Contents

ii B0640421_en | Operating instructions Control Panel RBG 3200

1 General ......................................................................................................................................................... 4

1.1 About these instructions ....................................................................................................................... 4

1.2 Safety information................................................................................................................................. 4

2 Installing the RBG 3200 .............................................................................................................................. 5

2.1 Connecting the bus cable ..................................................................................................................... 5

2.2 Setting end jumpers.............................................................................................................................. 5

2.3 Setting the module address .................................................................................................................. 6

2.4 Initial startup ......................................................................................................................................... 7

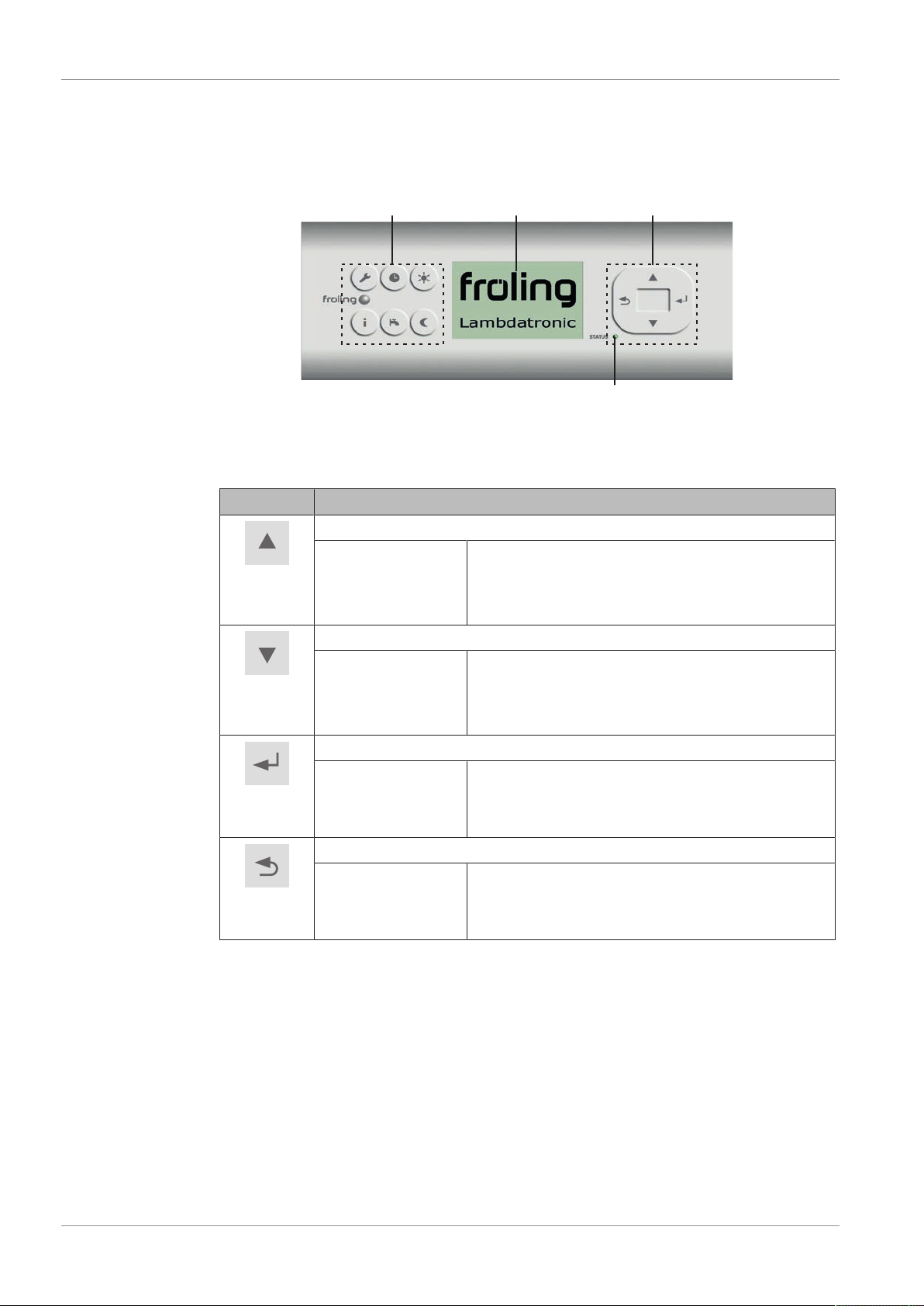

3 Overview of the basic functions ................................................................................................................ 8

3.1 Control keys and display....................................................................................................................... 8

3.1.1 Navigation keys.......................................................................................................................... 8

3.1.2 Status LED................................................................................................................................. 8

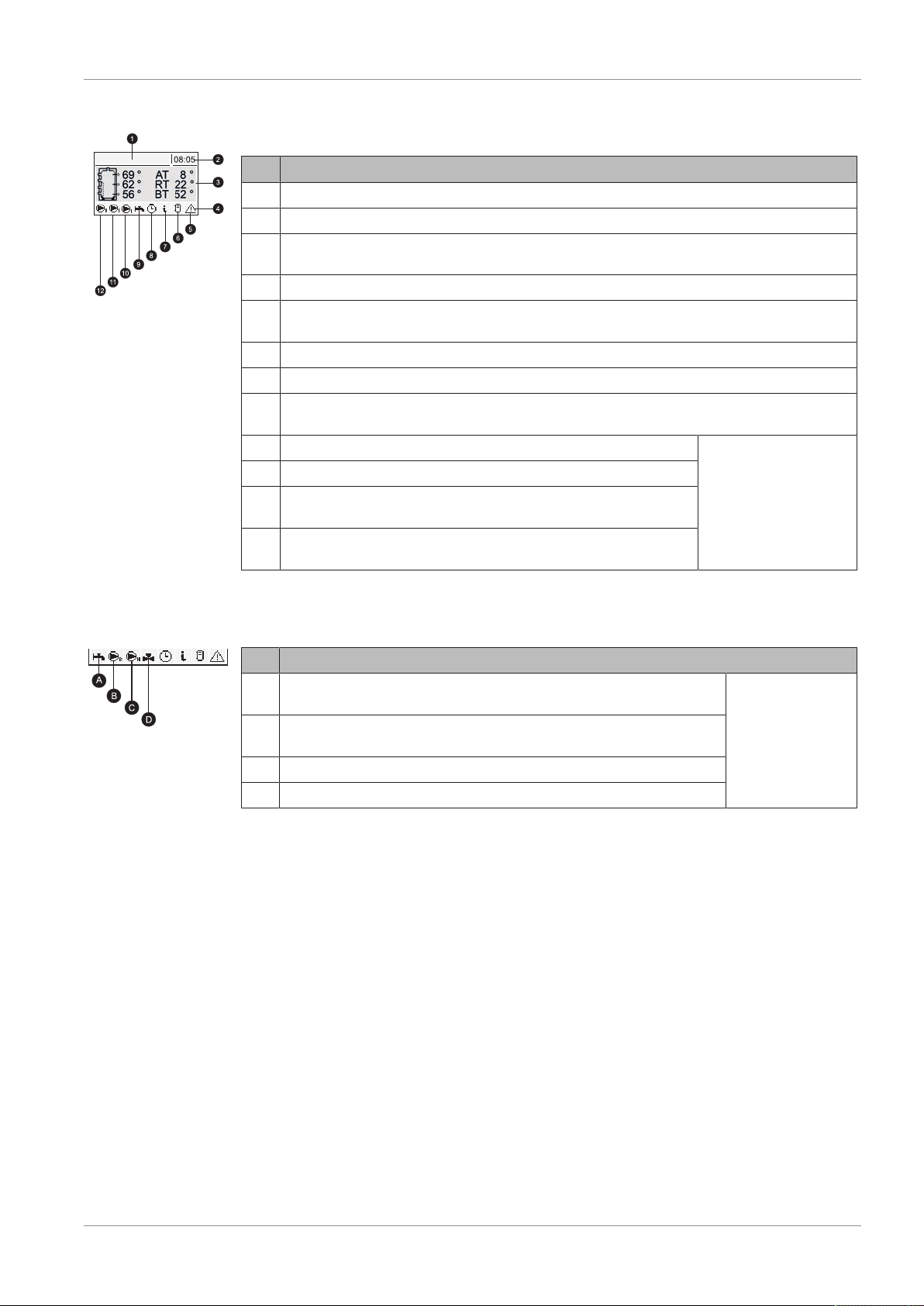

3.1.3 Graphic display .......................................................................................................................... 9

3.2 Function keys........................................................................................................................................ 10

3.2.1 Info key ...................................................................................................................................... 10

3.2.2 Service program key .................................................................................................................. 11

3.2.3 DHW tank program key.............................................................................................................. 11

3.2.4 Party program key...................................................................................................................... 12

3.2.5 Setback program key ................................................................................................................. 13

4 Operation...................................................................................................................................................... 14

4.1 Setting parameters ............................................................................................................................... 14

4.2 Setting times ......................................................................................................................................... 14

4.2.1 Deleting a time window .............................................................................................................. 15

5 Parameters overview................................................................................................................................... 16

5.1 Heating ................................................................................................................................................. 16

5.1.1 Heating - Status ......................................................................................................................... 16

5.1.2 Heating - Temperatures ............................................................................................................. 17

5.1.3 Heating - Times.......................................................................................................................... 18

5.2 Water .................................................................................................................................................... 18

5.2.1 Water - Status ............................................................................................................................ 18

5.2.2 Water - Temperatures................................................................................................................ 19

5.2.3 Water - Times ............................................................................................................................ 19

5.3 Solar ..................................................................................................................................................... 19

5.3.1 Solar - Status ............................................................................................................................. 19

5.3.2 Solar - Temperatures ................................................................................................................. 21

5.4 Buffer tank ............................................................................................................................................ 21

5.4.1 Buffer tank - Status .................................................................................................................... 21

5.4.2 Buffer tank - Temperatures ........................................................................................................ 22

5.5 Boiler 2.................................................................................................................................................. 22

5.5.1 Boiler 2 - Status ......................................................................................................................... 22

5.5.2 Boiler 2 - Temperatures ............................................................................................................. 23

5.6 Difference regulator .............................................................................................................................. 24

5.6.1 Difference regulator - Status ...................................................................................................... 24

5.7 Circulation pump................................................................................................................................... 24

5.7.1 Circulation pump - Status........................................................................................................... 24

5.7.2 Circulation pump - Temperatures .............................................................................................. 25

5.7.3 Circulation pump - Times ........................................................................................................... 25

5.8 System.................................................................................................................................................. 25

5.8.1 System - Current values ............................................................................................................ 25

5.8.2 System - Error............................................................................................................................ 25

5.8.3 System - Basic display parameters............................................................................................ 26

5.8.4 System - Language.................................................................................................................... 26