forede ZDMS 0.6/5S User manual

AUTOMATIC FIRE WATER MONITOR/CANNON

QUANZHOU FOREDE FIREFIGHTING EQUIPMENT CO.,LTD.

www.forede.com

CONTENTS

PRODUCT SAFETY INSTRAUCTION....................................................... - 1 -

SYSTEM INTRODUCTION............................................................................................... - 2 -

COMPONENT LIST.......................................................................................................... - 3 -

SYSTEM WIRING.......................................................................................................... - 4 -

INSTALLATION................................................................................................................ - 5 -

ZDMS DEVICE INSTALLATION.......................................................................... - 5 -

CONTROL BOX INSTALLATION.................................................................................... - 7 -

CENTRALIZED CONTROL CABINET INSTALLATION............................................ - 7 -

WIRING STEP................................................................................................................. - 8 -

CONNECTING BOX WIRING........................................................................................ - 8 -

CONTROL BOX WIRING.................................................................................. - 10 -

CENTRALIZED CONTROL CABINET WIRING........................................................... - 11 -

OPERATION INTRODUCTION....................................................................................... - 12 -

DEBUGGING METHOD.................................................................................................. - 14 -

PARAMETTERS........................................................................................................... - 16 -

OUTLINE DIMENSION................................................................................................... - 17 -

MOVEMENT ANGLE..................................................................................................... - 17 -

PRODUCT SAFETY INFORMATION

All personnel who may be expected to operate this equipment must be

thoroughly trained in its safe and proper use.

Before flowing water from this device, check that all personnel (fire service

and civilian) are clear of the stream path. Also confirm stream direction will

not cause avoidable property damage.

Become thoroughly familiar with the hydraulic characteristics of this

equipment, as well as the pumping system used to supply it.

Whenever possible, this equipment should be operated from remote location

to avoid exposing personnel to dangerous fire conditions.

Always open and close valves slowly to avoid water hammer.

After each use, and on a scheduled basis, inspect equipment per instructions

in the maintenance section.

Keep fingers and hands clear of moving parts.

Disconnect power before servicing and electric valve or electric valve

controller.

!WARNING

Do not attempt to disconnect or work on any electrical equipment in this

system unless power is removed or the area is known to be non-hazardous.

!ATTN

Before installing and operating this equipment, read this manual thoroughly.

Proper installation is essential to safe operation.

STSTEM INTRODUCTION

ZDMS Series Automatic Tracking And Positioning Fire Water Monitor/Cannon

is an organic combination of infrared / ultraviolet sensing technology, signal

processing technology, communication control technology, computer

technology and mechanical transmission technology.

Once a fire occurs, the device starts immediately. Two-dimensional scanning

of the fire source in the horizontal and vertical directions is performed. After

determining the two directions of the fire source, the central controller issues a

command and sends out a fire alarm signal. At the same time, the water pump,

valve and device are started Fire the water by aiming at the fire source. After

the fire source is extinguished, the central controller will issue a command to

stop the water spray. If there is a new fire source, the device will repeat the

above process, and will return to the monitoring state after all the fire sources

are extinguished.

The water injection form of this device is cylindrical water injection, with long

range, wide protection range, and very powerful fire extinguishing ability. It can

be widely used in indoor buildings with large area and large space, such as:

station waiting room, airport, passenger terminal, sports hall, Convention and

exhibition center, movie theater, dance hall, exhibition hall, shopping mall, etc.

COMPONENT LIST

IMAGE NAME MODEL DESCRIPTION REMARK

ZDMS Automatic

Tracking And

Positioning Fire

Water Monitor

/Cannon

ZDMS 0.6/5S

ZDMS 0.8/10S

Fire detection, positioning

and fire extinguishing

Standard

Solenoid Valve

(DN50)

DCF-SX(DN50) Turn on and off water flow Standard

Connecting Box JXH-SX-5 Wiring terminal for easy

wiring

Standard

Control Box XCKZ-SX Installed in the protection

site, used to receive and

send relevant instructions,

control devices and

solenoid valves.

Controllable 4 devices

Standard

Centralized Control

Cabinet

YCKZ-SX Security in the central

control room, remotely

monitor the status of the

protection site and control

any connected device.

Up to 80 units monitor

and 20 units control box

Optional

Y-Strainer GLQ-SX Installed in front of solenoid

valve

Optional

SYSTEM WIRING

INSTALLATION

DEVICE INSTALLATION:

!WARNING

When installing, it is forbidden to directly rotate the device shell or forcefully pull the water

nozzle to avoid damage to the gear transmission structure and the motor.

The installation point of the device must not have any obstacles within 0.5 meters in

diameter, so as not to affect the rotation of the device body; the horizontal direction of the

flange installation surface of the device and the ceiling or beam should be no less than 0.3

meters clearance.

The fixed position of the Connecting box must ensure that the cable of the device is away

from the flange surface of the device The length is more than 0.4 meters, so as to ensure that

the device does not tear the cable when rotating 360 °.

!ATTN

The device itself has a certain weight, and the load-bearing capacity of the pipe network at the

installation point must be considered during installation.

The device should be installed after the pipeline is installed, after flushing and pressure testing.

The pipeline connected to the flange of the device should be vertically downward, to ensure that

the nozzle is horizontal after the device is installed.

The flange plane of the pipeline connected to the flange of the device must be level to prevent

tilting.

After installation, the direction of the device head should be away from the protection range.

Handle gently when installing to prevent impact.

Not allowed to pull device manually

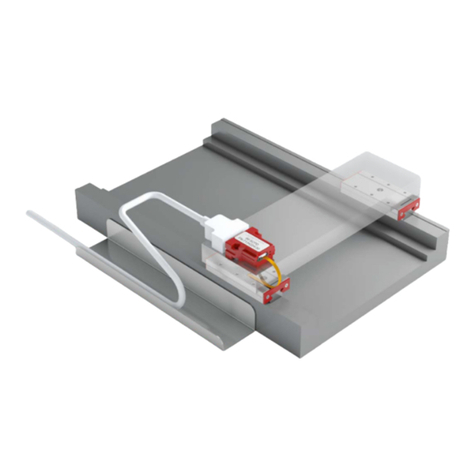

Connecting

Box

Pay attention to the installation spacing and the

length of the reserved line

CONTROL BOX INSTALLATION:

!ATTN

It is recommended to install the control box on the site near the wall and install it near the device.

The action of the device can be clearly observed, and it is close to the exit or the place that is easy

to evacuate.

The installation height of the on-site area control box is 1.5 meters above the ground of the fire

protection zone.

CENTRALIZED CONTROL CABINET INSTALLATION:

The Centralized Control Cabinet is installed and placed in the central control room

to centrally control multiple on-site control boxes. The main structure is a cabinet

with access line at the bottom.

Install four M8 expansion bolts on

the wall, the installation dimensions

are as shown.

There are 4 holes on the back of the

control box. Fix the control box with

screws or hang it on the wall

!WARNING

The Connecting box contains 220V high voltage and strong electricity, and with

electricity operation is prohibited during installation.

Before wiring, you must tear off the sticker on the bottom protective cover of the

device, remove the protective cover, and then dial the bottom dial switch according

to the dial code on the monitor body.

!ATTN

The 485 control cable of the Connecting box uses twisted-pair shielded cable. When

connecting each wire end, you must strictly connect the wire according to the attached cable

label. The shielding layer must be connected. This cable is a weak current cable and cannot be

laid in the same pipe as the power line. When using a wire channel, a separate wire channel

must be used.

When wiring, make sure that the length of the cable of the device is sufficient to leave the

flange surface of the device 0.4 meters or more, so that the device does not tear the cable

when rotating 360 °.

Keep the detection component of the device clean when wiring, and do not directly wipe the

light-receiving surface of the detection component with your hands.

When one area control box is connected to multiple Connecting boxes on site, between the

Connecting box and the Connecting box 485 communication lines need to be connected

hand in hand.

The outgoing video cable must use copper core copper mesh, select SYB75-5 within 300

meters Cable, if more than 300 meters, you need to use optical fiber.

WIRING STEP

Don’t operate with electricity Remove cover and dial-up

CONNECTING BOX WIRING:

The wiring steps are as follows:

Wiring Diagram Of The 12-Bit Terminal Of Connecting Box

1. The device leads a cable into the connecting box, the wiring method is shown in the above figure;

2. The connecting box leads 3 cables into the control box, which are 485 communication line ZR- RVSP2

× 1.5 (shielded twisted pair), Monitor power cable ZR-RVV2 × 1.5 and solenoid valve power cable ZR-

RVV2 × 1.5, the connection method is shown in the picture above;

3. A solenoid valve signal cable ZR-RVV2 × 1.5 leads to the solenoid valve from the connecting box, the

wiring is shown in the above figure;

4. A video signal cable SYB75-5 is led out of the connecting box to the centralized control cabinet, the

wiring is shown in the above figure;

5. Earth wire, the Double-color earth wire ZR-RVV1 × 1.5 that leads the device into the connecting box,

then leads from the connecting box to the flange of the pipeline equipment, and can also be grounded

through the internal circuit.

Connecting with ZMDS Monitor

CONTROL BOX WIRING:

!ATTN

Same as the connecting box, the site area control box contains 220V high-voltage strong

current, live operation is prohibited during installation.

When multiple area control boxes on site are connected to the centralized control cabinet,

between the control box and the control box CAN industrial bus needs to be connected

hand in hand.

The Earth wire must be grounded.

The wiring steps are as follows:

Wiring diagram of the air switch and wiring board of control box

1. Lead 3 cables into the connecting box from the control box, which are 485 communication cable ZR-

RVSP2 × 1.5 (shielded twisted pair), Monitor power cable ZR-RVV2 × 1.5 and Solenoid Valve power cable

ZR- RVV2 × 1.5, see schematic diagram for wiring method;

2. Two cables from the control box are connected to the centralized control cabinet, which are AC220V

power cord ZR-RVV-3 × 2.5 (connect to other external power supply when no centralized control cabinet

is installed) and CAN industrial bus ZR-RVSP3 × 1.5 , See wiring diagram for wiring method;

3. Grounding, the Earth wire and the shell must be effectively grounded.

CENTRALIZED CONTROL CABINET WIRING:

L N L N H L

Wiring diagram of the terminal of Centralized Control Cabinet

1. The Centralized Control Cabinet is equipped with wiring terminals, introducing 1 cable AC220V power

cable ZR-RVV-3 × 2.5, and leading 2 cables into the control box, which are AC220V power cable ZR-

RVV-3 × 2.5 With CAN industrial bus ZR-RVSP3 × 1.5, the wiring is shown in the figure above;

2. Grounding, the Earth wire and the shell must be effectively grounded;

3. Connect the video signal cable from each device to a special video plug, and then insert the plug into

the video input port of the recorder.

Control

Box

Power

Input

CAN

OPERATION INTRODUCTION

The device is mainly controlled by the control panel in the on-site area control box. The operation

instructions are as follows:

1. The left side of the panel is the status indicator, the corresponding status is as follows:

Marking Color Description Status

Working Green Control Box Working status Lights on: Working;

Lights off: Power off

Fault Yellow Fault or not Lights on: Fault Occurs;

Lights off: Normal

Silenced Green Alarm sound status Lights on: No alarm;

lights off: Alarm

Valve Green Working state of solenoid

valve

Lights on: Working;

Lights off: Power off

E-Stop Red E-Stop status Lights on: Button pressed;

Lights off: Button pops up

Fire Alarm Red Fire alarm report Lights on: System Fire Alarm;

lights out: No Fire Alarm

Valve On Green Valve status Lights on: Valve open;

Lights off: Valve closed

Pump On Green Pump status Lights on: Pump open;

Lights off: Pump closed

2. The upper middle of the panel is the LCD screen;

3. Direction buttons at the middle and bottom of the panel are up, down, left and right, which can control

the rotation of the ZDMS monitor up and down and left and right and the up and down selection of the

content of the LCD screen;

4. The right side of the panel is the control buttons, corresponding to the specific operations are as

follows:

Marking Description

Valve Open or close solenoid valves

Pump Opening and closing of pumps

Silenced Eliminate alarm sounds

SS/Fog Switching water straight and fog (not available for this ZDMS Model)

M/A Switching Device Control Manual / Automatic

Testing Testing Device

Verify Confirmation of operations

Reset Reset the device to standby

Locating Automatic locating fire

Settings Set the internal parameters of the device (used by the debugger)

Back Return to the previous layer

*The Centralized Control Cabinet is mainly controlled by the touch screen on the host. For operation instructions,

please refer to the manual of the Centralized Control Cabinet.

DEBUGGING METHOD

The debugging steps of the fire extinguishing system are as follows:

!ATTN

System debugging must be carried out after pressure test and flushing of water supply

system.

System debugging must be carried out before the scaffolding is removed on site (except

when the scaffolding is removed does not affect the location where the debugger contacts

the system's high-altitude equipment or the site where the equipment is on the ground).

The water source and power supply of the device system must meet the debugging

conditions.

Substances in the test area that may be damaged by water should be transferred or

waterproofed, and flammable substances should be transferred to a safe area.

Due to the large jet flow and high impact force of the device, on-site drainage measures

must be taken, safety measures for on-site participants and unpredictable incident handling

plans must be done.

Electrical circuits and electrical equipment in the test area that are careless or must be damp

due to water are not tested after the test can send electricity immediately, and it should be

identified and processed by professional technical personnel before sending electricity.

1. Check In Advance

A. Check whether the system wiring is correct;

B. Ensure that the start pump line between the centralized control cabinet and the fire pump group is

temporarily disconnected;

C. After confirming that the system wiring and wiring are normal, supply AC220V power to the system;

D. Test whether the basic functions of the buttons on the control box are normal.

2. Single Device Debugging

A. Single device manual function simulation debugging-set the device to manual state, use a lighter as a test

fire source at close range to test whether all the detection parts of the device body work normally;

B. Single device automatic function simulation debugging-set the device to the automatic state, disconnect

the power supply of the solenoid valve, and use the lighter as a test fire source for close-range simulation

simulation debugging of the automatic positioning function;

C. Single device automatic positioning and debugging-After the simulation and debugging is normal, turn on

the power of the solenoid valve, the central control host and the fire pump control cabinet are set to the

automatic state, choose one in the protected area of the device use a standard oil pan with a diameter of

Φ570mm and a height of 70mm, inject 40mm of clean water into the oil pan, and then add 500ml of car

gasoline to ignite it as a fire. Debug the automatic positioning and aiming function of the device. After the

positioning and aiming is normal, special attention should also be paid. Check whether the feedback of

signal lights such as valve opening and pump starting after positioning is normal.

3. Monitoring And Monitoring Equipment Debugging

Mainly adjust the monitoring range, installation angle and picture quality of the surveillance camera.

4. System Linkage Programming And Fire Pump Linkage Debugging

A. After confirming that the communication between the host and the pump set is correct, use the induced

fire inspection linkage program and the feedback records of the action feedback information and fire alarm

information of each device;

B. Check the positioning jet accuracy of each device. If adjustment is needed, the data in the on-site area

control box shall be modified accordingly by setting to ensure that each device will extinguish normally.

5. Multi-Device Debugging

A. Standard oil pan with test material diameter Φ570mm and height 70mm, filled with 40mm in the oil pan

Clean water, then add 500ml car gasoline to ignite as a fire;

B. Set the test device, centralized control cabinet and fire pump control cabinet to automatic state;

C. Ignite a fire in the experimental oil pan;

D. The device system finds the fire source, starts scanning and sends out fire alarm information to the on-

site area control box and centralized control cabinet;

E. Scanning and positioning of the fire source by the device is completed, the solenoid valve is automatically

opened and the pump start information is sent to the centralized control cabinet;

F. Fire extinguisher fire extinguishing;

G. When the fire extinguishment is completed or the on-site fire alarm signal disappears, the device will

continue to spray for 2-3 minutes (this time can be customized according to needs). After deep fire

extinguishment, the valve will automatically close and reset. Turn off the pump, valve and reset the device in

advance.

PARAMETTERS

MODEL ZDMS 0.6/5S ZDMS 0.8/10S

WORKING PRESSURE 0.6MPa 0.8MPa

FLOW RATE 5L 10L

JET RADIUS 34m 39m

MAX PROTECTION RADIUS 30m 35m

MONITORING RADIUS 50m 50m

JET MODE Columnar

MOUNTING HEIGHT 6~15m

TARGETING TIME ≤30s

HORIZONTAL ROTATIONAL

ANGLE

>360°

VERTICAL ROTATIONAL

ANGLE

-90°~+30°

OPERATING VOLTAGE AC220V

CONTROL MODEL On-Site Manual \ Remote Manual \ Automatic

WAY OF COMMUNICATION RS485

POWER CONSUMPTION Monitoring 1W,Sweeping 50W

DETECTOR TYPE Red ultraviolet compound

INLET DN50(GB/T 9112~9124-2010;PN16)

INSTALLATION Hanging

STANDARD GB 25204-2010

OUTLINE DIMENSION

MOVEMENT ANGLE

This manual suits for next models

1

Table of contents

Popular Measuring Instrument manuals by other brands

SEFRAM

SEFRAM MW 3950B user manual

Schneeberger

Schneeberger MINISLIDE MSQscale Mounting Instructions / Technical Information

Anritsu

Anritsu MP1900A Series quick start guide

Novasina

Novasina AW SPRINT Series operating instructions

Sencore

Sencore LC102 CALIBRATION PROCEDURE

schmersal

schmersal AES 2335 operating instructions