Regeneration Mode

Typically a system is set to regenerate at a time of low water usage. An example of a time

with low water usage is when a household is asleep. If there is a demand for water when

the system is regenerating, untreated water will be used.

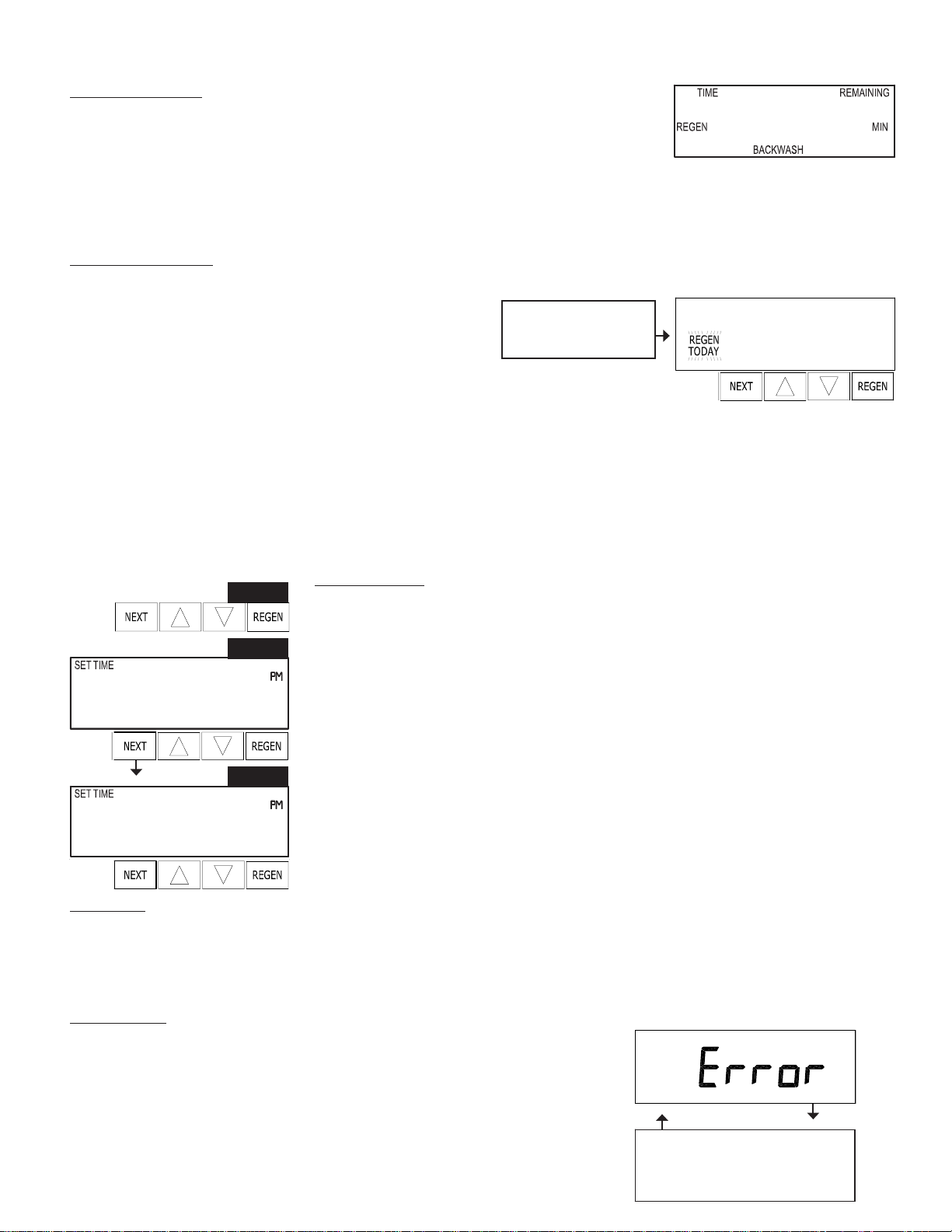

When the system begins to regenerate, the display will change to include information about

the step of the regeneration process and the time remaining for that step to be completed.

The system runs through the steps automatically and will reset itself to provide treated

water when the regeneration has been completed.

Manual Regeneration

Sometimes there is a need to regenerate the system sooner

than when the system calls for it, usually referred to as manual

regeneration. There may be a period of heavy water usage

because of guests or a heavy laundry day.

To initiate a manual regeneration at the preset delayed

regeneration time, press and release REGEN. The words "REGEN TODAY" will flash on the

display to indicate that the system will regenerate at the preset delayed regeneration time. If you

pressed REGEN in error, pressing the button again will cancel the request.

To initiate a manual regeneration immediately, press and hold REGEN for three seconds. The system will begin to

regenerate immediately. The request cannot be cancelled.

Power Loss

If the power goes out, the system will keep time for up to 8 hours or until the battery is depleted. If a power outage of more

than 8 hours occurs, the time of day will ash on and off which indicates the time of day should be reset. The system will

remember the rest. If a power outage lasts less than 8 hours and the time of day ashes on and off, the non rechargeable

battery should be replaced.

Error Message

If the word “ERROR” and a number are alternately ashing on the display

contact the OEM for help. This indicates that the valve was not able to function

properly.

Set Time of Day

The user can also set the time of day. Time of day should only need to be set after power

outages lasting more than 8 hours, if the battery has been depleted and a power outage

occurs, or when daylight saving time begins or ends. If a power outage lasting more than

8 hours occurs, the time of day will ash on and off which indicates the time of day

should be reset. If a power outage lasts less than 8 hours and the time of day ashes on

and off, the time of day should be reset and the battery replaced.

STEP 1U – Press and hold

STEP 2U - Current Time (hour): Set the hour of the day using or . AM/PM

toggles after 12. Press NEXT to go to step 3U.

STEP 3U - Current Time (minutes): Set the minutes of the day using or . Press

NEXT to exit Set Clock. Press REGEN to return to previous step.

STEP 1U

STEP 2U

STEP 3U

REGEN TODAY will

Flash if a regeneration

is expected “Tonight.”

8:00

until the time starts to change.

12:00

12:00

103