Forest-Master FM13SG User manual

15. 0

JF420

USER MANUAL

STUMP GRINDER FM13SG

TABLE OF CONTENTS

Preface 3

Safety precautions 4

Operation 6

Maintenance 10

Specifications 11

Parts list 12

Blade assembly 14

Handrail assembly 15

Brake assembly 16

Drive system assembly 17

Engine assembly 18

Stump Grinder FM13SG 2

PREFACE

Thank you for buying the Forest Master FM13SG Stump Grinder, another high-quality

machine from our company.

To get the most out of your purchase, please read this manual before using the stump

grinder.

We ask you to please read this manual carefully beforehand in order to familiarise

yourself with this product and after reading, please store this instructional manual for

future reference. Failure to follow the proper protocols listed in the manual may cause

personal injury to the operator or damage to equipment.

Stump Grinder FM13SG 3

SAFETY PRECAUTIONS

• Keep the working area clean and well lit.

• Do not operate the stump grinder in the presence of flammable liquids, gases or dust.

• Keep children and bystanders away while operating the stump grinder. Keep the area

free of all distractions.

• Only responsible, properly instructed indivuals should operate this machine.

• Inexperienced operators must always be carefully supervised.

• Do not expose stump grinders to rain or wet conditions.

• Stay alert, watch what you are doing and use common sense when operating a stump

grinder. Do not use a stump grinder while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating any stump grinders may

result in serious personal injury.

• Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

• Always wear earplugs to protect your ears.

• Do not start the engine until the machine is in the cutting position next to the stump.

• Do not overreach. Keep proper footing and balance at all times. This enables better

control of the stump grinder in unexpected situations.

• If devices are provided for the extraction and collection of dust, ensure these are

connected and properly used. Use of these devices can reduce dust related hazards.

• Check stumps to be removed for embedded nails, wire, metal fence posts and other

metallic objects and for rocks or other buried impediments which may become

dangerously thrown or cause unexpected machine movements when hit by the cutting

wheel.

• Make sure that all shields and guards are in place and are in good condition prior to

operating the machine. Check cutting wheel for damage or missing teeth and replace as

necessary.

Stump Grinder FM13SG 4

Stump Grinder FM13SG 5

• Ensure that everyone is in the vicinty is aware of the danger zone associated with this

machine(see diagram). You must avoid the danger zone at all times when the machine is

in operation.

• Make sure that no-one is working on underneath or close to the machine before

starting the engine or beginning to move the machine. Make sure that the area is free of

personnel.

• Don't make any alterations or modifications to your stump grinder.

• Check with your local council and utility providers for the locations of buried pipes and

cables where applicable, before operating the machine.

• Pay attention while handling fuel. It is flammable and the vapours are highly explosive.

• Never remove the fuel cap or add fuel with the power running. Stop the engine and

allow engine and exhaust components to cool before refueling.

• Do not smoke while adding fuel.

• Fill your engine with 10w-30 / 10w-40 / 15w-30 / 15w-40 non-synthetic engine oil

before use or serious damage will occur.

• Use extreme care when handling fuel. Fuel is extremely flammable and the vapors are

explosive. Never fuel machine indoors or while the engine is hot or running.

• Never refuel or store the machine in a place where there is open flame, spark or other

ignition objects.

• Do not attempt to start the engine if fuel is spilled. Wipe away the spillage and ensure

all fuel has dried before starting the machine.

• Always make sure the fuel cap is securely tightened and replace before starting.

• If the fuel tank needs to be drained, it should be done outdoors.

FUEL SAFETY

Stump Grinder FM13SG 6

OPERATION

ADDING OIL TO THE ENGINE

1. Only fill the fuel tank to a level 15mm lower than the top of the fuel tank. Do not

overfill.

2. Use the dipstick to check the oil level. Use 10w-30/ 10w-40/ 15w-30/ 15w-40

non-synthetic engine oil. Fill to the correct level before use.

The engine is shipped without oil. Fill to the correct level before use. Operating the

engine with no oil or oil at a low level will destroy the engine- this is not covered under

warranty.

STARTING THE ENGINE

1. Lock travel wheel by pulling brake lever fully back.

2. Make sure throttle is in slow position.

3. If the engine is cold, move the choke lever to the closed position.

4. Raise the cutter wheel 4 to 5 inches off the ground by pushing downwards on the

handle bar, hold it in that position.

The next step may cause the cutter wheel to rotate, keep everyone away.

5. Pull the starter rope lightly until resistance is felt then pull briskly. Do not allow the

rope to snap back, return it by hand to prevent damage to the starter.

6. Move the choke lever to the open position.

The next step causes the cutter wheel to rotate, keep everyone away.

7. Move the throttle to fast. if the engine is cold, allow the engine to idle(throttle set to

slow) for a few minutes before cutting.

Stump Grinder FM13SG 7

REMOVING STUMPS

• Remove all loose pieces of wood, stones, wire and other debris from the area before

beginning stump removal.

• Wind direction should be considered, as it influences the direction in which dust and

wood chips are directed.

• Never operate the grinder after dark.There will be no adequate light for the operator to

use the grinder safely.

• Always allow a cold engine time to warm up before cutting a stump.

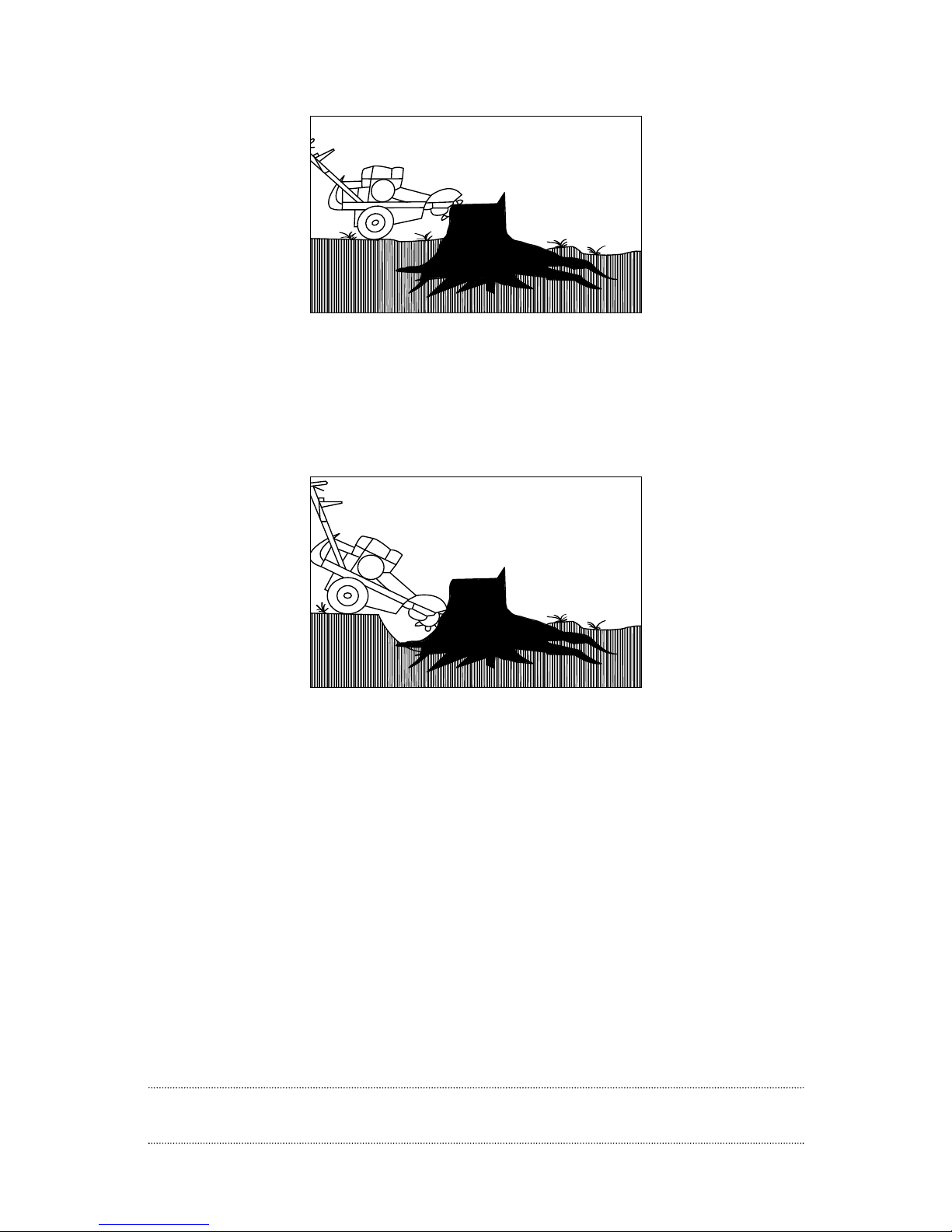

• Only the portion of cutting wheel within the 80 degree area shown below should

engage the stump. Never undercut the stump or use the bottom of the cutting wheel for

cutting purposes.

• Never leave the controls when the cutting wheel is rotating.

Operating Tips!

• Use smooth, comfortable side to side movements while operating.

• When it is desired to cut smaller roots, it may be more effective to do so before rather

than after cutting the stump.

• Should the chip build-up become excessive when cutting, shut off the machine, wait for

the cutting wheel to stop rotating, retract the machine from the stump and rake away the

chips. It is also possible to use the cutter wheel to push chips off to the side.

• In order to prevent any of the wheels becoming stuck in the hole. Move the grinder to

the other side of the stump to continue removal or by filling the hole with chips before

continuing.

Stump Grinder FM13SG 8

Prepare the grinder at the stump

Place it into position with the cutting wheel near the top edge of the stump.

Removing roots

1. Make sure the throttle is set to fast, the cutter wheel will accelerate to cutting speed.

2. Swing the cutting wheel to one side, then lower it into the nearest roots that are buried

at the foot of the stump.

3. Swing the cutting wheel before each sweep, until the roots are sufficiently removed.

4. Raise the cutting wheel until the centre of the cutting wheel is just above the top of the

stump.

5. Allow the cutter wheel to stop, release the brake and reposition the machine.

6. Lock the brake again.

Cutting the full stump

1. Make sure the throttle is set to fast. The cutter wheel will accelerate to cutting speed.

2. Direct the cutter wheel against the stump, beginning with the nearest top corner of the

stump, and steadily sweep it across the stump left and right, cutting away 1/2 inch of

wood with each sweep.

3. Raise and lower the cutter wheel between sweeps by lowering and raising the control

handle.

4. Roll the machine forward and back, by pushing and pulling on the control handle. To

do this, release the brake. Relock it when the machine has been repositioned and

continue cutting.

Stump Grinder FM13SG 9

Continue with final roots removal

Cut the remaining roots as described in STEP 2 until satisfactorily removed

SHUTTING OFF THE GRINDER

1. When stopping the machine after normal operation, lower engine speed to slow, and

push the emergency switch.

2. Set park brake before leaving the controls.

3. Shut off the engine by pushing the on/off switch.

NORMAL SHUTDOWN PROCEDURE

In consideration of your own safety and that of others, you should always use the

following normal shutdown procedures before departing from the controls for any reason

including cleaning, servicing, tranporting or inspecting the stump grinder. Never deviate

from this procedure unless so instructed in this manual or in an emergency that requires

it.

A rotating cutting wheel is very dangerous. Stand at controls and ensure that the cutting

wheel comes to a complete stop before doing anything else.

1. Move the engine throttle to the slow position.

2. Push the emergency (on/off) switch to stop the engine.

3. Set park brake before leaving controls.

EMERGENCY SHUT DOWN PROCEDURE

1. Immediately push the emergency (on/off ) switch for the engine will be shut off.

2. Be sure to allow all moving parts to come to a complete stop.

3. Pull the brake lever to engage the brake.

4. Rectify the emergency situation and return to normal operation.

MAINTENANCE

• Make sure all nuts, bolts and screws are tightened.

• Never store the equipment with petrol in the tank inside a building where fumes can reach

an open flame or spark. Allow the engine to cool before moving the grinder.

• To reduce fire hazards, keep the engine and petrol storage area free of grass, dirt and

excessive grease.

• Replace worn or damaged parts for safety. If the fuel tank has to be drained, this should

be done outdoors.

• Regularly check the oil level and add some oil or replace it if necessary.

• Frequently check the grinder and ensure that all bark and dirt deposits are removed from

beneath the deck.

• Lubricate the wheel axle and the bearings with grease regularly.

• Check the cutting wheel often. In order to achieve clean work the blade should always be

sharp and well balanced.

• Check the tightening of all bolts and screws at regularly intervals. Nuts and bolts that are

worn out or badly tightened can damage the engine or the frame.

• If the grinder hits an obstacle violently, stop the grinder and take it to a specialist for

inspection.

TRANSPORTATION

The stump grinder is designed to be transported via a van or small trailer. The machine is

equipped with grab bars that are to be used for both lifting the machine, and strapping it

down. This machine weighs approximately 110kg and should only be lifted using correct

apparatus or an adequate number of people working as a team.

There are legal road requirements for towing equipment and trailers (such as lighting and

licensing), it is the owner's responsibility to be aware of these laws and to adhere to them.

Stump Grinder FM13SG 10

SPECIFICATIONS

LCT Maxx Series 13hp Four Stroke

Stump Grinder FM13SG 11

Additional Information and Potential Changes

We reserve the right to discontinue, change, and improve this products at any time

without notice or obligation to the purchaser. The descriptions and specifications

contained in this manual were in effect at printing. Equipment described within this

manual may be optional. Some illustrations may not be applicable to your machine.

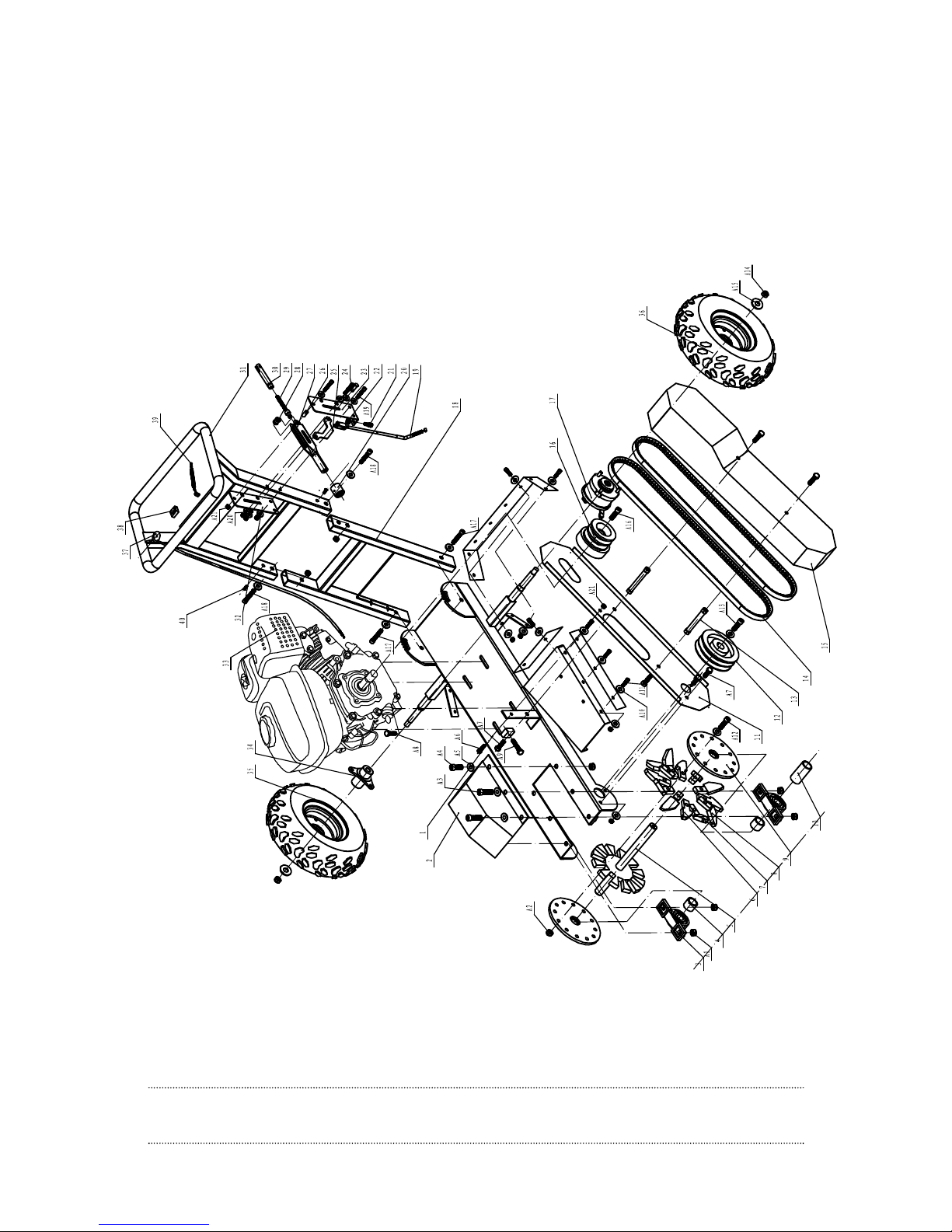

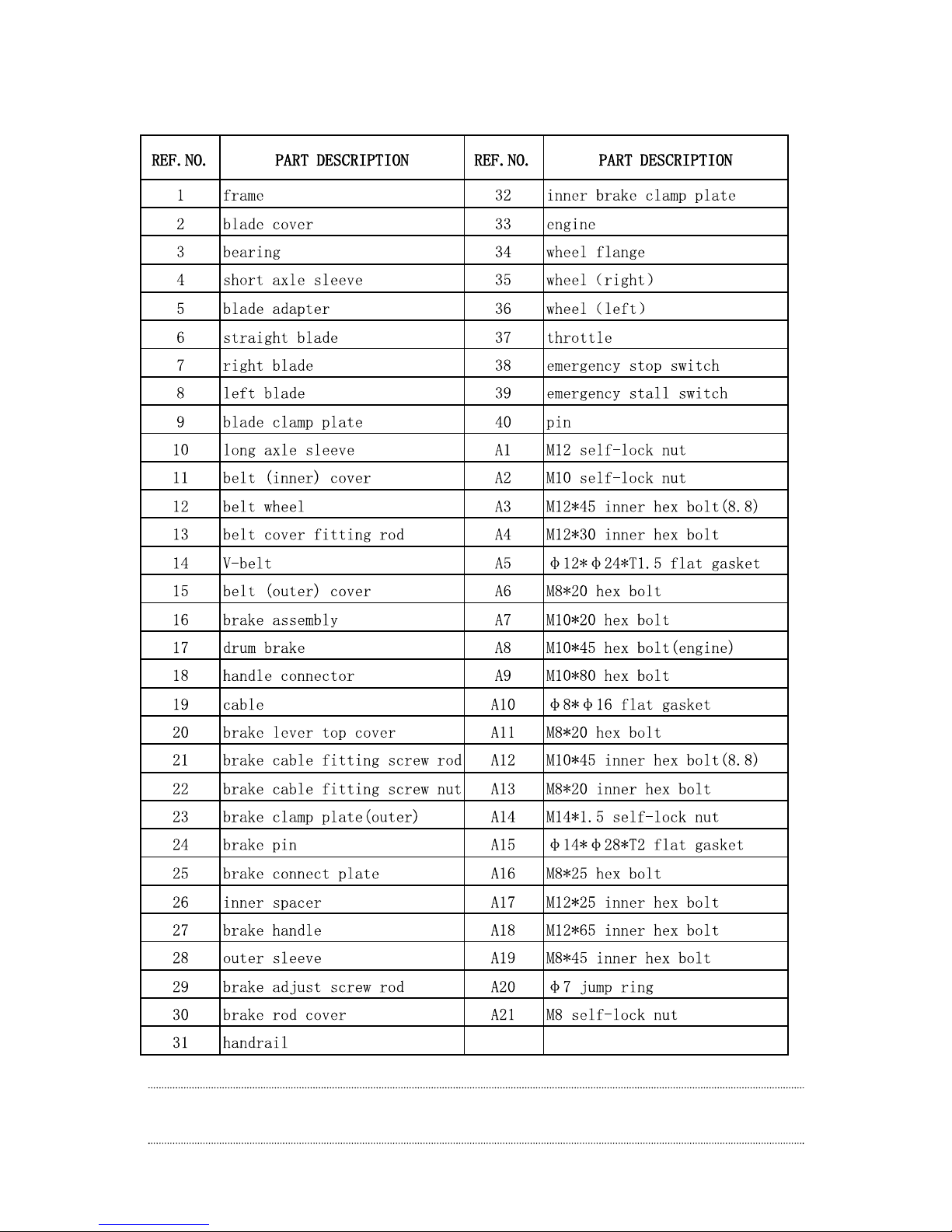

PARTS LIST

Stump Grinder FM13SG 12

Stump Grinder FM13SG 13

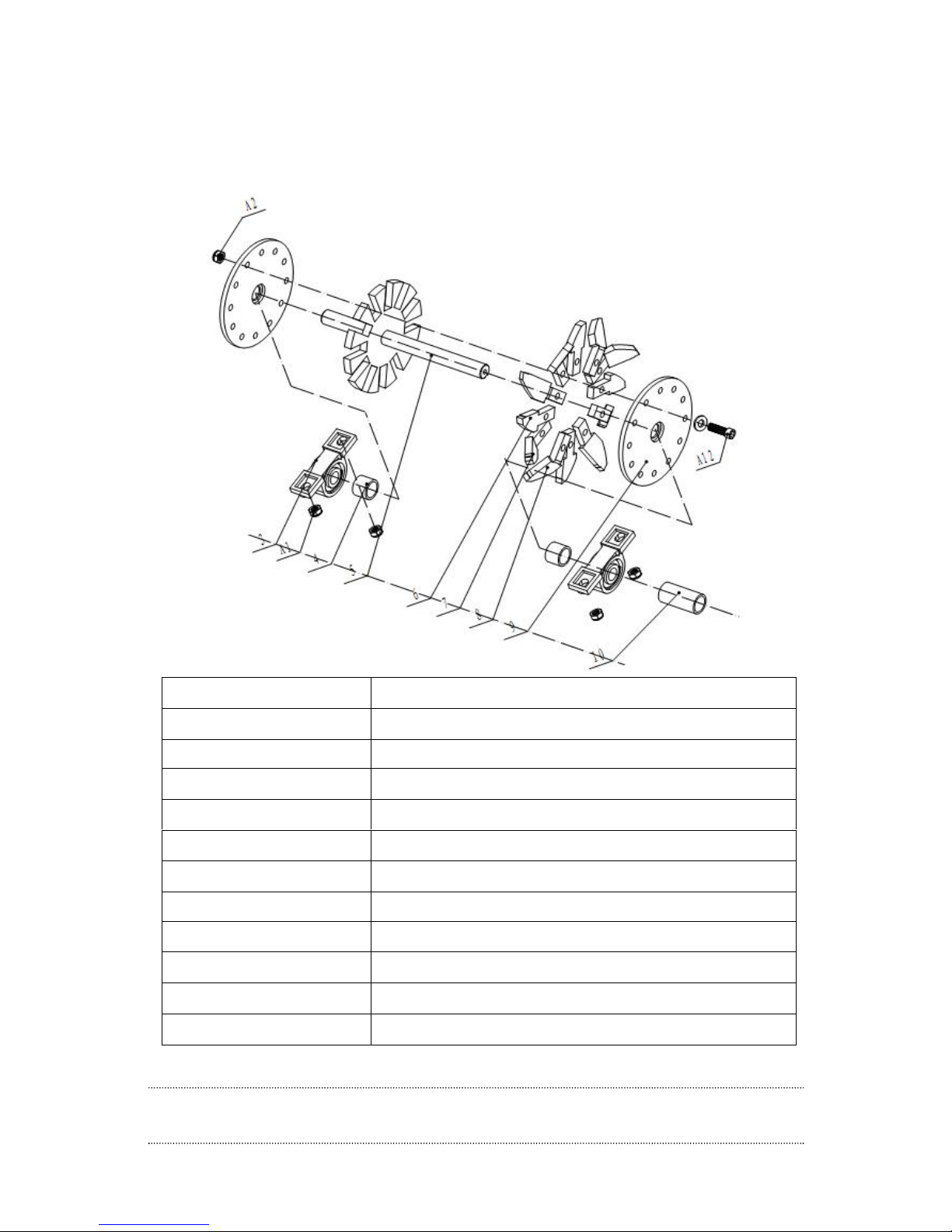

R E F. NO. DE SCR I PT I ON

3 B ear ing

A1 M 12 self-lock nut

4 Shor t axle sleeve

5 B lade adapter

6 Str aight blade

7 R ight blade

8 L eft blade

9 B lade clamp plate

10 L ong axle sleeve

A2 M 10 self-lock nut

A12 M 10*45 inner hex bolt(8.8)

Stump Grinder FM13SG 14

BLADE ASSEMBLY

R E F.NO. DES CR I PT I ON R E F.NO. DES CR I PT I ON

18 H andle connector 40 pin

31 handr ail A17 M12* 25 inner hex bolt

37 T hrottle A18 M12* 65 inner hex bolt

38 E mergency stop switch

39 E mergency stall switch

Stump Grinder FM13SG 15

HANDRAIL ASSEMBLY

R E F.NO. DES CR I PT I ON R E F.NO. DES CR I PT I ON

19 C able 27 B ra ke handle

20 B ra ke lever top cover 28 Outer sleeve

21 B ra ke cable fitting screw rod 29 B ra ke adjust screw rod

22 B ra ke cable fitting screw nut 30 B ra ke rod cover

23 B ra ke clamp plate(outer) 32 I nner bra ke clamp plate

24 B ra ke pin A19 M8*4 5 inner hex bolt

25 B ra ke connect plate A 20 7 jump r ing

26 I nner spacer A21 M8 self-lock nut

Stump Grinder FM13SG 16

HANDBRAKE ASSEMBLY

R E F.NO. DES CR I PT I ON R E F.NO. DES CR I PT I ON

11 B elt (inner) cover 16 B r ak e assembly

12 B elt wheel A 7 M 10*20 hex bolt

13 B elt cover fitting rod A13 M 8*20 inner hex bolt

14 V-belt A16 M 8*25 hex bolt

15 B elt (outer) cover A 21 M 8 self-lock nut

Stump Grinder FM13SG 17

DRIVE SYSTEM ASSEMBLY

Stump Grinder FM13SG 18

ENGINE ASSEMBLY

R E F.NO . DES CR I P T I O N

1 f r ame

2 bl ade cover

17 dr um br ake

33 engi ne

34 wheel f l ange

35 wheel ! r i ght "

36 wheel ! l ef t "

A1 M12 sel f - l ock nut

A2 M10 sel f - l ock nut

A3 M12*45 i nner hex bol t ( 8. 8)

A4 M12*30 i nner hex bol t

A5 12* 24*T1. 5 f l at gasket

A6 M8*20 hex bol t

A7 M10*20 hex bol t

A8 M10*45 hex bol t ( engi ne)

A9 M10*80 hex bol t

A10 8* 16 f l at gas ket

A11 M8*20 hex bol t

A14 M14*1. 5 sel f - l ock nut

A15 14* 28*T2 f l at gas ket

Stump Grinder FM13SG 19

Table of contents

Other Forest-Master Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Gaspo

Gaspo Vertical Garden Assembly instructions

EarthQuake

EarthQuake 9800 Series Operator's manual

Worx

Worx WG169E Safety and operating manual

Ozito

Ozito PXCPPA-200 instruction manual

LI-COR

LI-COR 6400-18 Installation and operational instructions

Suncast

Suncast Free Standing Pergola Assembly instructions