Javo Standard potting machine manual

Version 2010-11-1 Page 2

Contents

Introduction ........................................................................................................................................................ 1

Introduction ........................................................................................................................................................ 4

Supplier information ..................................................................................................................................................... 4

Intended use and non-recommended use.................................................................................................................... 4

Non-recommended use ................................................................................................................................................ 4

Conditions of use .......................................................................................................................................................... 4

Description of the machine........................................................................................................................................... 4

Operating principle ....................................................................................................................................................... 5

Workstations at the machine........................................................................................................................................ 5

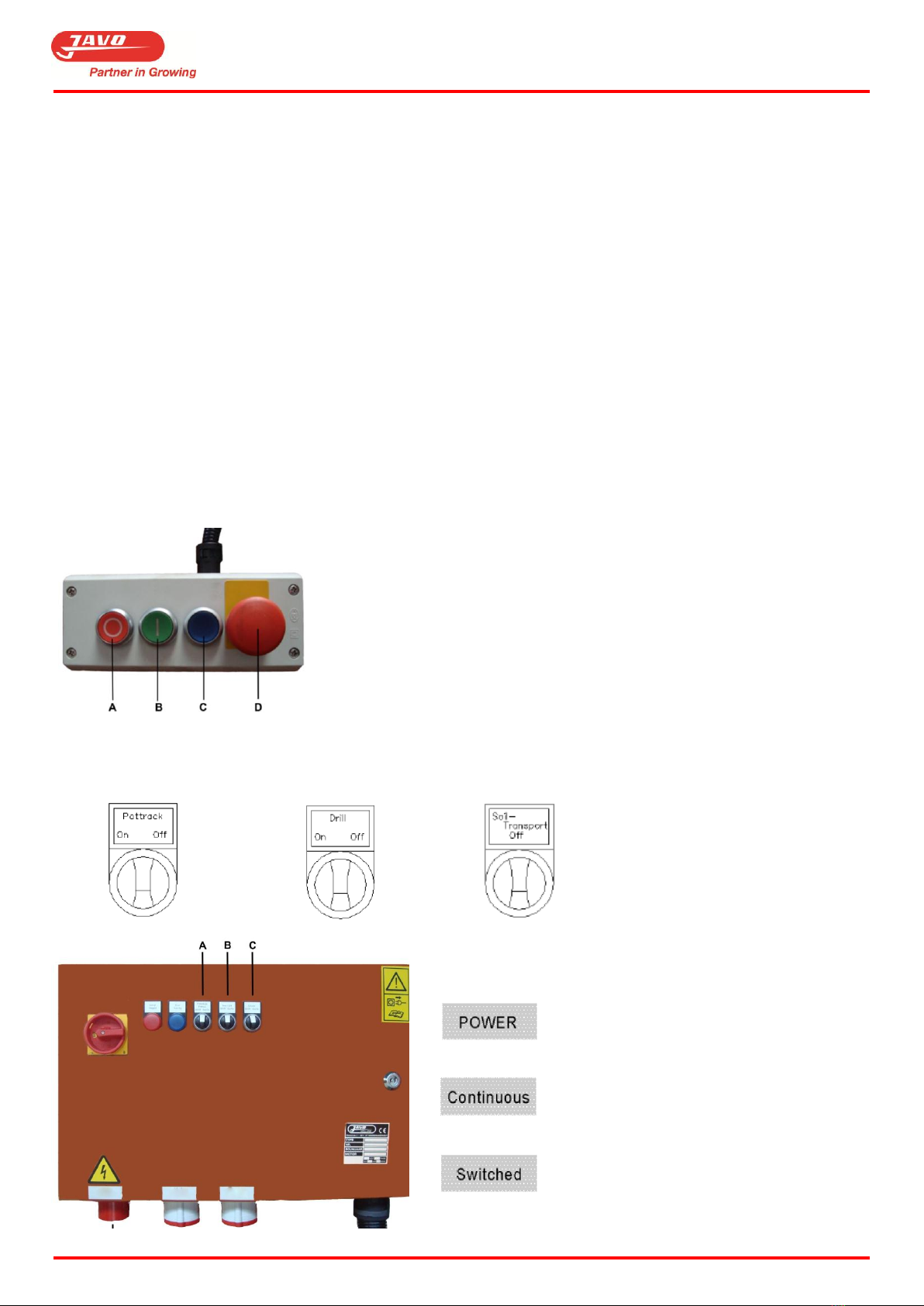

Controls......................................................................................................................................................................... 5

Safety .................................................................................................................................................................. 6

Use of personal safety equipment................................................................................................................................ 6

Important safety factors ............................................................................................................................................... 6

Safety precautions ........................................................................................................................................................ 6

Safety features on the machine.................................................................................................................................... 6

Safety precautions ........................................................................................................................................................ 6

Explanation of the symbols on the machine................................................................................................................. 7

Assembly, installation and commissioning............................................................................................................ 8

Location......................................................................................................................................................................... 8

Assembly / connection.................................................................................................................................................. 8

Setting-up / adjusting.................................................................................................................................................... 8

Covers and doors ...................................................................................................................................................... 8

Elevator direction of movement............................................................................................................................... 8

Drill direction of movement...................................................................................................................................... 8

Type of soil ................................................................................................................................................................ 8

Soil belt tension......................................................................................................................................................... 8

Pot track chain tension ............................................................................................................................................. 9

Elevator chain tension............................................................................................................................................... 9

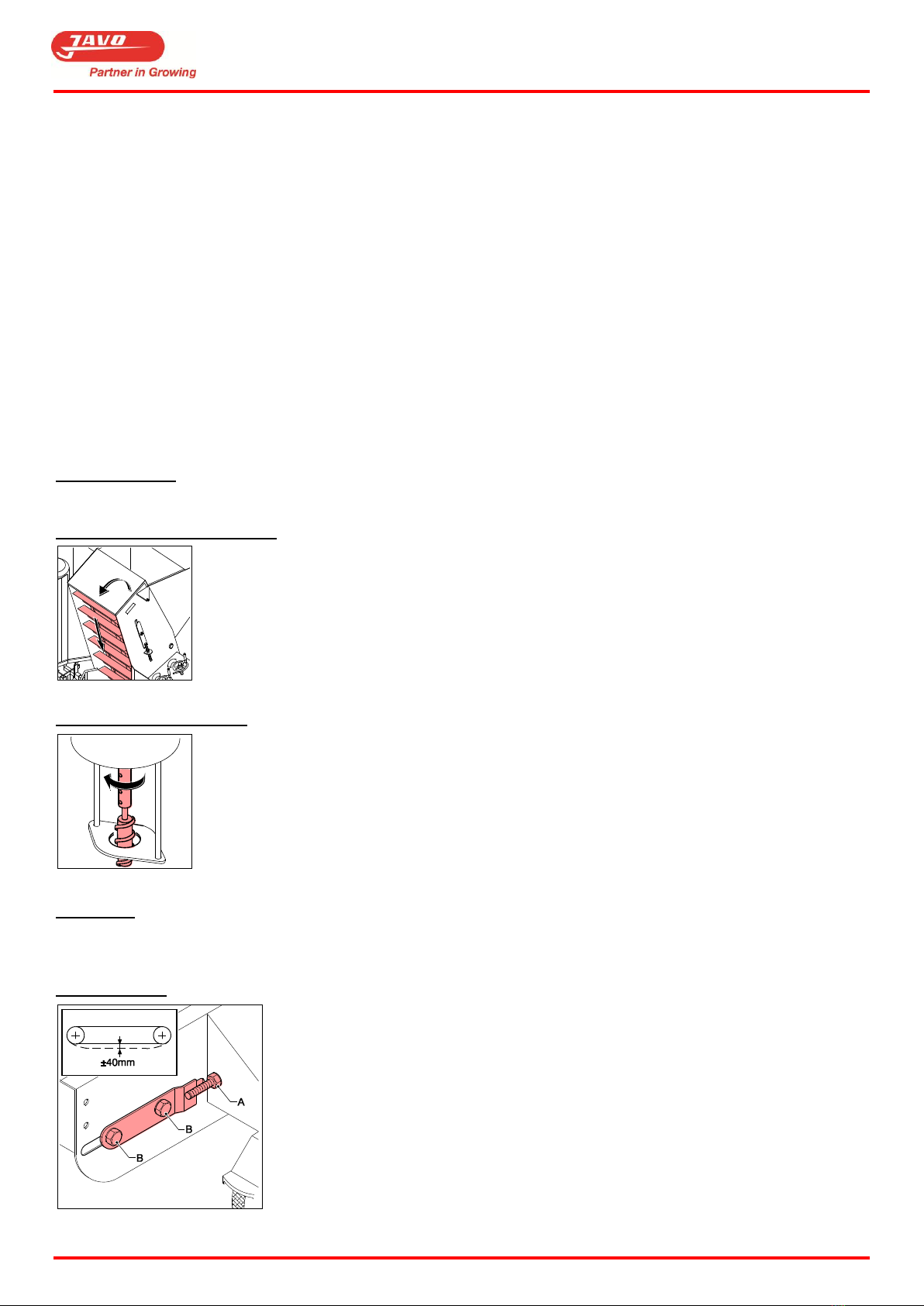

Centring the drill ....................................................................................................................................................... 9

Facilities to be provided by the user............................................................................................................................. 9

Operation .......................................................................................................................................................... 10

Setting-up and adjustments........................................................................................................................................10

Type of soil .............................................................................................................................................................. 10

Soil belt speed adjustment ..................................................................................................................................... 10

Controlling the pot track speed ..............................................................................................................................10

Pot size .................................................................................................................................................................... 10

Drill size ...................................................................................................................................................................11

Height of the leveller...............................................................................................................................................11