Thank you for purchasing the Model FT2A Thermal Gas Mass Flow Meter and Temperature

Transmitter from Fox Thermal. The Model FT2A is one of the most technically advanced ow

meters in the world. Extensive engineering effort has been invested to deliver advanced

features, accuracy measurement performance and outstanding reliability.

This Instruction Manual contains the electrical and mechanical installation instructions as well

as details for programming, maintaining and troubleshooting the meter.

This manual is divided into the following sections: Introduction, Installation, Wiring, Operation,

Maintenance, Troubleshooting, Appendices, Glossary and Index.

Theory of Operation

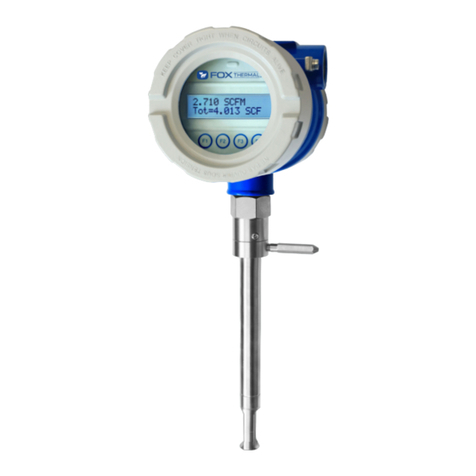

The Model FT2A is an innovative Thermal Mass Gas Flow Meter and Temperature Transmitter.

It is microprocessor-based and eld programmable. The FT2A thermal sensor operates on

the law that gases absorb heat. A heated sensor placed in an air or gas stream transfers

heat in proportion to the stream’s mass velocity. There are two sensor elements connected

to a balanced bridge circuit. One sensor element detects the gas temperature and a second

element is maintained at a constant temperature above the gas temperature. The energy

applied to the heated sensor to maintain a constant temperature differential (constant ∆ T) is

directly proportional to the mass ow velocity. The FT2A ow meter maintains accurate ow

measurement over a large temperature and pressure range.

Mass Flow

The Model FT2A measures mass ow; an advantage over other ow meters which measure

volumetric ow rate. Volumetric ow is incomplete because temperature and pressure are

unknown and must be measured separately. For example, the mass ow of a gas depends on

its temperature and pressure. As temperature and pressure changes, the gas volume changes

but not its mass. Therefore a device measuring mass ow is independent of temperature

and pressure. The Model FT2A provides a direct measurement of gas ow in Mass units (kg/

hr, lb/hr), standard units (SCFM, SLPM) or normal units (NM3/hr, NLPM) with no additional

temperature or pressure measurements required.

6

Introduction

Model FT2A

INTRODUCTION