Forkardt 3QLCLM User manual

3QLCLM

POWER CHUCKS

GERMAN

O P E R A T I N G M A N U A L

Table of contents

3QLCLM

Edition: 04/2014

2

Table of contents

1.0 General information about the documentation.................................................................................................4

1.1 General information .................................................................................................................................4

1.2 Explanation of symbols .............................................................................................................................5

1.3 Copyright...................................................................................................................................................5

2.0 Safety instructions............................................................................................................................................6

2.1 General .....................................................................................................................................................6

2.2 Intended use .............................................................................................................................................7

2.3 Operating instructions ...............................................................................................................................8

2.4 Maintenance and repair.............................................................................................................................8

2.5 Safety conditions for power chucks...........................................................................................................9

2.6 Notes.........................................................................................................................................................9

3.0 Transport and storage....................................................................................................................................10

3.1 Packaging, disassembly level .................................................................................................................10

3.2 Transport, handling and storage .............................................................................................................10

4.0 Design and function ......................................................................................................................................11

4.1 General description ...............................................................................................................................11

4.2 Constructive design.................................................................................................................................12

4.2.1 Technical data / main dimensions - power chuck type 3QLCLM.....................................................12

4.2.2 Design of power chuck....................................................................................................................14

4.2.2.1 Chuck complete ...........................................................................................................................14

4.2.2.2 Centrifugal force accessories .....................................................................................................14

4.2.2.3 Body complete.............................................................................................................................15

4.2.2.4 Chuck cover complete..................................................................................................................16

4.2.2.5 Jaw complete...............................................................................................................................17

4.3 Function of the power chuck ...................................................................................................................18

4.3.1 General information: ......................................................................................................................18

4.3.2 Centrifugal force compensation .....................................................................................................19

4.3.3 Lubrication .....................................................................................................................................19

4.3.4 Sealing of the power chuck .............................................................................................................19

4.4 Chuck jaw ..............................................................................................................................................20

4.4.1 General information.........................................................................................................................20

4.4.2 Safety instructions for top jaws ......................................................................................................20

4.5 General safety instructions.........................................................................................................................21

5.0 Clamping force ..............................................................................................................................................22

5.1 General information.................................................................................................................................22

5.2 Clamping force FSp0 ................................................................................................................................22

5.3 Dynamic gripping force ..........................................................................................................................23

5.4 Clamping force calculation .....................................................................................................................24

5.5 Determination of gripping force Fspz required for the machining process .............................................26

5.6 Permissible extension length .................................................................................................................28

6.0 Assembly ......................................................................................................................................................29

6.1 Actions to be taken before assembly .....................................................................................................29

6.1.1 Checking the spindle head for mounting the chuck flange .................................................................29

6.1.2 Checking the mounted chuck flange ..................................................................................................29

6.1.3 Adjustment of the drawbar...................................................................................................................30

6.1.4 Adjustment of the drawbar...................................................................................................................31

6.2 Assembly of the power chuck..................................................................................................................32

6.3 Procedure for assembling the power chuck ...........................................................................................32

6.4 Tightening torques of shaft screws ........................................................................................................34

6.4.1 Tightening torques of the chuck mounting screws: ............................................................................34

6.4.2 Torque of the jaw mounting screws .....................................................................................................34

6.5 Preparations for using the power chuck ................................................................................................36

6.6 Safety instructions .................................................................................................................................36

Table of contents

3QLCLM

Edition: 04/2014

3

7.0 Initial operation................................................................................................................................................37

7.1 Notes .......................................................................................................................................................37

7.2 Initial operation, operation........................................................................................................................38

7.3 Unauthorized operating modes................................................................................................................38

7.4 Safety instructions ..................................................................................................................................38

7.5 Behavior in case of faults.........................................................................................................................38

7.6 Measures during longer standstill ............................................................................................................39

7.7 Measures after longer standstill...............................................................................................................39

7.8 Oil selection.............................................................................................................................................40

8.0 Maintenance ...................................................................................................................................................41

8.1 Lubrication ..............................................................................................................................................41

8.2 Maintenance plan ...................................................................................................................................42

8.3 Disassembly of the power chuck..............................................................................................................42

9.0 Spare parts and customer service .................................................................................................................46

9.1 Spare parts .............................................................................................................................................46

9.2 Tools and accessories ............................................................................................................................46

9.3 Customer service ...................................................................................................................................47

10.0 Declaration of incorporation .........................................................................................................................48

Table of contents

3QLCLM

Edition: 04/2014

4

1.0 General information about the documentation

1.1 General information

This operating manual contains the required information for the intended use of 3-jaw power chuck with

balancing of centrifugal force type 3QLCLM. The manual is meant for technically qualified persons.

Qualified persons are:

•Persons, who are trained in handling of the power chuck as operating staff.

•Persons, who as commissioning and service staff possess educational qualification

required for commissioning and repair.

The instructions in this operating manual must be read and understood completely for

the operation, maintenance and repair of the power chuck.

We reserve the right to make technical changes necessary to improve the power chuck which may

result in deviations from the illustrations and information contained in this manual. This operating

manual may not be reproduced or copied, either in full or in part, utilized for the purposes of competition.

FORKARDT DEUTSCHLAND GMBH retains the copyright for this operating

manual.

The operating manual, prepared based on DIN V 8418, must be read, understood and followed by the

responsible operating staff.

Important details for the use of power chuck are pointed out in this operating manual. Faults in the

power chucks can be prevented and a trouble-free operation can be guaranteed only with the

knowledge of this operating manual.

•We would like to point out that we are not liable for damages and operational interruptions,

which may result from non-compliance of the operating manual.

•Please contact our customer service department if you still have any difficulties and they will be

happy to help you. Customer service - see corresponding section.

•This operating manual only refers to power chuck

Type 3QLCLM

•We reserve the right to make technical changes necessary to improve the power chuck, Type

3QLCLM, which may result in deviations from the illustrations and information contained in this

manual.

Table of contents

3QLCLM

Edition: 04/2014

5

1.2 Explanation of symbols

Safety instructions for preventing mortal hazards or material damages are highlighted in this operating

manual through the key terms and pictograms.

Indicates possible hazard. Death, severe bodily injury or significant material damages

can occur if the precautionary measures are not taken or if the safety instructions are

not followed.

Indicates an important information to prevent material damages or unwanted

operational states.

Indicates an important information for handling or additional information.

1.3 Copyright

This operating manual is meant for the assembly, operating and monitoring staff. It contains

specifications and drawings of technical nature, which may not be copied, reproduced, either in full or in

part, or utilized for the purposes of competition without authorization.

The company retains the copyright for this operating manual.

FORKARDT DEUTSCHLAND GMBH

Lachenhauweg 12

72766 Reutlingen

Germany

Telephone: +49 7127 5812 0

Fax: +49 7127 5812 122

Administration and central warehouse: Lachenhauweg 12, 72766 Reutlingen

Made in Germany

© 2014 COPYRIGHT FORKARDT DEUTSCHLAND GMBH

Table of contents

3QLCLM

Edition: 04/2014

6

2.0 Safety instructions

2.1 General information

Power chucks may result in risks if their use and handling does not correspond to the safety

requirements. The power chuck has been built based on state-of-the-art technology and is safe to use.

However, the power chuck can pose certain risks if it is used improperly or not as intended by

unqualified personnel.

The following instructions are meant for personal safety and prevention of damages to the described

product or connected devices.

Read this operating manual before starting work with the power chuck and follow all safety

instructions. Non-compliance with the instructions contained in this manual may result in

mortal danger, severe bodily injury or severe material damages.

•Only qualified staff are allowed to work with the power chuck.

•Unauthorized modifications and changes to the power chuck are not allowed.

•Use the power chuck only in perfect condition.

•Switch off the machine before working on the chuck and secure the machine

against unintentional restart.

•Only use original components and spare parts of the manufacturer. Warranty shall

not be applicable if foreign parts are used.

•Before starting work with the power chuck, check whether all safety equipment are mounted

•The system "lathe-clamping device-work piece" is mainly influenced by the work piece to be

produced, which may result in a residual risk. This residual risk must be evaluated by the

operating company.

The manufacturer is not liable for damages resulting from non-compliance with the

operating manual!

Table of contents

3QLCLM

Edition: 04/2014

7

2.2 Intended use

The 3-jaw power chuck with centrifugal force compensation of Type 3QLCLM is engaged through a

rotary double piston clamping cylinder. Its axial actuating force must be suitable for the power chuck.

The power chuck 3QLCLM must be used only for its intended purpose. Intended use is the

clamping of work pieces on lathes and other tooling machines.

The maximum gripping force and maximum speed of the chuck must not exceeded. The permissible

speed or the required gripping force must be determined for the application in accordance with the

applicable technical rules (e.g. VDI 3106). In case of doubt or accessories not provided by the

manufacturer, the threshold values must be approved by the manufacturer or redefined.

The following factors must be taken into consideration:

•Variable friction coefficient between work piece and top jaw

•Proportion of clamping diameter and working diameter

•Magnitude of the cutting force on the cutting tool

•Swing of the top jaw from the clamping point

•Decrease of the gripping force through centrifugal force due to external clamping

Even adherence to the assembly, commissioning, operating and repair conditions prescribed by the

manufacturer are part of intended use. Any and all other usage is considered improper use. The

manufacturer cannot accept liability for damage resulting from such use.

Table of contents

3QLCLM

Edition: 04/2014

8

2.3 Operating instructions

Rotary clamping devices must be secured with suitable covering hood or safety door before touching

in accordance with the regulations of the trade associations.

The machine must be stopped immediately in case of any faults in the power chuck

during operation. It can be operated again only if the fault is fixed.

After switching off clamping energy, loosen the work piece from the power chuck. The local safety

provisions and accident prevention regulations of the respective trade associations in their applicable

version are applicable for the operation of the power chuck.

2.4 Maintenance and repair

In case of maintenance work or inspection work on the power chuck, stop the machine and switch off

power supply to the clamping cylinder.

The power chuck is exposed to high loads when it is subject to speeds that are normal on rotary

machines. In case of occasional collisions between the tool and power chuck, e.g. faults in program

sequence, the power chuck can be damaged.

After a collision stop the lathe immediately and check the power chuck for damages. In

addition to easily identifiable damages, the tool may also have hidden damages such as

hairline cracks in the chuck head and damages to the sealing elements.

Check the affected parts of the power chuck in such case with a suitable and non-destructive test

method and check for cracks and replace the chuck in case of any damage.

Only use original FORKARDT spare parts.

Table of contents

3QLCLM

Edition: 04/2014

9

2.5 Safety conditions for power chucks

The safety conditions for the operation of power chucks are defined in the testing principles of the trade

associations as well as DIN, VDE and VDI guidelines. The individual test conditions are guaranteed

through following measures:

Test conditions

guaranteed by

The machine spindle can start only when the

complete clamping pressure is built up in the

clamping cylinder

1. Pressure switch in the clamping lines

2. Pressure indicator manometer

The machine spindle can start only if the tension is

in the permissible range of the jaw stroke

chucking stroke monitoring on the actuation

cylinder through electrical limit switch.

The clamping can be released only when the

machine spindle is stationary

Standstill monitoring at the

machine spindle

The work piece remains clamped up to spindle

standstill if there is failure of clamping energy

Non-return check valve in the actuation

cylinder

There will not be any change to the switch position

in case of electricity failure and return

Impulse-controlled way valve with

locked end positions

A signal will be sent for automatic or manual

spindle stop in case of failure of clamping energy

Pressure switch in the clamping line

2.6 Instructions

The operating manual, prepared based on DIN V 8418 and DIN EN 292, must be read, understood and

followed by the responsible operating staff.

Important details for the use of power chuck are pointed out in this operating manual. Faults in the

power chucks can be prevented and a trouble-free operation can be guaranteed only with the

knowledge of this operating manual.

We would like to point out that we are not liable for damages and operational interruptions, which may

result from non-compliance of the operating manual.

Please contact our customer service department if you still have any difficulties and they will be happy

to help you.

Table of contents

3QLCLM

Edition: 04/2014

10

3.0 Transport and storage

3.1 Packaging, disassembly level

The weight of the product and transport route are also decisive for the packaging type. The power

chuck are wrapped in oil paper or clear foil to protect against dirt.

Power chuck up to size of 315 mm 0:

- Packaging in folding cartons, with corresponding padding or - in case of longer transport route - by

filling the folding carton with foam.

Power chuck up to size of 400 mm 0:

- Packaging in wooden crates, with suitable filler material (e.g. Styrofoam chips) and with the

inclusion of accessories such as top jaws and chuck key.

Power chuck are delivered in completely assembled condition, intermediate or chuck flange

separately.

3.2 Transport, handling and storage

Report transport damages to the freight forwarder. Please report missing parts to the manufacturer

immediately by phone and in writing.

If the power chuck is not mounted immediately after delivery, it must be stored in a safe location. In

such case, cover the parts properly and protect against dust and moisture.

All blank parts of the power chuck as well as accessories are coated with preserving material to

provide better protection (e.g. Metal protector Plus, Molykote brand).

The scope and contents of the delivery is listed in the delivery notes and its completeness must be

verified when the power chuck is received.

The icons (in accordance with DIN 55402 Part 1) on the packaging must be followed, e.g.:

Top

Keep dry

Keep away from heat

Hand hooks

prohibited

Center of gravity

Attach here

Table of contents

3QLCLM

Edition: 04/2014

11

4.0 Design and function

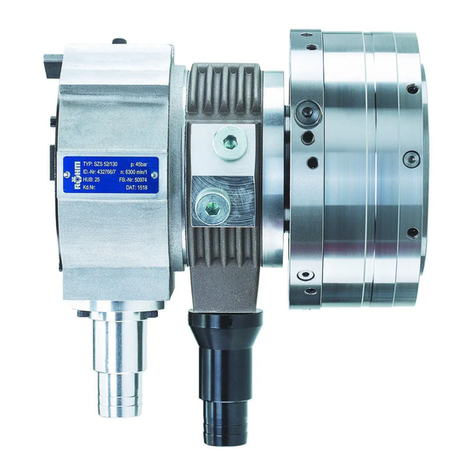

4.1 General description

3QLCLM power chucks are wedge hook chucks with large through hole, centrifugal force

compensation and integrated lubricant reservoir. Thanks to hermetic sealing, these are

maintenance-free and insensitive to dust. They are suitable for use as universal chucks for almost all

lathe operations:

- for heavy duty machining of disc and rod-shaped parts

- for delicate finishing of easily deformable work pieces.

The new series of 3QLCLM power chucks is a result of consistent development of existing power

chuck (QLC) and has proven design elements. Type 3QLCLM power chucks were developed by using

computer-assisted calculation methods and are manufacturing using high-quality steel with most

advanced production technology (developed and manufactured under ISO 9001). Power chuck sizes

of 160, 200, 250, 315 and 400 mm diameter. The main features of Type 3QLCLM power chuck are

described below:

•Innovative master jaw profile with optimal guide length.

•Jaw guides customized to profile to avoid loss of lubricant.

•Improved efficiency due to the multiple jaw guides and shortened jaw radius.

•Integrated lubricant reservoir with improved forced circulation.

•Zero backlash wedge hook mechanism for maximum gripping force and accuracy.

•Centrifugal force compensation for maximum speeds.

•Large through hole for rod works.

•Selected material pairing - all force-transmitting parts are hardened and polished

•Simplified form through piston connection in the chuck and not sliding in the rear side.

•Base jaw connections based on European and international standard.

•Developed and manufactured under ISO 9001.

•Thanks to suitable accessories - actuation cylinder, hard or soft top jaws matching the work piece

and drawbar or the pull rod as connection element between power chuck and actuation cylinder -

complete solution as modern and powerful power chuck device.

The zero backlash wedge hook mechanism (domestic and foreign patents) guarantees maximum

clamping accuracy, irrespective of functional and manufacturing-related dimensional differences of the

individual parts. Counterweights behind the master jaws reduce the centrifugal force of the jaw and

allow use of 3QLCLM - chuck with high or delicately reduced gripping force in all speed ranges. The

lubricant reservoir in the sealed chick body ensures the force-transmitting sliding surfaces with each

chuck stroke and ensures constant gripping force with extended maintenance intervals.

The jaw profile (patented) offers an optimal guide length for inner and outer clamping, reduces the

load and wear and tear and prevents entry of coolant fluid as well as spinning of lubricant grease. The

manufacturing of all chuck components in highest FORKARDT quality guarantees a long service life

and reliable function (monitoring with the most modern testing equipment / quality assurance in

accordance with ISO 9000).

Table of contents

3QLCLM

Edition: 04/2014

12

4.2 Constructive design

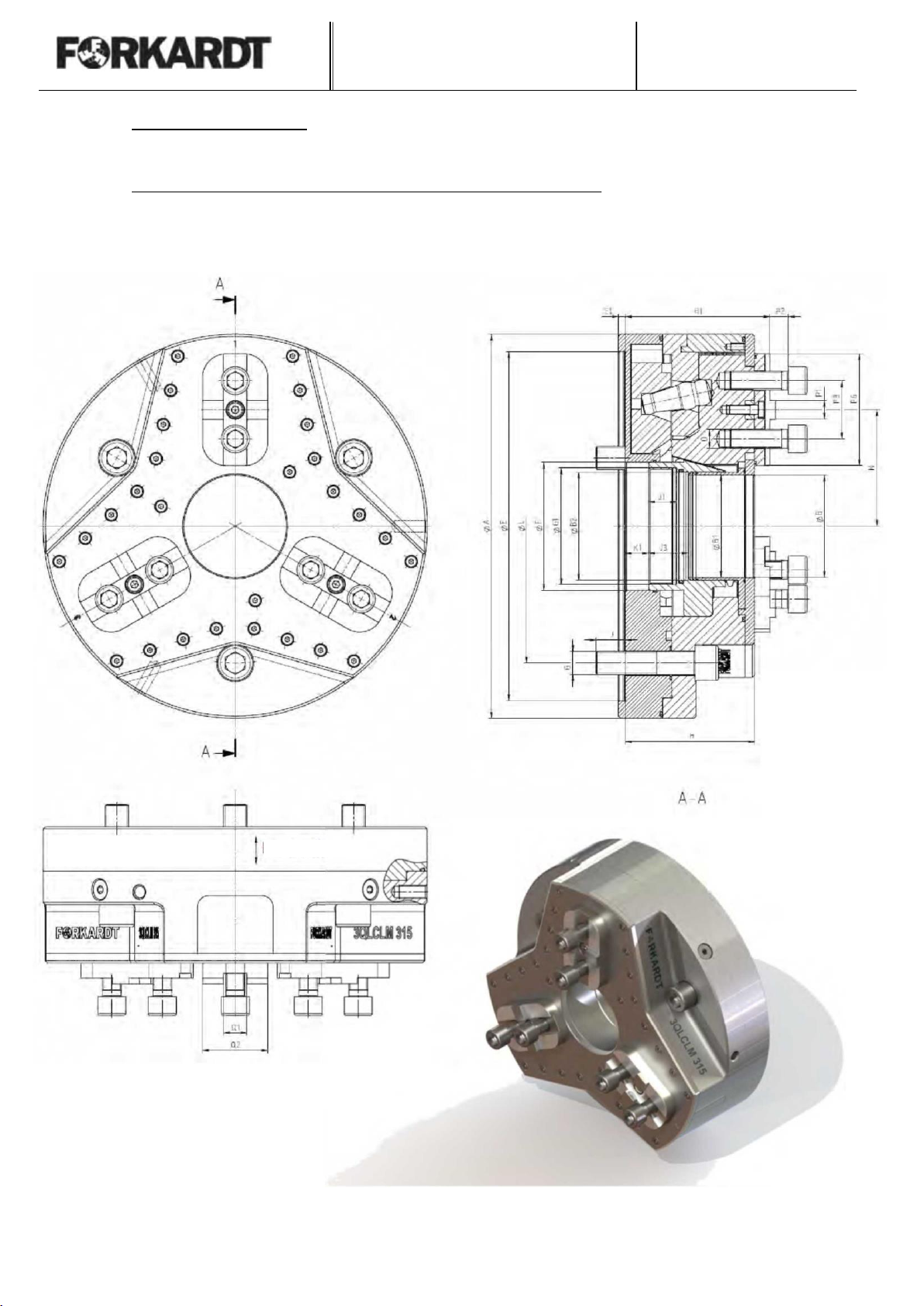

4.2.1 Technical data / main dimensions - power chuck type 3QLCLM

3QLC 315-LM-Z11-KDIN

max 4000 U/min

Fmax 60KN

Table of contents

3QLCLM

Edition: 04/2014

13

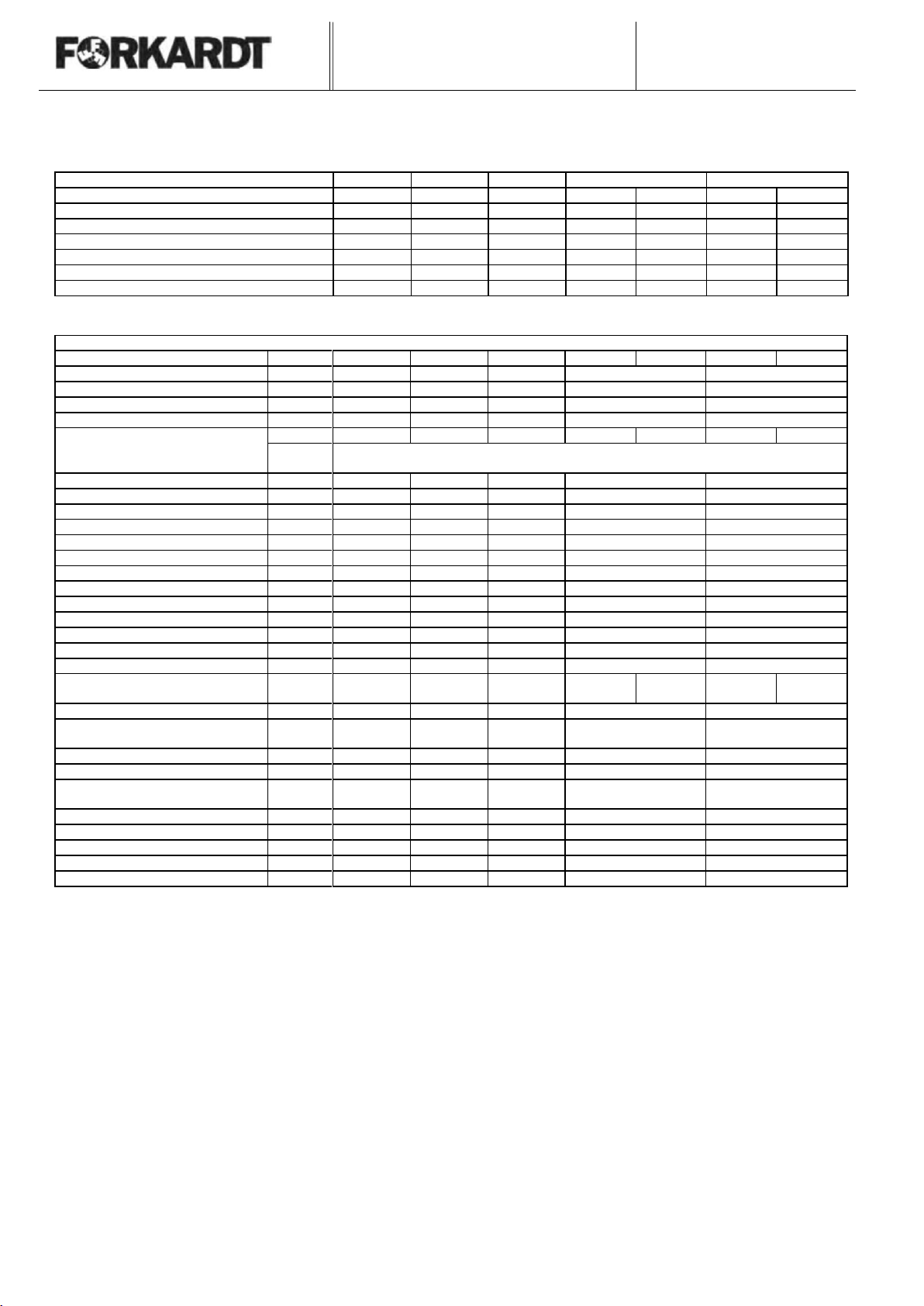

Technical data / main dimensions

Power chuck Type 3QLCLM

Chuck type 3QLCLM

160-38

200-54

250-72

315-88

400-126

Ident-No.

191203000

191216000

190476000

Max. actuation force - F max

daN

4000

6000

6000

Max. gripping force - Fsp max

daN

7000

9100

12000

Max. speed - n max

min-1

6300

4500

4000

Mass moment of inertia J

kgm2

0.138

0.81

0.81

Moment of inertia GD2

kgm2

0.552

3.24

3.24

Weight G

22.6

38.1

57.3

Dimensions

Spindle connection

ØC

Z5

Z6

Z8

Z8

Z11

Z11

Z15

Chuck size

ØA

175

215

265

330

415

Bore

ØB

38

54

72

88

126

Jaw connection (DIN 6353)

D

KDIN

KDIN

KDIN

KDIN

KDIN

Centering drawbar

ØB2

42

65

77

93

134

Chuck centering

ØE

140

170

220

220

300

300

380

E1

6

Piston bore

ØF

52

76

90

110

150

Fixing screws

G

M12x95

M16x110

M20x90

Thread connection drawbar

G1

M45x2

M68x2

M82x2

M100x2

M140x2

Jacking screw standard sleeve

G2

M4

M5

M6

M6

M6

Chuck height

H

101

101

111

111

141

Chuck height up to jaw support

H1

111

124

124

Mounting depth

H2

5

6

6

Cover height

H3

6

8

8

Thread length mounting bolt

J

20

23.6

30

Thread length actuator

J1

17.5

24

24

Pull length actuator

J2

23.5

34

34

Actuator stroke

K

20

20

20

Actuator position

K1

21.5

20

20

Pitch circle-Ø

Fixing screws

L

104.8

133.4

171.4

171.4

235

235

330

Jaw stroke

4.5

5.4

5.4

5.4

8

Jaw position to the center of

chuck

Nmax.

Nmin.

52

47.5

70

64.6

88

82.6

100

94.6

133

125

Jaw mounting bolt

O

M10

M12

M16

M16

M20

Distance jaw mounting bolt

P1

12.5

15

20

25

35

Minimum distance to jaw mounting

bolt

P2

12

12

16

16

Distance ti jaw mounting bolts

P3

25

30

40

50

70

Length of cross tenon

P4

70

84

96

Jaw width

Q

35

35

45

45

60

Groove width

Q1

16H7

16H7

20H7

20H7

25H7

Feather key width / slot width

Q2

10g6

12g6

16g6

16g6

25g6

Table of contents

3QLCLM

Edition: 04/2014

14

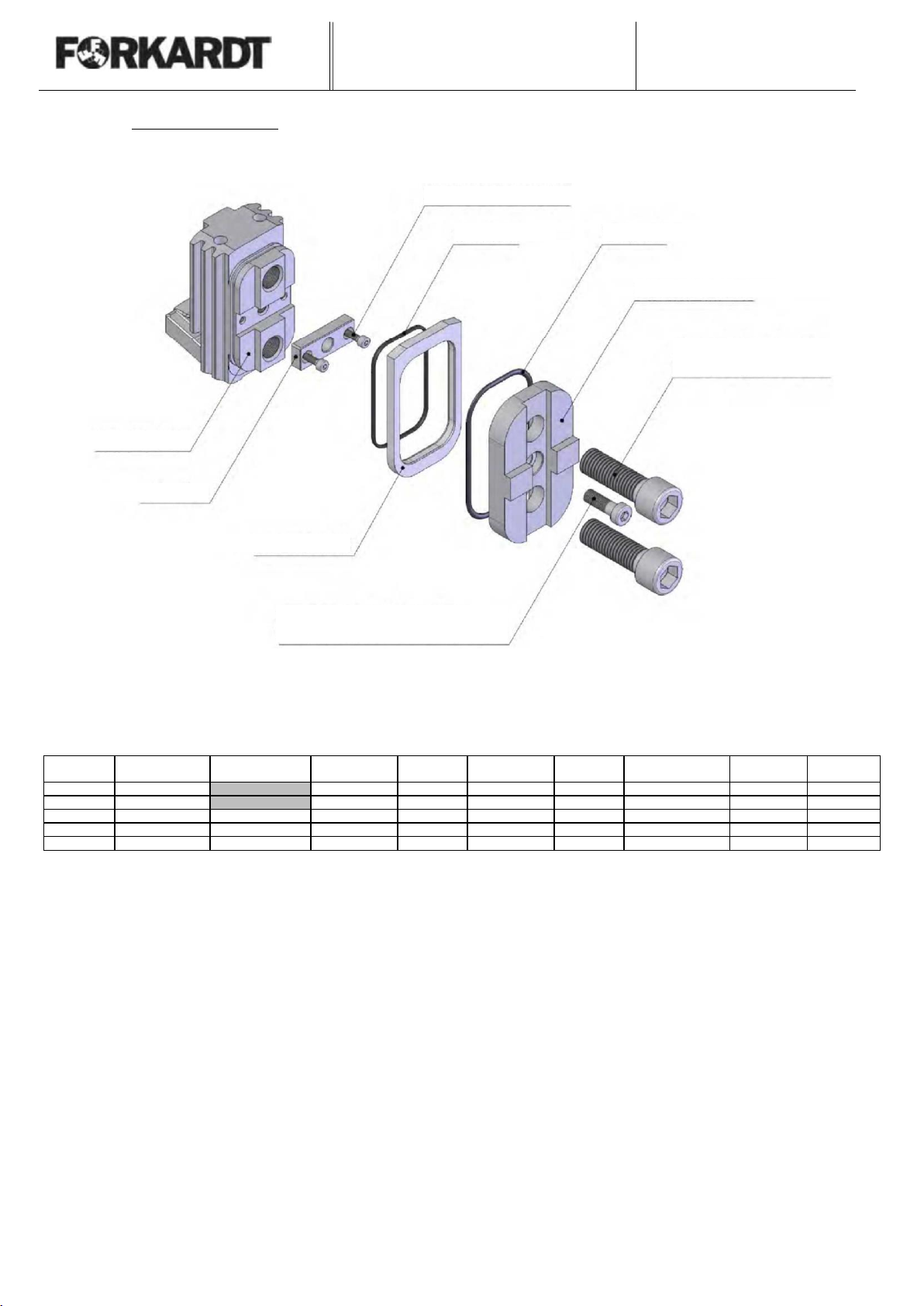

4.2.2 Design of the power chuck

4.2.2.2 Centrifugal force accessories

Chuck-Ø

Centrifugal force

weight

Lever

160

200

191062009

156122010

250

191216009

156584010

315

190476009

156584010

400

CHUCK BODY

JAW COMPLETE

CHUCK COVER

COMPLETE

4.2.2.1 Complete chuck

CENTRIFUGAL FORCE

ACCESSORIES

ACTUATOR COMPLETE

CHUCK

FIXING SCREWS

Lever

Centrifugal force

weight

Table of contents

3QLCLM

Edition: 04/2014

15

Chuck-Ø

Cylinder screws

cover fixing 1

Cylinder screws

cover fixing 2

Cover

O-Ring 1

O-Ring 2

Protective

sleeve

Countersunk

screw

160

-

-

200

701C004320

701C005350

191062005

-

-

191062002

703D004030

250

701D006350

701D006370

191216007

-

711A022030

191216004

703D004030

315

701D006350

701D006370

190476007

711H015037

711A030193

190476004

703D004030

400

Chuck-Ø

O-Ring 3

O-Ring 4

Frame

Locking

screw

Sealing disc

Actuator

O-Ring 5

160

-

200

-

711A020849

191062001

709C212150

171594044

191062003

711A020055

250

711A015050

711A015033

191216001

177821008

191216002

711A030112

315

711A015123

711A015123

190476001

709C212150

171594044

190476002

711A030127

400

4.2.2.3 Chuck body complete

COUNTERSUNK

SCREW

ACTUATOR

O-RING 5

LOCK SCREW

SEALING DISC

CHUCK BODY

O-RING 4

O-RING 3

O-RING 2

O-RING 1

PROTECTIVE SLEEVE

CYLINDER SCREWS

COVER FIXING 0

CYLINDER SCREWS

COVER FIXING 0

Table of contents

3QLCLM

Edition: 04/2014

16

4.2.2.4 Chuck cover complete

Chuck-Ø

Cylinder screws

Chuck cover

O-Ring 1

O-Ring 2

O-Ring 3

160

-

-

200

701B010360

191204001

711A020107

711A015015

711A015014

250

701B010380

191216005

711A030191

711A025075

711A025012

315

701B010380

190476005

711A030198

711A025026

711A025012

400

CYLINDER SCREW

CHUCK COVER

O-RING 3

O-RING 2

O-RING 1

Table of contents

3QLCLM

Edition: 04/2014

17

4.2.2.5 Jaw complete

Chuck-Ø

Cylinder screws

top jaws

Cylinder screw top

jaw

Sealing frame

O-Ring A

Adapter jaw

O-Ring B

Cylinder screw(s)

sliding block

Sliding block

Base jaw

160

200

701B012340

191064002

711A015028

191203001

711A020047

701C005320

191064003

191064001

250

701B016360

701C008360

191216008

711A178051

701B004340

190476010

191216003

315

701B016360

701C008360

190476011

711A020055

190476008

711B178054

701B004340

190476010

190476003

400

CYLINDER SCREW

O-RING A

O-RING B

ADAPTER JAW

CYLINDER SCREWS FOR TOP

JAWS

BASE JAW

SLIDING BLOCK

SEALING FRAME

CYLINDER SCREWS FOR FIXING THE

ADAPTER JAW

Table of contents

3QLCLM

Edition: 04/2014

18

4.3 Function of the power chuck

4.3.1 General information:

The power chuck is actuated through a standard hydraulic cylinder with monitoring of chucking stroke, by

using machine hydraulics or a separately provides hydraulic unit.

Depending on the type of work pieces to be machined, the following are used:

Partly open chuck

a hydraulic actuating cylinder

e.g. Type OKRJ...

or

Open chuck

a hydraulic hollow cylinder

e.g. Type OKHJ...

.

In some cases, hydraulic cylinder of

type PZRAJ or PZHAMJ is used.

The power chuck, fixed to the spindle head of a lathe, is actuated axially through a hydraulic clamping

cylinder and has the function to generate a gripping force to hold the work piece to be clamped through

the axial force generated by the clamping cylinder.

The pressure at the clamping cylinder must be adjusted such that the max.

permissible actuation force of the power chuck is not exceeded.

The axial actuation force of the clamping cylinder, which is spread on the actuator surface through

pressure, is transferred to the corresponding wedge guides of the master jaw through the wedge surfaces

laid out in the chuck actuator and these wedge guides wedge into each other during the clamping process.

The corresponding gripping force builds up radially on the work piece through the top jaws.

Clamping force at the chuck actuator causes jaw stroke to the inside (outside clamping). Compressive

force at the chuck actuator causes jaw stroke to the outside (inside clamping of hollow work pieces). The

power chuck type 3QLCLM is equally suitable for both clamping devices.

The monitoring of the clamping path is done through radially arranged limit switch on the clamping

cylinder.

Partly open chuck

Open chuck

Table of contents

3QLCLM

Edition: 04/2014

19

If the top jaw is adjusted to a specific clamping diameter, the jaw mounting bolts must be loosened

through two rotations with the Allen wrench (in accordance with 911) and the top jaw must be pushed

into the corresponding clamping diameter with the sliding blocks and screws.

If there is a change of top jaws from outer to inner clamping,

watch out for change in the direction of movement of the top jaws,

or if the top jaws are changed for example from hard top jaw type HB for roughing operation to soft top

jaw type WBL for finishing, then the jaw mounting bolts must be loosened through two rotations (with

Allen wrench) and the top jaw must be removed completely from the master jaw.

Clean any chips or dirt from the chuck bore and master jaw before removing the top

jaw from the master jaw!

If the processing of the clamped work piece is interrupted for many hours, the power chuck and/or the

clamping cylinder must be actuated again.

4.3.2 Centrifugal force compensation

Each master jaw is assigned to a counterweight through a reversing lever. When the chuck is rotated, it

uses its centrifugal force to balance the centrifugal force of the base and top jaw, which otherwise may

result in significant loss of gripping force. This simple, robust and direct centrifugal force compensation

system ensures high gripping force of the 3QLCLM power chuck in the entire speed range on the one

hand and allows selective processing with reduced gripping force on the other hand even at maximum

finishing speeds.

4.3.3 Lubrication

The movement of the centrifugal weight in the rear part of the chuck is used to supply lubricant to all

sliding surfaces during each chucking stroke. The excess lubricant inside the chuck is centrifuged to

the required points through the rotation of the chuck and is available again for the next chucking stroke.

When compared to the traditional chuck guides, the 3QLCLM type power chucks can use lubricants

with low viscosity, which can reach the sliding surfaces in a better way due to centrifugal capability.

This improves the reliability of the lubrication function and makes cleaning and maintenance of the

3QLCLM power chuck much easier.

4.3.4 Sealing of the power chuck

Type 3QLCLM power chucks maintenance-free thanks to their sealing and are sealed against entry of

lubricants and functional disruptions caused by the entry of coolants, dirt and chips.

Table of contents

3QLCLM

Edition: 04/2014

20

4.4 Clamping jaw

4.4.1 General information

The power chuck is a connecting element between the lathe and the work piece to be processed. The

power produced by the lathe is transmitted to the spindle nose by the power chuck and

to the transfer point between power chuck and work piece by the positive driving of the

closed chuck jaws.

Wide chuck jaws must be avoided

because they come to stop at the work

piece unevenly and cause radial

run-outs.

The power chuck is a connecting element between the lathe and the work piece to be processed. The

power produced by the lathe is transmitted to the spindle nose (by the power chuck) and

to the transfer point between power chuck and work piece (by the positive driving of the

closed chuck jaws). Chuck jaws are the radially moving elements of the power chuck, which hold the

work piece during machining. The chuck jaws consist of the master jaw (the connecting

link to the power-providing part of the power chuck) and the top jaw which is positively attached

(by serrations) to the master jaw and can thus be exactly positioned. The chuck jaws

have to be changed to suit the type of machining or the differences in size and shape of the work

pieces. The chuck jaws must be trained separately for optimal use and to prevent run-outs.

For the type QLCLM power chuck, the top jaw may have different holders for fixing to the

master jaw depending on the design:

•Cross tenon

•Different quick change systems

4.4.2 Safety instructions for top jaws

•Recalculate the strength of self-manufactured top jaws using the gripping force.

•Only use ORIGINAL mounting bolts for fixing the top jaws with due consideration of the

prescribed quality! (Cross tenon)

•Set the speed limiting device on the lathe to the permissible speed determined for the special

top jaws, as otherwise the centrifugal forces occurring at the jaws at higher

speeds will reduce the gripping force to such an extent that the work pieces will

no longer be securely held!

Comprehensive jaws come to stop

unevenly at the work piece on one

side and cause radial run-outs.

Power chuck center = workpiece

center or center of rotation

Center of eccentric chuck

diameter