Forward Lift RSM4T User manual

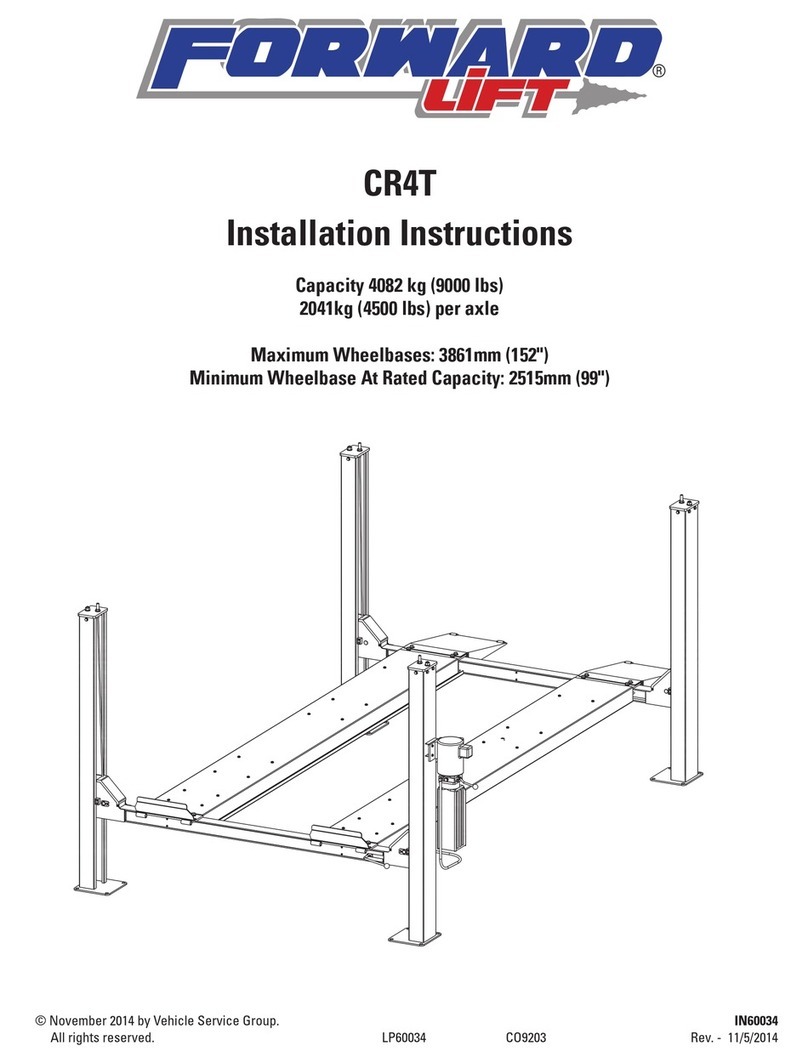

RSM4T

Capacity 4082 kg (9000 lbs)

2041kg (4500 lbs) per axle

Maximum Wheelbases: 3861mm (152")

Minimum Wheelbase At Rated Capacity: 2515mm (99")

IN20534

Rev. C 9/10/2010

© September 2012 all rights reserved. CO8347

I

N

S

T

A

L

L

A

T

I

O

N

I

N

S

T

R

U

C

T

I

O

N

S

I

N

S

T

A

L

L

A

T

I

O

N

I

N

S

T

R

U

C

T

I

O

N

S

IMPORTANT Reference ANSI/ALI ALIS,

Safety Requirements for

Installation and Service of Automotive Lifts

before installing lift.

2

Fig. 1

YOU WILL NEED A MIN. OF

15’ CLEARANCE IN REAR

TO INSTALL “T” ROD

SPECIFICATIONS

At full rise.......................................... 1962mm (77-1/4”)

Baseplate to baseplate length .......... 4731mm (186-1/4”)

Baseplate to power unit width .......... 3277mm (129”)

Column height .................................. 2221mm (87-7/16”)

Width of runways.............................. 508mm (20”)

Height of runways............................. 127mm (5”)

Width between runways ................... 1000mm (39-3/8”)

Lift Capacity...................................... 4082 kg (9000 lbs)

4731mm (186-1/4”)

4070mm (160-1/4”)

4299mm (169-1/4”)

4500mm (177-3/16”)

772mm

(30-3/8”)

5337mm (210-1/8”)

508mm (20”)

2413mm (95”)

2718mm (107”)

3023mm (119”)

3277mm (129”)

2221mm (87-7/16”)

1962mm (77-1/4”)

127mm (5”)

508mm (20”)

1000mm (39-3/8”)

4191mm (165”)

3

Non-Power

Unit Column

(3 each)

Power

Unit Column

(1 each)

Right Runway

Your Lift Is Operated Hydraulically By

The Use Of An Electric Power Unit

Lock Lever

To Release Locks

From Latch Bars

Approach

Ramp

Assembly

(2 each)

Crossbeam Assembly

(2 each)

Base Plate

(1) On Each Column

Rear Of Lift

Left Runway Has Cylinder, Cables, Pull

Bar Assembly And Sheaves Underneath.

These Mechanical Components Are Used

To Raise And Lower The Lift. Cables Will

Also Be Routed Around Sheaves In

Crossbeam Assemblies And Up Through

All (4) Columns.

A Quick Overview Of Your Lift

Remember! Prepare A Location For Your Lift Before You Unload It From The Truck.

Location Should Be A Level Surface.

Safety

Wear work gloves, steel toed shoes, and safety glasses during the

installation of your lift.

IMPORTANT

Avoid drug or alcohol use that will impair your

ability to install or operate your lift.

DANGER

Improper installation or improper use of

your lift could cause serious injury or death. Read installation

instructions and owner's manual thoroughly before installing or

operating your lift.

Unloading And Unpacking Your Lift

The components for your lift are heavy. The runways for these

lifts weigh in excess of 182 kg (400 lbs) each. The preferred

method for unloading your lift is by forklift.

If a forklift is not available a minimum of (4) people able to lift 57

kg (125 lbs) EACH will be needed to unload and assemble your

lift.

57 kgs

125 lbs 57 kgs

125 lbs 57 kgs

125 lbs 57 kgs

125 lbs

CAUTION

Shipping bands around packages are under

extreme tension. Have everyone stand clear when cutting

shipping bands.

Note: Use personal protective equipment as required - Lift smart

using preferred methods. See your Lifting It Right Manual, page

23.

Examine each lift component as you unload it to check for

shipping damage.

4

Attention! Use 4 People

To Place Runways

57 kg

125 lbs

57 kg

125 lbs

57 kg

125 lbs

57 kg

125 lbs

Openings In Columns

Fach Each Other

Left Front Column

(Power Unit Column)

3404mm (134”)

Power Unit

Bracket Faces Outward

5105mm (201”)

Right Front Column

Right Rear Column

Left Rear Column

Step 1: Setting Runways:

A.) If you haven't read previous pages, go back and do so now.

B.) Place runways in desired location according to Fig. 3.

Note: The runways weigh in excess of 182kg (400 lbs). Use a

minimum of 4 people to move these runways.

Fig. 2

Fig. 3

Step 2: Placing Columns:

A.) Place columns around runways as shown, Fig. 3. NOTE:

Dimensions are reference only to get the columns placed in their

approximate location. This will help to keep from moving around

as much in future steps.

5

Column Top Plate

Top Of Column

Ø12 Washer On Each

Side Of Column

M12 X 35 Hex Head Bolt

(4 On Each Column)

Ø12 Lockwasher

and M12 Nut

Fig. 5

Fig. 4

Step 3: Installing Latch Bar:

A.) Remove Column Top Plate as shown, Fig. 4.

B.) Install Rub Blocks as shown using M8 x 20 Socket Head Cap

Screw in location shown. Note orientation. The thick area will

always be to the inside of the lift.

C.) Place crossbeams on ground between columns.

IMPORTANT

NOTE ORIENTATION OF CROSSBEAMS. THE

SIDE OF THE CROSSBEAM WITH THE SHORT SIDE COVER GOES

Ensure Latch Bar

Goes Between

Crossbar and Retainer

Rub Block

TOWARDS THE INSIDE OF THE LIFT. THE CROSSBEAM WITH

THE FULL LENGTH SIDE COVER GOES TO THE OUTSIDE. THIS IS

CRITICAL FOR CABLE INSTALLATION.

D.) Slide columns into crossbeams until it hits the rub blocks.

E:) Insert (1) latch bar into each column. Be sure to slide through

Retainer as shown, Fig. 5. The bottom of the latch bar will insert

into the slot on the baseplate of the column.

6

Latch Bar

Latch Bar Stud

1/2"

Exposed

Latch Bar Nut

Adjust Latch Bar Jam Nut To

Allow Latch Bar Stud To Be

Adjusted 1/2” Out Of the Top

Of The Latch Bar Nut

Fig. 6

Fig. 7

Step 4: Reinstalling Column Top Plates:

A.) Install (1) column top plate in each column, Fig. 6. Make sure

latch bar jam nut is located far enough down the latch bar stud

to allow you to fully insert the column top plate in the top of the

column.

B.) After column top plates have been installed adjust latch bar

nut and latch bar jam nut as shown, Fig. 7.

Column Top Plate

Top Of Column

Latch Bar Stud

Ø20 Flat

Washer

M20 Latch Bar

Jam Nut

Ø12 Washer On Each

Side Of Column

M12 X 35 Hex Head Bolt

(4 On Each Column)

Ø12 Lockwasher

and M12 Nut

M20 Latch

Bar Nut

7

CABLES

SHEAVE PIN

SHEAVE PIN

M16 X 40 BOLT

Ø16 FLAT WASHER

Ø16 LOCK WASHER

M16 NUT

Fig. 9

Step: 5: Runway Installation (columns not shown for clarity):

A.) Use a minimum of (2) people to raise crossbeam assemblies

to first lock.

B.) Remove inside short crossbeam covers, Fig. 8.

C.) Using a mechanical device such as pulley or winch come

along, fully extend hydraulic cylinder (located under runway).

D.) Being careful not to cross or pinch cables, install runway to

crossbeams as shown, Fig. 9 & Fig. 10.

Fig. 8

8

Center Bar In Crossbeam

3/4”-16NC NYLON LOCK NUT

CABLE

Ø20 FLAT WASHER

Expose All Cable Studs 1/4''

Adjustments Will Be Made

Later When You Level The Lift

Slack Cable

Actuator

Sheave

Left Front Shown

Cable

Fig. 10

Fig. 12

Fig. 11

IMPORTANT

It is very important that the cables and

sheaves in yoke assemblies get installed properly. Failure to do

so will cause damage to your lift!

Step 6: Cable Routing:

A.) Route cables from runway to each column. When running

cable across the crossbeam, be sure cables run behind center

IMPORTANT

MAKE SURE CABLES DO NOT GET CROSSED

bar, Fig. 11. Run cables up each column keeping the cables on

the inside of the slack cable actuators, Fig. 10. You will need to

remove the Sheave Pins, Fig. 9 and Sheave, Fig. 10 in order to get

the cable routed properly. Once routed, re-install sheaves and

spacers.

B.) Attach cable studs to column top plates, Fig. 12.

9

Run nut down just

below impact section

of bolt. Drive anchor

into hole until nut and

washer contact base.

Clean hole.

Drill holes using

3/4” carbide

tipped masonary

drill bit per

ANSI standard

B94.12.1977

4-1/4”

Tighten nut with

Torque wrench to

110 ft.-lbs.

2-1/4”

3-1/4”

4-1/4”

Installation torque of 110 ft-lbs. is required for all anchor bolts.

A) Concrete Thickness & Hole Depth 4-1/4" (108mm)

B) Edge Distance 4-3/4" (121mm)

C) Hole Spacing 6-1/2" (165mm)

A

B

C

C

B

C

C

NOTE: If more than 2 horse shoe shims are used at any of

the column anchor bolts, pack non-shrink grout under the

unsupported area of the column base. Insure shims are held

tightly between the baseplate and floor after torquing anchors.

Step 7: Concrete and Anchoring: Concrete shall have a

compression strength of at least 3,000 PSI and a typical slab

thickness of 5-1/2” to 6”. In order to achieve required anchor

loads, a minimum concrete thickness of 4-1/4” and anchor

embedment of 3-1/4” is required at each anchor location. When

using the standard supplied 3/4” x 5-1/2” lg. anchors, if the top

of the anchor exceeds 2-1/4” above the floor grade, you DO

NOT have enough embedment.

Drill 3/4” dia. holes in concrete floor using holes in column

base plate as a guide. See Figures above for hole depth, hole

spacing, and edge distance requirements.

IMPORTANT

PUSH COLUMNS UP TIGHT AGAINST RUB

BLOCKS BEFORE DRILLING OR ANCHORING LIFT COLUMNS.

CAUTION

DO NOT install on asphalt or other similar

unstable surfaces. Columns are supported only by anchors in

floor.

IMPORTANT

Using the horse shoe shims provided, shim

each column base until each column is plumb. If one column

has to be elevated to match the plane of the other column, full

size base shim plates should be used. Recheck columns for

plumb.

IMPORTANT

PUSH COLUMNS UP TIGHT AGAINST RUB

BLOCKS BEFORE DRILLING OR ANCHORING LIFT COLUMNS.

Tighten anchor bolts to an installation torque of 110 ft-lbs. Shim

thickness MUST NOT exceed 1/2” when using the 5-1/2” long

anchors provided with the lift. Adjust the column extensions

plumb.

If anchors do not tighten to 110 ft-lbs. installation torque,

replace concrete under each column base with a 4’ x 4’ x 6”

thick 3000 PSI minimum concrete pad keyed under and flush

with the top of existing floor. Let concrete cure before installing

lifts and anchors.

NUT

WASHER

SHIM

ANCHOR

IMPORTANT PUSH COLUMNS UP TIGHT AGAINST RUB BLOCKS BEFORE DRILLING

OR ANCHORING LIFT COLUMNS

10

Fig. 14

Step 8: Installing Power Unit:

A.) Install power unit to power unit bracket, Fig. 13.

POWER UNIT

HYDRAULIC HOSE

ELBOW

M8 x 25 BOLT

M8 NUT Ø8 FLAT WASHER

Ø8 FLAT WASHER

Ø8 LOCK WASHER

SHOCK ABSORPTION WASHER

Step 9: Installing Hydraulic Hose:

A.) Attach 90° elbow onto power unit, Fig. 14.

B.) Install hydraulic hose onto 90° elbow of power unit and fitting

in side of runway, Fig. 14.

Step 10: Adding Hydraulic Fluid To Power Unit:

A.) Remove fill/breather cap and fill with Dexron III ATF only to fill

line on tank.

The capacity of the tank is approximately 12 liters.

Note: If fill/breather cap is lost or missing replace with original

equipment replacement part.

IMPORTANT

DO NOT substitute a different type of cap or

plug.

Fig. 13

11

Step 11: Electrical Service To Power Unit:

Have a certified electrician run appropriate power supply to

motor. Size wire for 20 amp circuit. See Motor Operating Data

Table.

CAUTION

Never operate the motor on line voltage less than

208V. Motor damage may occur.

IMPORTANT: Use separate circuit for each power unit. Protect

each circuit with time delay fuse or circuit breaker. For single

phase 208-230V, use 20 amp fuse. Three phase 208-240V, use 20

amp fuse. For three phase 400V (*E Model) and above, use 10

amp fuse. For three phase 380V (*S Model) use 16 amp fuse. All

wiring must comply with NEC and all local electrical codes.

Note: 60Hz. single phase motor CAN NOT be run on 50Hz. line

without a physical change in the motor.

IMPORTANT

T7

T1

T8

T2

T9

T3

T4

T5

T6

L1

L2

L3

T7 T4

T1

L1

T8 T5

T2

L2

T9 T6

T3

L3

T1

T2

T3

U2

V2

W2

W1

V1

U1

208-240V

50/60Hz. 3Ø

440-480V 50/60 Hz. 3Ø

380-400V 50 Hz. 3Ø

575V 60 Hz. 3Ø

Capacitor Box Attachment

L1

PE

L2

L3 MOTOR

1

3

5

2

4

6

DRUM

SWITCH

3 Phase

Supply

NOTES:

1. Unit not suitable for use in unusual conditions. Contact

Rotary for moisture and dust environment duty unit.

2. Control Box must be field mounted to power unit.

3. Motor rotation is counter clockwise from top of motor.

Three Phase Power Unit

MOTOR OPERATING DATA TABLE - THREE PHASE

LINE VOLTAGE RUNNING MOTOR VOLTAGE RANGE

208-240V 50/60Hz. 197-253V

400V 50Hz. 360-440V

440-480V 50/60Hz. 396V-528V

575V 60Hz. 518V-632V

Single Phase Wiring

Three Phase Wiring

SINGLE PHASE POWER UNIT WIRING

MOTOR OPERATING DATA - SINGLE PHASE

LINE VOLTAGE RUNNING MOTOR VOLTAGE RANGE

208V - 230V 60Hz 197V - 253V

208V - 230V 50Hz 197V - 253V

M

230V 60Hz

Single Ph

Black

Green

White

Up

Switch

Black White

Green

208-230V 60Hz

Single Phase

Attach ground wire here

Attach wire

to wire Attach wire

to wire

Wiring Should Be Done By A

Certified Electrician. Following All

National, State, And Local Electrical Codes

(4) M5 x 45 PHMS, Plated

(4) M5 x 10 PHMS, Plated

Capacitor Box To Power Unit

Drum Switch

And Cover

Re-seal Between

Box And Spacer

With Silicone

Sealer

Capacitor

Box

Gasket

12

IMPORTANT

Press Button

To Raise Lift

Push Down

On Lowering

Valve To Lower Lift

Onto Locks

ATTENTION!!! You CAN NOT Fully

Lower Your Lift Until You Complete Step 13!

Only Raise Runways To A Comfortable

Working Height!

Before Operating Lift,

Read and Heed Instructions In Owner's

Manual Along With All Safety, Caution,

And Warning Labels.

Fig. 15

Step 12: Raising Lift For Final Assembly Steps:

A.) Press the raise button on power unit, Fig. 15, and raise the

runways up to a comfortable working height, approximately waist

high.

B.) Push down on the lowering valve to lower the runways onto

locking latches.

IMPORTANT

You have not yet completed the locking latch

release linkage assembly at this point. Your lift will only lower onto

the locking latches. Do not lift the runway too high until you complete

step 13.

IMPORTANT

Always have everyone in the area move away

from the lift when it is in operation.

CAUTION

Keep feet clear of lift

while lowering.

NP253

CAUTION

Keep hands clear

of yoke ends

during lift

operation.

NP334

13

M6 x 25 BOLT

INSTALL CAM TO LATCH RELEASE ROD

INSTALL HANDLE TO CAM

INSTALL LINKAGES TO CAM

(ADJUSTMENT TO LINKAGES MAY BE NECESSARY)

M6 NYLON

LOCKNUT

M6 x 25 BOLT

M6 NYLON

LOCKNUT

M8 NYLON

LOCKNUT

M8 x 35 BOLT

Fig. 16

Fig. 18

Step 13: Inserting Latch Bar, Attaching Lock Cams And Latch

Release Handle:

A.) Remove outer crossbeam covers.

B.) Insert latch bar through crossbeam assembly and through left

side runway latch bar supports. Rod inserts from rear of lift and

comes out near the power unit on the front of the lift.

C.) Install Cam to Latch Release Bar as shown, Fig. 16.

Fig. 17

D.) Install Latch Release Handle to Cam as shown, Fig. 17.

E.) Install Linkages to Cam as shown, Fig. 18. Cam should sit

straight up and down when linkages are tight.

F.) Repeat for linkages on approach end.

G.) Re-attach outside crossbeam covers.

14

M12 x 20 BOLT

Ø12 LOCKWASHER

Ø12 FLAT WASHER

FRONT CHOCK

SPREAD COTTER PINS

AFTER INSTALLATION

Fig. 19

Fig. 20

Step: 14: Front Chock and Approach Ramp Installation:

A.) Attach front chock as shown, Fig. 19.

B.) Attach approach ramp with bar and cotter pins as shown, Fig.

20. Be sure to spread cotter pins after installation.

Step 15: Testing Your Lift:

A.) Push button on power unit to raise your lift.

B.) Pulling up on lock lever will release locking latches.

C.) Push down on the lowering valve to lower lift.

Note: Without pulling up on the lock lever the lift will only lower

onto the locking latches. Any time you lower the lift you will have

to raise your lift off of the locking latches, (approximately 1 inch),

and pull up on the lock lever to allow the locking latches to clear

the slots in the latch bars. Releasing the lock lever will re-engage

the locks. The lift will stop in the next locking position unless you

are below the lowest slots in the latch bars. After you clear the

lowest slots in the latch bars the lock lever may be released and

the lift will completely lower the lift to the ground.

15

Start At Right Front Column

To Begin Latch Bar Adjustments.

1/2"

1/4"

Start At Left Rear Column

To Begin Cable Adjustments

IMPORTANT

If Your Lift Is Moved To Another

Area In Your Garage, Depending On The Grade

Of The Floor, You May Need To Repeat Leveling

Your Lift Instruction From Above

Fig. 21

D.) Adjust your cables next starting at the left rear column. Lower

the lift below the last slot in the latch bars so that the runways are

only being supported by they cables.

E.) Adjust the left rear cable to expose 1/4 inch of the cable out of

the top of the nut, Fig. 21.

F.) Using the 4 ft. level adjust the rest of the cables until runways

are level. Exposed threads on cable studs may vary on the rest of

the columns.

Step: 16: Leveling your lift:

A.) Level the latch bars first. Make sure you have the lift off the

ground and lowered onto the locking latches.

B.) Start at the right front column and loosen jam nut and adjust

your latch bar until there is 1/2 inch of thread is exposed out of the

top of the nut on top of the column, Fig. 21. Retighten jam nut.

C.) Using a 4 ft. level adjust the rest of the latch bars until runways

are level. Exposed threads on the rest of the latch bars may vary

depending how level the surface is where your lift is located.

DATE REV. CHANGE MADE

12/12/2008 - New lift instructions.

12/7/2009 A Changed dimensions for lift specifications.

11/19/2010 B Updated drum switch for 3-phase motor graphic.

Installer: Please return this booklet to

literature package, and give to lift

owner/operator.

Thank You

Trained Operators and Regular Maintenance Ensures Satisfactory

Performance of Your Lift.

Contact Your Nearest Authorized Parts Distributor for Genuine

Replacement Parts. See Literature Package for Parts Breakdown.

Table of contents

Other Forward Lift Lifting System manuals

Popular Lifting System manuals by other brands

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL 265 Instruction and maintenance manual

Vestil

Vestil CART-550-AS instruction manual

Aqua Creek Products

Aqua Creek Products F-411RPL-AT1-02 manual

Aqua Creek

Aqua Creek F-105LAR instructions

Sealey

Sealey MPSD1 instructions

MoJack

MoJack WorkBench Instructions for assembly and operation

R. Beck Maschinenbau

R. Beck Maschinenbau HS 2000 FH operating manual

Titan Lifts

Titan Lifts Master Series Installation, operation & maintenance manual

Enerpac

Enerpac MLSF3 Operation and maintenance manual

ATH-Heinl

ATH-Heinl Pure Lift 2.40 user manual

Vitea Care

Vitea Care DAVID user manual

Sealey

Sealey MC402.V4 instructions