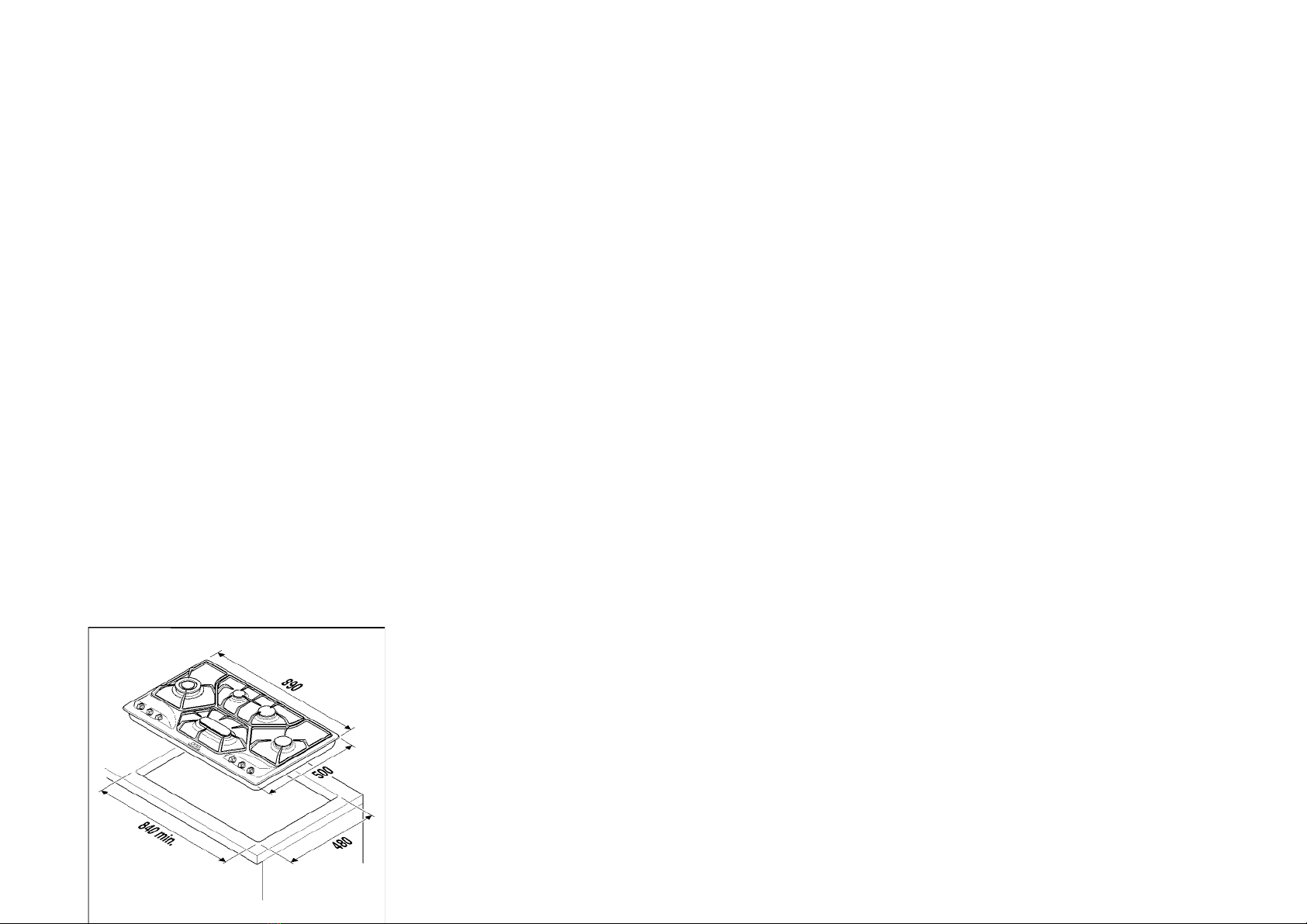

Franke POI63GAVDO User manual

Other Franke Hob manuals

Franke

Franke FRSM 905 C TOD BK User manual

Franke

Franke FMA 804 I F BK User manual

Franke

Franke MARIS FMA 839 HI User manual

Franke

Franke FMA 654 I F BK User manual

Franke

Franke Crystal User manual

Franke

Franke FSM 804 I B BK User manual

Franke

Franke MARIS Series User manual

Franke

Franke FHCL 604 3G TC User manual

Franke

Franke FMA 8391R HI User manual

Franke

Franke SMART FHSM 604 4I User manual

Franke

Franke FMY 808 I FP BK User manual

Franke

Franke FCI604B1 User manual

Franke

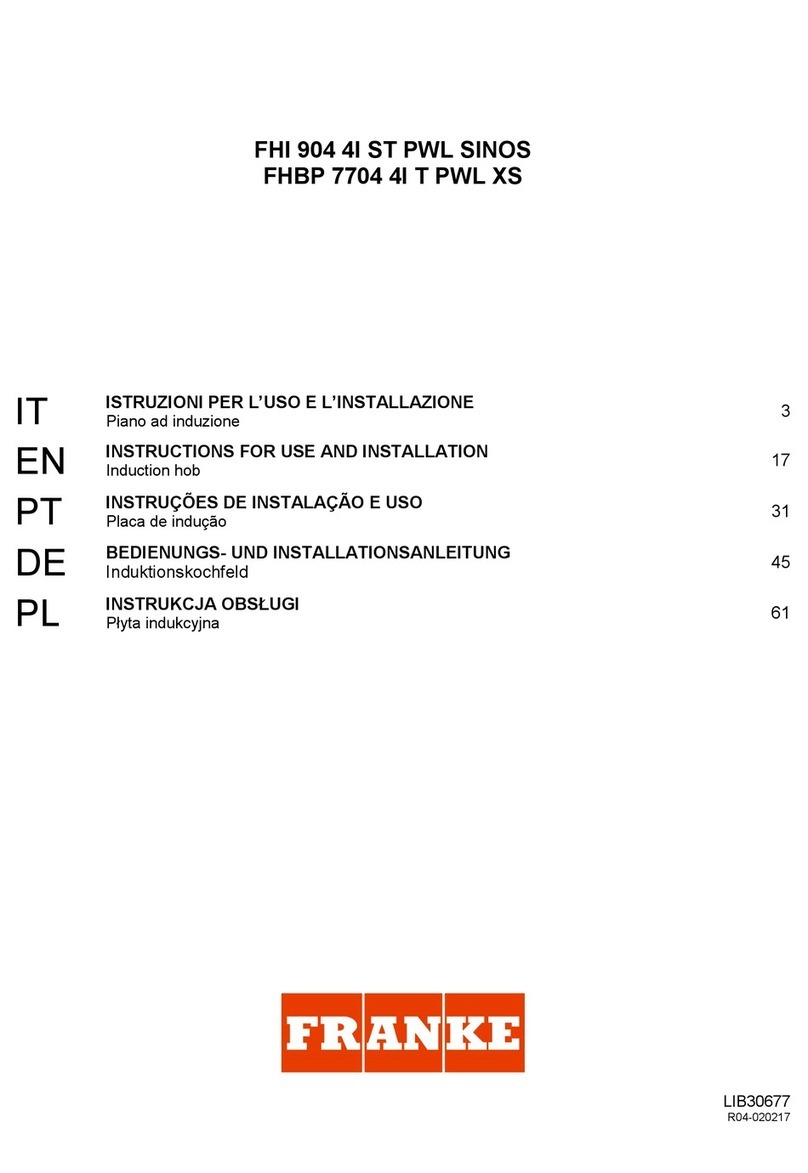

Franke FHI 904 4I ST PWL SINOS Operation manual

Franke

Franke FMY 8391R HI User manual

Franke

Franke FHT571 603C T User manual

Franke

Franke MARIS FH MA 604 4G User manual

Franke

Franke FHNE 604 3G TC User manual

Franke

Franke Mythos FHMT 302 1 FLEXI Operation manual

Franke

Franke Mythos 2gether FMY 839 HI User manual

Franke

Franke FHNS 604 4G BK C User manual