FireFlex TOTALPAC 2 PAR-3 User manual

Page 1 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

Controls Section

1. Product Description

The Control Panel Section of the Self-Contained TOTALPAC2

unit is an add-on cabinet that is installed on the top of the trim

enclosure at the factory. This cabinet is fabricated of Gauge

14 steel, painted fire red with baked powder paint making it

rustproof, the same finish as the Trim Enclosure.

The Control Panel Section is provided with a locked stainless

steel door on the front giving access to the basic controls of

the Control Panel. Once opened, the cabinet door gives

access to the Contractor's Terminal Strip (refer to FIELD

WIRING DIAGRAM for additional details), the control panel

main board, emergency batteries and other related

equipment. Refer to Figures 1 and 2 for additional details.

2. Self-contained TOTALPAC2Unit (with Viking PAR-3 Model

B-2 Control Panel)

The Viking PAR-3 Model B-2 Control Panel is a supervised,

24 Volt, microprocessor-controlled release control panel.

The panel is designed to operate the electric release

solenoid, in the release piping of deluge or preaction

systems. The panel is available for use with either 120VAC-

60Hz or 220VAC-50Hz power supplies. The battery

compartment can hold two 12 volt batteries which are

charged by an internal battery charger. Batteries are

available to provide up to 90 hours of backup power during

AC power failure.

The PAR-3 panel can be used with a wide range of

compatible initiating devices such as pull stations, heat

detectors (including linear heat detectors), photo-electric and

ionization smoke detectors.

A dip switch 'Function Selector' allows field programming for

one of four possible input/output combinations, of which only

two are available and Listed for use with the TOTALPAC2

System: Single Hazard Two Zone and Single Hazard

Crossed Zone.

Changing the position of the dip switch will cause the panel to

go on trouble condition.

Warning ! Only the two configurations above are

Listed/Approved with the TOTALPAC2Unit. Changing the

position of the factory set dip switches may eliminate the

Fire Protection capabilities of the system and/or void

Listing/Approval and Warranty. Consult FireFlex Systems

before making any change !

In fire conditions when an initiating device circuit (or

predetermined combination of circuits) is energized, the panel

activates the release and signaling circuits according to the

'Function Selector' setting.

On the panel's display board, the appropriate Alarm, Trouble

and Supervisory LED's will flash until the event has been

acknowledged. After depressing the Tone or Alarm Silence

button, the LED will remain steadily illuminated until the panel

is reset.

3. Technical Data

Approvals:

The PAR-3 Control Panel when provided in the Control

Panel Section of the TOTALPAC2Unit forms an assembly

that is Underwriters Laboratories Inc. Listed (Model B2

for UL Listed systems & B-2C for ULC Listed systems)

and Factory Mutual Research <FM> Approved. Refer to

GENERAL SECTION for additional details.

Cabinet:

Vented enclosure:

1 ½" to 3" Dia. Units: 36" x 20" x 14"

4" & 6" Dia. Units: 46" x 24" x 14"

Environment:

Temperature: 32oF. (0oC) to 120oF (49oC)

Humidity: 85% Relative Humidity (non-condensing) at

86oF (30oC) maximum.

Recommended nominal room temperature: 60-80oF

(15-27oC).

AC Power:

PAR-3C: 120VAC, 50/60Hz, 1.2 amps.

Wire size: minimum #14 AWG with 600 Volt insulation.

PAR-3E: 220/240VAC, 50/60Hz, 0.6 amps.

Wire size: minimum #14 AWG with 600 Volt insulation.

Battery:

Lead Acid only

Maximum charging circuit: 27.6 V, 1.5A

Initiating Device (input) Circuits:

Four style B (Class B)/Style D (Class A) circuits factory

wired: Input 1: Detection Circuit

Input 2: Detection Circuit

Input 3: Water flow (Alarm pressure switch)

Input 4: Supervisory circuit.

Power limited circuitry

Normal operating voltage: 24VDC (ripple = 1.0V p-p)

Alarm current: 15mA minimum

Short circuit current: 40mA maximum

Maximum detector current in standby: 2mA (max) per

zone

Maximum loop resistance: 100 ohms

End-of-Line resistor: 4,7K-½Watt (provided) - Note:

leave EOL resistor provided on all unused circuits.

Detector loop current is sufficient to ensure operation of

one alarmed detector per zone.

Supervisory current: 5mA (including EOL resistor)

Heat Detectors: Detection circuits allow for installation

of any number of listed or approved normally open

thermal detectors.

Smoke Detectors: Refer to Device Compatibility

Document on our Web site for a list of compatible smoke

detectors, information concerning the maximum number

of smoke detectors allowed per zone, and standby

requirements for the smoke detector used.

Also, refer to appropriate Fire Protection Equipment

Approval Guides.

Page 2 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

For supervised four-wire smoke detectors, connect the Power

Supervision Relay to the last detector base 24V screw

terminals. See ACCESSORIES.

Notification Appliance and Releasing Circuits:

Power limited circuitry

Two Style Y and two Style Y/Z circuits

Output 1: Alarm Bell (Style Y/Z)

Output 2: Waterflow or Trouble Horn (Style Y/Z)

Output 3: Releasing Circuit 1 (Style Y)

Output 4: Trouble Horn (Style Y)

Normal operating voltage: 24VDC

Total current available to all external devices: 2.25Amps

Maximum signaling current per circuit: 1.5Amps

Supervised circuitry

Maximum allowable voltage drop due to wiring: 2VDC

End-of-Line resistor: 4.7K-½Watt (provided) - Note: leave

EOL resistor provided on all unused circuits.

Refer to Device Compatibility Document on our Web site for a

list of compatible indicating appliances. Also, refer to

appropriate Fire Protection Equipment Approval Guides.

Alarm Relay:

Basic panel includes one non-silenceable Form-C dry alarm

contact rated 2 Amps at 30VDC and 0.5 amps at 20 VAC

(resistive).

Trouble Relay:

Basic panel includes one Form-C dry alarm contact rated at

2Amps at 30VDC and 0.5Amps at 30VAC (resistive).

Trouble relay will silence when trouble condition is cleared.

Zone Relay Module:

Model PAR-3 panel includes one Zone Relay Module (4XZM)

providing dry Form-C contacts controlled by each of the four

output circuits plus one general alarm and one panel/field

wiring trouble relay. See TABLE 2.

Power Outputs:

Four-wire Smoke Detector Power (resettable): Up to 200mA

total DC current available. Maximum ripple voltage: 1.0V p-p.

Non-resettable Power: Up to 200mA total (substracted from

four-wire smoke detector power) DC current available.

Maximum ripple voltage: 1.0V p-p.

RMS Regulated Power: Total current available for external

devices: 0.5Amp. (subtracted from the 2.25A available to

notification appliance circuits). Maximum ripple voltage:

100mV p-p.

4. Other features:

Front Panel Control Switches: (Refer to Figure 3).

Switch 1: Tone Silence

Switch 2: Alarm Silence

Tone Silence and Alarm Silence control switches can

be activated to acknowledge alarms. A second

"trouble" will resound the buzzer.

Switch 3: Alarm Activate

The Alarm Activate switch may be used to activate

signaling circuits and relays.

Switch 4: System reset.

The Reset switch clears any activated output

circuit. If alarm or trouble conditions exist when

the reset switch is pushed, they will re-activate

the panel.

Front Panel Zone Status LEDs:

When the panel is activated, zone status LEDs

illuminate, to indicate the status of Zone 1, Zone 2,

Alarm Pressure and Auxiliary Supervisory circuits.

Alarm (red) LEDs indicate activation of a detection

device.

Trouble (yellow) LED's indicate electrical circuit

failure such as short circuits and loose wiring.

Buzzer sounder

Alarm signals are latching.

Trouble signals are self restoring.

Alarm and Trouble resound.

Last event recall & Zone disable functions: Follow

procedure described in chapters 7 & 8.

Battery Fail and Earth Fault Supervision (see Figure 3

for location of LEDs).

Output circuits protected against false activation by a

two step command sequence.

Slide-in zone identification labels: Separate labels

included with PAR-3 Panel.

5. Accessories (order separately):

Batteries: Two batteries of the same AH rating are

required. Battery AH capacity shall be calculated with

the Battery Calculation Form provided in Chapter 9.

Battery sizes available are:

12V-7Amp-Hour – PN BATPS02407

12V-12Amp-Hour - PN BATPS02412

The 7AH Battery is normally sufficient to satisfy the 5

minutes of alarm after 24 hours requirement. For

FM's 90 Hours stand-by, the 12AH is normally used.

Batteries with larger AH capacity are also available

upon request.

Batteries plug-in connector is provided with the panel.

See BATTERIES TECHNICAL DATA to determine

which batteries meet standby battery requirements.

Wiring for 4-Wire type Smoke Detectors:

Depending on which Listed Smoke Detector is used

with the PAR-3 Model B-2 Control Panel, detector

maximum quantity is limited to between 15 and 30

per detection zone. For applications requiring more

detectors per detection zone, 4-Wire type smoke

detectors must be used. Refer to FIELD WIRING

DIAGRAM for additional details.

Optional Modules: One additional expansion connector is

available for installation of one of the following plug-in

modules:

LED Interface Module (4XLM): Provides the

interface required for connection of the PAR-3 Panel

to a Remote Status Annunciator (RZA-4X). Terminals

Page 3 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

are factory connected to the TBR Terminal Strip as shown

in the CONTROL PANEL OPTIONS data sheet.

Should a remote annunciator be required with the TOTALPAC2

system (not to be confused with connection to the building's

existing Fire Alarm Control Panel which is achieved through

the standard dry output contacts), a Remote Annunciator

RZA-4X is available. This annunciator requires the

installation of the LED Interface Module 4XLM, which must

be factory installed. Refer to CONTROLS OPTIONS

datasheet for additional details.

Zone Relay Module (4XZM): Provides and additional 4

sets of Form "C" relays. Terminals are factory connected to

the TBC Terminal Strip as shown herewith:

TBC

1

2

4

3

7

8

6

5

10

12

11

9

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

SYSTEM ALARM

SYSTEM TROUBLE

WATER FLOW

SUPERVISORY

Activated by detection zone

OR water flow condition.

Activated by any abnormal electrical

Activated by the opening of the deluge or

Activated by a supervised valve in abnormal

position OR by low air pressure condition

condition of the system

flow control valve OR by alarm line verification

RATED 2 Amp. at 30V.dc / 0.5 Amp. at 30 V.ac (resistive)

NOTE: AUXILIARY DRY CONTACT RELAY OUTPUTS

USE ONLY WITH POWER LIMITED CIRCUITS.

FM-072Q-0-53 A.dwg

6. Installation:

Prior to installation of external devices and wiring, review and

observe all instructions provided herewith. Field wiring must

be according to FIELD WIRING DIAGRAM for the specific

mode of operation required.

.1 All wiring must be done in accordance with national and/or

Local codes for fire alarm systems. The Authority having

Jurisdiction may have additional requirements.

.2 Mount the cabinet in a clean, dry, vibration free area where

temperature and humidity conditions do not exceed

limitations indicated in TECHNICAL DATA above.

.3 Verify that all initiating devices (detectors, pull stations) and

indicating appliances (bells, horns and strobes) are

compatible with the PAR-3 Control Panel. Refer to Device

Compatibility Document on our Web site and appropriate

Fire Protection Equipment Approval Guides.

.4 Wire all alarm initiating devices sequentially for proper

supervision.

.5 Pull required conductors and drill knockouts as

required.

Note: The control panel motherboard is factory pre-wired

and programmed for the configuration selected at the

time of purchase. All field wiring should be terminated

on the terminals provided as shown on the FIELD

WIRING DIAGRAM. No connection needs nor should

be made directly to the panel motherboard as this would

void warranty and might prevent the normal operation of

the unit.

.6 Prior to connecting to the panel, verify continuity of all

circuitry. Check for, and correct any short circuits.

.7 Make electrical connections to TBA terminal strip for

the detection and alarm circuits according to the

FIELD WIRING DIAGRAM for the system used.

.a Where indicated on the FIELD WIRING DIAGRAM,

install the 4.7 kΩ½ Watt End of Line Resistor

(provided in panel) at the remote end of circuit.

.b On all un-used circuits, leave the 4.7 kΩ½ Watt

End of Line Resistor (provided in panel) in place.

.c Maintain polarity on alarm bell and trouble bell

circuits. Do not energize the panel until all

associated modules and associated cables have

been connected.

.8 Prior to energizing the panel:

.a Verify that dip switches controlling panel operation

are in the proper position for the system used.

Refer to TABLE 1 and FIELD WIRING DIAGRAM.

.b Verify that all modules are securely and properly

positioned on their pins. If a module is loose,

carefully align all pins and press firmly into position.

TABLE 1 – Basic Program

Mode #1

Single Hazard

Two Zone

Mode #2

Single Hazard

Crossed Zone

Switch 1

Switch 2

OFF

OFF

ON

OFF

Outputs 1 & 3 –

Activated by an alarm

on either Zone 1 or

Zone 2.

Output 2 – Activated by

a waterflow alarm on

Zone 3.

Output 4 – Activated by

a supervisory condition

on Zone 4.

Output 1 – Activated by

an alarm on either Zone

1 or Zone 2.

Output 2 – Activated by

a waterflow alarm on

Zone 3.

Output 3 – Activated by

alarms on both Zone 1

and Zone 2

Output 4 – Activated by

a supervisory condition

on Zone 4.

Zones 1 and 2 refer to Initiating Device Circuits 1 and 2.

Page 4 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

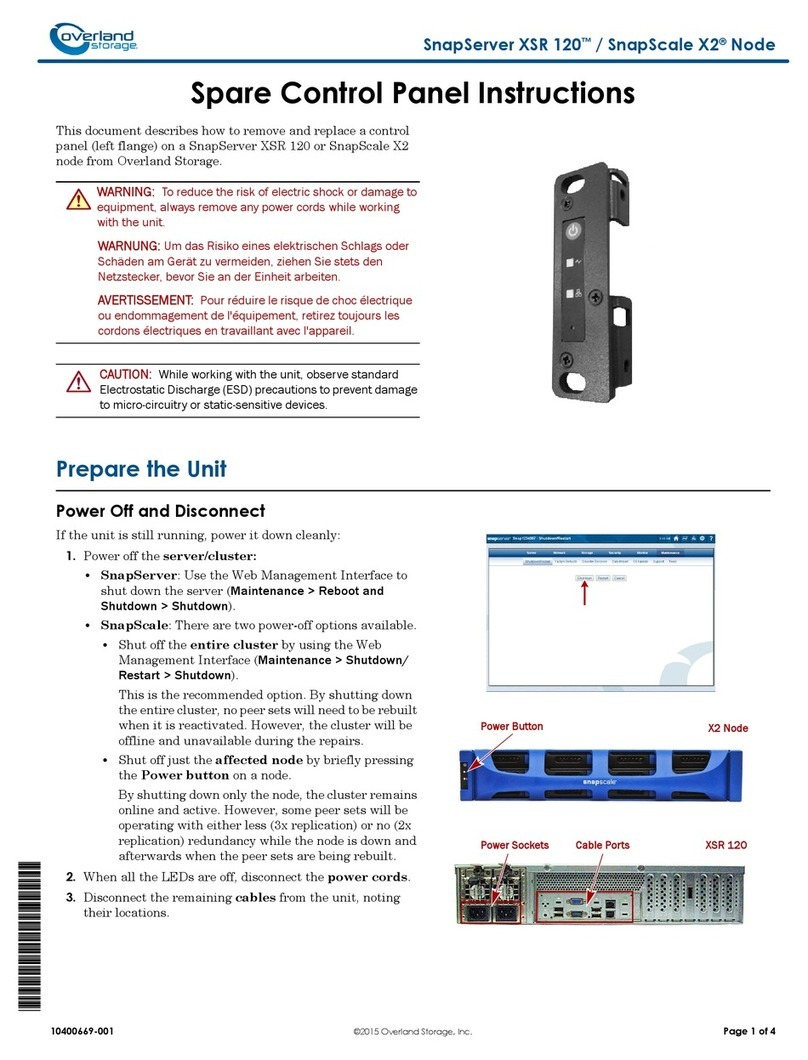

Figure 1: Cabinet Door Assembly:

FM-072Q-0-20 A.dwg

Control section hinged door

(recessed hinges on top)

Releasing panel controls

access door (stainless steel)

Control Panel

annunciator window

Door Lock

(with key alike keys) Flush door handle

Figure 2: Typical Control Equipment Layout:

FM-072Q-0-19 C.dwg

NOTE: Front door assembly not shown for clarity.

Spare Sprinkler Heads

Storage Rack

(12 heads capacity)

'TBA' Field Wiring Terminals Strip

('TBC' & 'TBR' also when provided)

Typical Control Panel

Motherboard Placement

'TBB' Field Wiring Terminal Strip

for 120 / 220 Vac Power Feed

(under protective cover)

Air Compressor Isolating

Switch - rated 20 Amp.

(E15)

Placement of optional

Status Annunciator Module (MEA)

or Fail-Safe Timer (Elevators)

Emergency Batteries

Page 5 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

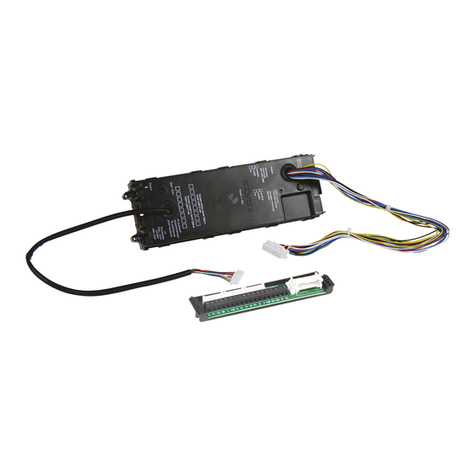

Figure 3 – Detail of PAR-3 Model B-2 Panel Annunciator:

NOTE: Front door assembly not shown for clarity.

Spare Sprinkler Heads

Storage Rack

(12 heads capacity)

'TBA' - 'TBC' & 'TBR' Field Wiring

Terminals Strip

PAR-3 Control Panel

Motherboard Placement

Emergency Batteries

BATT EARTH MICRO FAIL

DIP Switches for

System Programming

J9

Troubleshooting LEDs (3)

Placement of optional

Status Annunciator Module (MEA)

or Fail-Safe Timer (Elevators) J9 Battery connector

AC Circuit Breaker

OPT-1

OPT-2

Refer to labels

description for detail.

FM-072Q-0-24C.dwg

Page 6 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

6. System Status LEDs:

Alarm, Trouble and Supervisory LEDs will flash on and off

until the event(s) has been acknowledged (TONE or

ALARM SILENCE), at which point the LED will illuminate

steadily.

AC POWER: Green LED that illuminates steadily to

indicate presence of AC power.

SYSTEM ALARM: Red LED that flashes when an alarm

occurs.

SOLENOID OPERATED: Red LED that illuminates

steadily when the solenoid valve is activated.

SUPERVISORY: Yellow LED that flashes upon activation

of a supervisory device (main valve or Low air pressure).

SYSTEM TROUBLE: Yellow LED that flashes for any

trouble condition, including those associated with option

boards.

CIRCUIT TROUBLE: Yellow LED that flashes for trouble

conditions on output circuits.

ALARM SILENCED: Yellow LED that illuminates steadily

when the ALARM SILENCE switch has been pushed after

an alarm.

POWER TROUBLE: Yellow LED that flashes for low or

disconnected batteries and earth fault conditions.

BATT: Yellow LED that illuminates steadily on

motherboard when battery is low or not detected.

EARTH: Yellow LED that illuminates steadily on

motherboard during a ground fault condition.

MICRO FAIL: Yellow LED that illuminates on motherboard

when watchdog timer detects microprocessor failure.

Control Switches:

TONE SILENCE: Acknowledge alarms, troubles and

supervisory. The panel has alarm and trouble resound

with LED flash of new conditions.

The flashing trouble LED(s) illuminate steadily on TONE

SILENCE and the buzzer silences.

A Second trouble will resound the piezo. The piezo has

three sounds for alarm, trouble, and supervisory. Trouble

conditions are self restoring. Alarms and supervisories

latch and require RESET to clear.

ALARM SILENCE: Acknowledge for alarms and

supervisories. The ALARM SILENCE switch will silence

the local piezo, change any flashing alarm LEDs to steady,

and turn off the notification appliance circuits (not the

Releasing Circuits). The "ALARM SILENCED" LED will

illuminate. Alarm silence is a latching function and

requires a RESET to clear.

ALARM ACTIVATE: The ALARM ACTIVATE switch may

be used to activate Notification Appliance Circuits.

ALARM ACTIVATE also activates the System Alarm relay.

ALARM ACTIVATE is a latching function. Pressing

ALARM SILENCE silences the notification appliance

circuits and System Alarm Relay and lights the Alarm

Silenced LED. Pressing RESET returns the system to

normal.

SYSTEM RESET: The RESET switch breaks power to all

initiating circuits, 4-wire smoke power and option boards

and will clear any activated output circuits. If any alarm or

trouble still exists after reset, they will reactivate the panel.

Holding RESET down will perform a LAMP TEST function

and will activate the buzzer.

Zone Status LED(s):

The alarm and/or trouble LED(s) will flash until the

event(s) has been acknowledged (TONE or ALARM

SILENCE), at which point the LED(s) will illuminate

steadily. See detail below for the various configurations:

Double Interlocked

Preaction

Electric / PneuLectric

Deluge

ALARM LED

TROUBLE LED

ALARM LED

TROUBLE LED

ALARM LED

TROUBLE LED

(NOT USED)

TROUBLE LED

Double Interlocked

Preaction

Electric / Pneumatic

Double Interlocked

Preaction

Elevator Configuration

Single Interlocked

Preaction

DETECTION

ZONE 1

WATER FLOW

LOW AIR PRESS.

OR MAIN VALVE

WATER FLOW

LOW AIR PRESS.

OR MAIN VALVE

DETECTION

ALARM LOW AIR

PRESSURE

SYSTEM

PRESSURIZED

LOW AIR PRESS.

OR MAIN VALVE

DETECTION

ZONE 2

DETECTION

ZONE 1

DETECTION

ZONE 2

WATER FLOW

LOW AIR PRESS.

OR MAIN VALVE

DETECTION

ZONE 1

ELEVATOR AT

DESIGNATED

LOBBY

FAIL SAFE TIMER

DETECTION

ZONE 1

DETECTION

ZONE 2

WATER FLOW

MAIN VALVE

CONFIGURATION:

Page 7 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

7. Zone Disable:

Disabling a detection or a supervisory zone will prevent

the internal audible signal in the control panel or any

output circuit from activating upon activation of a

detection device in this zone. All four entry zones can be

disabled.

Note: The system could become non-operational

depending on the zones being disabled. Furthermore,

the control panel must not be in alarm condition to effect

this function.

.1 To disable a zone, the following routine must be

followed:

.a Press the button identified TONE SILENCE and hold

it until all lamps go out.

.b While holding the button identified TONE SILENCE,

press the following buttons in this order: ALARM

SILENCE, ALARM ACTIVATE and then SYSTEM

RESET.

Note: Do not release the button identified TONE

SILENCE until the routine is completed.

.c The red lamp identified DETECTION or DETECTION

ZONE X will now begin to flash.

.d To disable that zone, press the button identified

SYSTEM RESET. A disabled zone is identified by

an illuminated yellow lamp on the zone.

Note: The button identified SYSTEM RESET operates

alternately; therefore press this button again to

reactivate the zone.

.2 To select the next zone, simply press the button

identified ALARM SILENCE. To select the previous

zone, press the button identified ALARM ACTIVATE.

.a When selection of the disabled zones is completed,

release the button identified TONE SILENCE.

.b The yellow lamp identified SYSTEM TROUBLE will

flash. Silence the audible signal by pressing the

button identified TONE SILENCE.

.3 To reactivate the zones previously disabled, repeat the

procedure to disable the zones. Pressing the button

identified SYSTEM RESET will deactivate the yellow

lamp of the selected zone, and thus reactivate the zones

that were disabled.

Note: Resetting the control panel will not reactivate the

disabled zones. However if the control panel is in alarm

condition and you wish to reactivate zones that were

previously disabled, then the control panel must be

reset.

8. Last Event recall:

This function allows the user to review the previous

condition of the control panel.

Note: The control panel must not be in alarm condition

when performing this function.

To recall the last event, the following routine must be

followed:

.1 Press the button identified TONE SILENCE and hold it

until all lamps go out.

.2 While holding the button identified TONE SILENCE,

press the following buttons in this order: SYSTEM

RESET, ALARM ACTIVATE and then ALARM

SILENCE.

.3 The lamps in the control panel will indicate the previous

condition since the last control panel reset.

.4 Release the button identified TONE SILENCE to return

to the normal operation mode.

Page 8 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

9. BATTERIES TECHNICAL DATA:

Batteries are sealed construction, lead-acid rechargeable

that allow a trouble-free, safe operation in any position.

There is no need to add electrolyte as gases generated

during overcharge are recombined in a unique "Oxygen

Cycle".

No special handling precautions or shipping containers –

surface or air – are required due to the leak-proof

construction.

Under normal operating conditions four two five years of

dependable service can be expected in stand-by

applications or between 200 and 1000 charge/discharge

cycles depending upon depth of discharge.

The capacity of the batteries is expressed in amperes-hours

(AH) and is the total amount of electrical energy available

from a fully charged cell. The standard batteries provided

with the TOTALPAC2unit is 7AH capacity and should provide

enough power to provide the 5 minutes of alarm after 24

hours on stand-by required by UL and C-UL. 12AH batteries

are also available on option for the 90 Hrs standby period

requested by Factory Mutual (FM). The calculation chart

below shall be used to confirm batteries will be adequate.

.1 Standby Battery Requirements

The Standby Battery Current figure obtained in this table represents the amount of current that must be supplied by the

secondary power source (batteries) to sustain the control panel operation for one hour.

Control Panel (including a 4XZM Relay module) ..............................................................

with AC power lamp OFF, System trouble lamp and audible signal ON .096

If using an extra 4XZM Relay module ............................................................... add .008

If using a 4XLM / RZA-4X Driver / Annunciator combination ............................. add .019

Number

in use

Device current

(see Device

Compatibility Document

for data)

Total

current

Two-wire smoke detectors heads X =

Four-wire smoke detectors heads X =

End-of-line relays X =

Add Total current from the three lines above ª

If using 24Vdc RMS-Regulated Source (TBA-28/29) ............................ add load current

Total Standby Battery Current Amps

.2 Standby Period Required: Total Standby

Battery Current

Standby Time

(enter 24 or 90 hours

of operation)

amps X hours

Place result here for Standby AH ªAH

3. Alarm Battery Requirements +

Alarm AH (enter 0.25 for 5 minutes in alarm, or 0.5 for 10 minutes in alarm) AH

4. Total Ampere-Hour Calculations =

Total AH needed (add Standby AH & Alarm AH then multiply by 1.2 de-rating factor)AH

Select a battery with equal or greater AH rating than the Total AH obtained above. Batteries must be lead-acid type.

Notes:

1) Alarm AH assumes a maximum system draw of 3 amps in alarm for 5 minutes (0.25 AH) or for 10 minutes (0.5 AH).

2) NFPA 72-1993 Local Fire Alarm Systems standard requires 24 hours of standby power.

3) Factory Mutual Systems require 90 hours of standby power.

4) The battery charger in this panel will charge a maximum of 18 AH of batteries within 48 hours (7 AH minimum).

Page 9 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

TROUBLE SHOOTING:

SYMPTOMS PROBLEM SOLUTION

Circuit trouble LED

ON Notification appliance circuit trouble

1. Check TBA for proper connections.

2. Remove all field wiring and install dummy

ELR at ourput circuit. Check for supervisory

voltage across it (normal –2,3V), if problem

persists, replace circuit board.

3. Remove dummy ELR, reconnect field wiring

and measure voltage across output; (tourble –

5V, short 0V).

4. Check for ELR at last device.

5. Check field wiring.

Any of the right

column yellow LEDs

flashing

Initiating zone open circuit trouble

1. Check TBA for proper connections.

2. Remove field wiring for zone in trouble and

install dummy ELR (4,7K for 24V; 2,2K for

12V). If problem persists, replace circuit

board.

Any of the right

column yellow LED

steady ON

Zone disable Check ZONE DISABLE section

Missing or

Disconnected Check battery connections

Battery trouble Batt

yellow LED ON Low or damaged

battery

1. Remove batteries, check voltage across

charger output (17 to 19V for 24V; 8-10V for

12V), otherwise, replace circuit board.

2. Reconnect batteries, measure battery

voltage at battery terminals. If voltage is less

than 85% of rated voltage, allow them to

charge for 48 hours.

3. If problem persists, replace batteries.

Ground fault trouble Earth yellow LED

ON

1. Remove field wiring from TBA. Install

dummy ELR (4,7K for 24V, 2,2K for 12V).

2. Remove both battery leads.

3. If trouble clears, connect one circuit at the

time to pinpoint the problem.

4. If trouble does not clear, replace circuit

board.

System Trouble LED

ON

Power trouble LED

ON

OPT1, OPT2 jumper cutted Install optional module or replace jumper if

module is not used.

Any of the right column red LEDs ON Short on initiating circuit wiring

Remove field wiring and install ELR. If trouble

clears, look for faulty or incorrectly wired

devices.

4XZM: Associated LED doesn't activate for

alarm, trouble or supervisory conditions. Optional module trouble

1. Make sure module is properly installed.

2. Move disable switch SW1 on 4XZM to the

left.

RZA-4X buzzer doesn't sound for alarm,

trouble or supervisory conditions. 4XLM

1. Make sure that the 4XLM module is

installed on J7 and J8.

2. Check field wiring.

All RZA-4X LEDs stay ON Power wasn't removed prior to

installation Press system reset.

AC Power LED ON

Micro Fail yellow LED ON Microprocessor damaged. Replace circuit board.

Loss of main power Check incoming power (TBB).

System trouble LED ON Damaged circuit breaker Replace circuit board.

AC power LED OFF

Micro Fail yellow LED ON Microprocessor damaged. Replace circuit board.

Page 10 of 10

TOTALPAC2 Integrated Fire Protection System

PAR-3 Control Panel

FM-072G-0-05 C

Table of contents

Popular Control Panel manuals by other brands

Helo

Helo RA 18 product manual

Siemens

Siemens Sinamics G130 Basic Operator Panel 20 operating instructions

olympia electronics

olympia electronics BS-746 operating instructions

C & K Systems

C & K Systems Securit 802 Features

C & K Systems

C & K Systems System 2316E installation instructions

Spraying Systems

Spraying Systems AutoJet 1000+ quick start guide