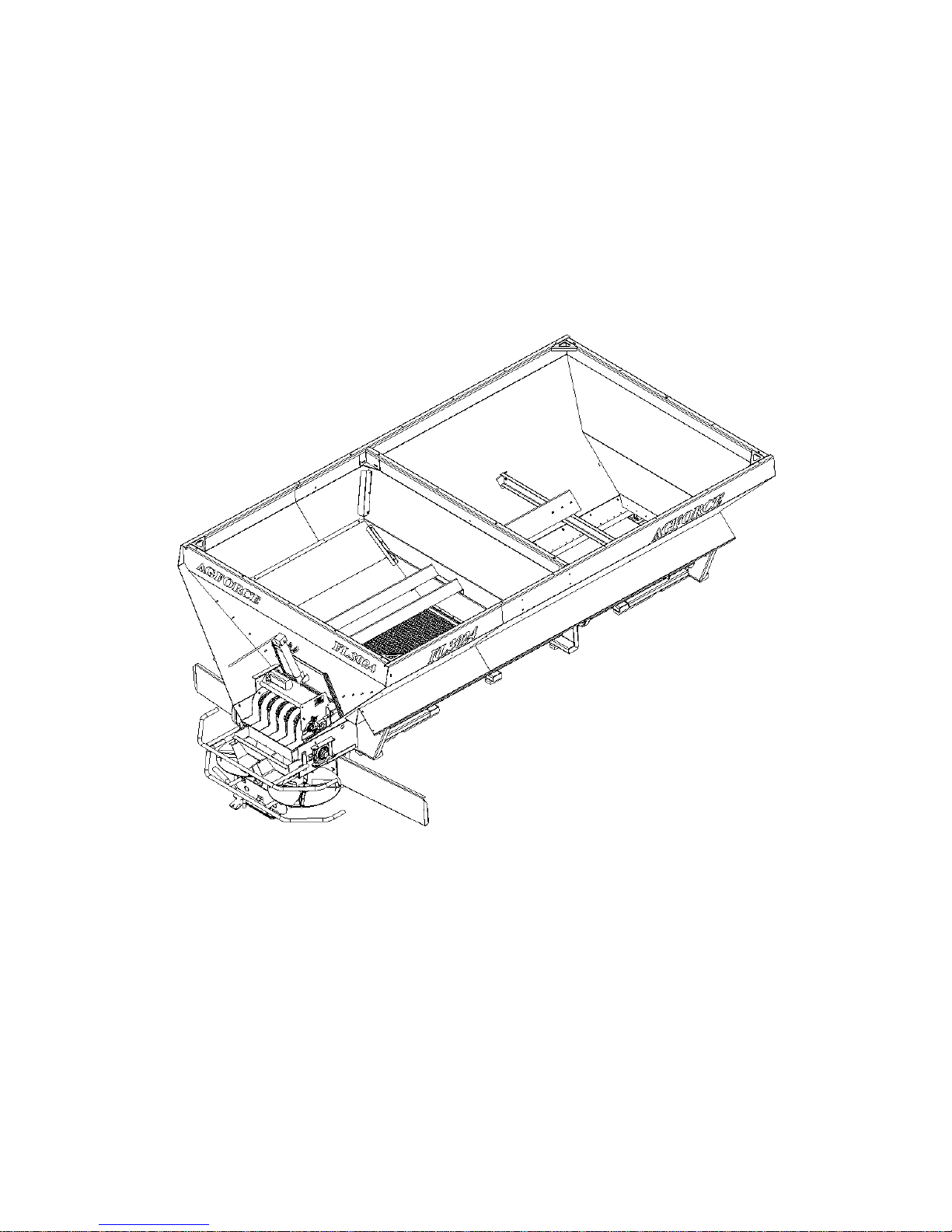

FORCE Unlimited DUO-FORCE Operating and maintenance manual

DUO-FORCE

By FORCE Unlimited

FORCE Unlimited

1504 S. Frederick Avenue

Oelwein, IA 50662

(319) 283-4863

www.forceunltd.com

FOR AGFORCE FL3024

F

F

F

O

O

O

R

R

R

C

C

C

E

E

E

U

U

U

N

N

N

L

L

L

I

I

I

M

M

M

I

I

I

T

T

T

E

E

E

D

D

D

L

L

L

L

L

L

C

C

C

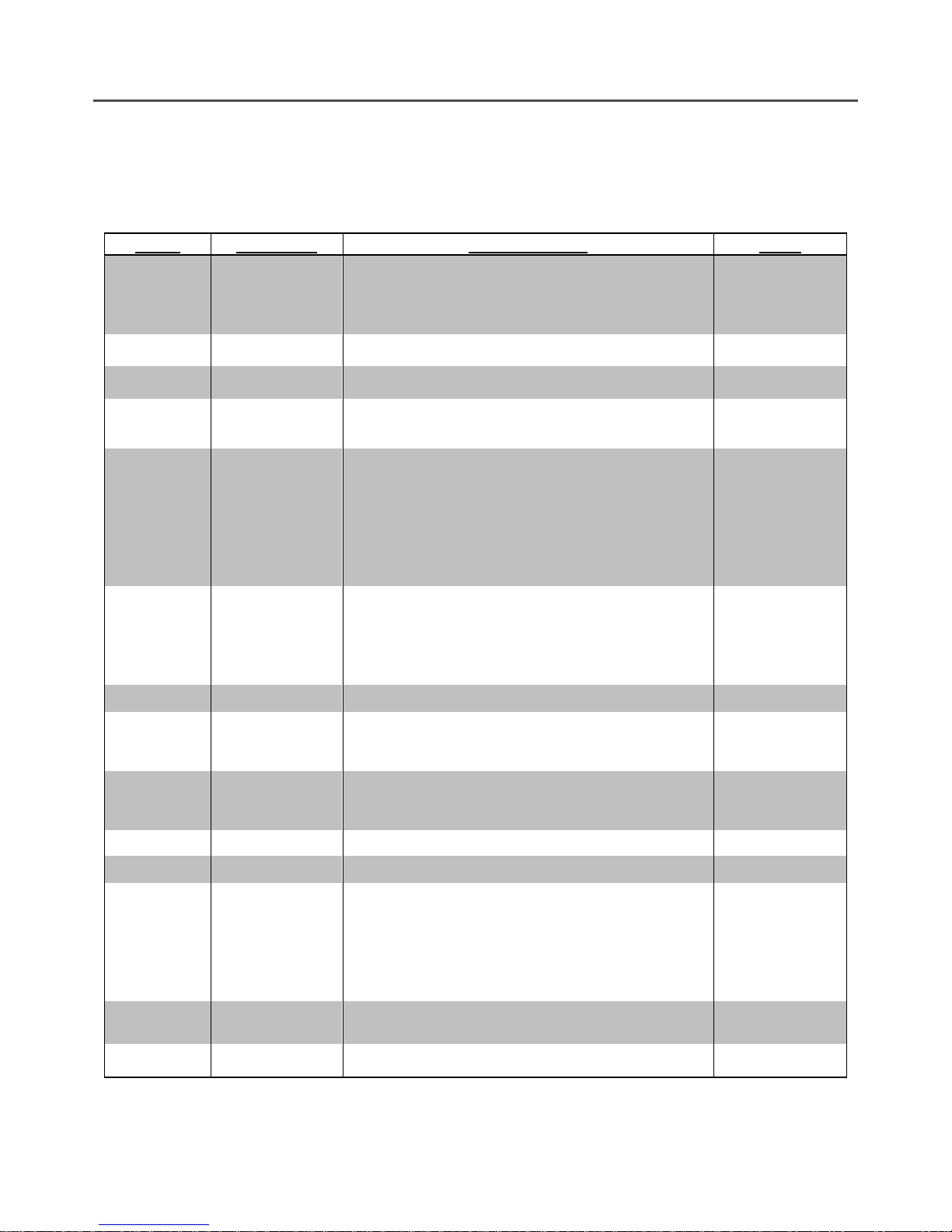

LIMITED WARRANTY

COMPANY NAME: _________________________________________________

COMPANYADDRESS: ______________________________________________

CITY: _______________________________ STATE: _______ ZIP: ___________

MODEL: ________________________________________

SERIAL NUMBER: _______________________________

DATE PURCHASED: _____________________________

DEALER NAME: ________________________________

DATE WARRANTY CARD RETURNED: _____________

VIA: _____ WEBSITE _____ MAIL

FORCE UNLIMITED LLC

LIMITED WARRANTY

FORCE Unlimited LLC has manufactured or is distributing the Product or Parts to which this warranty is attached.

It warrants that the Product or Parts will, under normal conditions of use and service, be free from material defects

due to faulty manufacturing for a period of twelve (12) months from the date of delivery to the original user. If any

Product or Part does not conform to this warranty, your Dealer will, at its option, repair or replace parts provided,

and you will pay all labor costs and costs for materials other than warranty parts. If Product or Part is defective in

materials or workmanship, you must promptly notify your Dealer and return to FORCE Unlimited or fax to 319-

283-3086 the warranty registration card within 30 days from the date of delivery to original user. The installation

of any Part that did not originate from FORCE Unlimited will void this limited warranty in its entirety. In the

event of repair or replacement, the warranty period shall not be extended beyond the original warranty period.

If you fail to return the warranty registration card (in parts manual) to FORCE Unlimited within thirty (30)

days after the date of delivery, this warranty shall not apply and your remedy for any defects in the Product

will be your responsibility.

The above warranty does not cover:

a. Product that is damaged by abuse, neglect, accident, or modification

b. Fluids, towing, telephone, travel, loss of vehicle, inconvenience

c. The product itself if parts are installed on the equipment that did not originate from FORCE Unlimited

The above warranty does not apply under the following conditions:

a. When Product has been improperly used or installed, modified, or fails because of defects or

inefficiency of components not furnished with the Product

b. When Product is used for purposes for which it was not originally designed or intended, or is used

under abnormal operating conditions

c. When the Dealer or end-user fails to follow FORCE Unlimited instructions regarding the Product

This warranty is extended only to the original user and is not transferable. In the event of a warranty claim,

you should promptly notify your Dealer and provide the following:

a. Model & serial number of the Product

b. Date of delivery to the original user

c. Part number of the defective Part

d. Description of the claim encountered

FORCE Unlimited LLC will bear no other expense including labor and material costs, other than those

specified above. Unless modified in writing and signed by both parties, this Limited Warranty is understood

to be the complete and exclusive agreement between the parties. No third party has authority to change or

modify this warranty in any aspect.

LIMITED WARRANTY

2 YRS

SHELL STRUCTURE, SPINNER FRAME (including inferior welds & cracking)

CONVEYOR GEARBOX (including gears, bearings & seals)

1 YR

SPINNER MOTORS & ADAPTERS (including bearings & seals)

CONVEYOR MOTORS (including bearings & seals)

VALVE MOTORS & CARTRIDGES

CONVEYOR CHAIN – BELT & FASTENERS

CONVEYOR SPROCKETS & BEARINGS

FAN & CONVEYOR RATE SENSORS

WEAR ITEMS

SPINNER FINS

SPINNER DISCS

MANUFACTURER HAS THE RIGHT TO REPLACE DEFECTIVE OR DAMAGED PARTS

WITH NEW OR REBUILT AT ITS OWN DISCRETION

PARTS DAMAGED FROM ABUSE OR IMPROPER MAINTENANCE NOT COVERED

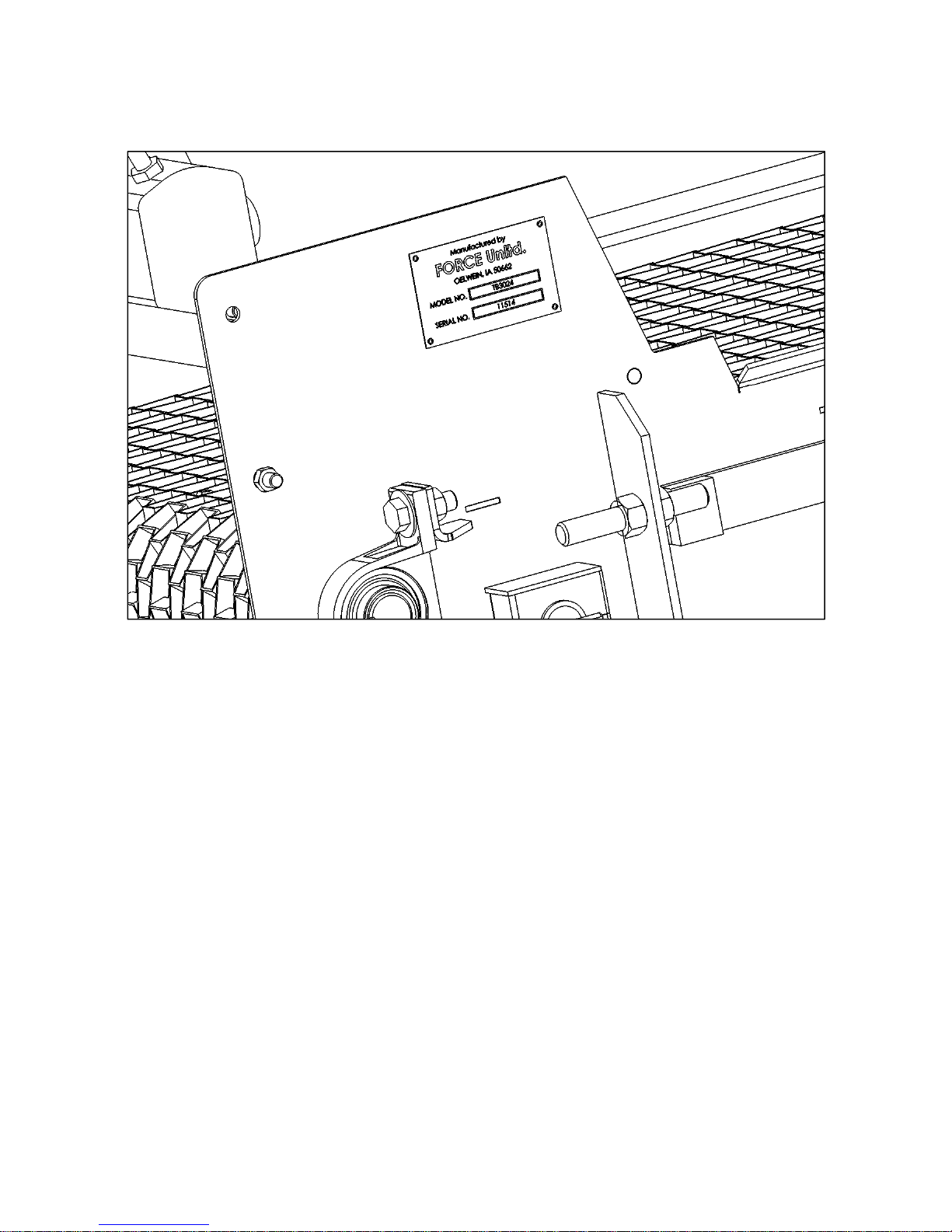

NOTE: THIS INSTRUCTIONAL MANUAL AND PARTS BOOK

ONLY APPLIES TO DUO-FORCE UNITS S/N 11514 AND AFTER.

IF YOUR UNIT USES RUBBER SEALING STRIPS INSTEAD OF

STAINLESS STEEL, OR HAS A SERIAL NUMBER PRECEDING

11514, CALL FORCE UNLTD. TOLL FREE AT 1-800-632-5986 FOR

DETAILS.

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Table of Contents

Table of contents

item

Page no.

Instructional Manual

Initial Setup & Maintenance

1

Duo-Force Removal

2

Duo-Force Installation

4

Duo-Force Valve Block Visual Reference

9

Parts Manual

Hydraulic System

DF-1.1

Conveyor Drive

DF-2

Take-Up and Flow Reducer

DF-3

Panel Assembly

DF-4

Dual Inverted “V”

DF-5

Hillside Flow Divider

DF-6

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 1

Duo-force

Initial setup & maintenance

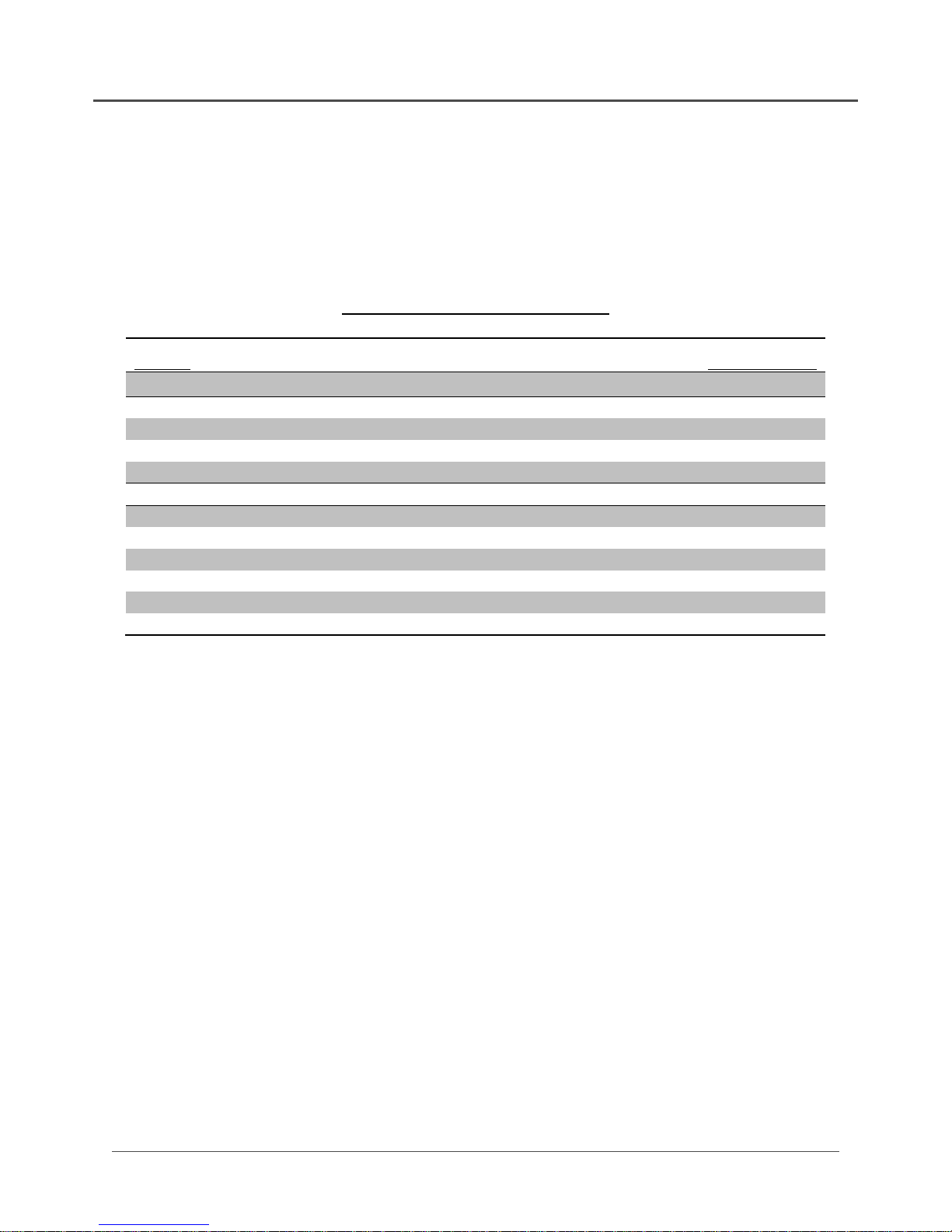

Sprocket Locations

FRONT OF BOX

BELT TRAVEL

NOTES:

1.) When flat wire belt is

properly tightened, you should

be able to lift the center of the

belt 1” – 1 ½” off the

conveyor bed.

2.) Check tension of 60 series

roller chain and flat wire

belting daily for first week of

operation and weekly

thereafter.

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 2

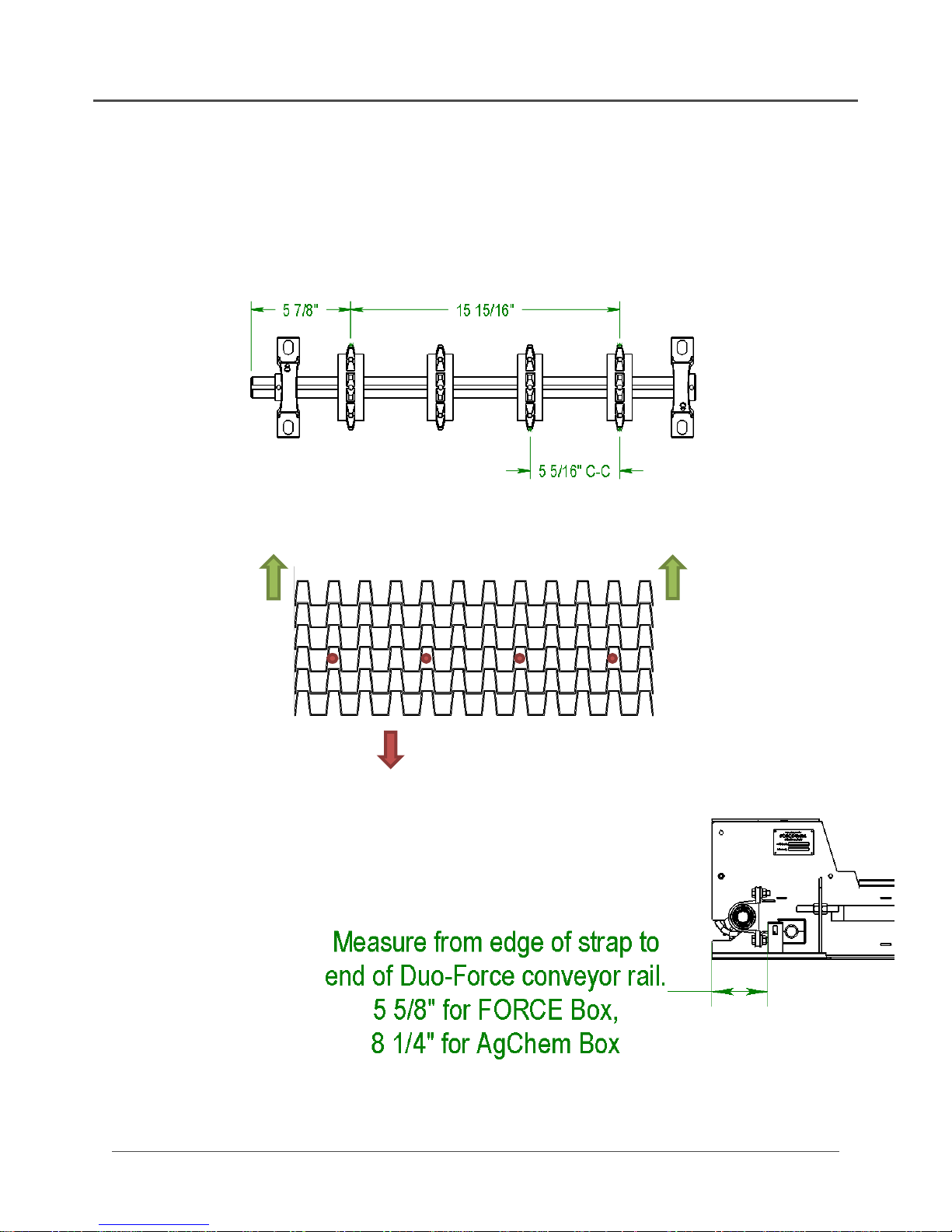

DUO-FORCE REMOVAL

1.) Unplug rate sensor (3 pin connector)

2.) Unplug bin level sensor if equipped

3.) Disconnect hydraulic hoses from motor

(Fig. A) and connect them together.

DO NOT plug the hoses!!

4.) Remove the tab bolts from each side of

the Duo-Force conveyor that are

common with the second-to-last chain

shield bolt on each side.

5.) Remove Hillside Flow Divider by

removing (2) bolts at rear of Duo-Force

insert. (Fig. B) Hillside Flow Divider will

then slide out.

6.) If necessary, loosen the four Take-Up

Cover Sealer bolts to release tension

(Fig. C)

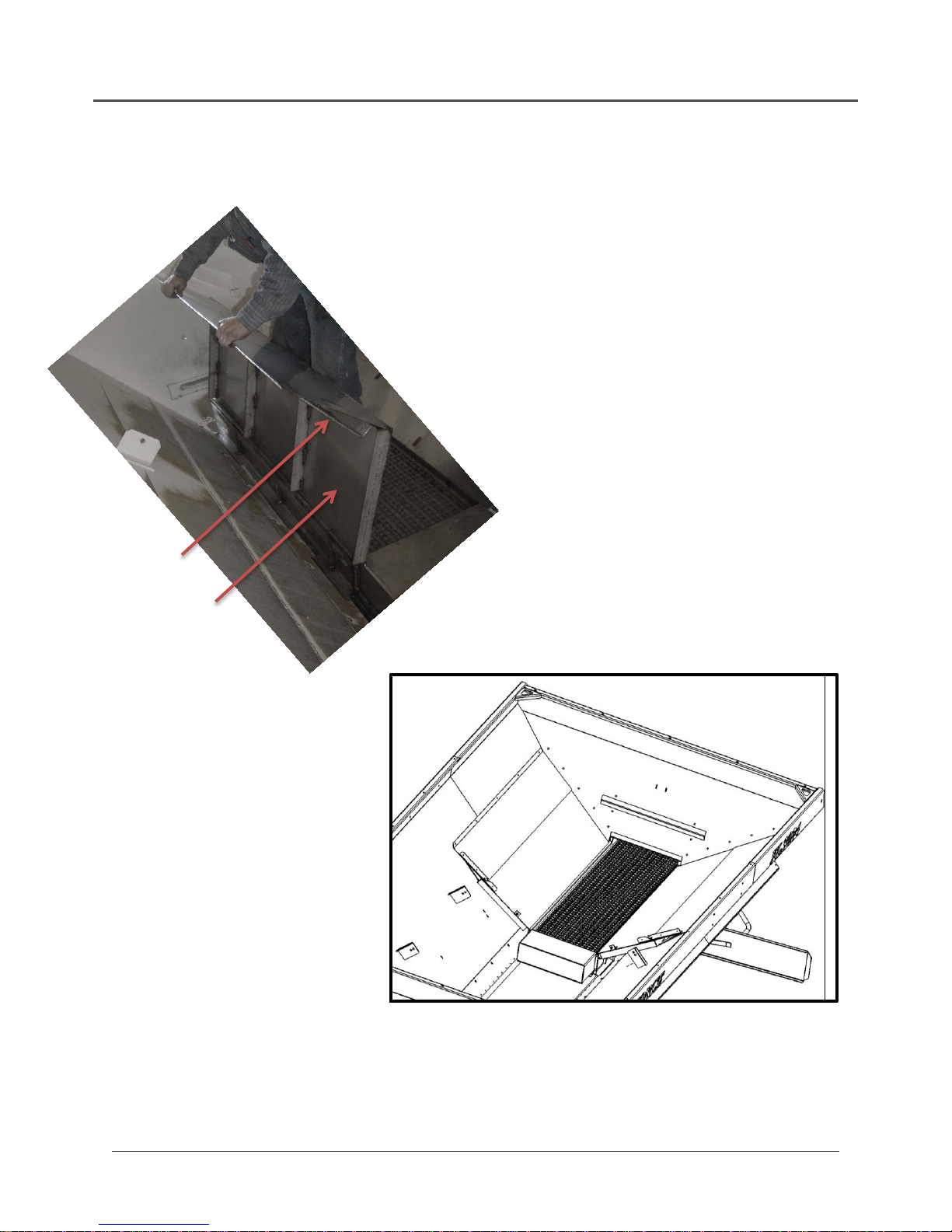

7.) With a second person monitoring from

inside the AgForce box, insert fork truck

forks under the Duo-Force insert and

carefully slide it out (Fig. D)

8.) Remove Hinged Panel bolts to allow

Hinged Panels to swing and lay down

on AgForce box sides (Fig. E)

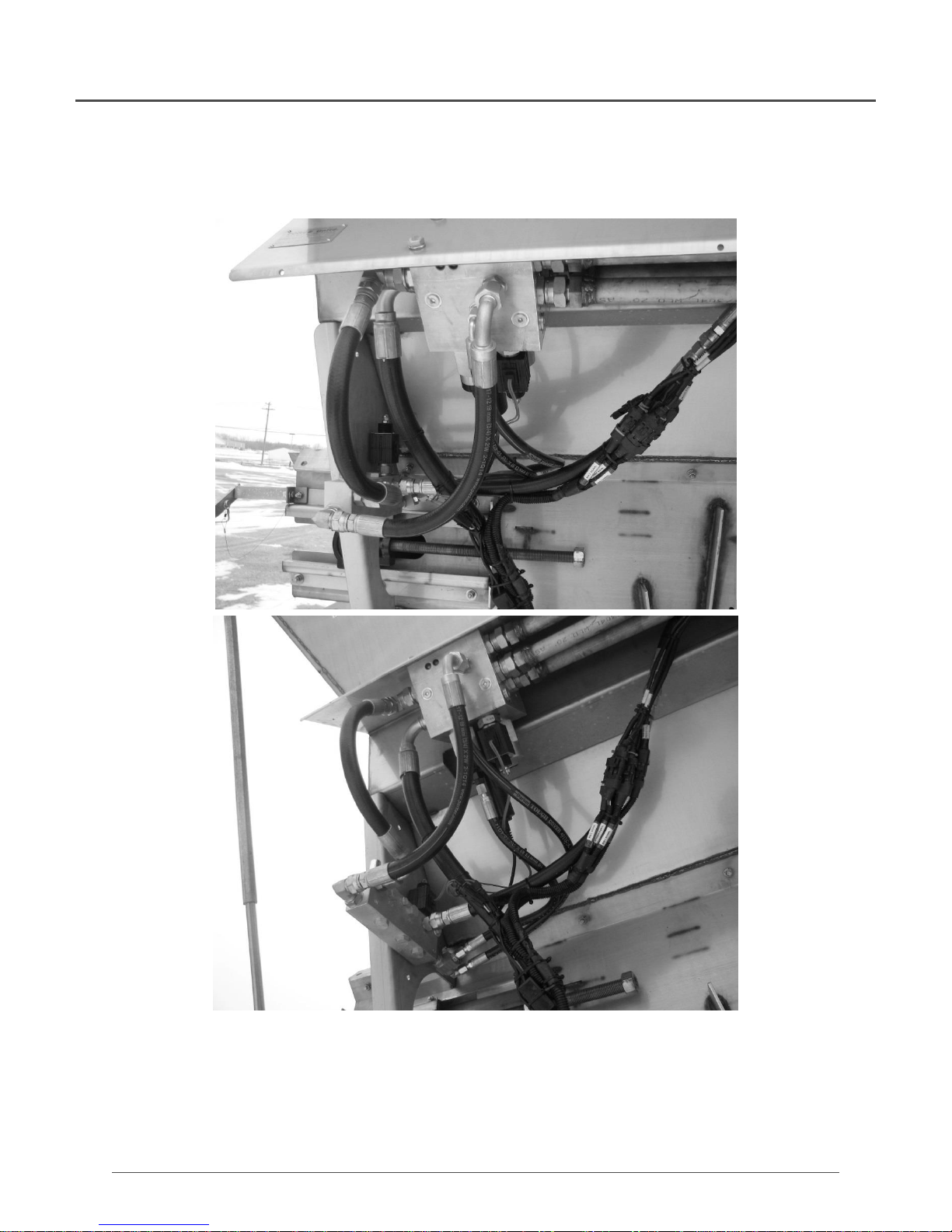

Fig. A

Fig. B

Fig. C

Note: Inverted “V” removed for clarity

Note: It is not necessary to remove

either Box Divider or the Inverted “V”. If

greater flow is desired, the Lower Box

Divider can be removed.

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 3

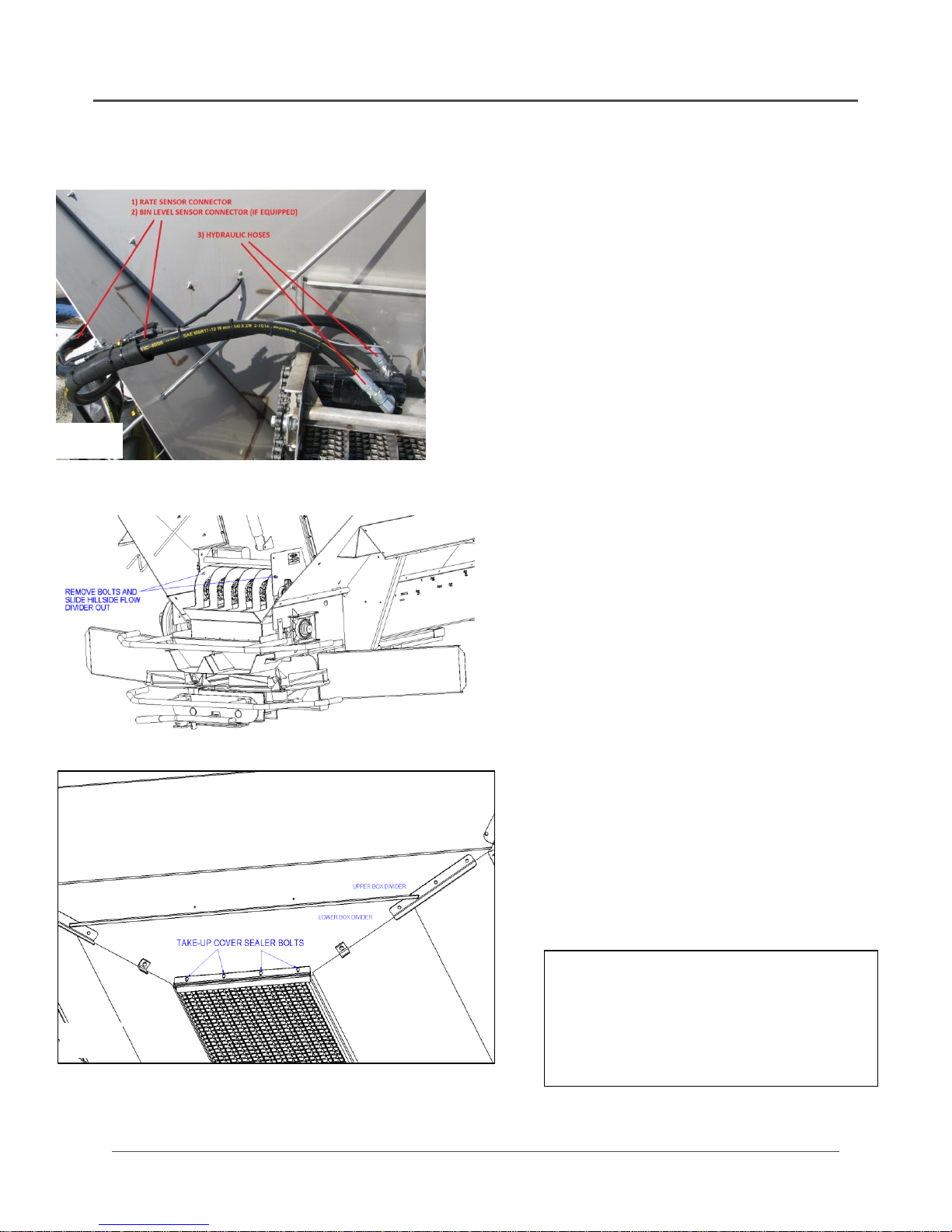

DUO-FORCE REMOVAL (Continued)

Fig. D Removing Duo-Force insert with fork truck

Fig. E Removing Hinged Panel Bolts

Inverted “V” removed for clarity

NOTE: Hinged Panels MUST be

re-fastened to the Box Divider

before reinstalling the Duo-Force

conveyor insert

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 4

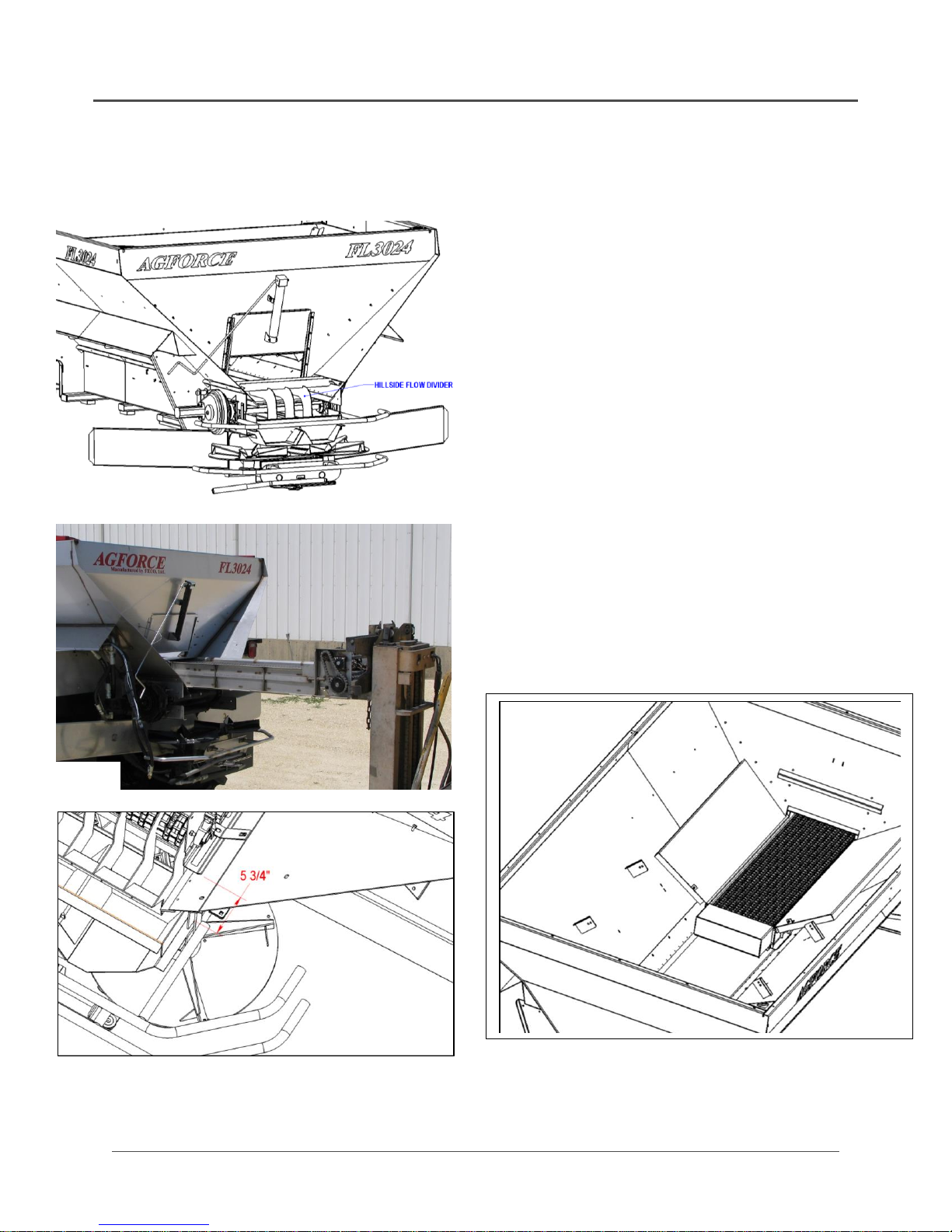

Duo-force installation

1.) Open Feedgate all the way and remove

Hillside Flow Divider and its brackets (Fig. A)

DO NOT replace chain shield bolts that were

common to the Hillside Flow Divider brackets

yet

2.) Using a fork truck, insert Duo-Force conveyor

insert (Fig. B)

3.) Slide conveyor insert in so that brackets align

with second chain shield bolt holes. Make

sure that brackets are bolted to conveyor

insert properly (See Instructional Pg. 1).

Measurement from end of Duo-Force

conveyor insert to end of AgForce chain

shield should be 5-3/4”(Fig. C). Replace

chain shield hardware

4.) Place Hinged Panels in box as shown in Fig. D

Fig. A

Fig. B

Fig. C

Fig. D

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 5

DUO-FORCE INSTALLATION (continued)

1.) Sdg

2.) Asdf

3.) Asdf

4.) Asd

5.) Asdg

6.) Asd

7.) Asdf

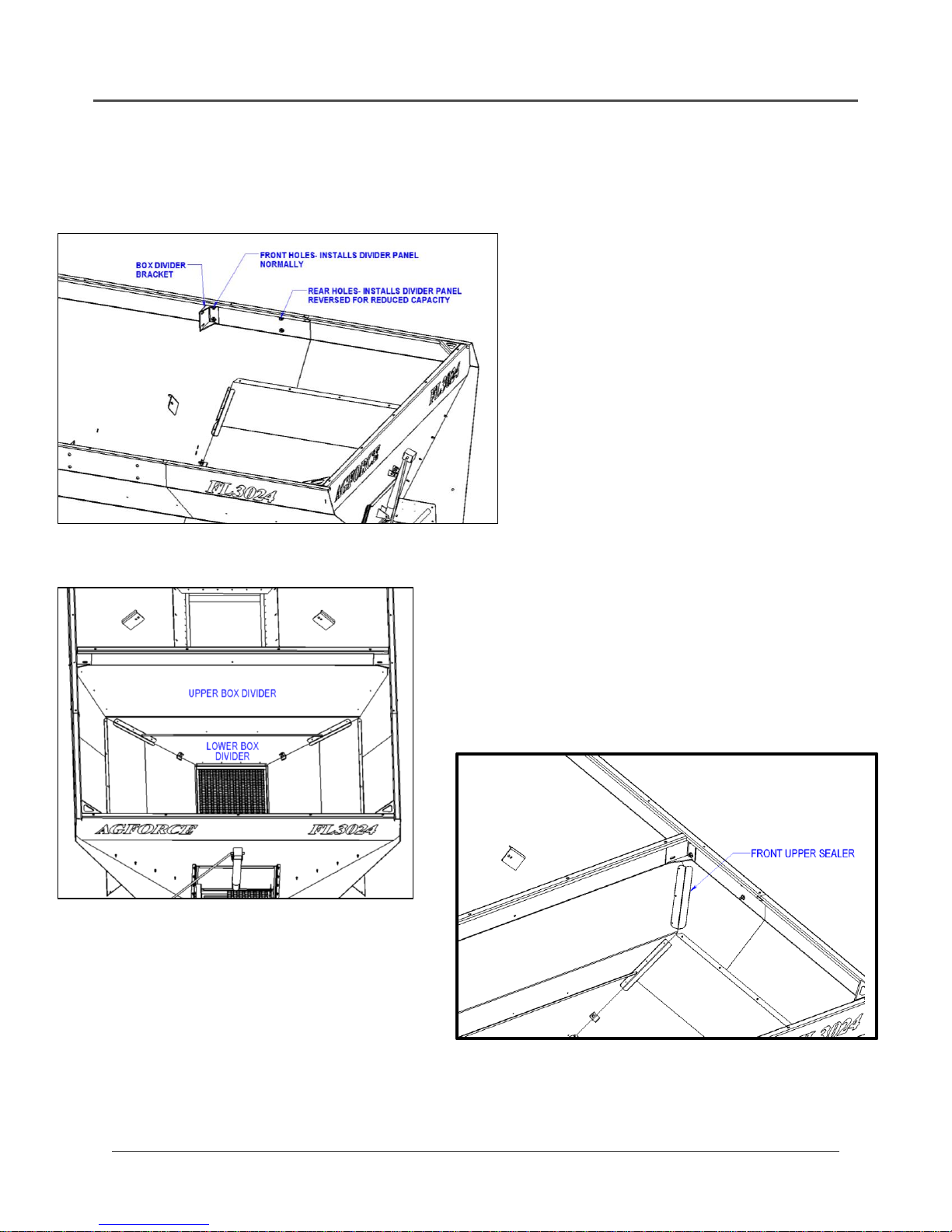

8.) LOOSELY bolt in Box Divider Brackets on

box sides according to desired position of

Box Divider panel using ½” UNC x 1”

button head bolts, ½” flat washers and

nylon lock nuts (2 of ea. per side). Plug

unused set of holes with same style of bolt

(Fig. G)

1.) Asd

2.) A

3.) Asdf

4.) Asdf

5.) Adsf

6.) Asdf

7.) LOOSELY bolt Box Gusset panels to box sides

using 3/8” UNC x ¾” button head screws and

nylon lock nuts (5 per side)

5.) Hook the bent flange of the Hinge Panel under the

“fingers” on the back side of the Box Gusset panel (Fig. E)

Box Gusset

“finger”

Hinged

Panel

Fig. E

6.) Align front edges of Box Gusset and Hinged Panel, and

lay down flat against box sides (Fig. F)

Fig. F Box Gusset Panel Installation

Note: Do not tighten any

hardware down until all

panels, dividers and sealers

have been installed.

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 6

1.) SF

2.) ASDF

3.) ASDF

4.) ASDF

5.) ASDF

6.) ASDF

7.) ASDF

8.) ASDF

9.) Install Upper & Lower Box Divider

Panels and bolt together using ½”

UNC x 1” carriage bolts, ½” flat

washers, lock washers and ½” UNC

hex nuts (3 of ea.)

10.) LOOSELY bolt Box Gusset panels to

Box Divider panels using ¼” UNC x

1” bolts, ¼” lock washers and ¼”

UNC hex nuts (3 of ea. per side).

11.)LOOSELY bolt Hinged Panels to

Lower Box Divider panel using 3/8”

UNC x 1” bolts, 3/8” flat washers,

lock washers and 3/8” UNC hex nuts

(1 ea. per side)

12.) Install upper Box Divider Sealers

using ¼” UNC x 1” bolts, ¼” lock

washers and ¼” UNC hex nuts (1 ea.

per side)

DUO-FORCE INSTALLATION (continued)

Fig. G Box Divider Bracket Installation

Fig. H Box Divider Panel Installation

Note: Sealer panels are intentionally

under-bent so when properly bolted

down, the sealer holds tightly against the

box side.

Fig. J Upper Box Divider Sealer Installation

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 7

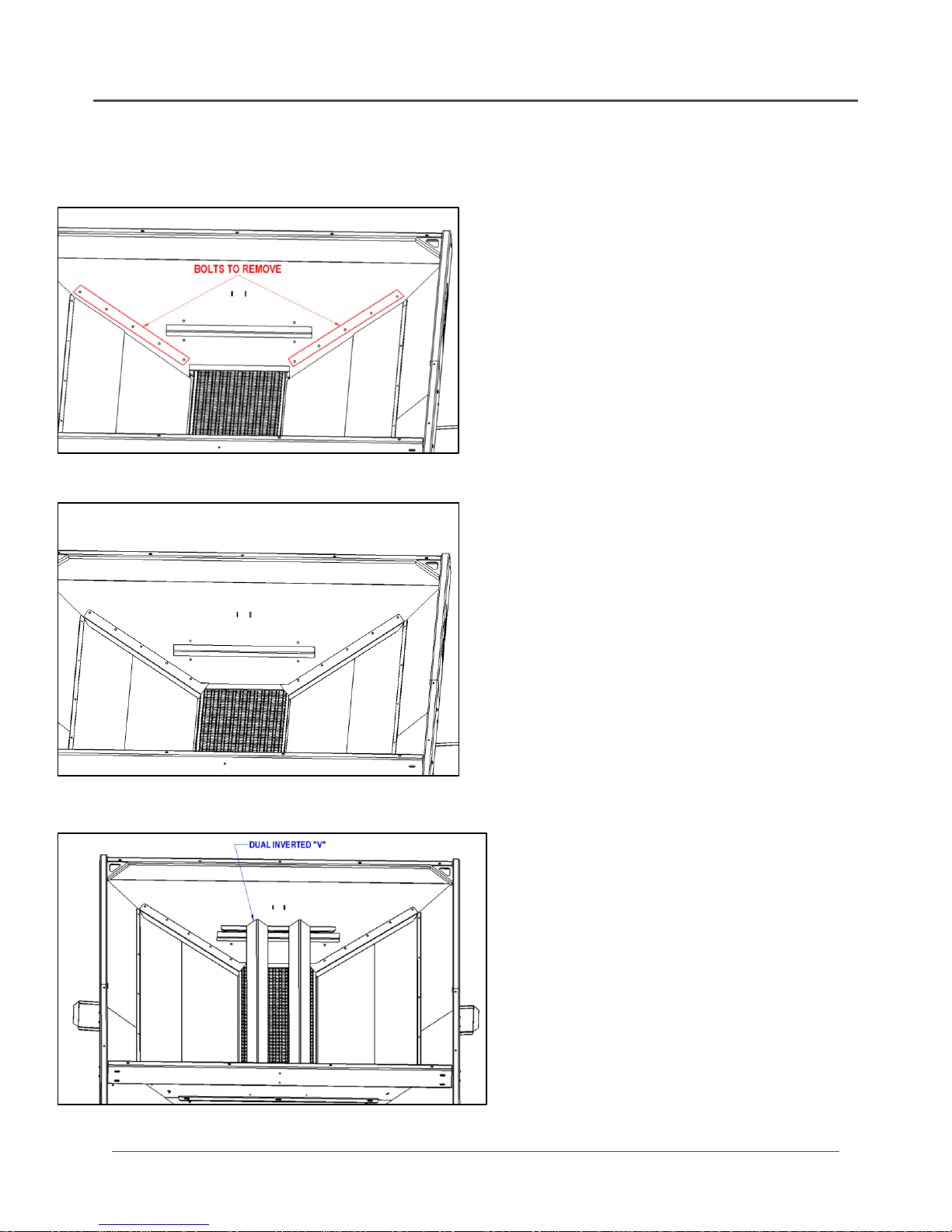

DUO-FORCE INSTALLATION (continued)

Fig. M

1.) Asdf

2.) Asdf

3.) Asdf

4.) Asdf

5.) Asdf

6.) Asdf

7.) Asdf

8.) Asd

9.)

10.) Asdf

11.) Asdf

12.) Asdf

13.) Install Take-Up Cover Sealer to Lower Box

Divider panel using ¼” UNC x 1” bolts, ¼”

lock washers and ¼” UNC hex nuts (4 of ea.)

14.) Remove third bolt from each Feedgate

Slide and eight bolts plugging unused holes

on the rear panel if present and set aside

(Fig. K)

15.) Install Rear Sealers using hardware

removed, or ¼” UNC x 1” bolts, ¼” lock

washers and ¼” UNC hex nuts (5 of ea. per

side) (Fig. L)

16.) Remove top Feedgate Slide bolts and set

aside

17.) Install Dual Inverted “V” (Fig. M). The 90-

degree mounting flange bolts to the Upper

Box Divider panel, and the over-bent

mounting flange bolts to the rear box panel

through the top Feedgate Slide bolt holes.

Reuse Feedgate Slide hardware for the

rear, and use ¼” UNC x 1” bolts, ¼” lock

washers and ¼” UNC hex nuts (2 of ea.) for

the front.

18.) Securely tighten all bolts from previous

steps. Be sure that all panels and sealers

are secure, as well as the conveyor

mounting straps from Step 3.

19.) Caulk around any gaps between sealers

and/or panels as necessary

Fig. K Bolt Removal

Fig. L Rear Sealers Installed

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 8

DUO-FORCE INSTALLATION (continued)

1.) Ads

2.) Asd

3.) Asdf

4.) Asdf

5.) Asdf

6.) Asdf

7.) Asdf

8.) Asdf

9.) Asdf

10.) Asdf

11.) Asdf

12.) Asfd

13.) Asdf

14.) Asdf

15.) Asdf

16.) Asdf

17.) Asdf

18.) S

19.) S

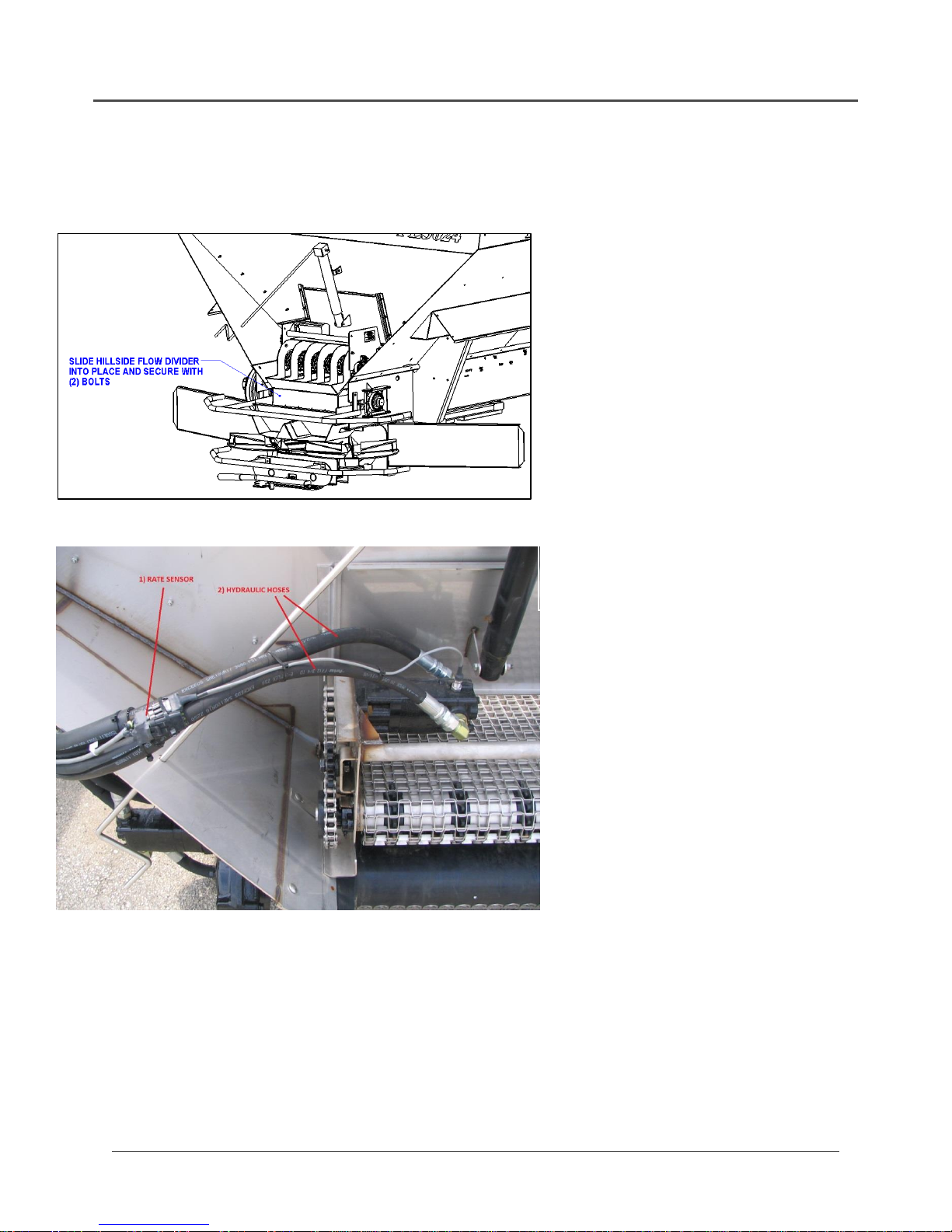

20.) Install Hillside Flow Divider by

fitting slotted holes on to conveyor

insert pegs. Secure with 3/8” UNC x

1” bolts, 3/8” lock washers and 3/8”

UNC hex nuts (2 of ea.)

21.)Plug in electrical connector for rate

sensor and for bin level sensor (if

equipped)

22.) Disconnect Duo-Force hoses from

each other and connect to fittings

on Duo-Force conveyor motor

Fig. N Hillside Flow Divider Installation

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Instructional Pg. 9

Agforce valve block configuration

With duo-force

Note: This page is for visual reference only.

For details, see Parts Page DF-1.1

PASS. SIDE

REAR

DRIVER'S SIDE

REAR

ROUTE HOSE UNDER BOX IMMEDIATELY IN FRONT OF SPINNER ASSY

TO RETURN PORT ON REAR

OF DUO-FORCE MOTOR

TO PRESSURE PORT ON TOP OF

TRI-FORCE MOTOR (DRIVER'S SIDE)

TO RETURN PORT

ON TOP OF QUAD

FORCE MOTOR

(PASS. SIDE)

TO RETURN HOSE

FROM CONVEYOR

MOTOR TEE

TO PUMP

TO RETURN HOSE

FROM CONVEYOR

MOTOR TEE

TO PRESSURE PORT ON BOTTOM OF QUAD FORCE MOTOR (PASS. SIDE)

TO RETURN PORT

ON BOTTOM OF

TRI-FORCE MOTOR

(DRIVER'S SIDE)

TO PRESSURE PORT ON FRONT

OF DUO-FORCE MOTOR

4

3

2

3

7

7 17

162

12

9

8

10 1

5 6A

6

2

8

13

18 1114

20

19

21

29

15

22

30

26

27

49

43 31

2332

38

39

40

41

42

42

41

43

38

47

46

45

24

25

51

44

48

28

44

31

33

35

50

37

36

34

**CONNECT HOSES 23 & 25 WHEN

REMOVING QUAD FORCE

**CONNECT HOSES 32 & 51 WHEN

REMOVING TRI-FORCE

**CONNECT HOSES 45 & 46 WHEN

REMOVING DUO-FORCE

RETURN FLOW TO MAIN VALVE

BLOCK (IN PLACE OF ITEM #10)

POSITION OF RELIEF

VALVE IN MAIN BLOCK

(ITEM #9)

PRESSURE INLET,

CONNECT ITEM #14

TO PRESSURE PORT

ON MAIN BLOCK

(IN PLACE OF ITEM #8)

RETURN, CONNECT HOSE

#20, REMOVE ITEM #10

MULTIBIN VALVE BLOCK

(ITEM #34) MOUNTS TO

THE FRONT DRIVER'S

SIDE BOX GUSSET AS SHOWN

HOME OF THE "FORCE" FIELD Pg. QF-1.1

CONNECTIONS FOR UNITS

W/ DUMP VALVE

force unltd.

agforce w/ duo-force,tri-force & quad force hydraulic

setup w/ multibin valve block

SPREADERS*GPS EQUIPMENT*CONVEYORS

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE” FIELD Pg. DF-1.2

DUO-FORCE HYDRAULIC SETUP PARTS KEY

CONTINUED

ITEM PART NO. DESCRIPTION QTY.

1 1211-00 Main Valve Block - Hydraulic 1

2 1202-119 Plug 5

3 1202-117 Adapter - Straight 3

4 1202-210 Adapter - Elbow 1

5 1211-80 Cartridge - PSI Compensator 1

6

6A

1211-01A

1211-011A

Valve - Hydraulic Servo

Valve – PWM - Conveyor

2

2

7 1202-118 Plug 2

8 1202-116 Adapter - Straight 1

9 1211-945 Valve - Hydraulic Relief 1

10 1202-1800 Adapter - Elbow 1

11 1211-80K Seal Kit As Req’d

12 1211-95K Seal Kit As Req’d

13 1211-01K Seal Kit As Req’d

14 1207-131 Hose Assembly 1

15 1211-0820 Check Valve 3

16 1202-109 Adapter - Straight 1

17 1211-605 Check Valve 1

18 1211-801 Modified Cartridge - PSI Compensator 1

19 1207-601 Hose Assembly 1

20 1207-602 Hose Assembly 1

21 1207-603 Hose Assembly 1

22 1207-604 Hose Assembly 1

23

24 1207-606 Hose Assembly 1

25

26 1211-94 Valve - Hydraulic Relief 1

27 1211-94K Seal Kit As Req’d

28 1211-081 Valve Plug Cartridge 2

29 1211-08A Proportional Valve 1

30 1211-08K Seal Kit As Req’d

31 1202-1090 Adapter - Straight 2

32 1202-1180 Plug 2

33

34 1211-001

1200-310

1209-40

1209-42

1205-21

Multi-Bin Valve Block - Hydraulic

Requires:

Hex Head Bolt - 3/8” UNC x 3” MS

Flat Washer - 3/8” MS

Lock Washer - 3/8” MS

Hex Nut - 3/8” UNC MS

1

2

6

2

2

35 1202-25 Adapter- Straight 1

36 1222-7 Shuttle Valve - Remove Ball 1

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Pg. DF-1.3

Duo-force hydraulic setup parts key (continued)

ITEM

PART NO.

DESCRIPTION

QTY

37

1202-2056

Adapter- Elbow

1

38

1202-3015

Adapter- Tee

1

39

1202-102

Adapter- Straight

1

40

1

41

1

42

1

43

1202-202

Adapter- Elbow

2 w/o Dump Valve

3 w/ Dump Valve

44

45

1207-15

1207-16

1207-17

Hose Assembly (12’ Box)

Hose Assembly (13’ Box)

Hose Assembly (14’ Box)

1

46

1207-18

Hose Assembly

1

47

1202-1035

Adapter- Straight

1

48

1202-2095

Adapter- Elbow

1

49

50

1202-1074

Adapter- Straight

1

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

HOME OF THE “FORCE”FIELD Pg. DF-2

DUO-FORCE CONVEYOR DRIVE

ITEM

PART NO.

DESCRIPTION

QTY.

1

1217-99

Drive Sprocket

Requires:

Set Screw- 5/16” UNF x 5/16” Lg.

Key Stock- ¼” Sq. x 1”

1

2

1

2

1217-30

1200-350

1209-61

1209-63

1205-36

Pillow Block Bearing

Requires:

Set Screw- 5/16” UNF, 5/32” Hex

Hex Head Bolt- ½” UNC x 1-1/2” SS

Flat Washer- ½” SS

Lock Washer- ½” SS

Hex Nut- ½” UNC SS

2

2 ea.

2 ea.

2 ea.

2 ea.

2 ea.

FORCE UNLTD. SPREADERS * GPS EQUIPMENT * CONVEYORS

Duo-force conveyor drive (continued)

ITEM

PART NO.

DESCRIPTION

QTY.

3

1217-45

1220-144

Sprocket- Flat Wire Belt

Requires:

Key Stock- ¼” Sq. x 1-1/2”

Set Screw- 3/8” UNF x 3/8”

4

1 ea.

2 ea.

4

1233-61

Drive Shaft

1

5

1208-92

Pipe Clamp & Hardware

1

6

6

1233-1045

1233-1045 XLG

Conveyor Frame- Duo-Force & Duo-Force LTD

Conveyor Frame- Duo-Force XLG (18’ Box)

1

1

7

1213-145

1220-144

1200-403

1209-63

1205-36

1213-145 SK

Hydraulic Motor

Requires:

Key Stock- ¼” Sq. x 1-1/2” Lg.

Socket Head Cap Screw- ½” UNC x 1-1/2” Lg.

Lock Washer- ½” SS

Hex Nut- ½” UNC SS

Seal Kit

1

1

4

4

4

1

8

1217-995

Sprocket- Idler

Requires:

Hex Head Bolt- 5/8” UNC x 2” M/S

Flat Washer- 5/8” M/S

Nylon Lock Nut- 5/8” UNC M/S

1

1

1

1

9

1217-960

Sprocket- Motor

10

1233-60

Roller Chain w/ Connector

Requires:

20 Links

1

11

1233-40

1205-51

Weldment- Take-Up Bracket

Requires:

Hex Nut- 5/8” UNC M/S

1 LH, 1 RH

2 ea.

12

1233-42

Snub Roller Shaft

1

13

1233-41

Snub Roller

3

14

1233-10

1200-302 SS

1209-41

1209-43

1205-27

Conveyor Mounting Strap

Requires:

Carriage Bolt- 3/8” UNC x 1” SS

Flat Washer- 3/8” SS

Lock Washer- 3/8” SS

Hex Nut- 3/8” UNC SS

2

1 ea.

1 ea.

1 ea.

1 ea.

15

1233-1

Flat Wire Belt- Duo-Force & Duo-Force LTD

Flat Wire Belt- Duo-Force XLG

As Req’d-

Specify Length

16

1233-2

Connecting Rod- Flat Wire Belt

1

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions