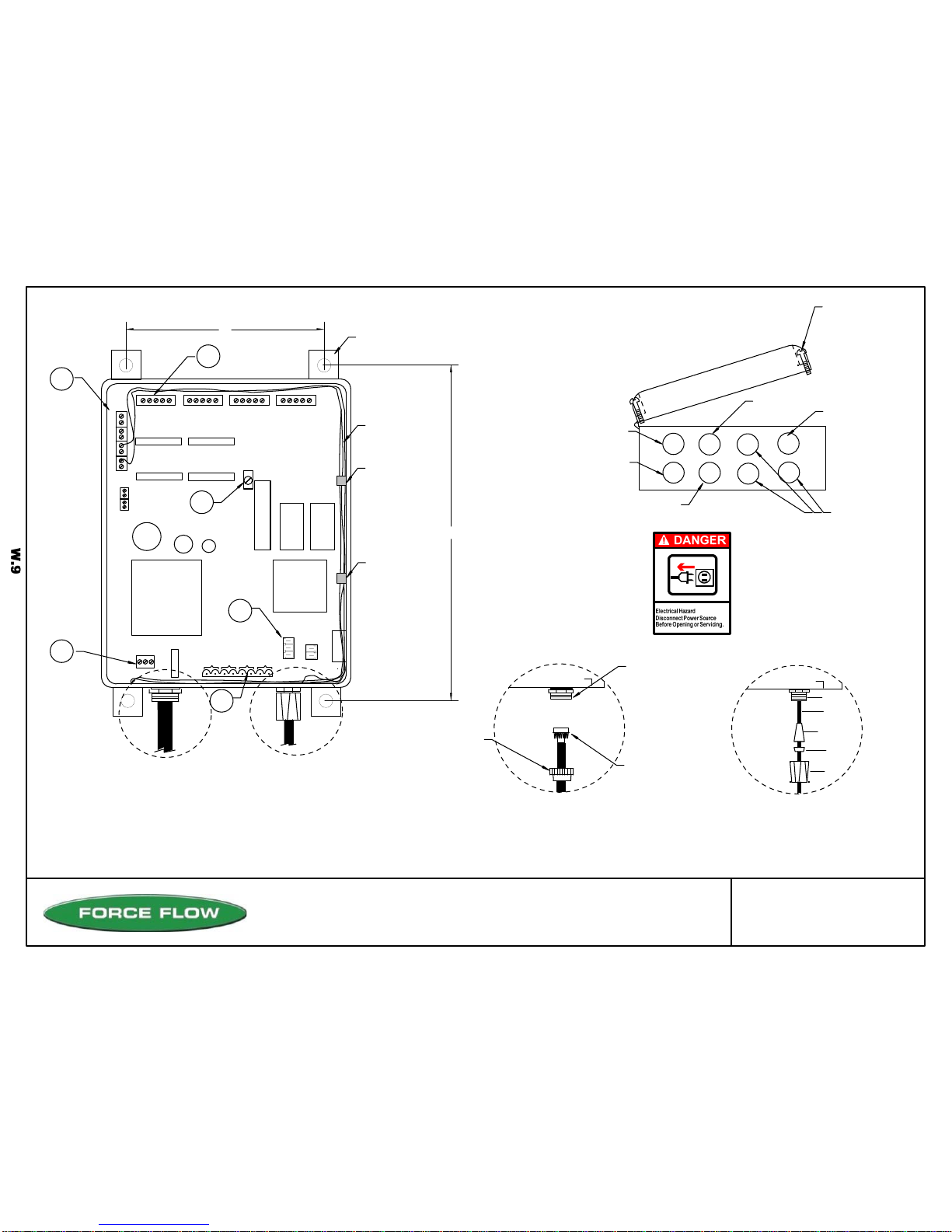

4-20mA

CONNECTIONS

LOAD CELL/ULTRASONIC CONNECTIONS

#1 #2 #3 #4

DISPLAY ANGLE

ADJUSTMENT (BLUE)

EPROM

RAM

CPU

POWER SUPPLY

POWER IN

CONNECTOR SLEEVE

PLASTIC WASHER

RUBBER GROMMET

CABLE

CONDUIT FITTING

BOX

#1#2#3#4

BOX (FRONT VIEW)

1/4" CORD CONNECTOR, USED FOR:

32

4

1

6 SLOTTED PAN

HEAD SCREWS.

(TIGHTEN SCREWS

EVENLY TO

GET UNIFORM SEAL

ON COVER GASKET)

3RD: ATTACH TO CONDUIT

OR CABLE CONNECTOR

FITTING ON BOX

2ND: SCREW CONDUIT

CONNECTOR ONTO

CONDUIT

1ST: SLIP CONDUIT

FITTING BASE

OVER CONDUIT

1/2" CONDUIT CONNECTOR, USED FOR:

5

LOAD CELL CABLE

ULTRASONIC CABLE

POWER

4-20 MA SIGNAL

RELAY WIRING

COMMUNICATIONS

6

NOTE:

Mount Indicator at "EYE LEVEL"

for easy viewing.

FUSE

BOX (BOTTOM VIEW)

1

3

42

2430 Stanwell Dr, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP/MD

Date: 09/01/95

Revised: 12/05/06 PR328

Scale: NONE

DrawingNumber

File: T4\NEW O&M 2007\W9 WIZ NEW PR328 INDI.tcw 29893

WIZARD 4000 INDICATOR

WIRING REFERENCE

4-20mA WIRING,

LOAD CELL CABLE,

ULTRASONIC CABLE

WIRE/CABLE

CLAMP

CORD

CONNECTION

CONDUIT

CONNECTION

LOAD CELL/ULTRASONIC

SENSOR (1/4" CORD

CONNECTION)

4-20mA OUTPUT

(1/2" CONDUIT

CONNECTION)

RS485/RS232

(1/2" CONDUIT

CONNECTION)

110V/240V POWER CONNECTION

(1/2" CONDUIT CONNECTION)

RELAYS (1/2" CONDUIT CONNECTION) OPTIONAL LOAD

CELL or ULTRASONIC

(1/4" CORD

CONNECTION)

BOX

CONDUIT

CONNECTION CORD

CONNECTION

P1

+24VDCfor

Ultrasonics

RELAYS

#1

#2

#3

#4

+

_

T

G

R

RS485

RS232

WIRE/CABLE

CLAMP

6'

13"

MOUNTING

FIXTURE

®

EPROM

RAM

CPU

POWER

SUPPLY

POWER IN

Scale#1

HI

LO

Scale#1#2#3#4

11 12 13 14

SH

-X1

+X1

+S1

-S1

+X2

+S2

-S2

-X2

SH

+X3

+S3

-S3

-X3

SH

+X4

+S4

-S4

-X4

SH

NOTE:Forbestviewing,mountindicatorat"eyelevel".

LOAD CELLS

or

ULTRASONIC

SENSORS

FUSE

RELAYS

#1

#2

#3

#4

6"

13"

WIRE CABLE CLAMP

DISPLAY ANGLE

ADJUSTMENT (Blue)

MOUNTING

FIXTURE

4-20mA OUTPUT

Drawing Number

File: T4\NEW O&M 2007\W10 WIZ NEW PR328 INDIA.tcw

29892

WIZARD 4000 INDICATOR

COMPONENT LAYOUT

Scale#2

Scale#3

Scale#4

W.10

P1

+24VDCfor

Ultrasonics

RS232 (J1)

+

_

R

G

T

RS485

RS232

RS485 (J4)

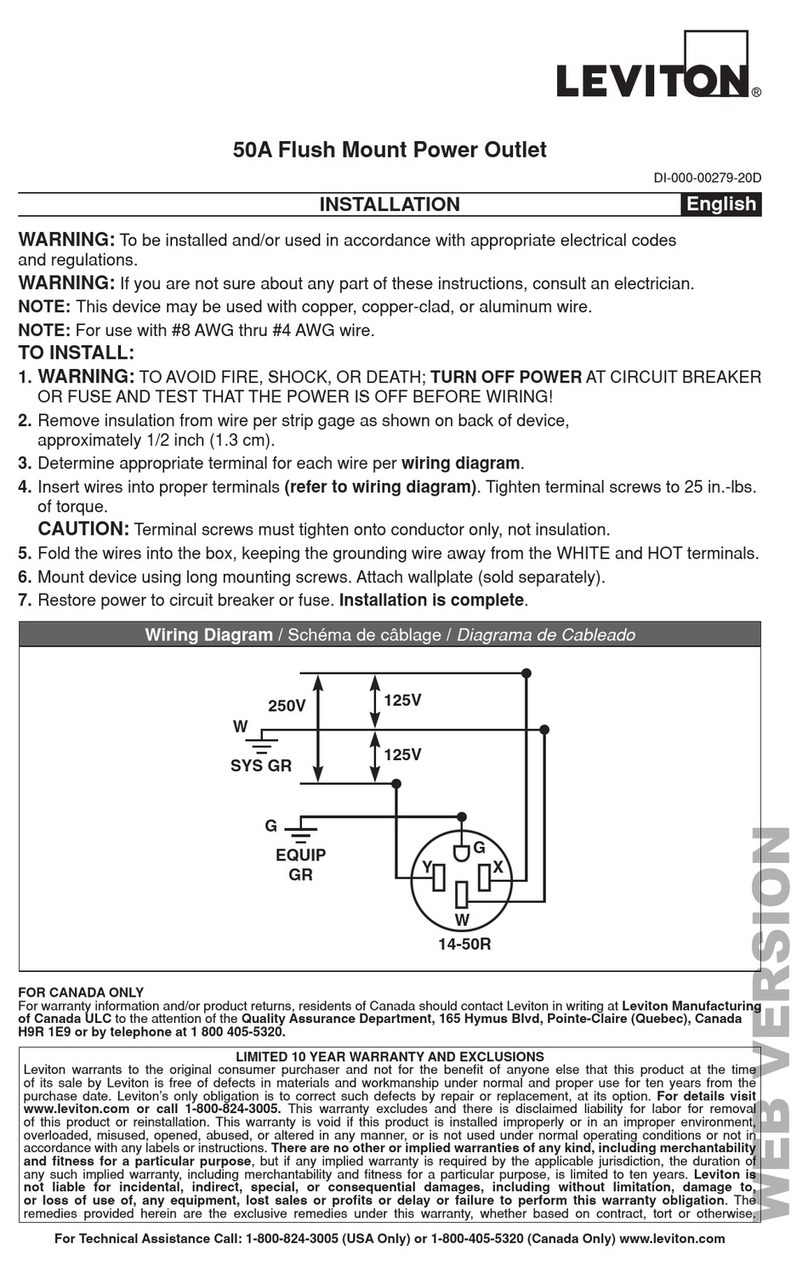

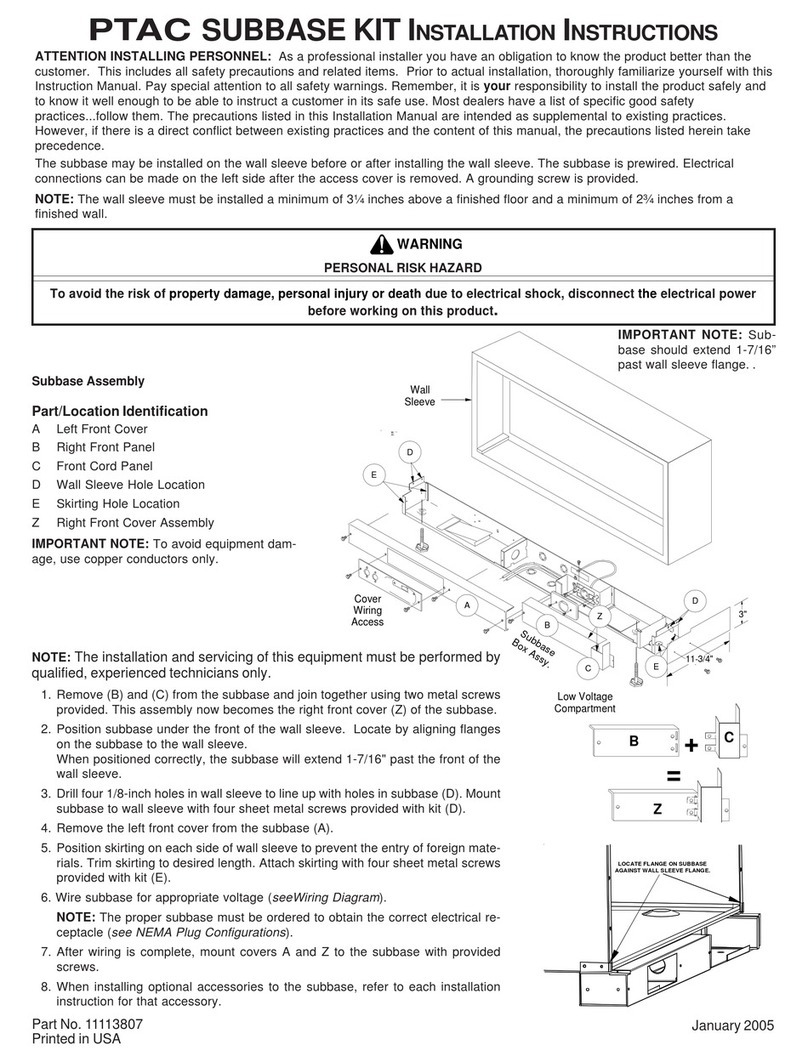

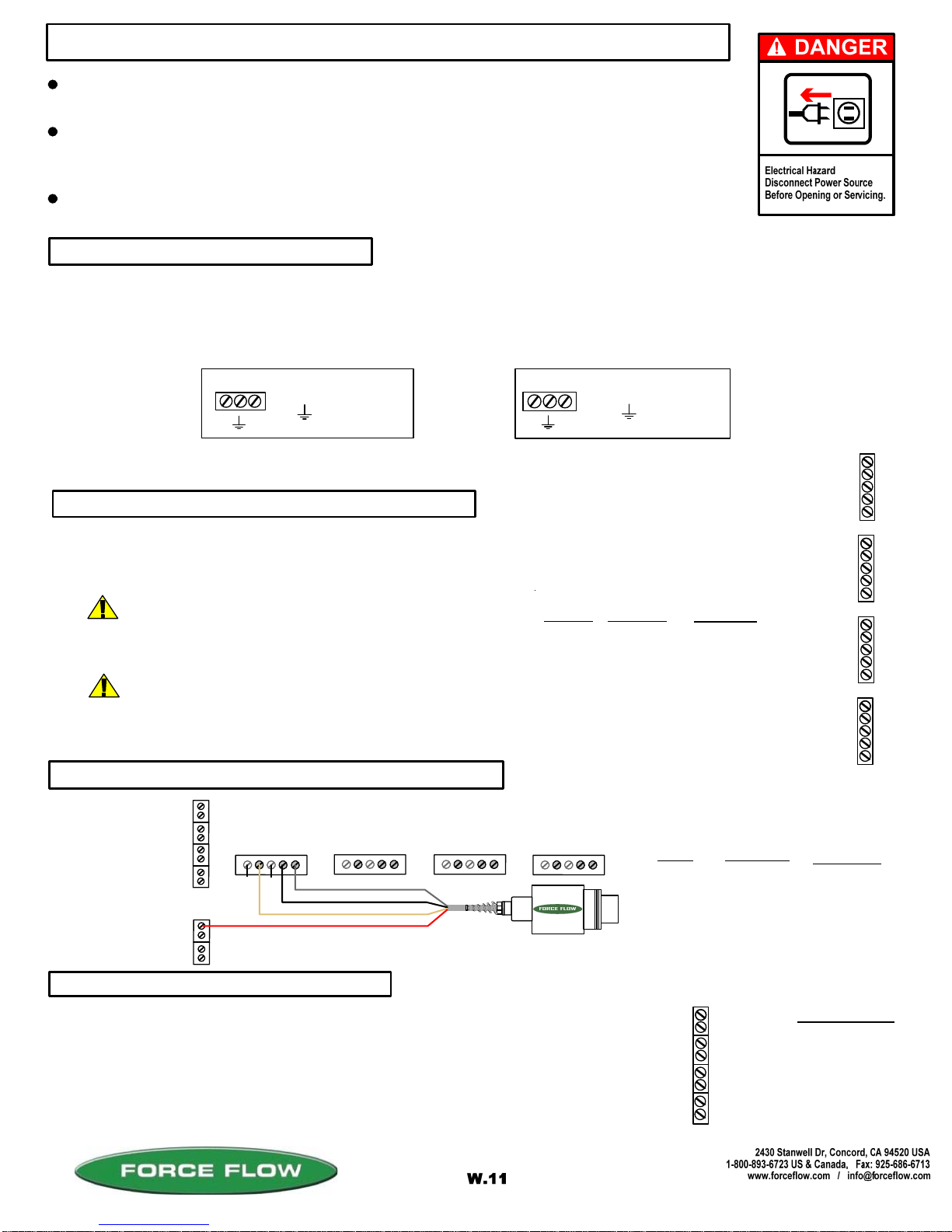

TURN OFF MAIN POWER BEFORE CONNECTING !! Use a dedicated 110/220 VAC (using 220 VAC requires

changing the voltage selector switch position to 220 VAC. This switch is located between the incoming power

connector and the power transformer) power line, connected directly to the main power panel at the facility. DO NOT

connect any other inductive loads, relays, etc. to this power line ! Resulting power surges can damage the

electronics !!! Use far left bottom port and connect per following: (NOTE: Use 1/2" conduit connector)

QUESTIONS ? Help Hotline: 1-800-893-6723

Your 4-20 MA signals are internally powered for up to 900 OHMS each.

DO NOT use external loop power. Run 4-20 MA wiring up the right hand

side of enclosure using the cableclamps to keep wires off of PC Board.

(NOTE: Use 1/2" conduit connector). If more than one (1) 4-20 MA

signal is used, you may use the same conduit and connector, but DO NOT

run 4-20 MA signals with any other power lines, which carry an inductive load.

+ 4-20MA LOOP

- 4-20MA LOOP

DESCRIPTION

POWER IN (110 VAC)

The Wizard 4000 indicator is shipped with the load cell(s) already connected. If routing load cell cable through conduit

or trimming cable length, remove cable connector from motherboard, then cable from connector and finally cable from

Wizard enclosure. After routing cable through conduit or trimming length, reverse above procedure to reconnect. A

separate cord connector is provided into the enclosure for each load cell cable.

+ EXCITATION

+ SIGNAL

- SIGNAL

- EXCITATION

SHIELD

WIRE COLOR

RED

GREEN

WHITE

BLACK

BRAIDED WIRE

PC BOARD

+ X

+ S

- S

- X

SH

+X4

+S4

-S4

-X4

SH

+X3

+S3

-S3

-X3

SH

+X2

+S2

-S2

-X2

SH

+X1

+S1

-S1

-X1

SH

Scale#4

Scale#1

Scale#2

Scale#3

DESCRIPTION

-

+

-

+

-

+

-

+

14

13

12

11

Scale #4

= HOT

= GROUND

= COMMON

3 4-20 MA SIGNALS

2 IF "LOAD CELL" CONNECTION

1 POWER HOOK-UP

+ C

File: T4\NEW O&M 2007\W11 WIZ NEW PR328 WZININST.tcw

04/08/08 MT

Scale #3

Scale #2

Scale #1

+ C

+

C

WIZARD 4000 INDICATOR INSTALLATION & WIRING

ALL CONNECTORS HAVE A "PLUG-IN" FEATURE TO ASSIST IN CONNECTING WIRES.

REMOVE THE CONNECTOR FROM THE BOARD BEFORE ATTACHING WIRES.

ALWAYS SHUT OFF MAIN POWER, AS WELL AS POWER TO ANY AUXILIARY EQUIPMENT

THAT WILL BE INSTALLED IN THIS UNIT, BEFORE OPENING FRONT OF CASE !!

INDICATOR IS NOT APPROVED FOR USE IN HAZARDOUS LOCATIONS. IF YOUR INSTALLATION

CONSTITUTES AN EXPLOSIVE OR COMBUSTIBLE ENVIRONMENT, PLEASE CONSULT FACTORY

FOR SAFETY PRECAUTIONS.

2 IF "ULTRASONIC SENSOR" CONNECTION

P1

+X1

+S1

-S1

-X1

SH

+X2

+S2

-S2

-X2

SH

+X3

+S3

-S3

-X3

SH

+X4

+S4

-S4

-X4

SH

Scale #1 #2 #3 #4

RED (+ EXCITATION) to -V

WHITE or CLEAR to +MA

B LACK (GROUND) to - MA

SILVER or BARE (SHEID) to GRD

BOARD

P1

+SI

- X1

SH

WIRE COLOR

RED

WHITE

BLACK

SILVER

DESCRIPTION

+ EXCITATION

+ SIGNAL

GROUND

SHIELD

UNUSED

UNUSED

14

13

12

11

= HOT

= GROUND

= HOT

+

C

POWER IN (220 VAC)

OR

CHOOSE THE 2ND STEP THAT RELATES TO THE EQUIPMENT PURCHASED:

®

ROUTING CABLE IN CONDUIT

TRIMMING LOAD CELL CABLE

More than one load cell can be routed in a single

conduit. Load cells must not share conduit with

power lines or wiring from any inductive load.

Wizard 4000 is pre-calibrated at factory based on supplied cable lengths. Depending

on how much cable is trimmed, field recalibration of Wizard may be required for best

accuracy. Contact factory for more information.

(OPTION MODEL NO. WMA420)

CAUTION should be observed whenever box is open to avoid damage or memory loss by static

electricity. DO NOT touch any of the circuit board, other than the intended contact noted in these

instructions. Carpets especially can build up static electricity.

The Wizard display has been factory adjusted for standard "eye level" viewing.

If you install your indicator at a height other than eye level, you may adjust the

display angle for best viewing. Turn the blue screw potentiometer (R9 located

near the middle of the motherboard) clockwise or counter clockwise until display

appears correct at your viewing angle. The potentiometer is a 30 turn, no stop

design. A slight click will be heard when you reach min. or max. adjustment.

Be sure that indicator power circuit is sufficiently protected against transient lightning strikes

and power surges. Improper protection may void your warranty.

STATIC ELECTRICITY PROTECTION

LIGHTNING ~ SURGE PROTECTION:

6 DISPLAY VIEW ANGLE ADJUSTMENTS

5 RELAY OPTION

4 MODBUS SERIAL COMMUNICATION OPTION

QUESTIONS ? Help Hotline: 1-800-893-6723

W.12

File: T4\NEW O&M 2007\W12 WIZ NEW PR328 WZININ2A.tcw

05/23/08 MT

NO: Circuit IS complete until relay is activated. (i.e. turning OFF a pump)

RELAYS

NC: Circuit is NOT complete until the relay is activated. (i.e.turning ON a warning light).

#1

OUT(1)

IN(1)

OUT(2)

IN(2)

OUT(3)

IN(3)

OUT(4)

IN(4)

SOLID STATE relays for external apparatus (pumps, valves,

alarms, etc) may be ordered either Normally Open (NO) or

Normally Closed (NC).

SOLID STATE relays are rated at: 3amp Max. (fused @ 4amp) 1.5amp motorload.

The Wizard 4000 is provided with a separate 1/2" conduit connector for your relay wiring.

To format relays, go to SETUP MENU 12, "ALARM/RLY CONFIG".

DRY CONTACT relays (SCADA, PLC, etc) inputs may be ordered either Normally Open

(NO) or Normally Closed (NC).

DRY CONTACT relays are rated at: 0.5amp @ 12VDC maximum (fused @ 1amp).

#2

#3

#4

The Wizard 4000 is provided with a separate 1/2" conduit connector for your serial port

communication wiring. DO NOT co-locate inductive load wiring or power lines with

communication wiring. Attach your communication wiring per the following:

RS232 RS485

Data OUT line

+

_

R

G

T

RS485

J1

Data IN line

Signal Ground Positive

Negaitive

R9

Potentiometer (blue)

located near middle

of motherboard

FOR RS485 SHIFT JUMPER

TO RIGHT 2 PINS

FOR RS232

SHIFT JUMPER

TO LEFT 2 PINS

(OPTION MODEL NO's: W5ASP-OD, CD, OS, CS)

(OPTION MODEL NO's: WRS232 & WRS485)

J4

RS232

This function allows the user to find out the last time and date the

"Amount Used" display was cleared or reset for each scale.

Press "ENTER" key to continue.

ACTION REQUIRED:

DIGITAL DISPLAY:

2 DATE LAST CLEARED

1 ALARM HISTORY

USER MENU (WIZARD 4000)

QUESTIONS ? Help Hotline: 1-800-893-6723

W.13

File: T4\NEW O&M 2007\W13 WIZ NEW WZPR328 DAY1.tcw

03/21/08 MT

MENUS

USER SETUP

USER MENU

ALARM HISTORY 1

ALARM HISTORY

3 BL 9/25 9:10

USER MENU

DATE LAST CLRD 2

Step 1

Step 1

Step 2

CH# 1 CLEARED

Step 2

8/19/ 5 14:15

Displays DATE and TIME the "AMOUNT USED" function was

last cleared (for approximately 1 minute). Use the "MENU"

arrow keys to toggle through other channels. Example: Channel 1

was last cleared on 8/19/05 at 14:15 hours (2:15 pm).

3 CLEAR AMOUNT USED

USER MENU

CLR AMOUNT USED 3

Step 1

CLEAR ALL CHAN ?

Step 2

Clears or resets the "AMOUNT USED" and 'DAILY USAGE"

displays to zero.

SELECT CHANNEL

Step 3

NO YES

ARE YOU SURE

Step 4

, enter CH# 1

Press "ENTER" key to continue.

Use 'MENU" arrow keys to choose "NO" or "YES".

Press "ENTER" key to accept. Choosing NO takes

you to Step 3 to choose which channels. Choosing

YES asks "ARE YOU SURE?" and clears ALL channels

NO YES

Use 'MENU" arrow keys to choose which channel to clear.

Press "ENTER" key to accept.

Use 'MENU" arrow keys to choose "NO" or "YES".

Press "ENTER" key to accept.

A

llows the user to retrieve the time, date, and type of alarm for

the most recent 10 alarm conditions.

3 = Channel

You may scroll through these items with the "MENU" arrow keys, or simply

enter the Menu Item Number to jump straight to that menu item.

MENU Arrow Keys: There are 2 menus that may be accessed via the "MENU" keys. The "USER" Menu

and "SETUP" Menu. The "USER" Menu has 8 menu items, and these are functions that are used for

day-to-day operations. The "SETUP" Menu has 17 menu items, and these are functions that are used

during equipment start-up, or if your chemical feed operation has been changed.

ALARM CODE ABREVIATIONS: 3 B L

A = Setpoint A

B = Setpoint B

R = Feedrate

D = Daily

LC = Load Cell Failure

BK = Low Bulk Supply

SF = Slow Fill

H = High

L = Low

Press "ENTER" key to continue.

Channel 3 had a SETPOINT B LOW LEVEL condition

on 9/25 at 09:10 hours (9:10 am). Press "ENTER" key

to continue. "DEL" key to return to "USER" menu.

Sets time and date.

Press "ENTER" key to continue.

ACTION REQUIRED:

DIGITAL DISPLAY:

5 SET TIME & DATE

USER MENU continued...

QUESTIONS ? Help Hotline: 1-800-893-6723 W.14 File: T4\NEW O&M 2007\W14 WIZ NEW PR328 DAY2.tcw

03/21/08 MT

USER MENU

VIEW TOTAL 4

CHAN 1, 2

tNET 26.0 LB

USER MENU

SET TIME & DATE 5

Step 1

Step 1

Step 2

6 SET BULK SUPPLY

This display shows that the total Net weight of channels 1 and 2

is 26.0 lbs. Press enter again for total feed rate of channels 1 &

2, and again for total usage on channels 1 & 2.

SET TIME & DATE

Step 2

Example: YEAR 2005 = "5", YEAR 2010 = "10"

Press "ENTER" key after each enter to get

MONTH, DAY, HOUR and MINUTES.

Note: Use Military time for HOURS (1 to 24).

YEAR=

MONTH=

DAY=

HOURS=

MINUTES=

5

9

27

14

15

Press "ENTER" key to continue.

USER MENU

SET BULK SUPPLY 6

Step 1

A

llows user to view the remaining inventory in their bulk supply

tank even though they have no level sensor hooked up to the

bulk tank. Before filling your day tank, press the “TANK LOAD”

key & follow the menu prompts. The Wizard will then subtract

how much is added to the day tank from the remaining bulk

supply number. This function must be turned on under the

BULK SUPPLY selection in the SET UP MENU. Press “ENTER”

key to continue.

#2 BULK SUPPLY

LBS = 2900

Step 2 This display shows that Channel #2 has a bulk supply tank that

contains 2900 lbs of chemical

7 VIEW TARE

USER MENU

VIEW TARE 7

Step 1

#3 VIEW TARE

LBS = 25.0

Step 2

Press "ENTER" key to continue.

Tare weight will be displayed. Example: Channel #3

tare weight is 25.0 lbs.

A

llows users to view the tare weight of their tank. This function

is only active when the system is configured for “portable

tanks” like chlorine, drum, carboy and tote scales.

4 VIEW TOTAL

A

llows user to view the combined Net, Rate and Usage for more

than 1 channel. This function must be configured under the

SETUP VIEW TOTAL selection in the SET UP MENU. Allows you

to choose which channels to total.

Press "ENTER" key to continue.

tNET = Net Weight

tRATE = Feed Rate

tUSED = Total Usage

ACTION REQUIRED:

DIGITAL DISPLAY:

USER MENU continued...

QUESTIONS ? Help Hotline: 1-800-893-6723

W.15

File: T4\NEW O&M 2007\W15 WIZ NEW PR328 DAY3.tcw

03/21/08 MT

USER MENU

SET ZERO 9

SET ZERO

NO YES

Step 1

Step 2

8 SET ZERO

SELECT CHANEL

, enter CH# 1

Step 3

Allows user to "zero" the scale or sensor when tank or

scale is empty. If tank is not empty but weight of chemical

in tank is known, SET ZERO allows user to adjust display

to read this known weight.

Press "ENTER" key to continue.

Select channel (scale or sensor number) using arrow keys,

then press ENTER.

NOTE:

If system was not initially zeroed BEFORE chemical was added to tank, the NET WT

may not accurately reflect the actual amount in tank.

To adjust without emptying tank, use the zero function located in SETUP MENU 15,

"FIELD CAL". That zero function prompts for MINIMUM AMOUNT (amount of chemical

currently in tank).

ARE YOU SURE

Step 3

NO YES

Use MENU keys (UP/DOWN ARROWS) to select NO or YES,

then press ENTER.

Use MENU keys (UP/DOWN ARROWS) to select NO or YES,

then press ENTER.

Press "ENTER" key to continue.

ACTION REQUIRED:

DIGITAL DISPLAY:

1 DISPLAY FORMAT

QUESTIONS ? Help Hotline: 1-800-893-6723

W.16 File: T4\NEW O&M 2007\W16 WIZ NEW PR328 SETUP1.tcw

03/21/08 MT

SETUP MENU

DISPL FORMAT

1

SELECT FORMAT

SINGL DUAL

Step 1

Step 2

2 CHANNEL ID

SETUP MENU

# CHANNEL ID # 2

Step 1

#1 CHANNEL ID#

Step 2

Press "ENTER" key to continue.

NUMBER = 1

AUTO SCAN ?

NO YES

Step 3

ALTERNATING TIME

SECONDS = 6

Step 4

Configures how many channels are displayed simultaneously,

and whether the auto scan is engaged.

Choose a single channel to be displayed, or 2 channels to be

displayed if a multichannel indicator is being used.

Use “MENU” arrow keys to select. If “YES” is selected, the

Wizard will automatically scan all the channels in the Wizard

without the operator having to touch any keys. Display Format

menu is exited if “NO” is selected.

A

llows you to set the scan time period in seconds from one

channel to the next.

If there are multiple Wizard controllers on a single site, this

function allows you to assign an Identification Number from 1-

99 for each channel.

Use the numeric keypad to enter any number from 1 to 99.

3 100 PERCENT

SETUP MENU

100 PERCENT 3

Step 1

#1 100 PERCENT

Step 2

Press "ENTER" key to continue.

GAL = 400.00

A

llows you to tell the Wizard what value you consider 100% full.

This will calibrate the BAR GRAPH and PERCENT function for

the “Display Select” key.

Enter value that you consider 100% full.

MENUS

USER SETUP

You may scroll through these items with the "MENU" arrow keys, or simply

enter the Menu Item Number to jump straight to that menu item.

SYSTEM ADDRESS

Step 3

NUMBER = XXX

Set MODBUS device address (1 to 247)

*Only visible if OPTIONAL MODBUS Serial Communication enabled.

MENU Arrow Keys: There are 2 menus that may be accessed via the "MENU" keys. The

"USER" Menu and the "SETUP" Menu. The "USER" Menu has 8 menu items and these are

functions that are used for day-to-day operations

The "SETUP" Menu has 17 menu items, and these are

functions that are used during equipment startup,

or if your chemical feed operation has been changed.

Press "ENTER" key to continue.

ACTION REQUIRED:DIGITAL DISPLAY:

4 AUTO LOAD

SETUP MENU continued...

QUESTIONS ? Help Hotline: 1-800-893-6723

W.17

File: T4\NEW O&M 2007\W17 WIZ NEW PR328 SETUP2.tcw

SETUP MENU

AUTO LOAD 4

#1 TANK NET

LBS = 2000

Step 1

Step 2

6 MOTION BAND

SETUP MENU

MOTION BAND

6

Step 1

#2 MOTION BAND

Step 2

Press "ENTER" key to continue.

GAL = .02

For portable tank (load on/ load off) applications, this allows

you to set the net weight of the container so that when using

the “TANK LOAD” key, the Wizard will automatically load the

net weight of the containers that you are loading.

Enter the value of the net weight that your containers are

filled with: Examples

2000 lbs = Ton Containers USA

150 lbs = 150 lb cylinders USA

907 kgs = Canadian ton containers

1000 kgs= Metric ton containers

Press "ENTER" key to continue.

5 FILTER BAND

SETUP MENU

FILTER BAND

5

#1 FILTER BAND

GAL = 0.70

Step 1

Step 2

A

llows you to steady a fluctuating display. This function will only help

smooth out fairly rapid fluctuations. Slow, long term fluctuations (over

minutes or hours) will likely not be corrected by changing the filter

value. Contact factory for assistance in correcting slow, long term

display fluctuations.

A

llows you to steady a fluctuating display. This function will only help

smooth out fairly rapid fluctuations. Slow, long term fluctuations (over

minutes or hours) will likely not be corrected by changing the filter

value. Contact factory for assistance in correcting slow, long term

display fluctuations.

Menu operations such as TANK LOAD, ZERO and FIELD

CALIBRATION require the Wizard in certain steps to store a weight

value before moving to the next step. MOTION BAND determines how

steady the weight reading is required to be before the Wizard accepts

the value and continues on. The greater the value, the greater the

fluctuation allowed.

Changing this value will rarely be required. If a menu operation will not

advance from the “Wait …” screen, you may ESC from the operation

then increase this value and try the function again. The “WAIT . . .”

screen indicates the Wizard is waiting for the weight to stabilize

(sloshing chemical in tank) to a value within the MOTION BAND value.

This value can be set to any number greater than 0.

ACTION REQUIRED:DIGITAL DISPLAY:

SETUP MENU continued...

QUESTIONS ? Help Hotline: 1-800-893-6723

W.18

File: T4\NEW O&M 2007\W18 WIZ NEW PR328 SETUP3.tcw

PERIOD BASE

MIN HOUR

Step 3

Step 4

Use "MENU" arrow keys to choose MINUTES or HOURS.

Press "ENTER" key to accept.

UPDATE PERIOD

MINUTES = 1

Step 5 SHIFT START HOUR

0 - 23 0

Step 6 #2 PAUSE/PROJ

NO YES

Use the “MENU” arrow key to choose NO or YES. Choosing

YES turns on the “PAUSE & PROJECT” feature which allows

the Wizard to keep track of chemical usage while your tank is

getting refilled. By pressing the “TANK LOAD” key before and

after your tank fill is done, the Wizard calculates how much

was used during the fill process based on total time and most

recent feed rate. The Wizard then adds this amount back to

your usage data.

Enter the hour at which you want the daily usage accumulator

to begin (in military time). “0” is midnight; 8 is 8am, 13 is 1pm,

etc.

Use "MENU" arrow keys to update increment. Press "ENTER"

key to accept.

MIN Choices: 1, 2, 5, 10, 20, 30, 60

HOUR Choices: 1, 2, 4, 6, 8, 12, 24

7 SYSTEM TIME BASE

SETUP MENU

SYSTEM TIME BASE

Step 1

Step 2

Press "ENTER" key to continue.

RATE TIME BASE

HOUR DAY

A

llows configuring of feed rate update periods, daily usage

update periods, and whether the pause and project function

is used.

Use "MENU" arrow keys to choose time base of

HOUR or DAY. Press "ENTER" key to continue.

7

Allows you to choose between "Lbs (or Gallons) per day" and "Lbs. (or gallons) per hour" and allows you

to set your sample time or "update period" for your feed rate function.

IMPORTANT NOTE FOR SETTING UP YOUR "UPDATE PERIOD":

In general, if your feed rates are fairly constant on a daily basis, the longer you set your update period for,

the more accurate your feed rate function will be. However, if your feed rate varies from hour to hour or

minute to mintue, choose a shorter update period to give you a more accurate feed rate at a point in time.

You may have to experiment with different update periods to get the desired result for your application.

For certain applications with very low feed rates (less than 2% of full scale capacity per day), low sample

times will not give you accurate readings.

Use a Longer

Update Period

HIGH FEED

CONSTANT

LOW FEED (less than 2% capacity/day)

N/A (Not Accurate)

Use a Short

Update Period

Use a Short or

Long Update Period

FLUCTUATING

ACTION REQUIRED:

DIGITAL DISPLAY:

SETUP MENU continued...

QUESTIONS ? Help Hotline: 1-800-893-6723 File: T4\NEW O&M 2007\W19 WIZ NEW PR328 SETUP4.tcw

04/08/08 MT

Step 2 #2 MONITOR BULK

NO YES

9 BULK SUPPLY

SETUP MENU

BULK SUPPLY

Step 1

Press "ENTER" key to continue.

9

# OF 4-20 PORTS

2 ACTIVE

Step 2

P1 USED FOR CH #

Step 3

, enter 1

PORT 1 CHAN 1

Step 4

, enter NET

PORT 1 RANGE FS

Step 5

GAL = XXXX.X

Momentarily displays number of active 4-20mA ports, then

automatically advances to Step 3.

Designate whether you would like NET, RATE, DAILY USAGE

or BULK data to be sent out on this port. Use the the “MENU”

arrow key to select then press “ENTER” key to continue

Use the numerical keypad to input what full scale output you

would like 20 mA to be equal to. 4 mA is always equal to 0.

Use "MENU" arrow keys to choose NO or YES, then press

"ENTER" key to continue.

SETUP MENU

CONFIG 4-20 OUT

Step 1

8 CONFIG 4-20mA OUT If you have 4-20 mA output hardware installed on your

motherboard, this allows you to configure your 4-20 outputs to

send either: NET; RATE; DAILY USAGE or BULK TANK data,

and set full scale value ( 20 mA = full scale).

Press "ENTER" key to continue.

8

FIXED TANK APPLICATIONS ONLY:

Step 2 #1 AUTO REFILL

LEVEL BATCH

10 AUTO REFILL

SETUP MENU

AUTO REFILL

Step 1 Press "ENTER" to continue to next screen.

10

Continued...

This option is used for stationary day tanks that refill their

Chemical from a bulk supply tank. By turning this function

on, it allows you to inferentially track remaining chemical in

the bulk supply tank.

This item is only available if you have purchased the

ARC4000 option.

LEVEL mode: Fills tank to preset level.

BATCH mode: Fills (adds) preset amount.

Designate which channel (1-4 or "TOTALS" you would like Port 1

(P1) output to be on. Use "MENU" arrow keys to select then press

"ENTER" key to continue. Repeat process for additional ports.

(OPTION MODEL NO. ARC4000)

Step 3 #1 AUTO REFILL

SEMI AUTO

SEMI requires operator to initiate fill using TANK LOAD key.

AUTO begins refill automatically.

(LEVEL MODE ONLY)

Other manuals for WIZARD 4000

2

Table of contents

Other Force Flow Accessories manuals