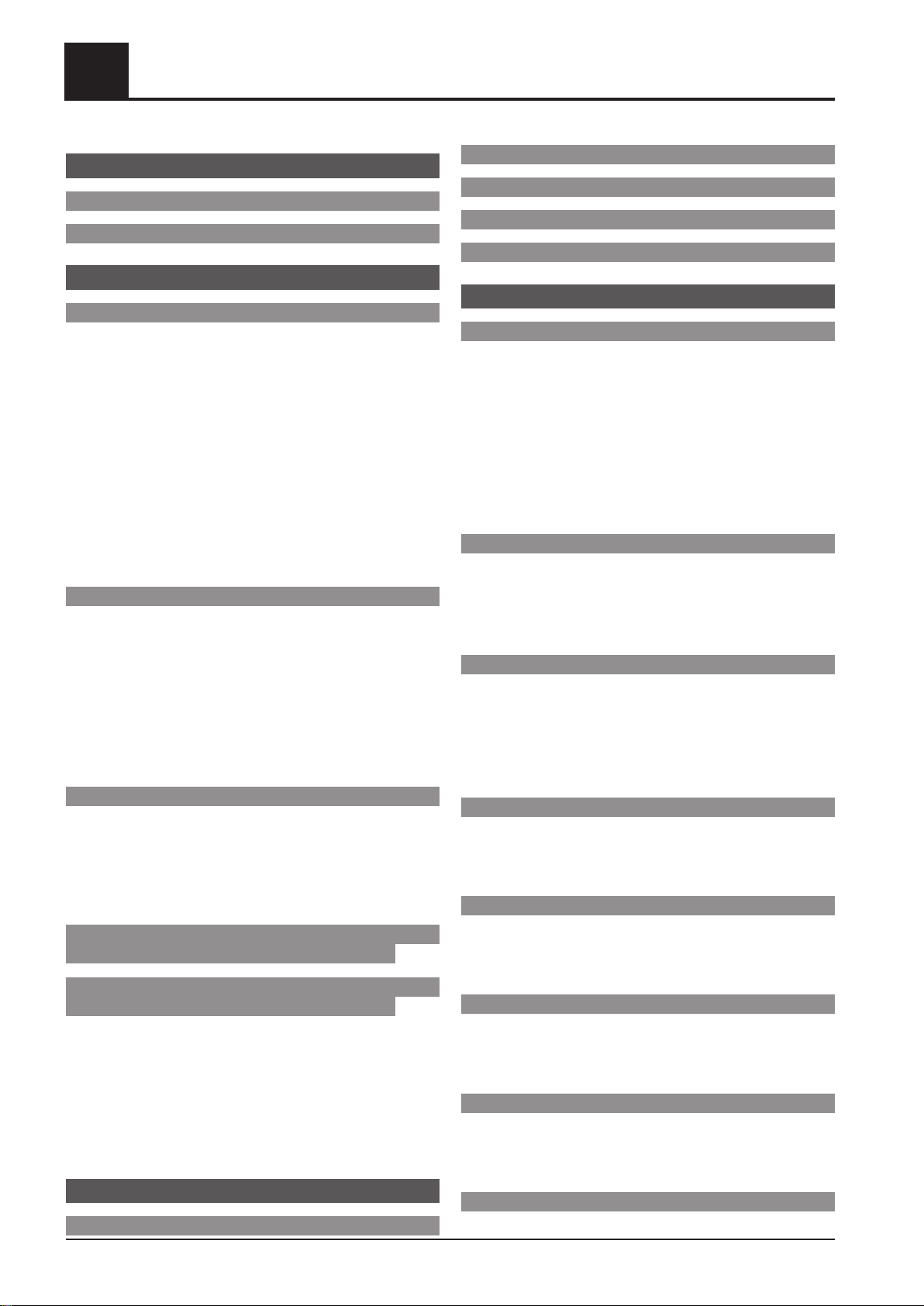

1 General 4

1.1 About these instructions 4

1.2 Safety information 4

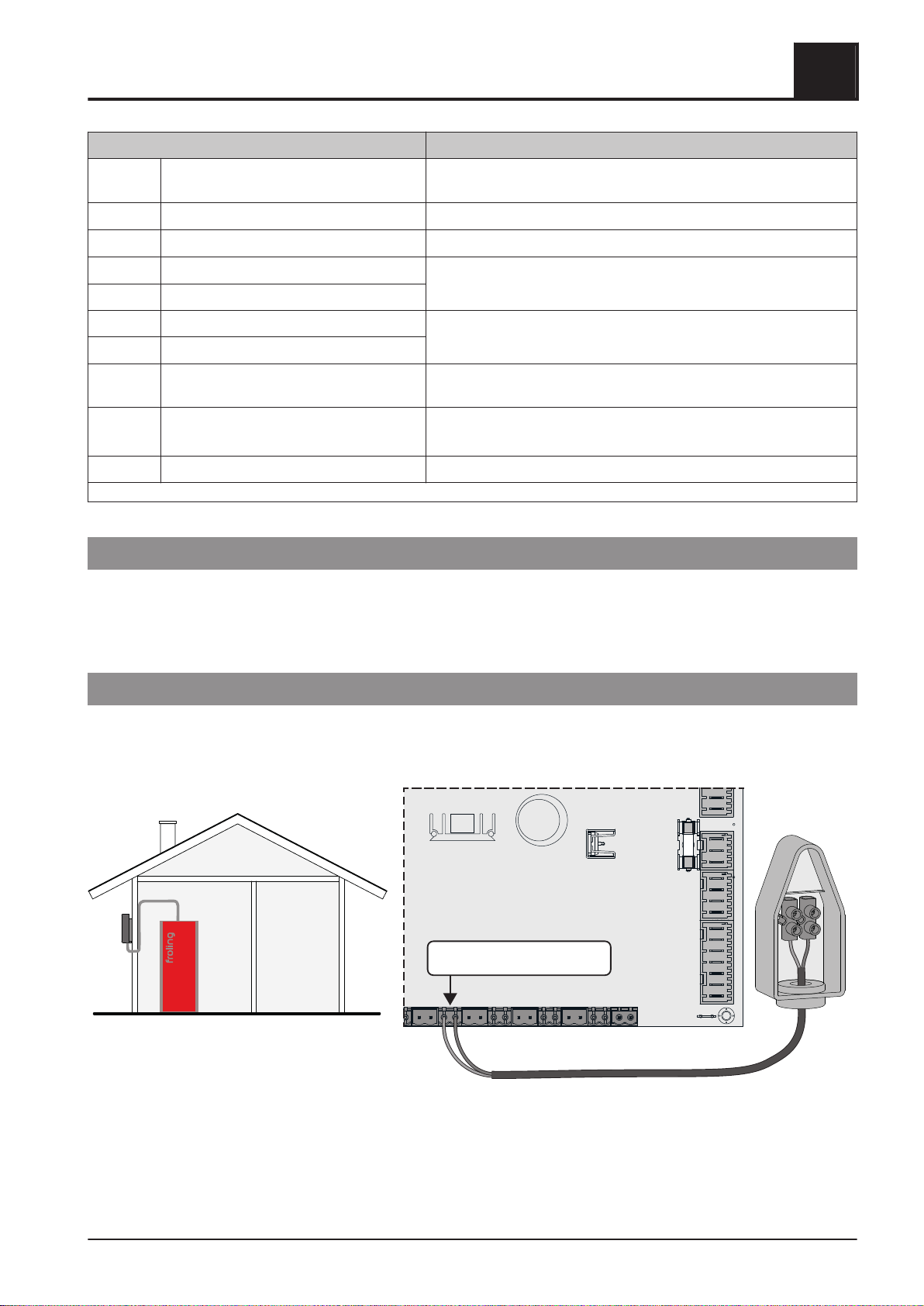

2 Power connection and wiring 5

2.1 Core module and connection options 5

2.1.1 Board view - core module 5

2.1.2 Mains connection 7

2.1.3 Connecting the outside temperature

sensor

7

2.1.4 FRA room temperature sensor 8

2.1.5 Boiler enable contact 8

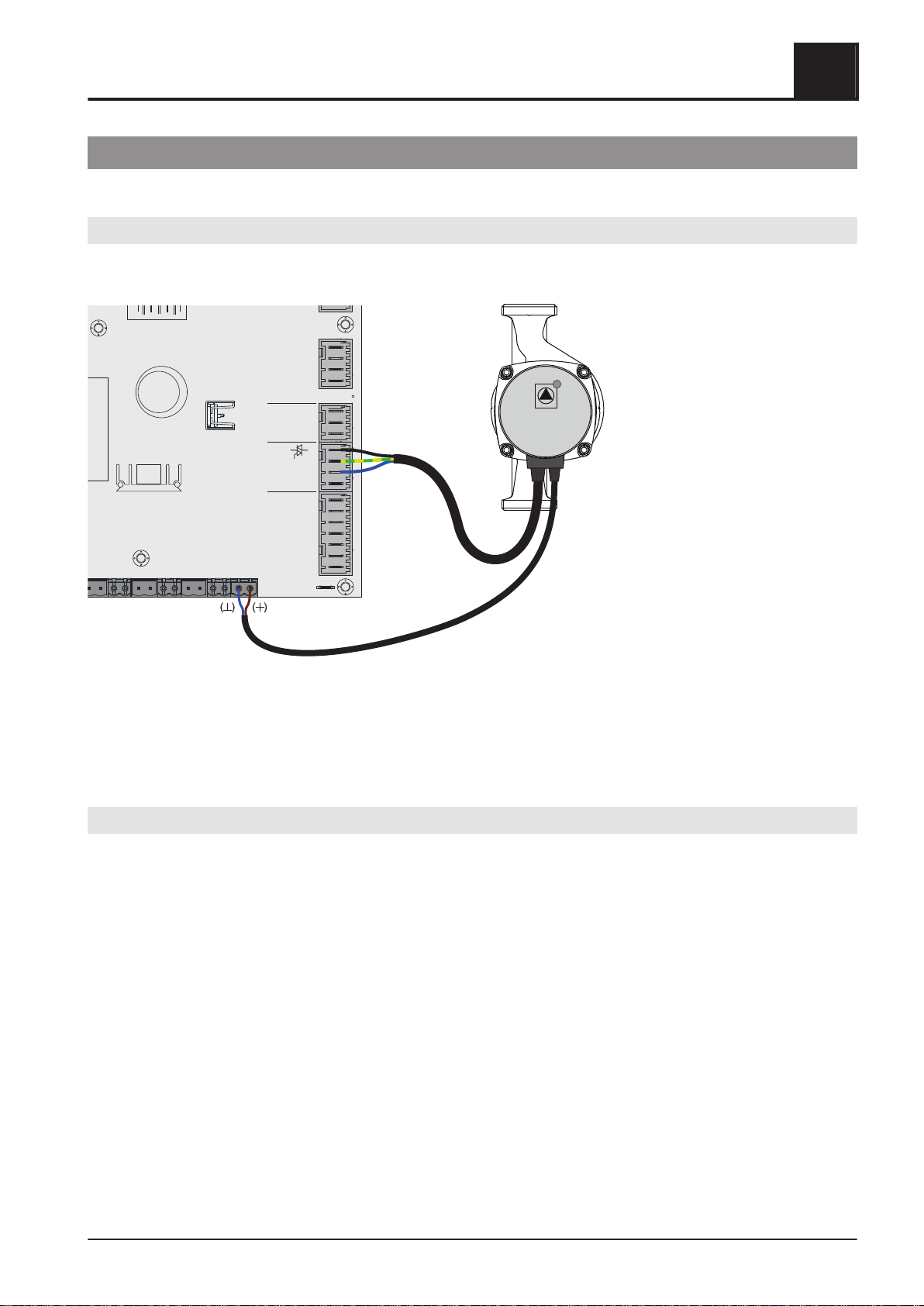

2.1.6 Connecting a circulating pump to the core

module

9

2.1.7 Connecting an isolating valve to the core

module

10

2.1.8 Heating circuit pump 0 / burner relay 12

2.1.9 Operating signal 12

2.2 Expansion modules 13

2.2.1 Heating circuit module 13

2.2.2 Hydraulic module 14

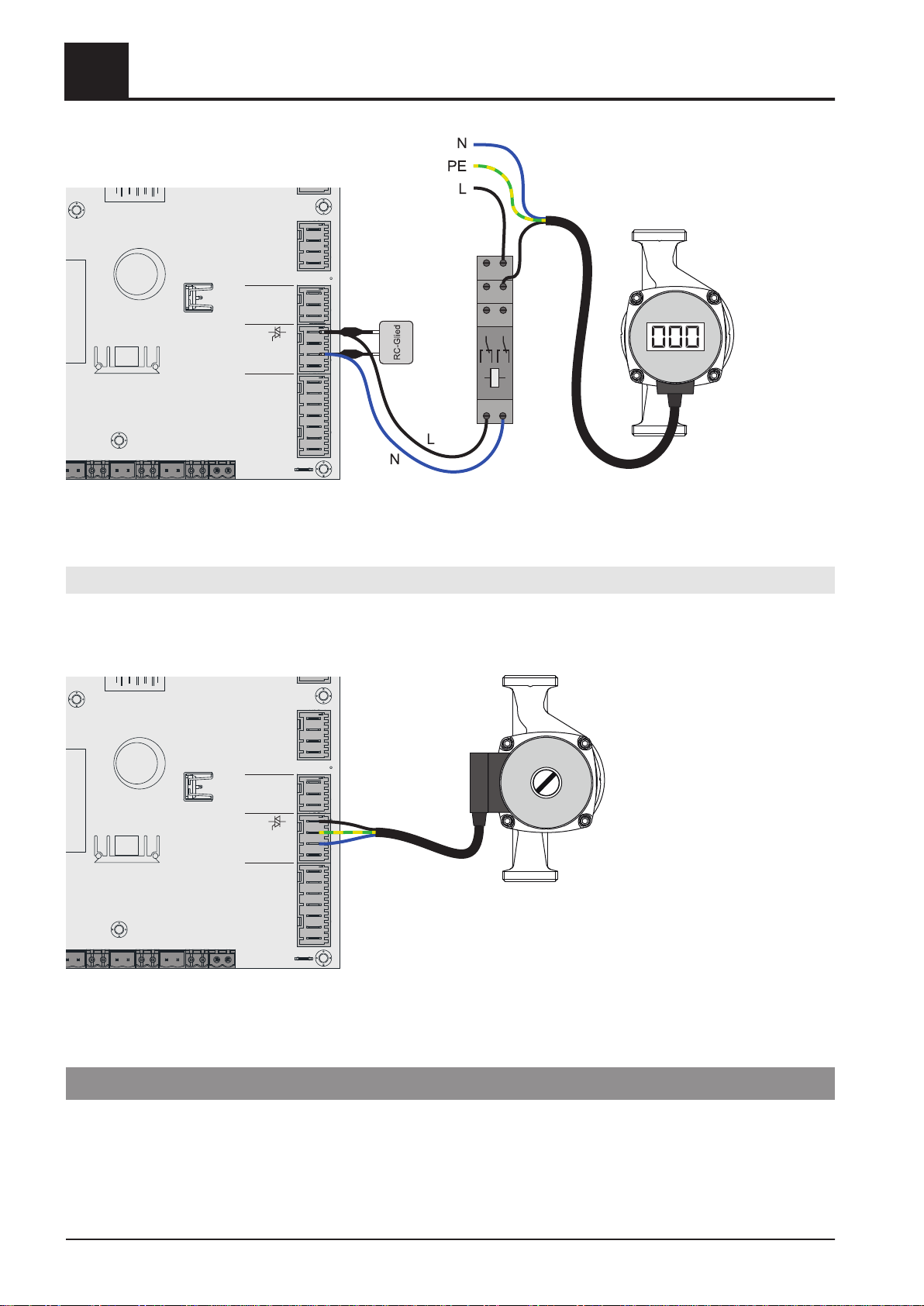

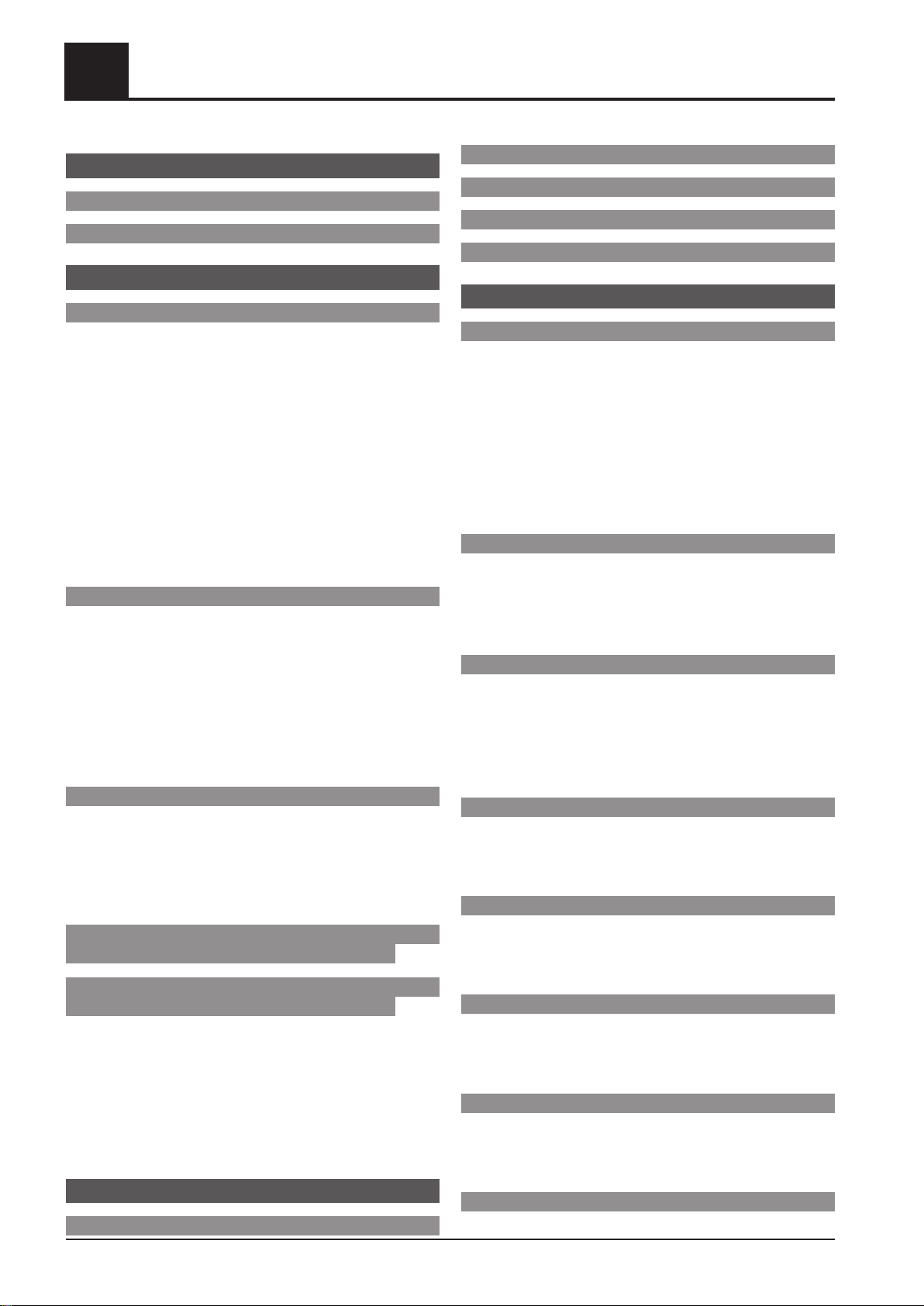

Connecting a circulating pump to the hydraulic

module

15

Connecting an isolating valve to the hydraulic

module

19

2.2.3 Pellet module 20

2.2.4 Pellet module expansion 22

Automatic room air flap

23

2.3 BUS connection 24

2.3.1 Connecting the bus cable 25

2.3.2 Setting end jumpers 25

2.3.3 Setting the module address 26

2.3.4 Potential equalisation / potential

separation

27

2.4 Connection information according to

pump types

28

2.5 Connection options with standard

delivery

29

2.5.1 System 0 (DHW tank / one heating

circuit)

29

2.5.2 System 0 (two heating circuits) 30

2.5.3 System 1 (layered tank / two heating

circuits)

31

2.5.4 System 1 (hygienic layered tank / two

heating circuits)

32

3 Initial startup 33

3.1 Switching user level 33

3.2 Default configuration 33

3.3 Setting the system selection 34

3.4 Before heating up for the first time 36

3.5 Starting the system on initial startup 36

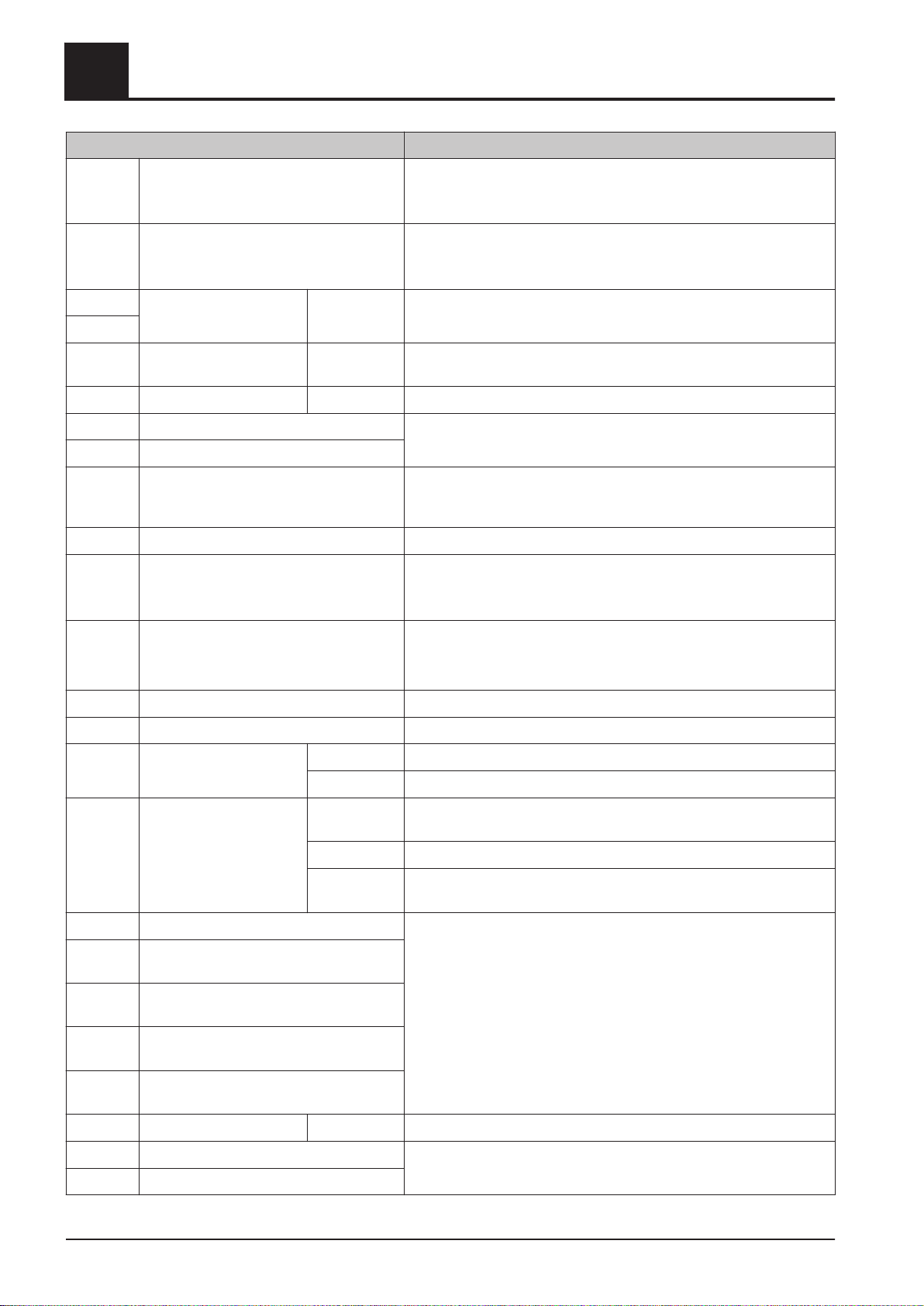

4 Parameters overview 37

4.1 Heating 37

4.1.1 Heating - Status 37

4.1.2 Heating – Temperatures 38

4.1.3 Heating - Times 39

4.1.4 Heating - Service 39

4.1.5 Heating - Heating up program 40

Heating up programs

41

Configure program 8

41

Heating circuits used

41

4.1.6 Heating - General settings 42

4.2 Water 43

4.2.1 Water - Status 43

4.2.2 Water - Temperatures 43

4.2.3 Water - Times 44

4.2.4 Water - Service 44

4.3 Solar 46

4.3.1 Solar - Status 46

4.3.2 Solar - Temperatures 47

4.3.3 Solar - Times 48

4.3.4 Solar - Service 48

4.3.5 Solar - Heat meter 50

4.4 Buffer tank 51

4.4.1 Buffer tank - Status 51

4.4.2 Buffer tank - Temperatures 52

4.4.3 Buffer tank - Service 52

4.5 Boiler 2 53

4.5.1 Boiler 2 - Status 53

4.5.2 Boiler 2 - Temperatures 53

4.5.3 Boiler 2 - Service 54

4.6 Feed system 55

4.6.1 Feed system - Times 55

4.6.2 Feed system - Service 55

4.6.3 Feed system - Consumption 56

4.7 Network pump 57

4.7.1 Network pump - Status 57

4.7.2 Network pump - Temperatures 57

4.7.3 Network pump - Service 58

4.8 Difference regulator 59

4.8.1 Difference regulator - Status 59

Table of contents

2 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com