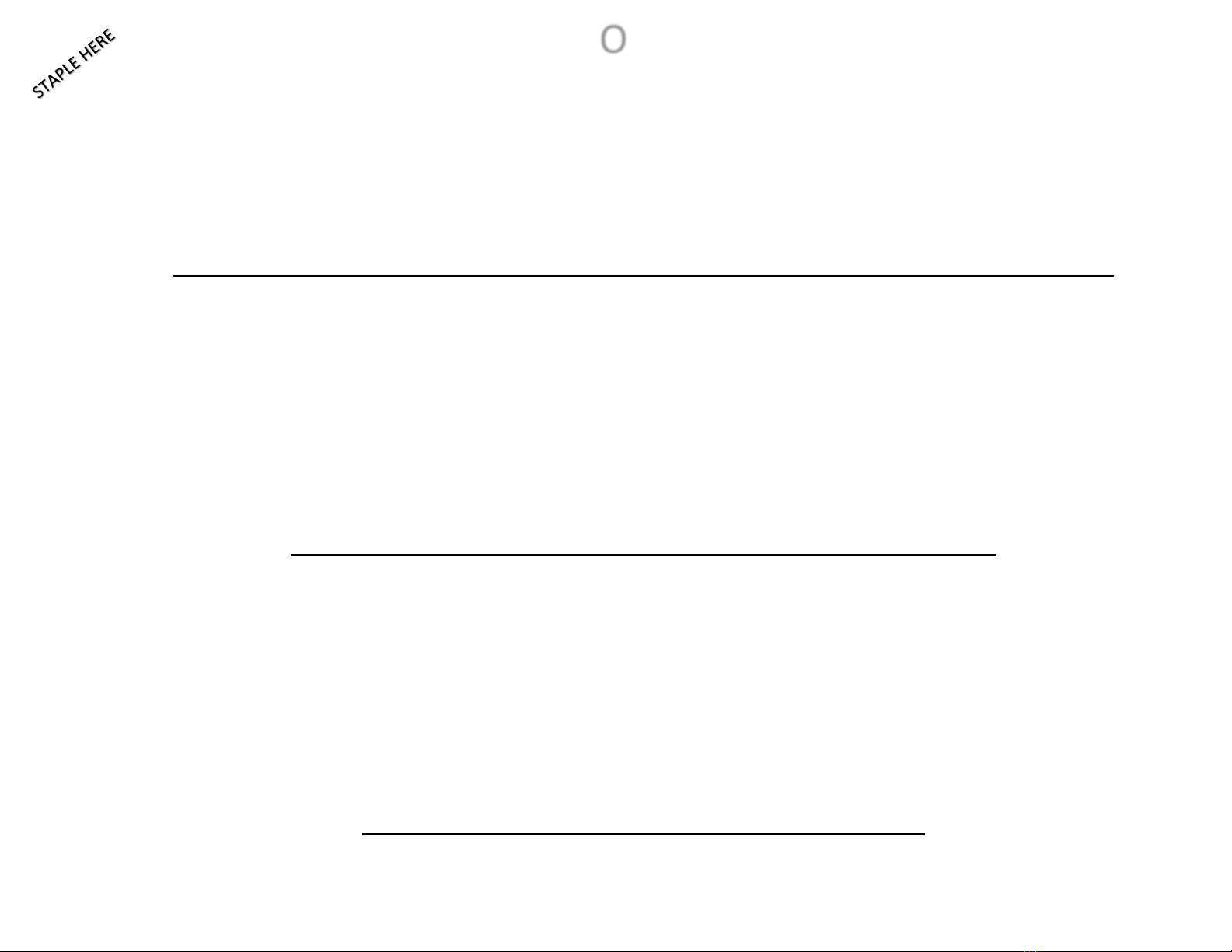

Part No 60121508 Rev E 3 Instructions, Force NRG Customer Assembly

Small Components and Verification

1) For each “Small Component Bag” (1-4), remove the verification sheet

and lay out on a flat level surface.

2) Remove small components from bag and place them on the verification

sheet in their outlined areas

a. NOTE: From hereon we will refer to the “Small Component

Verification” sheet and their associated components by the

sheet number located at the top right-hand corner of the page.

3) Once you’ve confirmed that all small components are present. Proceed

to the assembly instructions

4) If you discover any components are missing, please contact our

Customer Service Department with your serial number and the Part

Number / Description of the missing component(s).

topendorders@invacare.com

Preparing for Assembly

1) Your product has shipped with the basic tools required to assemble

your product. We do recommend you also have the following tools to

optimize the assembly process

a. Sharp Scissors or Side Cutters

b. Torque Wrench

c. Medium/Large flathead screwdriver

d. Tape Measure

e. Air Pump

f. Some good music, an amusing friend and your drink of choice…

Are you ready? Cool… Let’s do this.

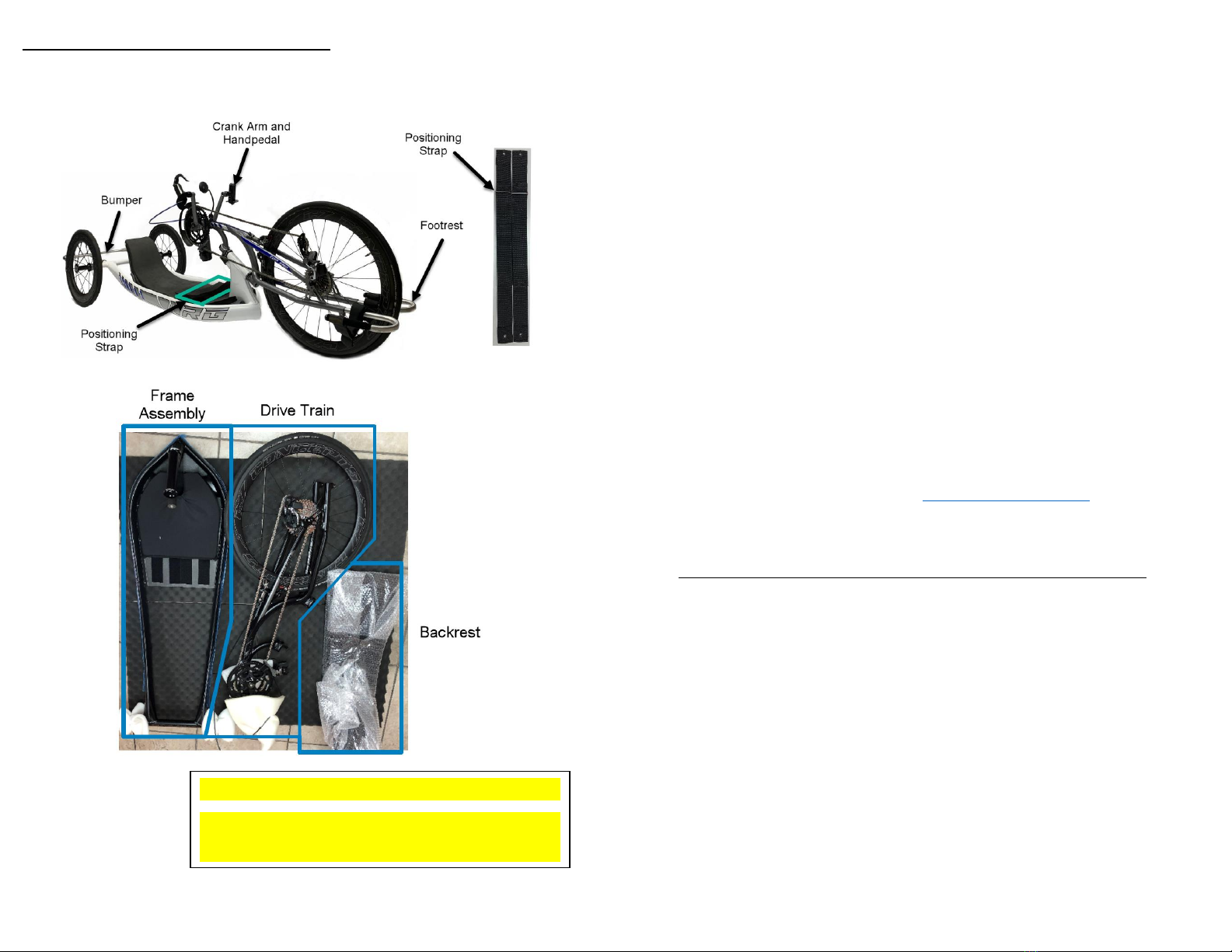

1. Fork and Frame Assembly

a. Take the steer tube assembly from [SHEET #2]

b. Remove top end cap, top headset cap, upper crown race ring,

upper dust ring and top bearing from steer tube assembly –

leaving lower headset assembly components in-tact.

c. Install the steer tube assembly into the frame following Figure

D. Once installed, position the steer tube with approximately 2”

protruding out from the bottom of the headtube.

d.

e. Reinstall the upper headset assembly components following

figure D. You will need to ensure that the headset components

are positioned as closely to the head-tube as possible. If done

correctly, you should no longer be able to see the bearings. You

can also use the “Small Component Verification” sheet for a

more detailed view of the component orientation.

i. NOTE: Dust rings have a taper on the inside of one

side. The taper should be against the race ring and the

flat side against the bearing.

f. Take the packing insert which the drivetrain front wheel was

secured in and place it under the front of the frame to raise the

steer tube from your work surface a couple of inches. If

assembling on a large table, positioning the frame so that the

steer tube is at the edge of the table will negate the need to

prop up the front of the frame

g. Install the drivetrain to the frame using 5mm Allen Key from

[SHEET #1] and fork hardware from [SHEET #2].

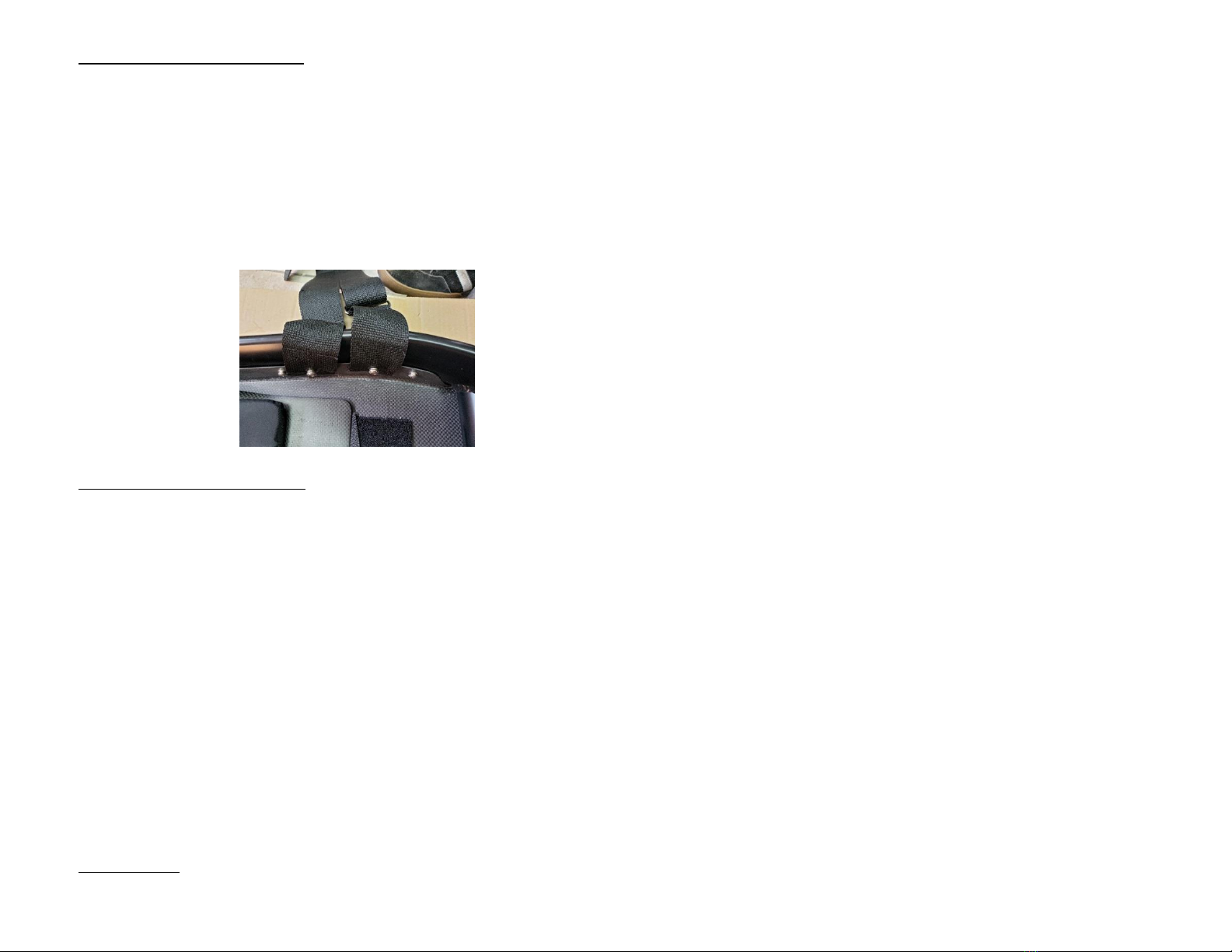

h. Rotate fork clamps open (see next page, line “ii”) and place the

fork onto the steer tube. With the fork in place, rotate the

clamps closed. If having difficult closing the clamps, make sure

the clamps are positioned so that they clear the headset

assembly

i. NOTE: This is the most difficult part, after this it’s

smooth sailing. If you’re having difficulty getting both

clamps to close –it is because the tolerances between

the two clamps is very tight for performance reasons.

It is recommended to get the bottom clamp closed

with hardware finger tightened and then have that