MODEL FT1 FLOW METER TROUBLESHOOTING GUIDE

Rev. B

Precision Mass Flow Measurement

An ON

I

CON Brand

Phone: (831) 384-4300 • Fax: (831) 337-5786 • www.foxthermal.com

Section C: Investigating ow meter inaccuracy:

1. How high or low is the ow meter reading and at what ow rate? Please provide specic data.

2. Conrm that the 4mA and 20mA scaling in the PLC or DCS matches the scaling in the ow meter's settings. If

you are using the 4-20mA output also conrm that the measurement unit (SCFM, KG/HR, NM3H, etc.) in the

Fox meter is the same as in your PLC/DCS.

3. Did the meter ever read accurately or do you believe it has measured incorrectly since it was installed?

4. If measuring a gas mixture, have you checked to be sure that the mixture parts equal 100%? If not, what gas

are you currently measuring?

5. Has there been any change in meter location or pipe conguration?

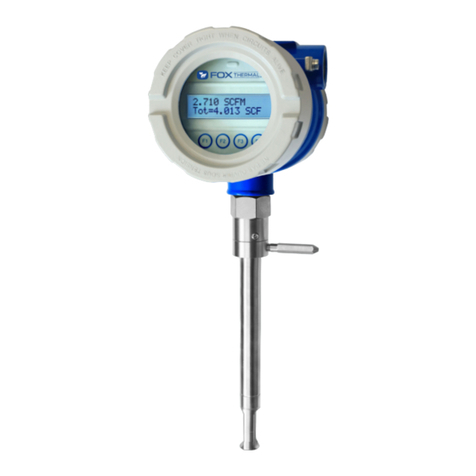

6. Is the insertion depth setting in accordance with Fox Thermal installation instructions? Refer to FT1 Instruction

Manual for insertion depth.

7. What is the inside diameter (ID) of the pipe? Is the actual pipe ID the same as listed on the ow meter's

Calibration Certicate?

8. Compare the STP (Standard Temperature and Pressure) settings (values and units) in the meter with the

information recorded on the calibration certicate. Do the settings match? This is a requirement for accurate

measurement.

9. How much straight pipe is upstream and downstream of the ow meter? Fox recommends a minimum of 15

diameters of straight pipe upstream of the ow meter and 10 diameters downstream. Refer to FT1 Instruction

Manual for upstream and downstream conditions for insertion and owbody types.

10. Is the ow indicator on the ow meter probe pointing in the direction of ow? If your meter is an inline-type,

is the ow body or spool piece installed with the ow conditioner on the upstream side of the sensor? Refer to

the FT1 Instruction Manual for information regarding the direction of ow.

For assistance contact the Fox Thermal Service Department:

Phone: 831-384-4300