Fortress Technologies 40 User manual

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly

before installing or servicing this equipment.

WARNING!

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

FOR YOUR SAFETY

Instruction, Service, Installation, and Care Manual

Please read this manual completely before attempting to install or operate this

equipment. Notify carrier of damage! Inspect all components immediately.

40 - 50 - 75

Fryer Gas Cabinet

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

Warranty/TECH Support Call: 800•722•6075

or Email us at: service@fortress-cke.com 407 Jeffrey’s Lane

Goldsboro NC 27530

DANGER

IMPORTANT

WARNING

CAUTION

WARNING

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

2

IMPORTANT SAFETY INSTRUCTIONS

Your safety and the safety of others are very important.

THIS MANUAL CONTAINS IMPORTANT SAFETY INFORMATION. READ

CAREFULLY AND SAVE FOR FUTURE CONSULTATION.

This is the Safety Alert Symbol. This symbol alerts you to

potential hazards that can kill or injure you and others. All

safety messages will follow the Safety Alert Symbol and

either the words ”DANGER”, “WARNING”, “CAUTION”,

or "IMPORTANT".

DANGER means that failure to heed this safety

statement may result in severe personal injury or death.

IMPORTANT means it is essential information that the

customer must follow with regard to the equipment.

WARNING means that failure to heed this safety

statement may result in extensive product

damage, serious personal injury, or death.

CAUTION means that failure to heed this safety

statement may result in minor or moderate

personal injury, or property or equipment damage.

All safety messages will alert you to what the potential hazard is, tell you how to reduce

the chance of injury, and let you know what can happen if the instructions are

not followed.

This appliance is not intended for use by persons with lack of experience and

knowledge regarding this type of equipment, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

Cleaning and user maintenance shall not be made by inexperienced persons without

supervision.

Periodically check if the hose and gas regulator are within their expiration date.

If you constantly smell gas, turn off the equipment quickly and check if your

equipment gas connections are leaking. If the problem persists, contact your

nearest authorized dealer.

WARNING: Risk of re / ammable materials.

Warranty/Tech Support 800•722•6075

Service, Installation

& Care Manual

3

IMPORTANT SAFETY INSTRUCTIONS

• Installation must conform with local codes, or in the absence of local codes, the

National Fuel Gas Code, ANSI Z223.1 (latest edition). In Canada, installation should

conform to installation codes for gas burning appliances and equipment standard

CAN/CGA-B149.1 or the propane installation code, CAN/CGA-B149.2, as applicable.

• Installation must be performed according to the manufacturer’s instructions and by

qualied and authorized persons.

• For repairs, contact an authorized service technician only and request original

replacement parts.

• Before operating the equipment and whenever there is any doubt about its operation,

the user has the duty to read and understand this manual in detail.

• Install the equipment in a place where there is sufcient physical space for perfect

handling of the equipment.

• Never use your equipment without rst installing it correctly.

• If any abnormalities in operation are observed when using the equipment, discontinue

use, close the manual gas shut off valve, and call an authorized service technician to

correct the problem.

• Any unauthorized alteration and / or tampering is DANGEROUS and will void all

warranties.

• Close the gas valve that powers the equipment and check if the knobs are in the

closed position when: not in use, before servicing and cleaning the equipment.

• Use three or more people, or a load lifting device to move and install it.

• Do not soil, remove or obstruct the identication labels.

• For proper operation of the appliance, do not obstruct the ow of gas and ventilation.

• When your equipment is in use, accessible parts can become hot, and children should

be kept away.

• Ensure that children do not play with the equipment.

• Always check if the gas connections are correctly installed, have no malfunctions and

no gas leaks.

IMPORTANT

Intended for Industrial / Professional use Indoors.

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

4

Important Tips

• Ensure that children do not play with the equipment.

• Always check if the gas connections are correctly installed, have no malfunctions and no

gas leaks.

• Carefully keep this manual for future reference.

• Failure to follow the instructions in the consumer manual for equipment installation

conditions will void your warranty.

• For repairs, contact an authorized service technician only and request original

replacement parts.

• Before operating the equipment and whenever there is any doubt about its operation,

the user has the duty to read and understand this manual in detail.

• Install the equipment in a place where there is sufcient physical space for perfect

handling of the equipment.

• Never use your equipment without rst installing it correctly.

• If any abnormalities in operation are observed when using the equipment, discontinue

use, close the manual gas shut off valve, and call an authorized service technician to

correct the problem.

• Any unauthorized alteration and / or tampering is DANGEROUS and will void all

warranties.

• Close the gas valve that powers the equipment and check if the knobs are in the closed

position when: not in use, before servicing and cleaning the equipment.

• Use three or more people, or a load lifting device to move and install it.

• Do not soil, remove or obstruct the identication labels.

• For proper operation of the appliance, do not obstruct the ow of gas and ventilation.

• When your equipment is in use, accessible parts can become hot, and children should be

kept away.

Warranty/Tech Support 800•722•6075

Service, Installation

& Care Manual

5

© Copyright 2021 Fortress. All rights reserved.

Reproduction without written permission is prohibited.

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS................................................................2

Important Tips..............................................................................................................4

RECEIVING AND INSPECTING THE EQUIPMENT..........................................6

01. INTRODUCTION....................................................................................................6

02. EQUIPMENT INSTALLATION .......................................................................... 7

2.1 Equipment Installation Instructions........................................................ 7

2.2 Recommendations Before Installation .................................................8

2.3 Installation - Gas Standards and Codes...............................................8

2.4 Gas Installation...............................................................................................9

2.4.1 Gas Supply to the Appliance............................................................ 10

2.4.2 Quick Disconnect Connection........................................................ 10

2.5 Gas Leak Check .............................................................................................11

2.6 Positioning .......................................................................................................11

2.7 Foot Leveling..................................................................................................12

2.8 First Time Use ................................................................................................12

2.9 Turning on the Equipment - Product Ignition..................................13

03. CLEANING AND MAINTENANCE................................................................ 14

3.1 Cleaning............................................................................................................ 14

3.1.1 Cleaning the Inside of the Equipment ........................................... 14

3.1.2 Cleaning the Outside of the Equipment ...................................... 15

3.2 Maintenance .................................................................................................. 16

3.2.1 Preventive Maintenance...................................................................... 16

04. KNOWING THE EQUIPMENT.........................................................................17

4.1 Main Features..................................................................................................17

05. TECHNICAL SPECIFICATIONS..................................................................... 18

5.1 Equipment Dimensions and Weight ..................................................... 18

5.2 Technical Data .............................................................................................. 18

06. WARRANTY ......................................................................................................... 19

NOTES .............................................................................................................................21

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

6

RECEIVING AND INSPECTING THE EQUIPMENT

01. INTRODUCTION

Even though most equipment is shipped crated, care should be taken during unloading

so the equipment is not damaged while being moved into the building.

1. Visually inspect the exterior of the package and skid or container. Any damage should

be noted and reported to the delivering carrier immediately.

2. If damaged, open and inspect the contents with the carrier.

3. In the event that the exterior is not damaged, yet upon opening, there is concealed

damage to the equipment, notify the carrier. Notication should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the damaged equipment. This

should be done within 5 days from receipt of the equipment.

5. Freight carriers can supply the necessary damage forms upon request.

6. Retain all crating material until an inspection has been made or waived.

IMPORTANT

Conversion, gas line connection, thermostat calibration, burners, manometer gas

pressure adjustment, etc. are all part of the normal installation and will not be paid

under warranty. If a warranty technician is called and the unit is installed incorrectly,

the end user may be charged.

Proper installation of this gas appliance is the sole responsibility of the end user. It is

the buyer's responsibility to determine if the installer is qualied in the installation

procedures.

FOR MAINTENANCE, SERVICE, REPAIRS OR INSTALLATIONS - contact the

factory to schedule authorized service.

Warranty/Tech Support 800•722•6075

Service, Installation

& Care Manual

7

The equipment you have purchased from Fortress™is "Built to Last".

Quality, performance, and innovative design built-in, brings value and reliability

to your business! Please read this manual carefully to know and understand your

equipment to ensure its correct operation for maximum performance.

The proper care and use will help for the life your purchase.

Upon receipt of the equipment, make sure that the equipment is not defective. For

assembly, verify rst if the accessory kit has the following items: (4) adjustable legs and

an instruction manual.

Place the equipment the workplace carefully and adjust the foot level.

The gas pressure regulator supplied with the equipment must be installed when the

appliance is connected to the gas supply. Installation must comply with local codes or, in

the absence of local codes, with the national combustible gas code.

Gas equipment supply piping must be at least 3/4" in diameter.

Adequate space must be left in front of the device for proper maintenance and

operation. Provisions should be incorporated into the kitchen design to ensure an

adequate supply of fresh air and adequate clearance for combustion chamber overhead

operations, for proper combustion and ventilation.

02. EQUIPMENT INSTALLATION

2.1 Equipment Installation Instructions

IMPORTANT

FAILURE TO INSTALL THE PRESSURE REGULATOR WILL VOID

YOUR WARRANTY.

MODEL

Combustible Non-combustible

Rear Sides Rear Sides

Fryer Gas Cabinet 8" 6" 0" 0"

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

8

02. EQUIPMENT INSTALLATION

Clearances

The appliance area must be kept free and clear of all combustibles.

Rating Plate

Information on this plate includes the model, serial number, BTU/h input of the

burners, operating gas pressure in inches WC, and whether the appliance is oriced for

natural or propane gas. When communicating with factory about a unit or requesting

special parts or information, rating plate data is essential for proper identication.

2.2 Recommendations Before Installation

Before installing the gas supply system, observe the pipes and ttings, check

the components for dirt, clean internally with compressed air to eliminate

possible particles, and prevent burners and valves from becoming clogged.

After cleaning, use thread sealant to connect the equipment to the gas network. For

correct application, avoid concentrating the compound on the rst two threads of the

pipe, otherwise it may generate particles that will clog the system injectors.

2.3 Installation - Gas Standards and Codes

Warranty/Tech Support 800•722•6075

Service, Installation

& Care Manual

9

02. EQUIPMENT INSTALLATION

2.4 Gas Installation

Your gas appliance will give you peak performance when the gas supply line is of

sufcient size to provide the correct gas pressure. The gas line must be installed to

meet the local building codes or National Fuel Gas Code ANSI Z223.1 Latest Edition.

In Canada, install the appliance in accordance with CAN/CGA-B149.1 or .2 and local

codes. Gas line sizing requirements can be determined by your local gas company

or, in North America, by referring to the National Fuel Gas Code, Appendix C, Table

C-4 (for natural gas) and Table C-16 (for propane). The gas line needs to be large

enough to supply the necessary amount of fuel to all appliances without losing

pressure to any appliance.

Installation of this appliance must be in accordance with local installation codes,

including:

1. The appliance and its individual shut off valve must be disconnected from the gas

supply piping system during any system pressure testing when this test pressure

exceeds 1/2 PSI (3.45 kPa).

2. The appliance shall be isolated from the gas supply piping system by closing the

manual shut off valve during any pressure test of the gas supply piping system at test

pressures equal to or less than 1/2 PSI (3.45 kPa).

Gas Connection

The external thread of equipment’s intake-tube is 3/4" NPT. For proper operation,

the gas supply line must be the same size or larger. Gas line size should not be reduced

at any point along the supply line.

Manual Shut Off Valve

A gas pressure regulator and a shut off valve supplied by the technical shall be

installed in the gas service line before the appliance - in a physical location where it can

be reached quickly in an emergency.

THE PRESSURE AT THE GAS CONTROL VALVE SHALL NOT EXCEED

1/2 PSI.

Never supply the appliance with a gas other than the one that is indicated on the

data plate. Using the incorrect gas type will cause improper operation and could

result in serious injury or death. If you need to convert the appliance to another

type of fuel, contact the dealer your purchased it from.

Never use an adapter to make a smaller gas supply line t the cooker connection.

This may not allow the correct amount of gas ow for optimum burner

operation,resulting in poor cooker performance.

WARNING

IMPORTANT

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

10

2.4.1 Gas Supply to the Appliance

2.4.2 Quick Disconnect Connection

A properly sized and installed gas line will deliver a supply pressure between

7.0” W.C. (17.4 mbars, 1.74 kPa) and 10.0” W.C. (24.9 mbars, 2.49 kPa) natural gas or

between 11.0” W.C. (27.4 mbars, 2.74 kPa) and 13.0” W.C. (32.4 mbars, 3.25 kPa) for

propane to all appliances connected to the supply line, operating simultaneously at

full demand.

02. EQUIPMENT INSTALLATION

In North America, gas appliances equipped with casters must be installed with

connectors that comply with the Standard for Connectors for Movable Gas Appliances,

ANSI Z21.69.CSA 6.16 Latest Edition. This connection should include a quick

disconnect device that complies with the Standard for Quick Disconnect Devices

for Use With Gas Fuel Appliances ANSI Z21.41.CSA 6.9 Latest Edition.

Warranty/Tech Support 800•722•6075

Service, Installation

& Care Manual

11

02. EQUIPMENT INSTALLATION

2.5 Gas Leak Check

2.6 Positioning

Before lighting the equipment and putting it into operation, check all gaskets on the

gas supply line for leaks. For this, do not use any type of wrench to check for leaks, use a

sudsy soap and water solution.

Follow the steps below for the correct procedure to power on:

1. Turn on the manual gas valve on the inlet side of the gas supply line.

2. Check for gas leaks at the exible coupling or gas connector connection using

a soap solution.

3. In moderation, spray or scrub the solution with soap on gas connections - active

bubbling indicates the location of the gas leak.

4. If a gas leak is detected, turn off the manual gas valve at the inlet side of the gas line.

Call your certied and licensed service technician.

5. If the equipment has no gas leak, continue with the equipment operating instruction.

• I Installation must be on a at and level surface.

• Install the equipment under hoods or exhausts.

• There must be a distance of at least 8" (203.2 mm) at the rear, 6" (152.4 mm) at

the right and left of the equipment from combustible surfaces as shown in the

gure below.

1 - Foot Regulator

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

12

02. EQUIPMENT INSTALLATION

2.7 Foot Leveling

For the proper functioning of the Fryer Gas

Cabinet it is ideal that the equipment is level

and perfectly xed to the work surface. To

adjust the leveling, turn item 1 (identied in

the drawing) counterclockwise to open and

clockwise to close to nd the best position

to operate the equipment safely.

2.8 First Time Use

To protect the equipment against possible damage caused by shock or balance from

transportation, the sides and front of the equipment have a protective PVC lm.

Remove any plastics, straps, or protective lm from the equipment before operating

the equipment.

In addition, you should perform a cleaning with the help of a sponge, neutral soap and

water in small amounts. Follow the steps as shown below:

1) Check that the ball valve knob (item 1) is in the closed position.

2) Fill the equipment tank with vegetable oil or vegetable shortening to the level

indicated in item 2.

3) After the procedure, use the steps in chapter 2.9 for ignition of the equipment

ensuring perfect use and observing the desired temperature rise.

IMPORTANT

NEVER CONNECT PRODUCT WITH TANK WITHOUT WATER OR OIL.

D - Indicator

C - Release Thermostat

B - Pilot mode position

A - Knob

Legend:

Warranty/Tech Support 800•722•6075

Service, Installation

& Care Manual

13

02. EQUIPMENT INSTALLATION

2.9 Turning on the Equipment - Product Ignition

To operate the equipment, do the following:

1. Open the manual gas supply valve (which will release gas into the equipment).

2. Turn the gas valve knob (1) to pilot mode (B) and squeeze it for 30 seconds to release gas into

the system to complete the ow to the pilot.

3. Put your lighting device (wick) in contact with the pilot (2). Keep the knob squeezed for 15 to

30 seconds.

Note: If after the procedure the pilot ame goes out, repeat steps 2 and 3 until it remains lighted.

4. Turn the knob (1) to the "ON" position (C) and then turn the temperature manipulator (3) to

the desired temperature position.

5. Wait a few seconds, the burner ame will ignite and the valve will ensure the system operates

smoothly with ame cycles to ensure the temperature set in step 3.

Do not use toxic or high chemical cleaning materials. See all instructions given by

the cleaning equipment manufacturer.

DANGER

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

14

03. CLEANING AND MAINTENANCE

3.1 Cleaning

3.1.1 Cleaning the Inside of the Equipment

Procedures for cleaning the fryer (cleaning the fryer once a day is reccomended):

1) To perform the drainage, wait for the oil to cool and perform the process with

the help of the acessory tube (1) that is attached to the equipment, as shown in

the image below. Then thread the pipe as shown below and open the valve. Use a

container at the outlet of the pipe for oil removal.

2) After oil has been removed, pour hot water into the pan to clean and remove excess

debris (left over from the last procedure) from the inner surface of the fryer. Wait to

drain and close the valve.

3) Following cleaning, close the valve and ll with water and neutral detergent.

4) Let the soluction boil at 100 °C (212 °F) for 15 minutes. Add the frying baskets for

cleaning and switch off the gas system, then scrub the inner walls with a plastic

bristle brush.

5) Open the hot water drain valve and rinse the bowl with clean water, it is advisable

to use vinegar to neutralize residual detergent, approximately 250ml to 20 liters of

water.

6) Rinse again with clean water.

Clean the fryer only after the oil is at room temperature as the oil and hot parts

of the equipment can cause severe burns to the operator.

Never move the fryer when it has vegetable fat or oil in the pan.

We recommend using different containers for water and oil removal. The latter

should be disposed of in an appropriate place according to the environmental

legislation of your region.

IMPORTANT

Warranty/Tech Support 800•722•6075

Service, Installation

& Care Manual

15

03. CLEANING AND MAINTENANCE

3.1.2 Cleaning the Outside of the Equipment

The equipment has stainless steel external coating and for its correct cleaning it is

necessary to follow the following guideline:

• First, let the equipment cool down. Normal daily dirt can be removed with a mild

detergent or soap solution applied with a damp cloth. Wash and dry thoroughly.

• Use a non-abrasive sponge with mild detergent and water to clean the equipment.

• Use a soft dry cloth to nalize the cleaning process.

• Never use sharp or abrasive materials (with corrosive elements in the formula).

• The oil should be replaced when it has: foam, smoke, sharp color and odors.

• Do not use water jets directly on the equipment.

• Wash stains or hardened foods with hot water. To remove debris, never use strong or

abrasive cleaners as they may damage the stainless steel, thus leaving it vulnerable to

corrosion.

The maintenance of the equipment should only be performed by a technician

authorized by the manufacturer.

The operator should be familiar with how to connect and disconnect the

restrictions/removable parts. If the restriction is removed for maintenance or

cleaning, it must be reconnected before using the equipment again.

IMPORTANT

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

16

03. CLEANING AND MAINTENANCE

3.2 Maintenance

Maintenance is one of the precautions to be taken for a good equipment life. Proper

cleaning, installation, checking and equipment life all contribute to reduced maintenance.

Before any maintenance, verify that the gas connections, regulators or check valves must

be completely closed and disconnected from the equipment.

3.2.1 Preventive Maintenance

To reduce downtime and maximum efciency, service your appliance once or twice a

year, depending on the amount of use. To do this, ask a technician to:

• Examine the air inlets at the rear and bottom of the equipment as well as the air vents

that are located in the hood at the top of the equipment at least twice year.

• Clean and adjust burners, regulators etc. twice a year.

• Check and calibrate the equipment gas supply system pressure at least once a year.

Warranty/Tech Support 800•722•6075

Service, Installation

& Care Manual

17

04. KNOWING THE EQUIPMENT

The Fryer Gas Cabinet has been designed and manufactured to offer the user the best in

the market for cafeteria, restaurant and kitchen equipment in general.

The equipment was developed to obtain a more uniform cooking process in the food. For

this, the tank acts as an intermediary between the heat source (re) and the food, and it is

through its caloric capacity that the equipment guarantees the best avor in the food.

The fryer is designed only for the use of oil or vegetable fat in the cooking process with

the food. Water may only be used for cleaning equipment.

The tank assembly is developed with innovative design, prizing for the functionality and

efciency of heat distribution.

The gas distribution and are assembly is assembled and tested with rigorous quality

processes to ensure the safety and efciency of cast iron burners.

The fryer has a thermopile that has two functions, the rst being to ensure that the pilot

ame remains in operation so that in a heat demand the main burner will be lit. The

second function is to provide safety to the opeator in order to detect the existence of a

ame for safety purposes by closing the possible gas ow to a burner.

This should be lit only once a day, and so should stay on throughout the workday as

consumption is very low.

In addition, 6" (152 mm) swivel castors can be purchased separately for the equipment.

• Available in 40 lb (16 l), 50 lb (20 l) and 75 lb (30 l) sizes.

• Tank - stainless steel providing durability for a high production output.

• 1 1/4'' Full port drain valve for fast draining.

• Cabinet - Stainless steel front, door and sides.

• Millivolt Thermostat, 200 ° F – 400 ° F (93.3 °C – 204.4°C).

• High-Temperature safety limit switch.

• Thermo-Safety pilot with built-in regulator.

• Separate Manual gas shut offs, for front servicing.

• Heavy-duty cast iron burners.

• Tubes constructed of heavy gauge metal.

• Heavy gauge deector system providing a quicker recovery time.

4.1 Main Features

H

W

D

Models Exterior Product Dimensions & Weight Shipping Crate Dimensions & Weight

Width (W) Depth (D) Height (H) Fw Weight Width Depth Height Weight

FGF40L 16” 3 1 7/32” 48 27/64” 15 11/32” 110 lb 22 41/64” 35 7/16” 58 17/64” 150 lb

FGF50L 16” 31 7/32 ” 48 27/64” 15 11/32” 143 lb 22 41/64” 35 7/16” 58 17/64” 283 lb

FGF75L 20” 33 45/64” 48 27/64” 18 45/64” 157 lb 26 37/64” 35 7/16” 58 17/64” 209 lb

GAS SUPPLY

Models Burners PROPANE GAS NATURAL GAS Manifold Pressure

kcal/h BTU/h kcal/h BTU/h Propane Gas Natural Gas

FGF40L 322,700 90,000 22,700 90,000

10” W.C 4” W.C

FGF50L 430,300 120,000 30,300 120,000

FGF75L 537, 800 150,000 37, 80 0 150,000

800•722•6075 Warranty/Tech Support

Service, Installation

& Care Manual

18

05. TECHNICAL SPECIFICATIONS

5.1 Equipment Dimensions and Weight

5.2 Technical Data

Warranty/Tech Support 800•722•6075

19

LIMITED ORIGINAL COMMERCIAL EQUIPMENT WARRANTY

Fortress warrants that the equipment, as supplied by the factory to the original purchasers,

is free from defects in materials and workmanship because of normal use for a period of

one (1) year from the original purchase date or a maximum of eighteen (18) months after

the shipment date from Fortress. When evaluating the warranty of each piece of Fortress

equipment, proper installation, and start-up in accordance with the instruction manual will

be considered. Warranty coverage includes Fortress equipment that is sold only in the

Continental United States. Repairs under this warranty are to be performed by a Fortress

authorized gas appliance service company that is located nearest to the equipment’s

location where the equipment is to be repaired.

This standard warranty is subject to the following conditions and limitations.

This warranty is limited to product(s) sold by Fortress to the original buyer in the continental

United States. Original installation must occur within one (1) year of the date of the original

purchase, and proof of the installation date must be provided. Equipment must be located

at the original installation location regardless of the same owner. The Fortress warranty is

limited to the repair or replacement of any part found to be defective. The Fortress warranty

will cover normal labor charges incurred in the repair or replacement of a warranted piece

of equipment. This warranty does not apply to any product(s) which have not been installed

in accordance with the directions published in the appropriate installation and operation

manuals. Fortress will bear no responsibility or liability for any product(s) which have been

mishandled, abused, misapplied, misused, subjected to harsh chemical action or poor

water quality, eld modied by unauthorized personnel, damaged by ood, re, or other

acts of nature, or which have altered or missing serial numbers. Fortress warranty does

not authorize the use of any product(s) in a non-commercial application, including but

not limited to residential use. The use or installation of the product(s) in non-commercial

applications renders all warranties, express or implied, null and void, including any

responsibility for damage, costs, and legal actions resulting from the use or installation of

the product(s) in any non-commercial setting. Adjustments such as calibrations, leveling,

tightening of fasteners or utility connections normally associated with original installation

are the responsibility of the installer. Should service be required at times that normally

involve premium labor rates, the owner shall be charged for the difference between normal

service rates and such premium rates. Exceptions to the standard warranty period are as

listed: A two (2) year warranty for fryer tanks only will apply. Warranty shall not apply to

defects attributable to the usage environment, for example from using dirty, corrosive water,

poor quality gas, or electricity of incorrect current rating or voltage. All damage due to

800•722•6075 Warranty/Tech Support

20

LIMITED ORIGINAL COMMERCIAL EQUIPMENT WARRANTY

overvoltage is excluded from the warranty. Non-clog range top open burners have a lifetime

warranty. Original purchased replacement parts supplied by Fortress will be warranted for

30 days from the parts invoice date. This warranty is for parts cost only and does not include

freight or labor charges.

Fortress assumes no liability for misuse or inadequate maintenance of the Product. In no

event shall the user by entitled to recover incidental or consequential damages. Including but

not limited to; damages for inconvenience, food loss, rental or replacement equipment, loss

of prots, or other commercial loss. Warranties stated above are the only warranties made

in connection with the sale and distribution of Fortress products. ANY AND ALL OTHER

EXPRESSED STATUTORY AND IMPLIED WARRANTIES APPLICABLE TO THE PRODUCT

INCLUDING, WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR USE ARE EXPRESSLY DISCLAIMED. The warranty information set forth

above shall be governed by and construed in accordance with the laws of the State of North

Carolina and, if applicable, the laws of the United States of America. The warranty, as stated,

is extended only to the original owner/user and is not assignable. Fortress reserves right to

change product specications without notice due to constant product improvement.

Thank you for your support and

purchasing with us!

– Fortress Team

This manual suits for next models

2

Table of contents

Other Fortress Technologies Computer Hardware manuals

Popular Computer Hardware manuals by other brands

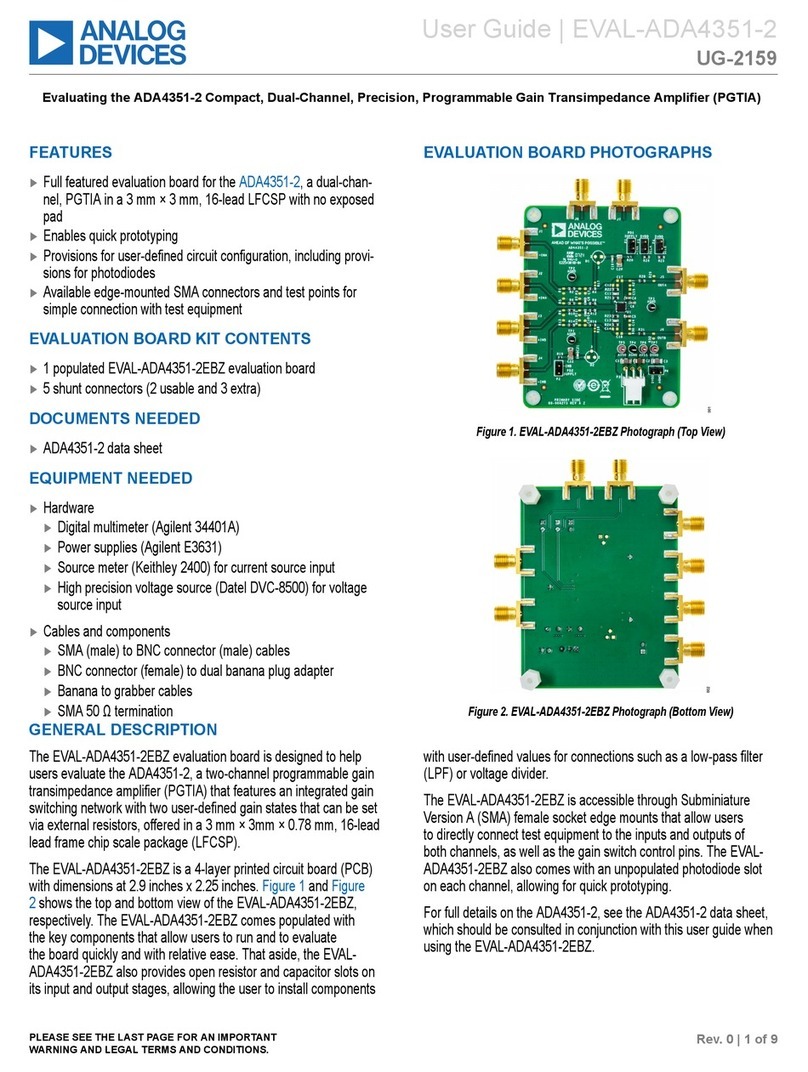

Analog Devices

Analog Devices EVAL-ADA4351-2 user guide

LinMot

LinMot E1100 Series user manual

Yamaha

Yamaha MMP1 Setup guide

PCB Piezotronics

PCB Piezotronics YT356A32 Installation and operating manual

Infineon

Infineon 6EDL SPI LINK user guide

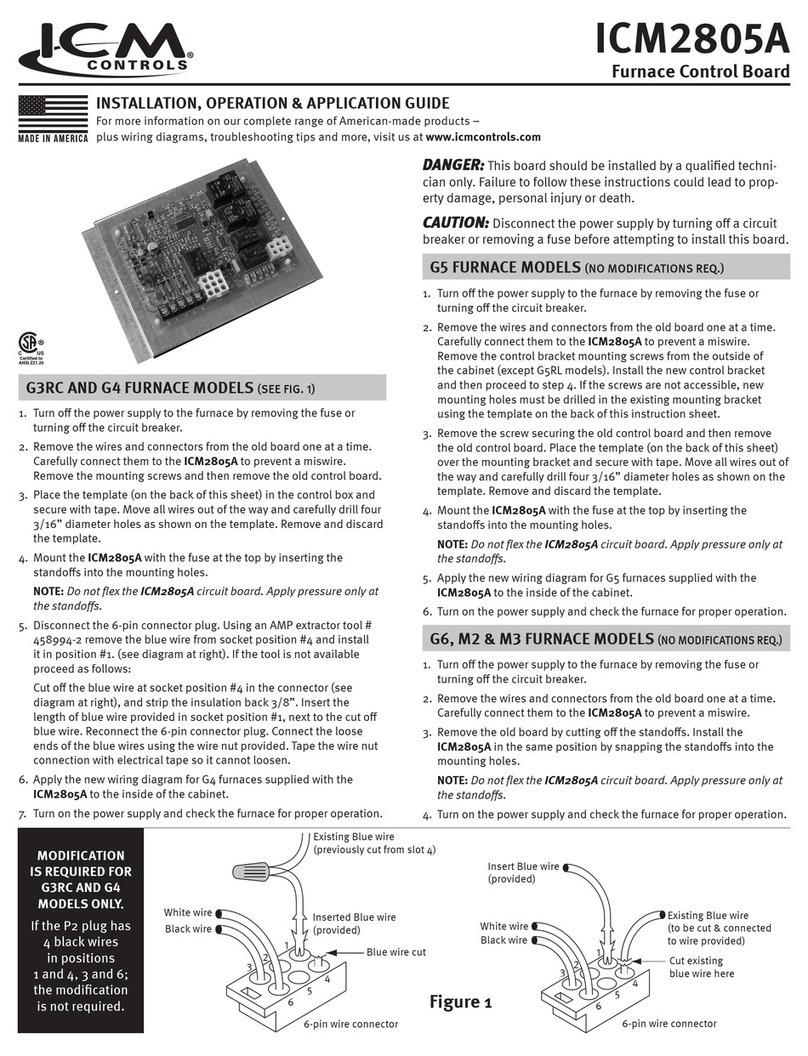

ICM Controls

ICM Controls ICM2805A Installation, operation & application guide