Forms + Surfaces levele User manual

T 1.800.451.0410 | F 412.781.7840 | www.forms-surfaces.com

page 1 of 7 | 10-16-17

LEVELe®ELEVATOR INTERIORS WITH LIGHTPLANE

INSTALLATION INSTRUCTIONS

© 2017 Forms+Surfaces® | All dimensions are nominal. Specifications and pricing subject to change without notice. For the most current version of this document, please refer to our website at www.forms-surfaces.com.

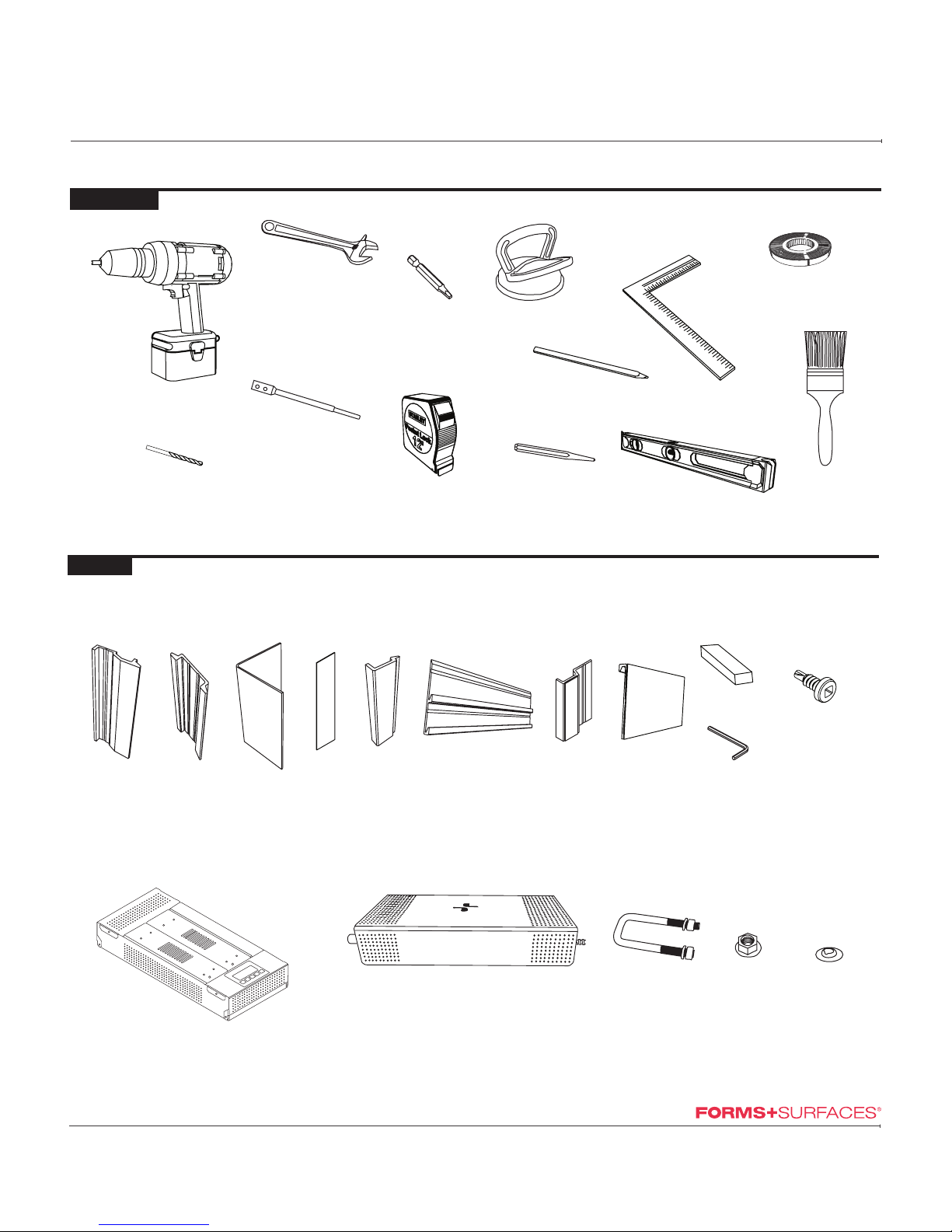

TOOLS NEEDED

IMPACT

DRILL

SQUARE MASKING TAPE

PENCIL

LEVEL

TAPE

MEASURE

CRESCENT WRENCH

3/8" DRILL

BIT

CENTER

PUNCH

BRUSH

SUCTION

CUP(S)

DRILL BIT

EXTENDER

#8-18 SQUARE / PHILIPS

COMBO DRIVE BIT

U-BOLT LOCKING DISC

3/8" - 16

FLANGE NUT

INCLUDED

CEILING COMPONENTS

STANDARD LEVELe COMPONENTS

LIGHTPLANE COMPONENTS

LIGHTPLANE PANEL

POWER BOX

ALLEN

KEY

MOUNTING

EXTRUSION

PANEL

CLIP CORNER

REVEAL

FRONT

REVEAL

COVER

EXTRUSION

BASE CLEAT BASE

SUPPORT

BASE

FACING

SPACER

CEILING POWER BOX

#8 x 1/2"

SELF TAPPING SCREW

W/ #2 SQUARED

DRIVE HEAD

T 1.800.451.0410 | F 412.781.7840 | www.forms-surfaces.com

page 2 of 7 | 10-16-17

LEVELe®ELEVATOR INTERIORS WITH LIGHTPLANE

INSTALLATION INSTRUCTIONS

© 2017 Forms+Surfaces® | All dimensions are nominal. Specifications and pricing subject to change without notice. For the most current version of this document, please refer to our website at www.forms-surfaces.com.

Install (2) Front Reveals.

• Position Front Reveals and install using

factory installed VHB tape.

Note: Detail is inside view of front corner.

45

Install (2) Corner Reveals.

• Position Corner Reveals and hold them in

place with masking tape.

• Cover no more than 1/8" of the reveal with

tape.

3

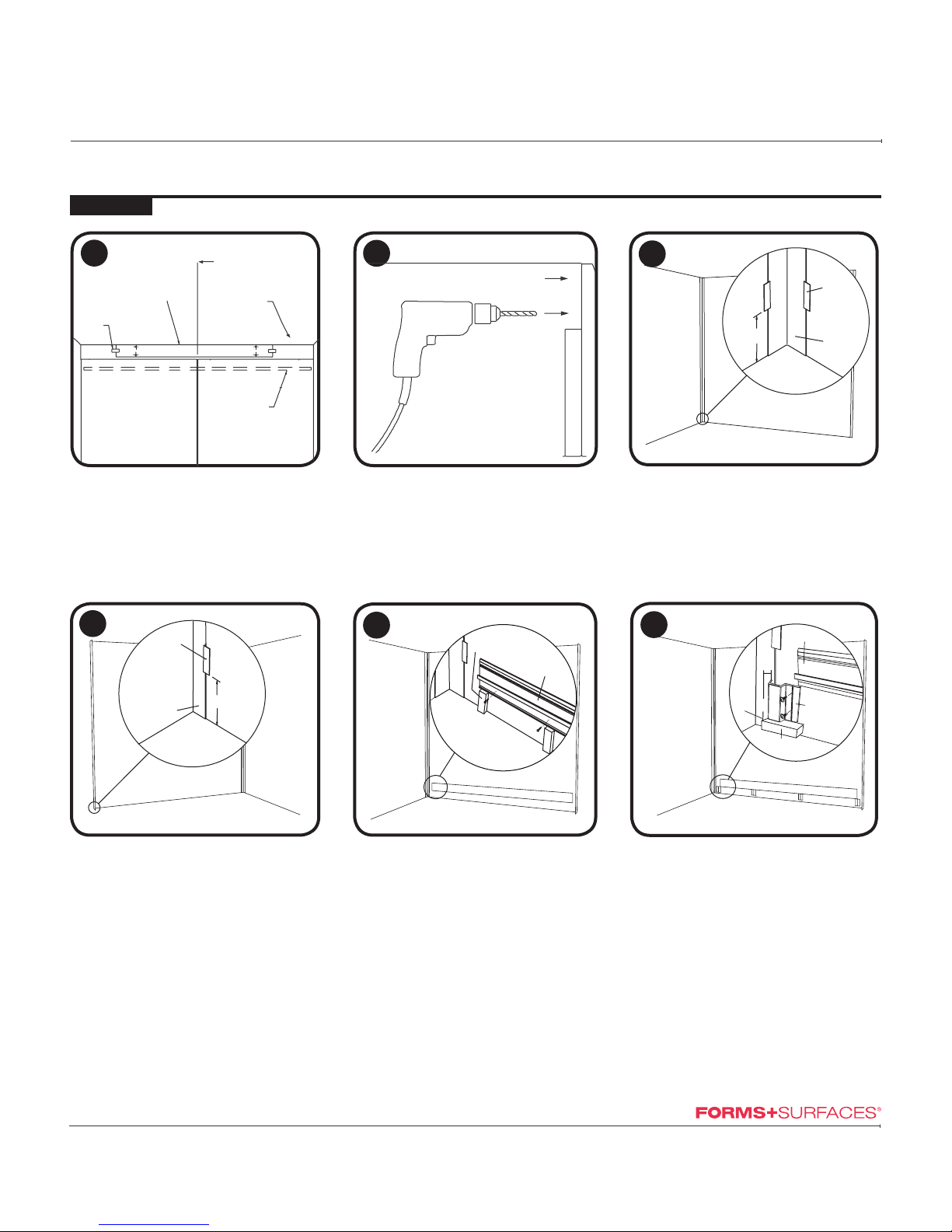

STEP BY STEP

REARSIDE

SIDE REAR REAR

SIDE

Front Corner

Reveal

Masking

Tape

Side

Wall

8" min.

Front Wall

or COP

Finished Floor

Rear Corner

Reveal

8" min.

Masking

Tape

Finished Floor

Install Base Cleats.

• Using the provided 3.5" spacers for

height, position the Base Cleat on the

center of the rear wall.

• Ensure the Base Cleat is level before

proceeding.

• Secure the Base Cleat with the provided

self-drilling screws.

• Repeat for the remaining side walls.

• Note: The standard base height is 3.5".

• Custom-sized spacers will be provided for

custom base heights. Please reference

your shop drawings for proper installed

height.

Finished Floor

Base Cleat

3.5" Spacer

6

SIDE REAR

Install Base Supports.

• Determine the location of the left- and

right-most Base Supports.

• Start at the center point of the cab wall,

measure half the length of the Base Facing

in each direction and mark the end points.

• Install the left- and right-most Base Supports

approximately 1/4" from your markings and

every 18" - 24" in between.

• Base Supports should be flush with the

bottom of the Cleat.

1/4"

Base Cleat

Base

Support

1/2" Spacer

End

Point

Mark

Masking

Tape

Cab Canopy

Ceiling Location

Center of Side Wall

Panels

Paper Template

Provided

1

Temporarily attach provided paper template

for ceiling installation.

• Center and level paper template on wall.

• Using center punch, mark holes as indicated

on template.

Drill holes to insert the U-bolts.

• Remove the template and drill eight 3/8"

diameter holes into cab shell where

marked with center punch.

2

T 1.800.451.0410 | F 412.781.7840 | www.forms-surfaces.com

page 3 of 7 | 10-16-17

LEVELe®ELEVATOR INTERIORS WITH LIGHTPLANE

INSTALLATION INSTRUCTIONS

© 2017 Forms+Surfaces® | All dimensions are nominal. Specifications and pricing subject to change without notice. For the most current version of this document, please refer to our website at www.forms-surfaces.com.

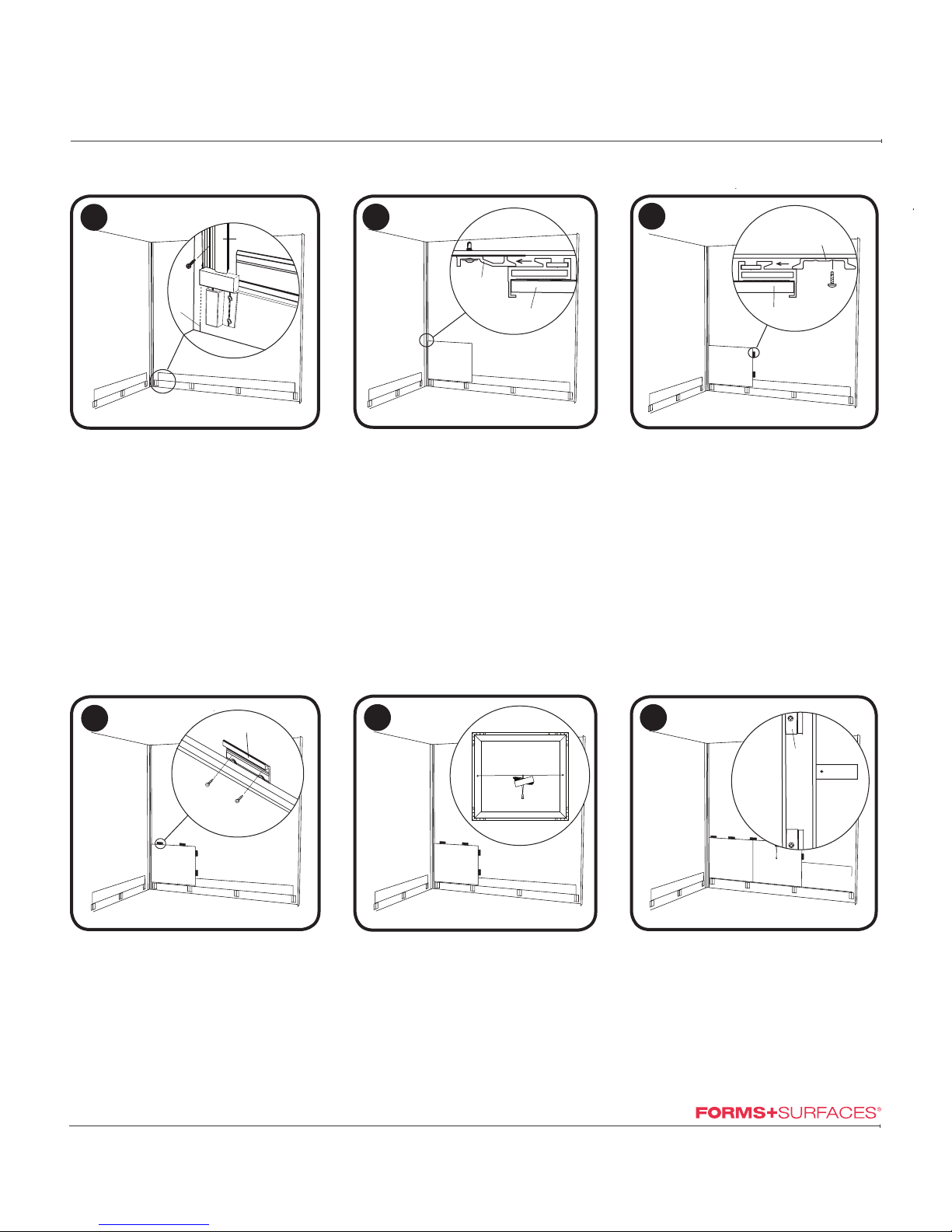

Install (1) Mounting Extrusion

• Align Mounting Extrusion vertically with

the endpoint. Use the provided 1" spacer

above the Base Support to set the

Mounting Extrusion at the proper height.

• Be sure the mounting extrusion is square

relative to the base.

• Attach using provided self-drilling screws.

• Install (1) Mounting Extrusion per side

wall. If LightPlane Panels are adjacent

to Mounting Extrusion, the extrusion will

need to be cut to avoid damage to the

exit wire(s).

78

Install 1st Panel.

• Remove debris from Mounting Extrusion

and Base Cleat with a brush prior to

installation.

• The first panel will engage into the vertical

Mounting Extrusion and Base Cleat.

• It is important that lower panels are

installed straight and level, and engage

fully with the mounting extrusion.

9

Attach side Panel Clips.

• Attach the clips as shown, using the provided

self-drilling screws.

• One panel clip should be installed every

18-24" for proper alignment. Note: Detail is

top view.

10

Install top Panel Clips.

• Attach the clips as shown, using the provided

self-drilling screws.

• One panel clip should be installed every 18-

24" for proper alignment.

REAR

SIDE REARSIDE REARSIDE

REARSIDE

Installed Panel

Panel Clip

TOP VIEW

Installed Panel

Panel Clip

Panel

Mounting

Extrusion

TOP VIEW

1" Spacer

End

Point

Mark

Mounting

Extrusion

11

Identify LightPlane Panel(s).

• LightPlane Panels will arrive with attached

leads and quick connects zip tied on back side

of panels.

• Cut zip ties and place leads on front of panel.

• LEVELe LightPlane Panels are installed using

the same steps as LEVELe panels. LightPlane

Panels have an attached, visible power lead.

BACK VIEW 12

Install Panel Clips to side of panel.

• Attach the clips as shown, using the provided

self-drilling screws.

• One panel clip should be installed every

18-24" for proper alignment, but panel clips

should not obstruct wire exit locations, as

indicated on LightPlane Panels.

CAUTION

DO NOT OBSTRUCT

WIRE EXIT LOCATIONS

Installed

Panel

LightPlane

Panel

Panel

Clip

T 1.800.451.0410 | F 412.781.7840 | www.forms-surfaces.com

page 4 of 7 | 10-16-17

LEVELe®ELEVATOR INTERIORS WITH LIGHTPLANE

INSTALLATION INSTRUCTIONS

© 2017 Forms+Surfaces® | All dimensions are nominal. Specifications and pricing subject to change without notice. For the most current version of this document, please refer to our website at www.forms-surfaces.com.

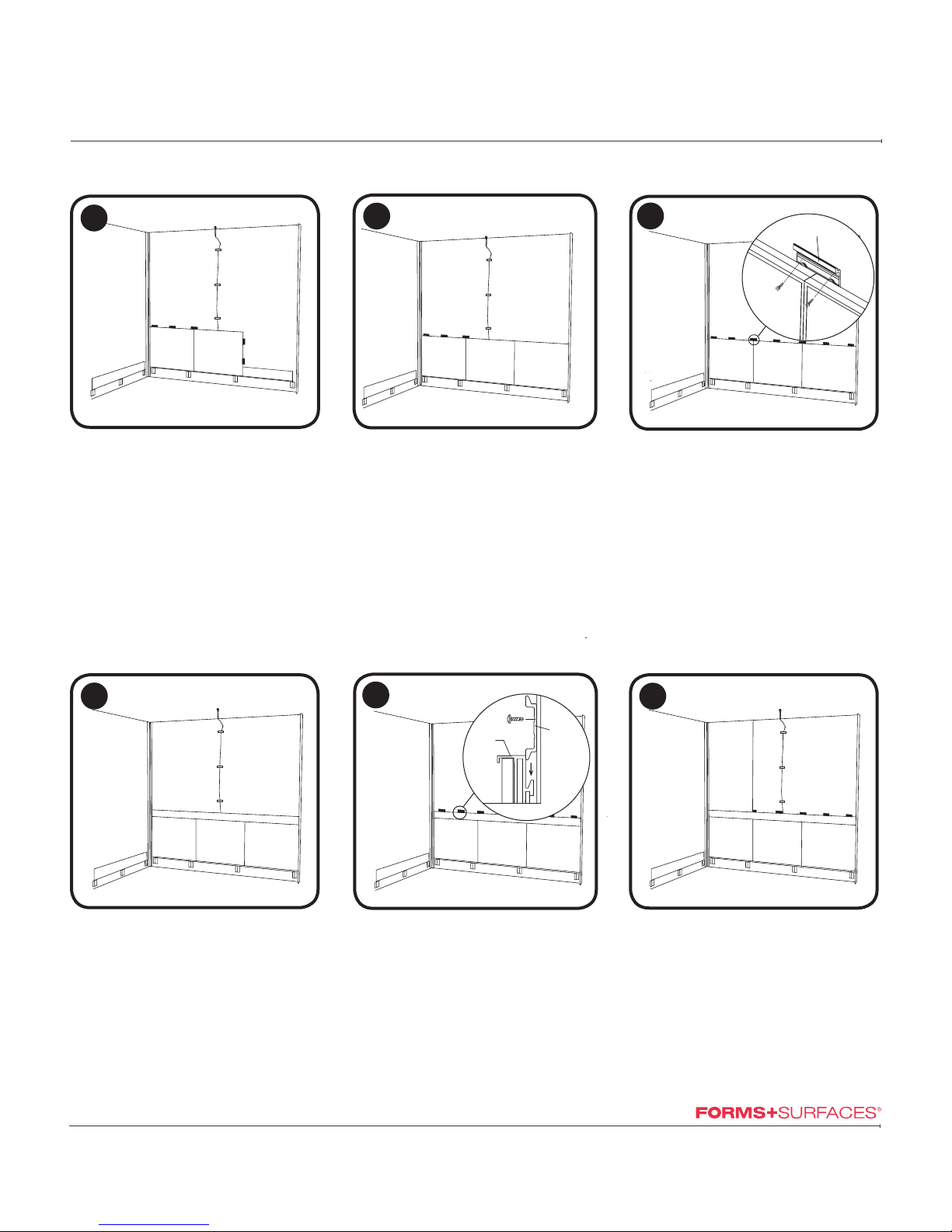

Repeat steps 8-10 as required.

• No side Panel Clips are installed for last panel

of row.

• At any point where two panels meet, Panel

Clips should cross over both panels, as

seen above, to ensure ideal panel alignment.

15

Install Handrail Panel.

• Configurations with a handrail panel come

with handrails factory installed on a single

panel.

• For configurations in which handrails must

span multiple panels, shoulder bolts will be

installed. Once all panels are installed, slide

handrail onto shoulder bolts and tighten

underside set screws with provided allen key.

16 17 18

REAR

SIDE

REARSIDE

Install top Panel Clips.

• Attach the clips as shown, using the provided

self-drilling screws.

• One panel clip should be installed every 18-

24" for proper alignment.

REAR

SIDE REARSIDE

Continue to Install Panels in sequence.

• Rest the first upper panel on the Panel Clips

to position the first upper panel over the

Handrail Panel. Refer to step 8 for detail.

Panel 1

Panel Clip

Panel 2

Installed

Panel Panel Clip

SIDE VIEW

14

REAR

SIDE

Install next Panel in sequence.

• Using the installation sequence document

provided with your elevator interiors, install

panels in the order indicated using the

method described in steps 8-10.

• Panels must engage fully with Hanging

Clips and Panel Clips.

• Debris in the Hanging Clips, Mounting

Extrusion or Panel Clips will prevent the

panel from engaging fully.

13

Attach lead to elevator interior wall.

• Attach the lead(s) to the wall with masking

tape.

• There will be enough lead for the quick

connect to reach the cab shell ceiling. The

lead will run through the milled slot in the

frame.

T 1.800.451.0410 | F 412.781.7840 | www.forms-surfaces.com

page 5 of 7 | 10-16-17

LEVELe®ELEVATOR INTERIORS WITH LIGHTPLANE

INSTALLATION INSTRUCTIONS

© 2017 Forms+Surfaces® | All dimensions are nominal. Specifications and pricing subject to change without notice. For the most current version of this document, please refer to our website at www.forms-surfaces.com.

19 20

REAR

SIDE

Install Panel Clips.

• Attach the clips as shown, using the

provided self-drilling screws.

See step 9 for detail.

• One panel clip should be installed every

18-24" for proper alignment.

REARSIDE

Repeat steps 18-19 as required.

• No side Panel Clips are installed for last

panel in row.

22 23

21

REAR

SIDE

Repeat steps 5-21 for remaining walls.

• Install all panels for remaining walls as

indicated in previous steps.

Install (2) Cover Extrusions on each wall.

• Cover the screws and Mounting Extrusion

with the Cover Extrusion provided.

• The Cover Extrusion is backed with

factory supplied foam tape.

Install (1) Mounting Extrusion on remaining

side of rear wall.

• Position Mounting Extrusion and attach

using provided self-drilling screws.

• If LightPlane Panels are adjacent to Mounting

Extrusion, the extrusion will need to be cut to

avoid damage to the exit wire(s).

• Mounting Extrusion must engage fully with

panels.

REARSIDE REAR

SIDE

Installed

Panel

Mounting

Extrusion

TOP VIEW

Installed Panel

Mounting

Extrusion

Cover Extrusion

VHB Tape

TOP VIEW LightPlane Panels

Power Source

24 LightPlane Panel

Lead with

Quick Connect

Secure LightPlane Panel power source to

cab shell ceiling.

• Mount the LightPlane Panel power box

securely to the cab shell ceiling.

• The LightPlane Panel leads will be fed

through an opening in the cab shell

ceiling.

T 1.800.451.0410 | F 412.781.7840 | www.forms-surfaces.com

page 6 of 7 | 10-16-17

LEVELe®ELEVATOR INTERIORS WITH LIGHTPLANE

INSTALLATION INSTRUCTIONS

© 2017 Forms+Surfaces® | All dimensions are nominal. Specifications and pricing subject to change without notice. For the most current version of this document, please refer to our website at www.forms-surfaces.com.

25

Connect power source to LightPlane

panel lead(s).

• Using the quick connects, attach the

LightPlane Panel leads to the power box

leads.

• Adjust the LightPlane Panel potentiometer

to desired brightness prior to installing the

ceiling.

• Secure excess lead to ceiling to keep it

out of view.

Attach U-bolts to elevator shell.

• Attach U-Bolt using provided retainer

clip, washers and 3/8" - 16 flange nut.

26

Hang ceiling from U-bolts.

• Lift ceiling, engaging U-Bolts into

hanging clip on ceiling.

27

Adjust the position of the ceiling.

• Slide ceiling to center between wall panels.

Position retainer and locking disc.

• Slide retainer and locking disk against

bracket.

Secure elevator ceiling.

• Tighten set screw in locking disk with

provided allen key to secure the ceiling in

place.

28 29 30

4"

T 1.800.451.0410 | F 412.781.7840 | www.forms-surfaces.com

page 7 of 7 | 10-16-17

LEVELe®ELEVATOR INTERIORS WITH LIGHTPLANE

INSTALLATION INSTRUCTIONS

© 2017 Forms+Surfaces® | All dimensions are nominal. Specifications and pricing subject to change without notice. For the most current version of this document, please refer to our website at www.forms-surfaces.com.

32

REAR

SIDE

Install Base Facing.

• Complete the installation by installing the

bases.

• Remove backer from VHB tape on Base

Supports.

• The Base Facing will engage with the

previously installed Base Cleat. Center Base

Facing, aligning with end point markings.

• Press firmly to secure Base Facing to VHB

tape on Base Supports.

Base

Cleat

Base

Facing Base

Support

SIDE VIEW

31

Connect Ceiling Power Box to local power.

• Remove the cover from the power box.

• Insert the local power supply conduit into the

power box opening.

• Secure the ground wire to the junction point.

• Return the cover to the power box and secure

with provided screws.

• Remove the backer from the factory-installed

VHB tape on the bottom of the power box,

and secure it to the cab ceiling.