Shimadzu MOC-120H User manual

321-78153

Aug, 2014

ELECTRONIC MOISTURE METER

MOC-120H

SERVICE MANUAL

SHIMADZU CORPORATION

Kyoto,JAPAN

- 0 -

Contents

1. Table of Malfunction Causes 1

2. Troubleshooting 5

3. Service Mode of MOC-120H 13

4. Replacing the Heater Assembly 14

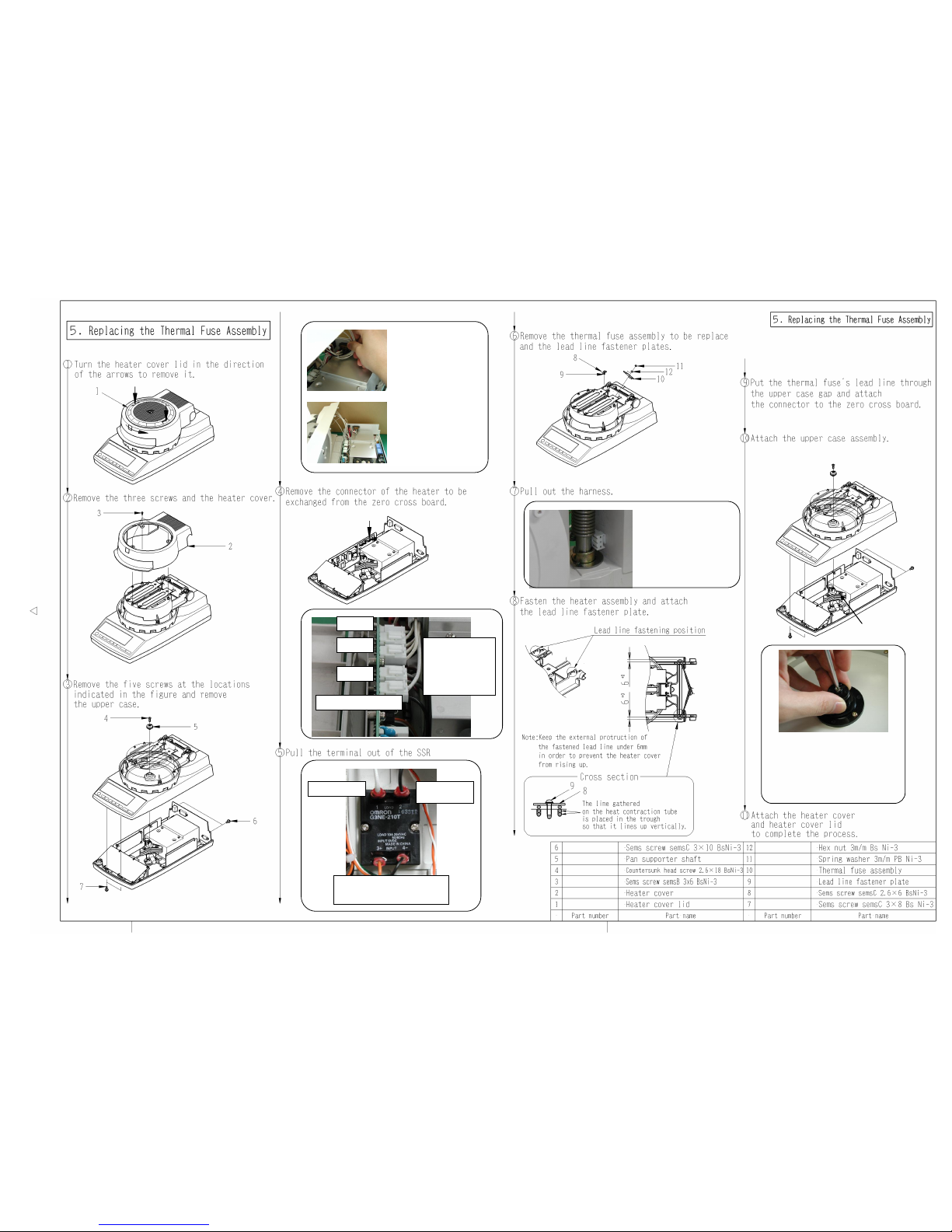

5. Replacing the Thermal Fuse Assembly 15

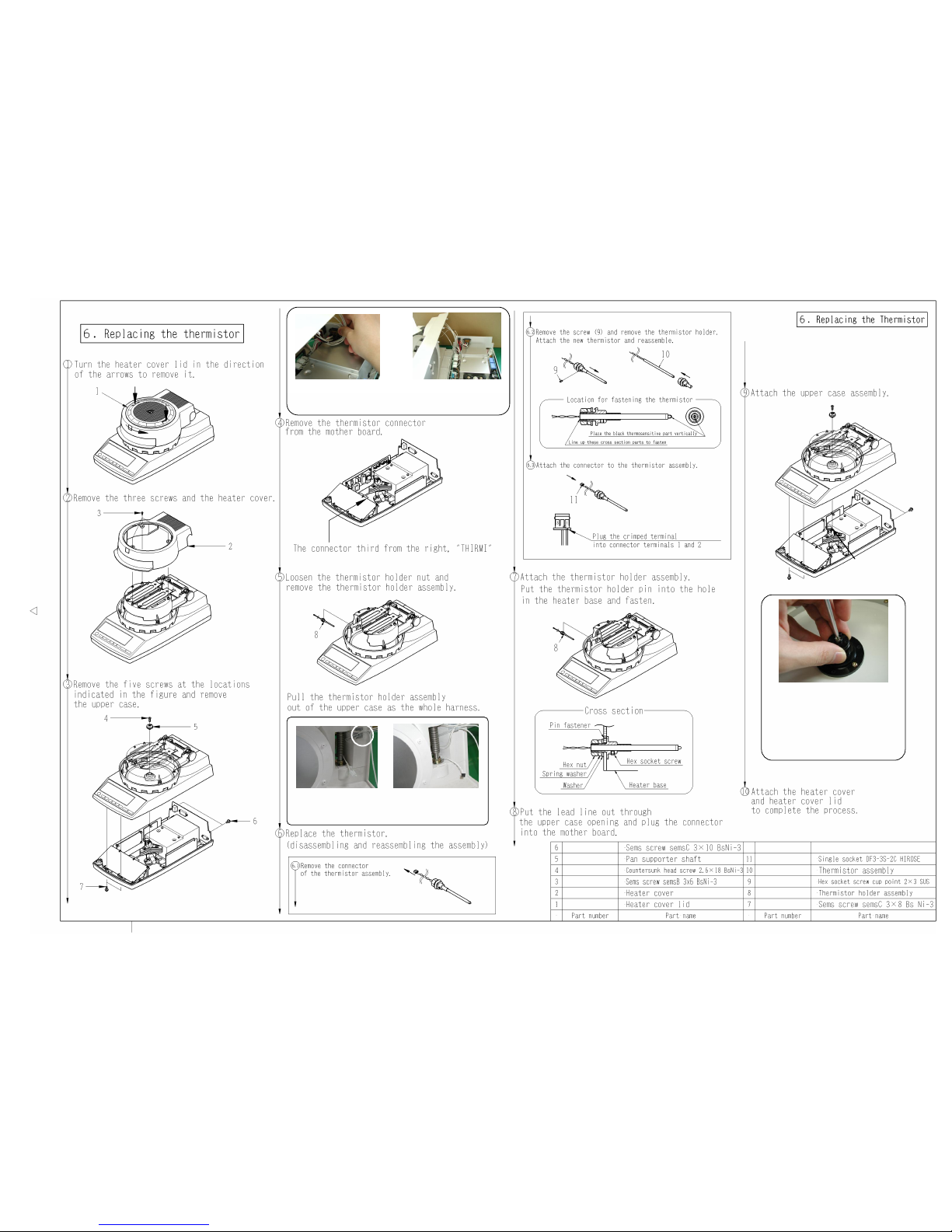

6. Replacing the Thermistor 16

7. Replacing the Motherboard 17

8. Replacing the Motor and PI Board Assembly 18

9. Replacing the Balance Assembly 19

10. Readjusting the Heater Cover 21

11. Adjusting the Linearity of the Electric Balance Unit 22

12. Parts list 23

- 1 - - 1 -

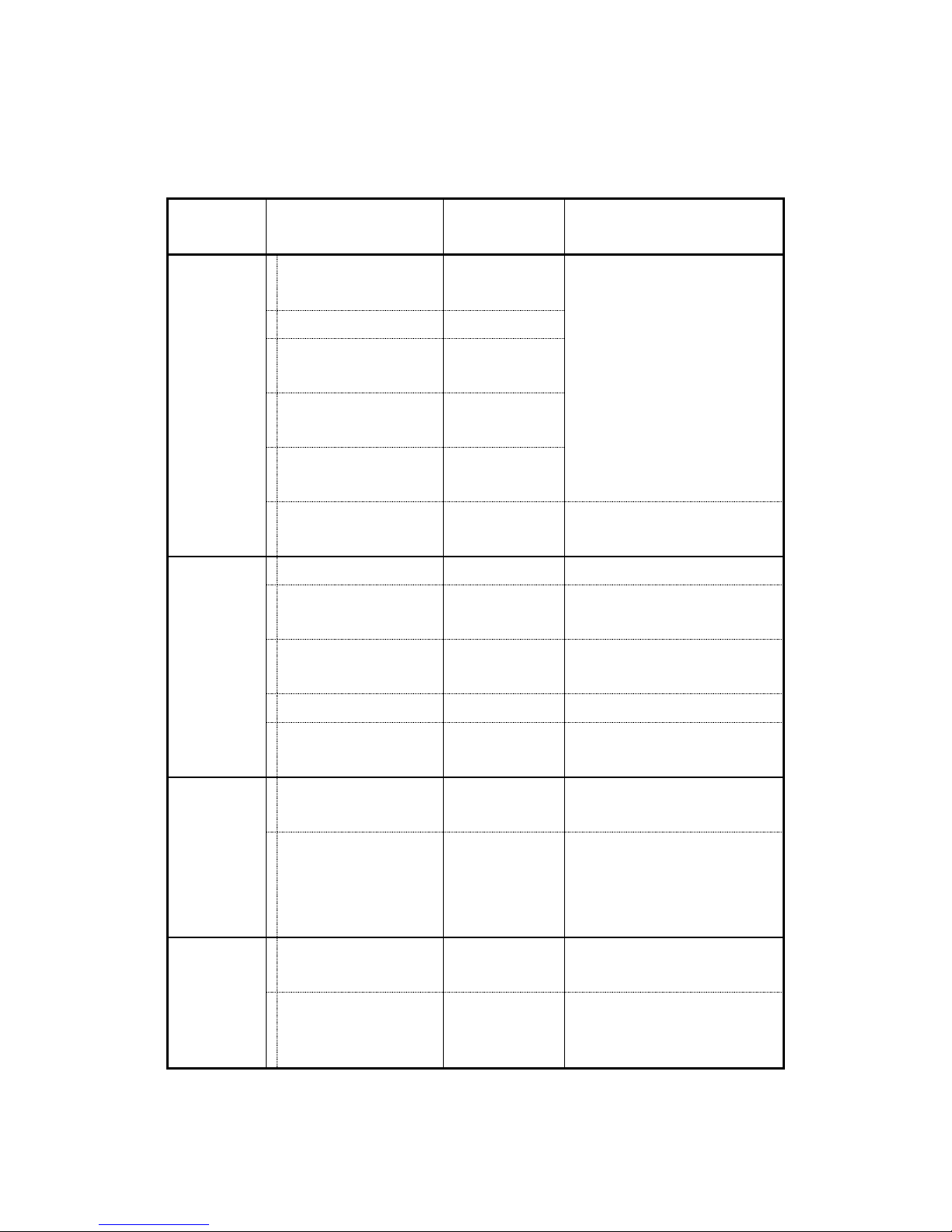

1.Table of Malfunction Causes

Malfunction

Causes

Solutions

Inspection Method After

Repairs

Power will not

turn on

(LCD does

not light)

1

Power cord not

connected

Connect power

cord

Turn power on again

2

Fuse disconnected

Replace fuse

3

Power voltage

malfunction

Use with correct

power

4

Bad inlet connector

contact

Reattach

connector

5

SW power malfunction

Replace SW

power

6

Motherboard

malfunction

Replace

motherboard

Complete acceptance

inspection

Heater does

not light up

1

Heater disconnected

Replace heater

Heat drift test

2

Thermal fuse

disconnected

Replace thermal

fuse

Check heater light up visually

3

Bad heater connection

contact

Reattach

connector

Heat drift test

4

SSR malfunction

Replace SSR

Heat drift test

5

Zero cross board

malfunction

Replace zero

cross board

Heat drift test

Mass

measurement

is unstable

(values

constantly

changing)

1

Lift unit touching

another part

Readjust lift unit

Heat drift test

2

Balance malfunction

Replace balance

Complete acceptance

inspection

“CHEO” or

“-oL” display

does not

disappear

1

Motherboard

malfunction

Replace

motherboard

Complete acceptance

inspection

2

Balance malfunction

Replace balance

Complete acceptance

inspection

- 2 - - 2 -

Malfunction

Causes

Solutions

Inspection Method After

Repairs

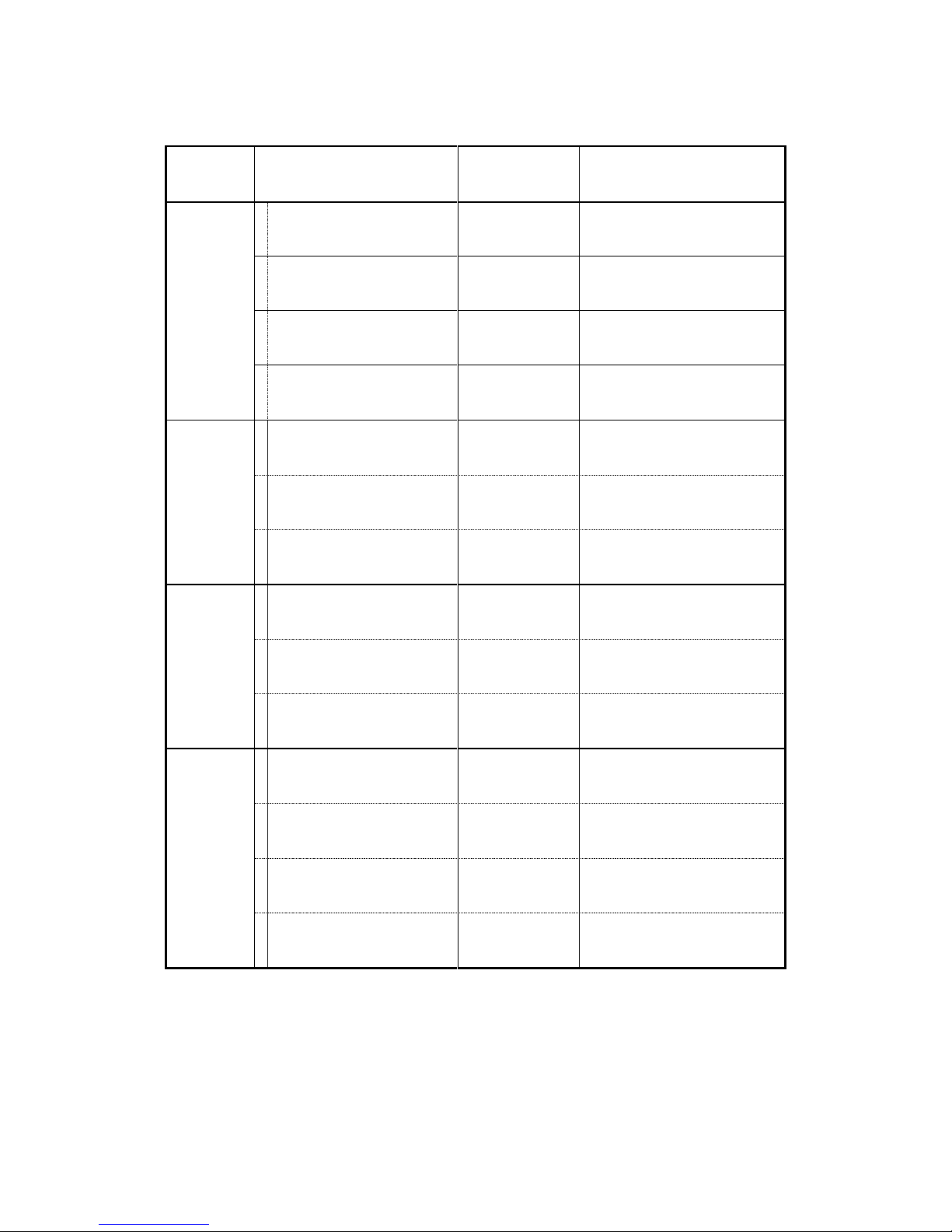

Er. 102, 103,

104

Er. 201, 202

1

Incorrect usage

Use properly

Check proper usage

2

Malfunction due to ROM

ver. 7212 or earlier

Replace

motherboard

Complete acceptance

inspection

3

Improper lift unit adjustment

Readjust lift unit

Heat drift test

Er. 301, 302

1

Bad thermistor connection

contact

Reattach

connector

Check at room temperature,

heat drift test

2

Thermistor malfunction

Replace

thermistor

Check at room temperature,

heat drift test

3

Motherboard malfunction

Replace

motherboard

Complete acceptance

inspection

Er. 303

1

Improper thermistor

attachment position

Reattach

thermistor

Check at room temperature,

heat drift test

2

Thermistor malfunction

Replace

thermistor

Check at room temperature,

heat drift test

3

Motherboard malfunction

Replace

motherboard

Complete acceptance

inspection

Er. 304

1

Malfunction due to ROM

ver. 7212 or earlier

Replace

motherboard

Complete acceptance

inspection

2

Bad thermistor connection

contact

Reattach

connector

Check at room temperature,

heat drift test

3

Thermistor malfunction

Replace

thermistor

Check at room temperature,

heat drift test

4

Motherboard malfunction

Replace

motherboard

Complete acceptance

inspection

Er. 305

1

Heater disconnected

Replace heater

Heat drift test

2

SSR malfunction

Replace SSR

Heat drift test

3

Motherboard malfunction

(runaway)

Replace

motherboard

Complete acceptance

inspection

Er. 306

1

Improper usage

Use properly

Check proper usage

2

Heater SW malfunction

Replace heater

SW

Check operation during

measurement

- 3 - - 3 -

Malfunction

Causes

Solutions

Inspection Method After

Repairs

Er. 401

1

Bad balance connector

contact

Reattach

connector

Complete acceptance

inspection

2

Balance board malfunction

Replace balance

board

Complete acceptance

inspection

3

Motherboard malfunction

Replace

motherboard

Complete acceptance

inspection

4

Balance malfunction

Replace balance

Complete acceptance

inspection

Er. 501, 502

1

Incorrect usage (CAL

method)

Use properly

Check proper usage

2

Bad balance connector

contact

Reattach

connector

Complete acceptance

inspection

3

Balance malfunction

Replace balance

Complete acceptance

inspection

Er. 601, 602

1

Bad motor connector

contact

Reattach

connector

Check operation during

measurement

2

Motor malfunction

Replace motor

Check operation during

measurement

3

Motherboard malfunction

Replace

motherboard

Complete acceptance

inspection

Er. 603

1

Bad motor connector

contact

Reattach

connector

Check operation during

measurement

2

Improper PI board

attachment

Reattach PI

board

Check operation during

measurement

3

PI board malfunction

Replace PI board

Check operation during

measurement

4

Motherboard malfunction

Replace

motherboard

Complete acceptance

inspection

- 4 - - 4 -

Malfunction

Causes

Solutions

Inspection Method After

Repairs

Er. 701, 702

1

Incorrect usage (power

selection SW)

Use properly

Check proper usage

2

Power voltage problem

Use correct

power

Turn power on again

3

SW power malfunction

Replace SW

power

Turn power on again

Er. 801, 802

1

Motherboard malfunction

Replace

motherboard

Complete acceptance

inspection

- 5 - - 5 -

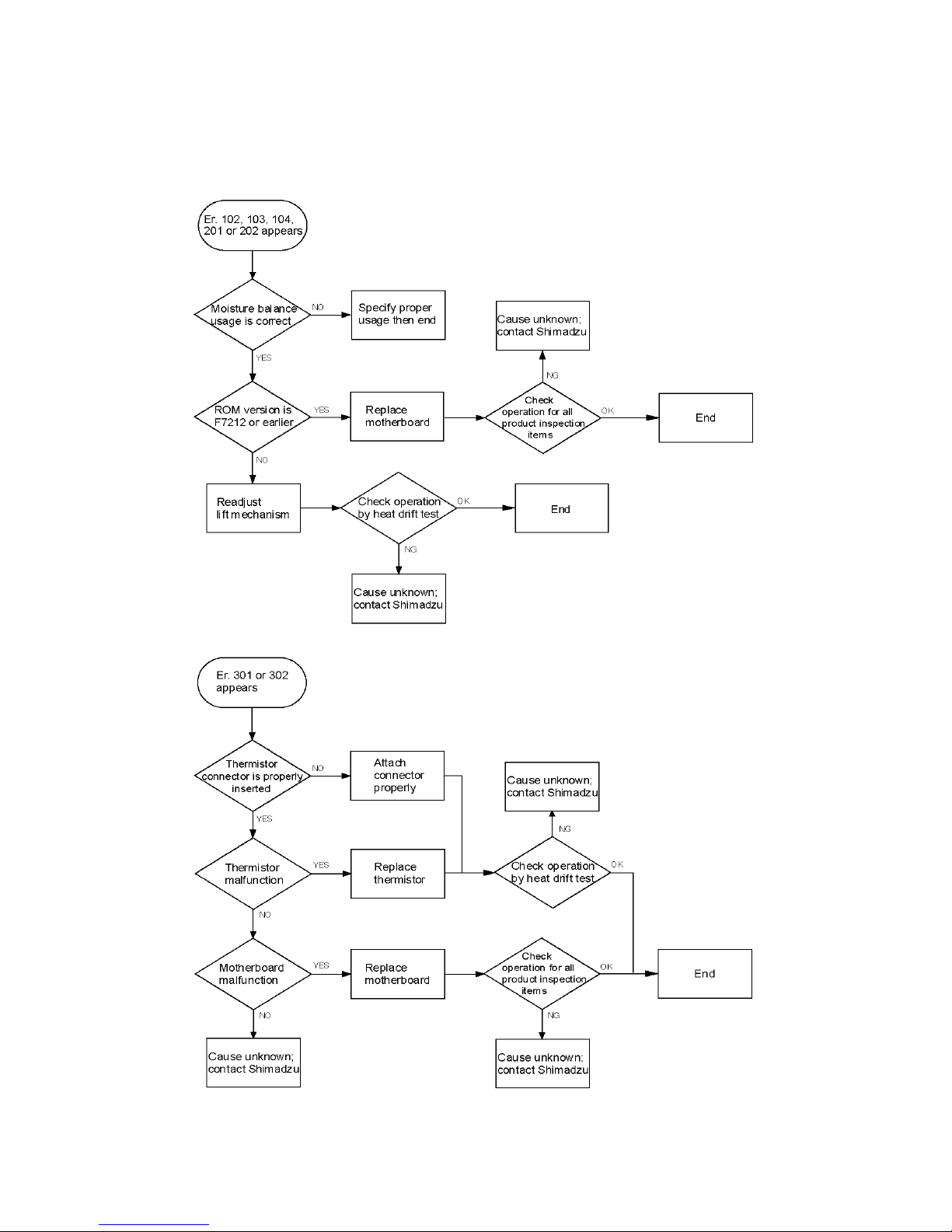

2.Trouble shooting

2-1【Er. 102, 103, 104, 201, 202】

2-2【Er. 301, 302】

- 6 - - 6 -

2-3【Er. 303】

2-4【Er. 304】

- 7 - - 7 -

2-5【Er. 305】

2-6【Er. 306】

- 8 - - 8 -

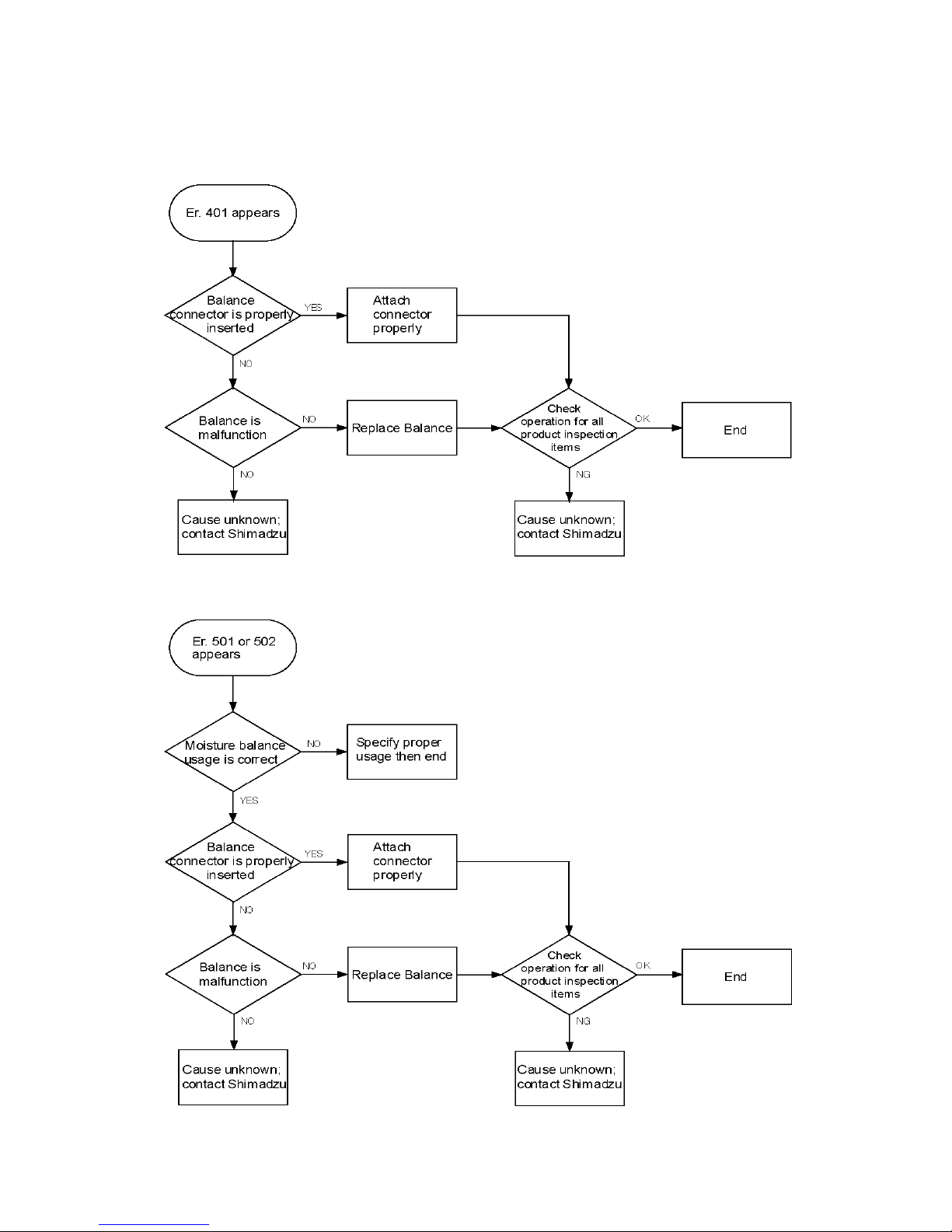

2-7【Er. 401】

2-8【Er. 501,502】

- 9 - - 9 -

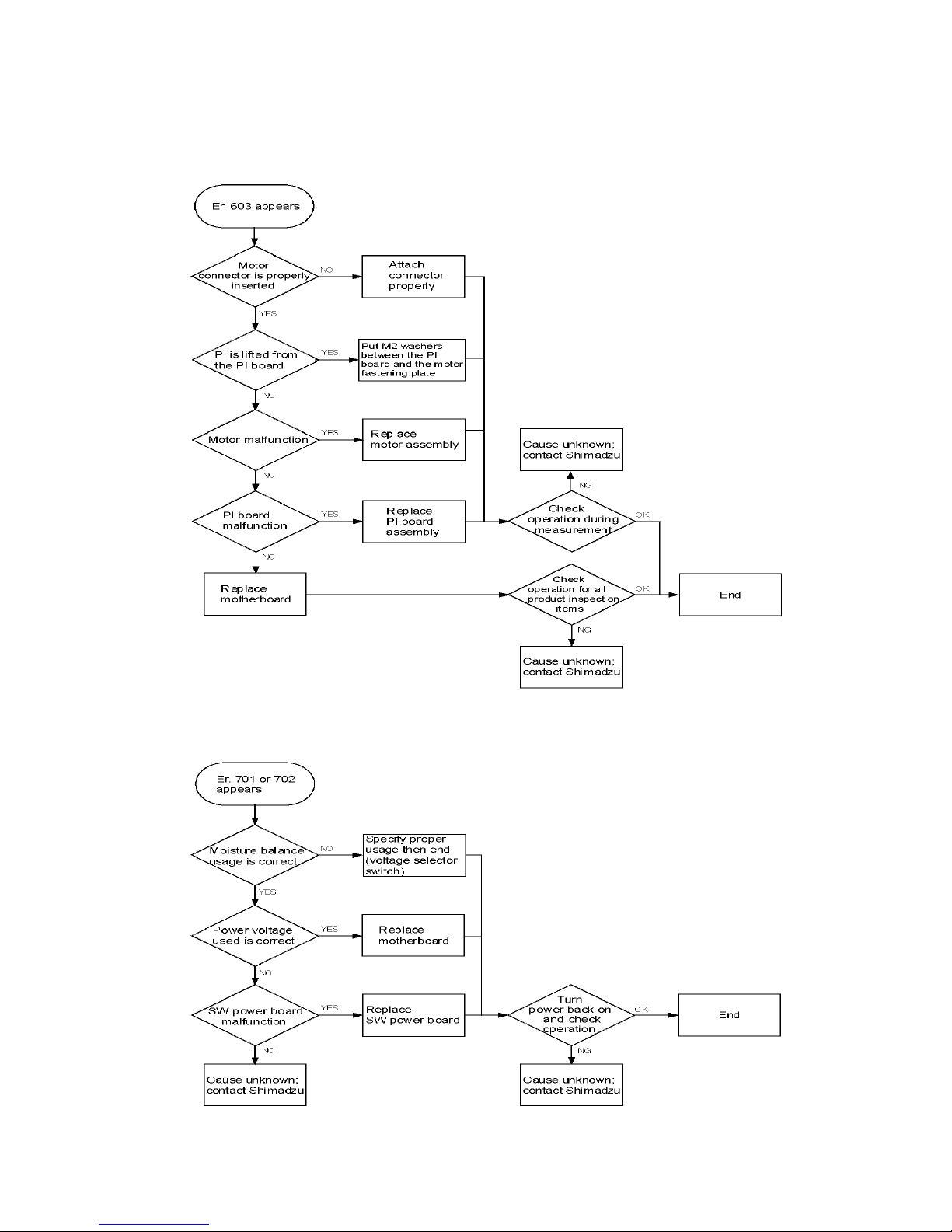

2-9【Er. 603】

2-10【Er. 701,702】

- 10 - - 10 -

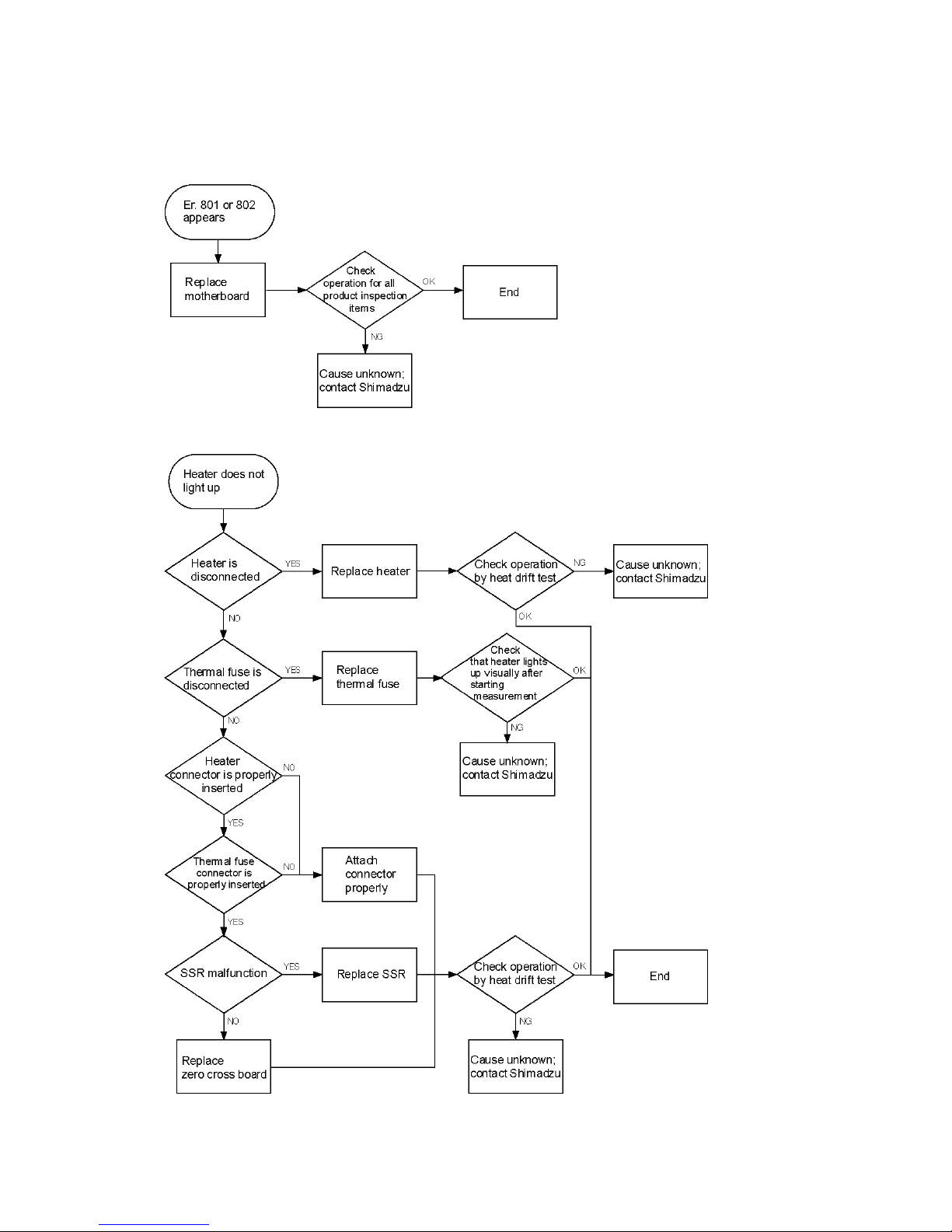

2-11【Er. 801 or 802】

2-12【Heater does not light up】

- 11 - - 11 -

2-13【Mass Measurement is Unstable】

2-14【After Turning Power On, “CHEO”, “-oL” or Other Display Does Not Turn Off】

- 12 - - 12 -

2-15【Power will not turn on (LCD does not light)】

- 13 - - 13 -

3.Service Mode of MOC-120H

Key 1

Key 2

Action

START+TARE+ENTER

Power SW

EEPROM data set to factory setting

CONDITION+MENU

Balance TAD, WAD output in measuring

START or TARE

All segment indicate

ENTER

START

(Hold 5sec)

EEPROM data output

UP

Range of zero trucking set

DOWN

LCD test mode

ENTER

TARE

(Hold 5sec)

Software Ver. indicate

SELECT

Key inspection mode

UP

Power High time indicate

DOWN

S/N input

UP

MENU

(Hold 5sec)

Maker name input

DOWN

Model name input

- 14 -

Zero cross board

Heater

Heater

Power

SSR/Thermal Fuse

Of the connectors on the upper

part of the zero cross board,

the two on the back portion of

the device are for the heater.

Remove the lead line from

the cord clip at the side of

the connector and the cord

clip on the upper case.

Pull the connector out

through the location shown

in the picture. When doing

this, kinks in the lead line will

make it difficult to pull out so

pull any kinks straight before

pulling out.

To prevent the pan supporter arm (the female

thread side) from turning when attaching the

pan supporter shaft (top), tighten the screws

while holding the pansupporter shaft as shown

in the picture.

If the pan supporter arm turns and touches

other parts, accurate measurements are not

possible.

Also, please note that tightening it too much

can cause breaking or cracks.

Pan support arm

Open the upper case

while taking care with the

harness lead.

Open while pushing it over

to the left and stand it up

as is without completely

disassembling.

- 15 - - 15 -

Open the upper case

while taking care with

the harness lead.

Open while pushing it

over to the left and

stand it up as is without

completely

disassembling

Zero cross board

Heater

Heater

Power

SSR/Thermal Fuse

Of the connectors on

the upper part of the

zero cross board, the

two on the most front

portion of the device

are for the thermal

fuse.

To prevent the pan supporter arm (the

female thread side) from turning when

attaching the pan supporter shaft (top),

tighten the screws while holding the pan

supporter shaft as shown in the picture.

If the pan supporter arm turns and

touches other parts, accurate

measurements are not possible.

Also, please note that tightening it too

much can cause breaking or cracks.

Pan support arm

Thermal fuse

via zero cross

Thermal fuse

Of the four SSR connectors, two at

the back of the device are

connected to the thermal fuse

Remove the lead line from the

cord clip at the side of the

connector and the cord clip on

the upper case.

Pull the connector out through

the location shown in the

picture. When doing this, kinks

in the lead line will make it

difficult to pull out so pull any

kinks straight before pulling

out.

- 16 - - 16 -

Open the upper case

while taking care with the

harness lead.

Open while pushing it over

to the left and stand it up

as is without completely

disassembling

Remove the lead line from

the bottom case cord clip

and the cord clip shown

circled in the picture.

Pull the connector trough

and out as shown in the

picture.

To prevent the pan supporter arm (the

female thread side) from turning when

attaching the pan supporter shaft (top),

tighten the screws while holding the pan

supporter shaft as shown in the picture.

If the pan supporter arm turns and

touches other parts, accurate

measurements are not possible.

Also, please note that tightening it too

much can cause breaking or cracks

Pan support arm

- 17 - - 17 -

Open the upper case

while taking care with

the harness lead

Open while pushing it

over to the left and

stand it up as is without

completely

disassembling.

To prevent the pan supporter arm

(the female thread side) from

turning when attaching the pan

supporter shaft (top), tighten the

screws while holding the pan

supporter shaft as shown in the

picture.

If the pan supporter arm turns and

touches other parts, accurate

measurements are not possible.

Also, please note that tightening it

too much can cause breaking or

cracks.

Peel off the LCD protection sticker

Check whether there is

a jumper line to the

SW0

FD720 : No line

MOC120H : Has line

Set the battery

If the buzzer seal is

still on, remove it.

Front

Bac

k

12V

2P

MOTOR

6P

SSR

3P

THIRMO

6P

PN-847

4P

232C

6P

BALANCE

6P

THIRMI

3P

●Checking the board

●Connector Attachment Notes

The name printed on the motherboard and number of pins for

each connector.

Connector types "MOTOR", "THIRMO", "BALANCE", and

"232C" all have 6 pins each while "SSR" and "THIRMI" have

three pins each.

Pay close attention to "BALANCE" and "232C" as their

plugs are right next to each other.

●Entering the Serial Number (Hidden Mode)

In mass display mode,

▼+ Tare/Start (hold down for 5 seconds)

"Sn" will appear in the center of the LCD and a serial number will appear as

four digits at a time.

Change the letters and numerals by pressing ▲and ▼and confirm each

digit by pressing ENTER.

●Entering the Date and Time

In mass display mode,

Menu

Press Select 3 times.

DATE will appear on the lower part of the LCD.

Press ENTER

The current date display format will appear (YMD, etc.).

To change the format, press Select and ENTER after setting.

Set "YEAR" by pressing ▲and ▼and press ENTER after setting.

Set "MONTH, DAY" and "HOUR, MINUTE" the same way.

After setting "MINUTE" and pressing ENTER, the clock will start at zero

seconds.

- 18 - - 18 -

Open the upper case

while taking care with the

harness lead.

Open while pushing it over to the

left and stand it up as is without

completely disassembling.

To prevent the pan supporter arm (the

female thread side) from turning when

attaching the pan supporter shaft (top),

tighten the screws while holding the pan

supporter shaft as shown in the picture.

If the pan supporter arm turns and

touches other parts, accurate

measurements are not possible.

Also, please note that tightening it too

much can cause breaking or cracks.

Pan support arm

Other manuals for MOC-120H

1

Table of contents

Other Shimadzu Measuring Instrument manuals

Shimadzu

Shimadzu TOC-V CPH User manual

Shimadzu

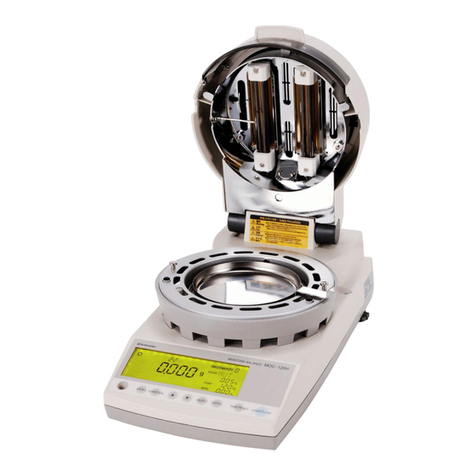

Shimadzu MOC63 User manual

Shimadzu

Shimadzu UV-1800 User manual

Shimadzu

Shimadzu MOC-120H User manual

Shimadzu

Shimadzu AGS-X Series User manual

Shimadzu

Shimadzu AA-7000 Series User manual

Shimadzu

Shimadzu PDA-7000 User manual

Shimadzu

Shimadzu UV-2401 PC User manual

Shimadzu

Shimadzu MOC63u User manual

Shimadzu

Shimadzu GCMS-QP2010 Series User manual