Contents

Table of contents

1About this operating manual.........................................................................................3

2Safety ...............................................................................................................................4

2.1 Intended use.....................................................................................................................4

2.2 Qualification of personnel.................................................................................................4

2.3 General safety instructions...............................................................................................4

2.4 Special safety instructions................................................................................................5

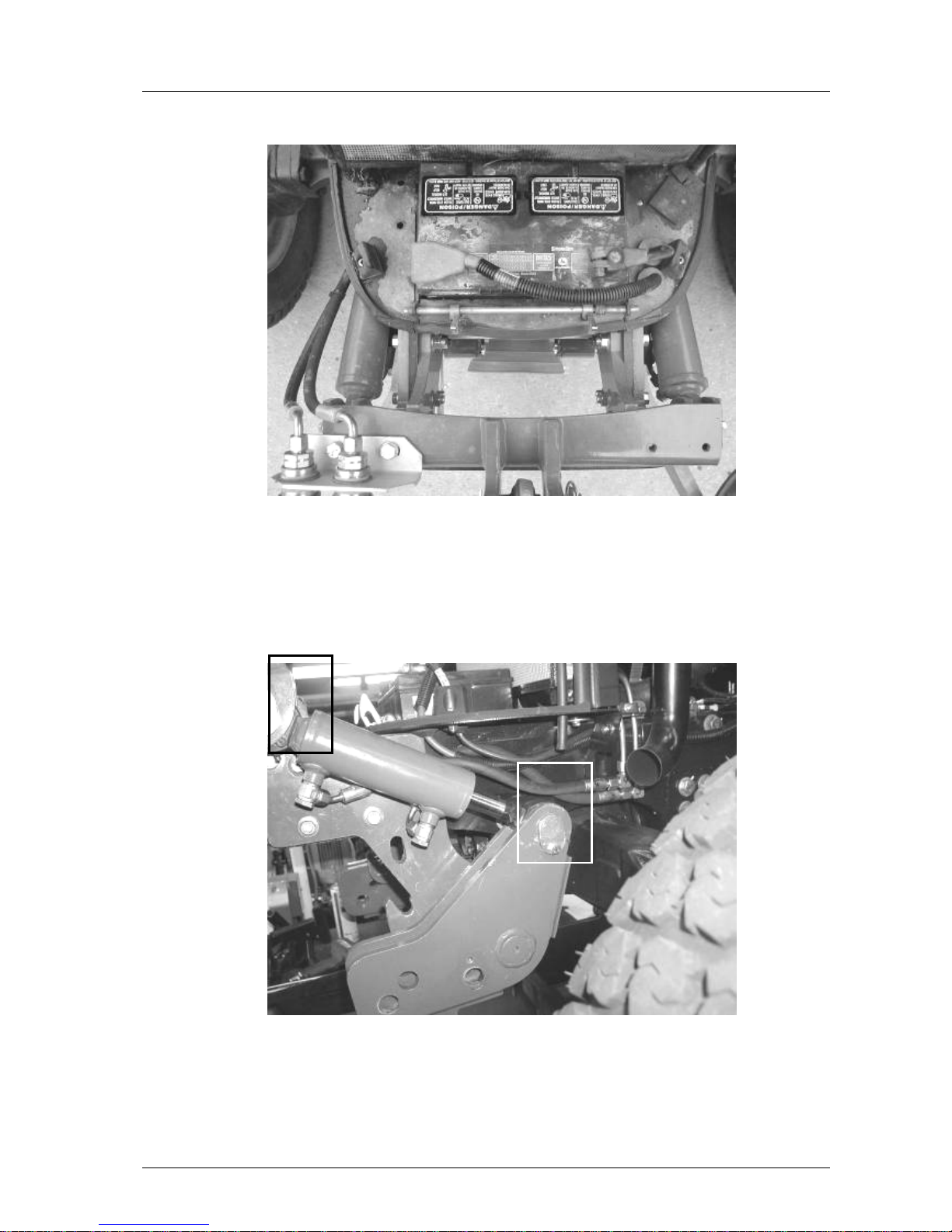

3Installation.......................................................................................................................6

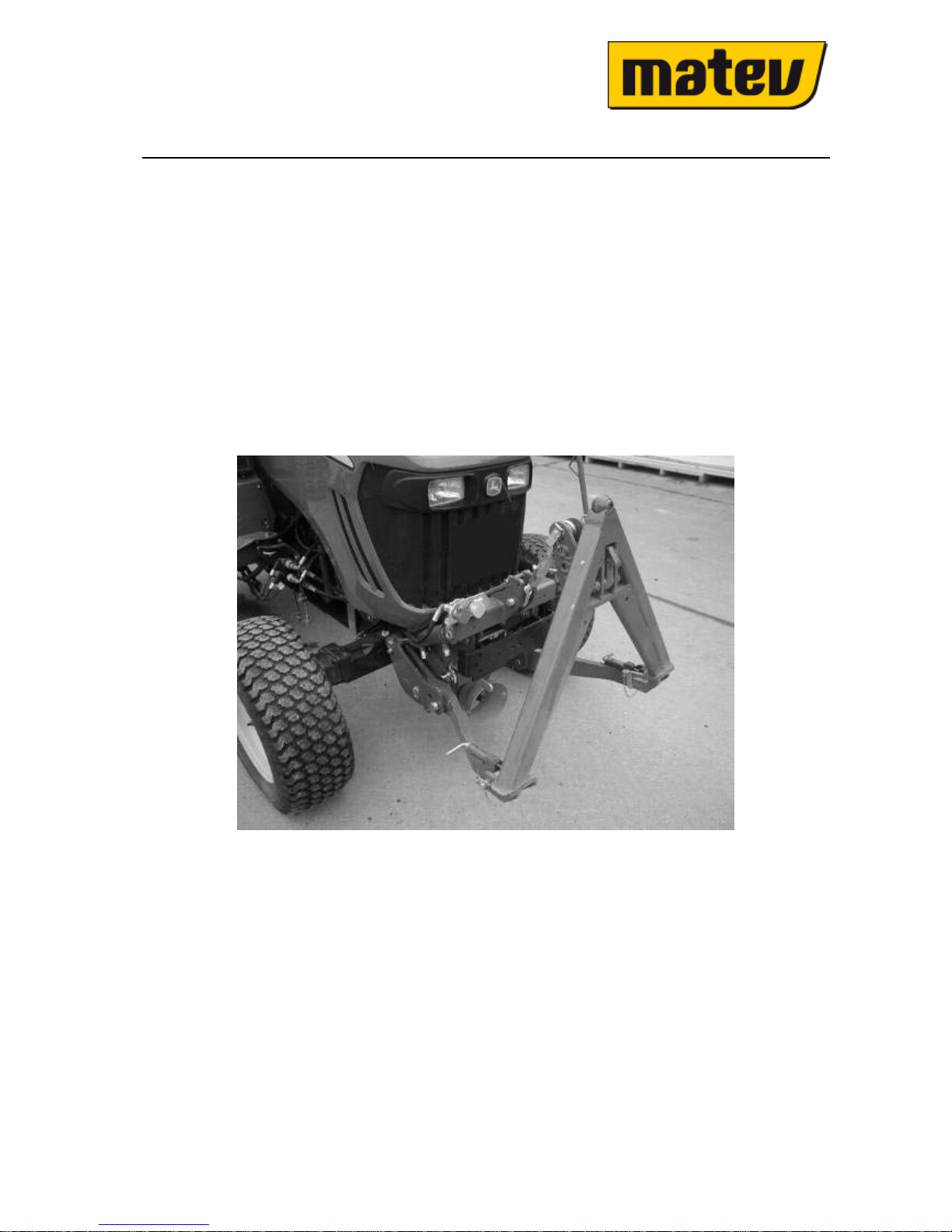

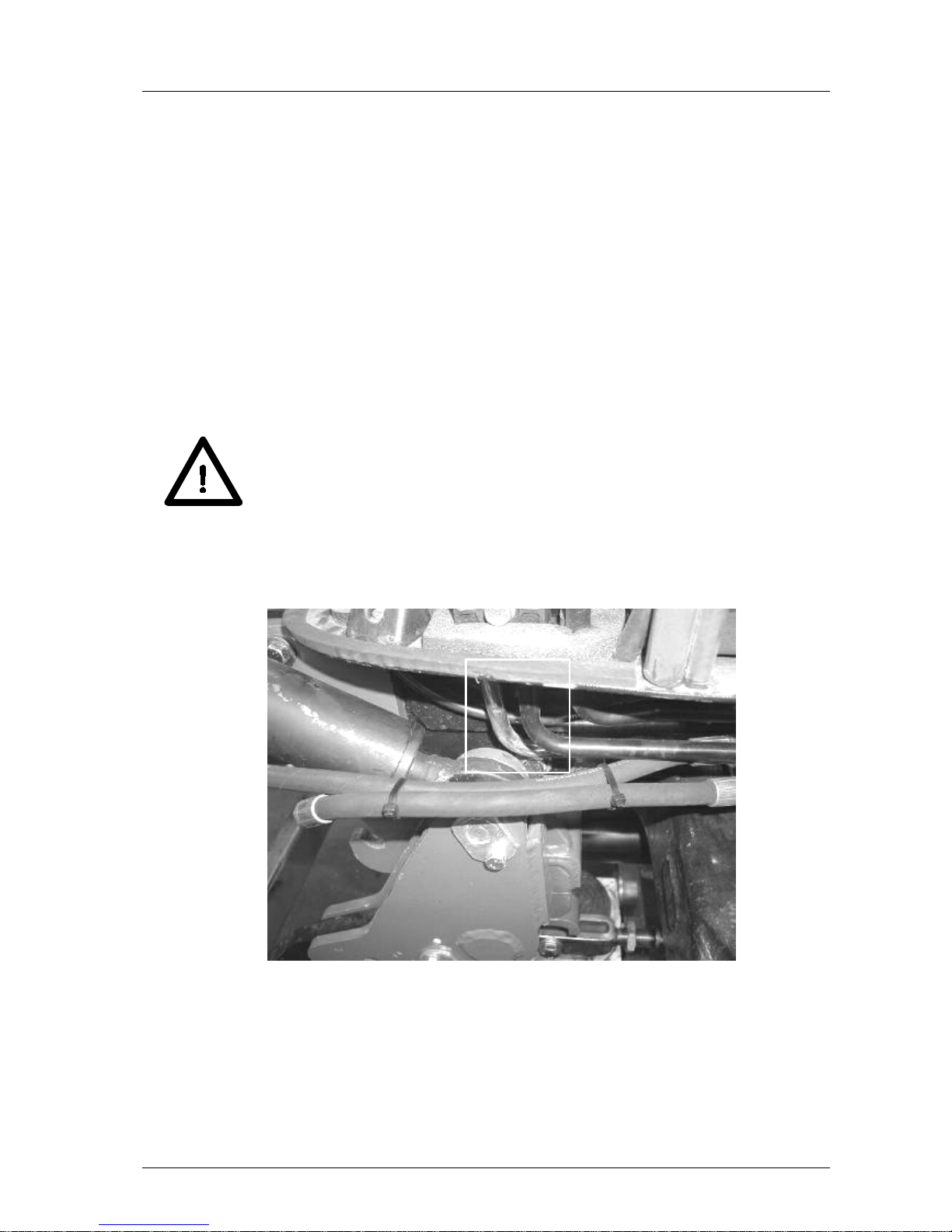

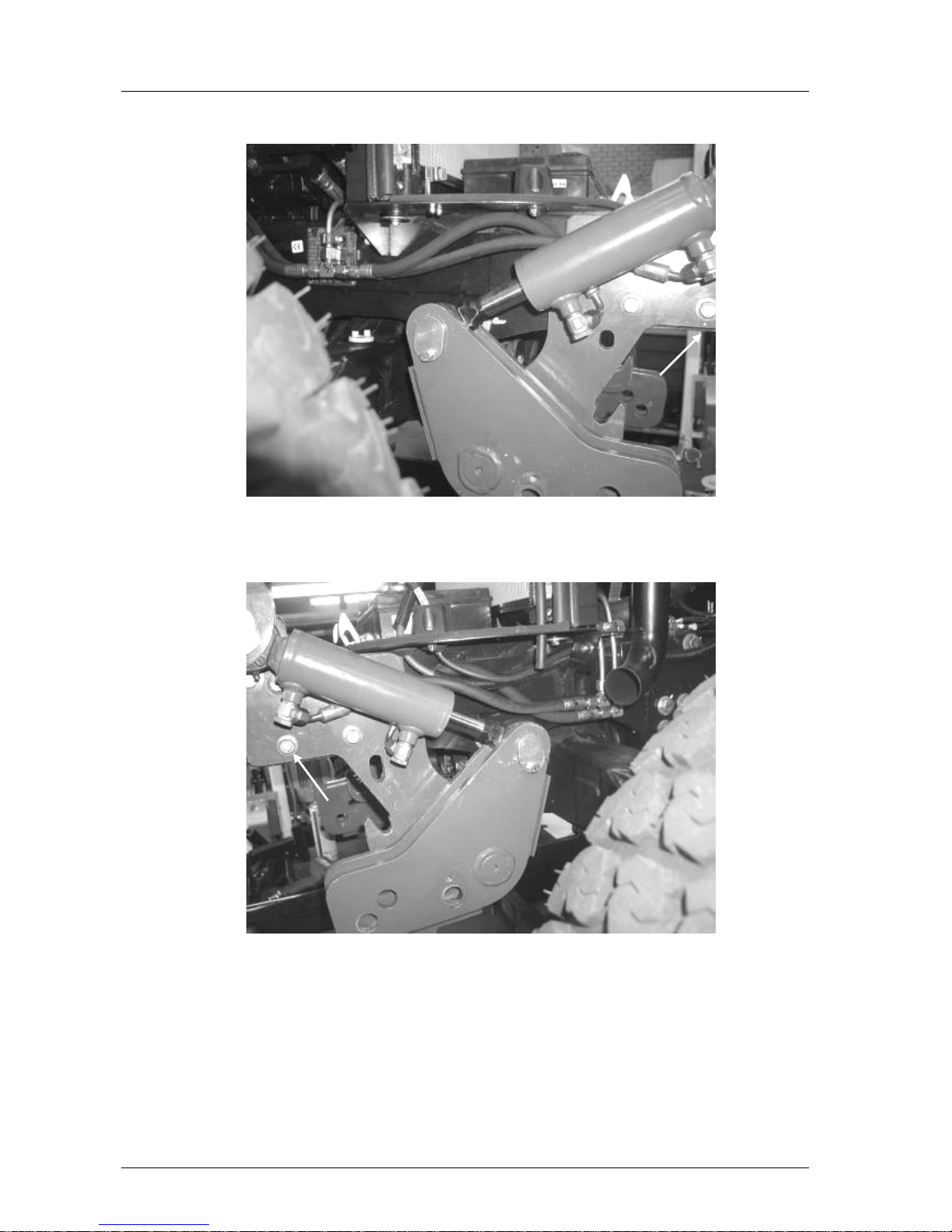

3.1 Mounting the front power lift.............................................................................................6

3.2 Installing and removing the front PTO shaft...................................................................17

3.3 Mounting the attachment kit for the mower....................................................................21

3.4 Mounting the front hydraulic extension kit......................................................................22

3.5 Mounting the front guard.................................................................................................22

4Operation.......................................................................................................................24

4.1 Front power lift with front load operation........................................................................24

4.2 Adjusting the mower.......................................................................................................27

4.3 PTO drive shaft...............................................................................................................27

5Maintenance..................................................................................................................28

5.1 General ...........................................................................................................................28

5.2 Service ............................................................................................................................28

5.3 Repair..............................................................................................................................28

6Disposal.........................................................................................................................28

7Technical data...............................................................................................................29

8Warranty.........................................................................................................................29

9List of illustrations........................................................................................................30

10 EC Declaration of Conformity .....................................................................................31