Franke SANX400 User manual

Other Franke Plumbing Product manuals

Franke

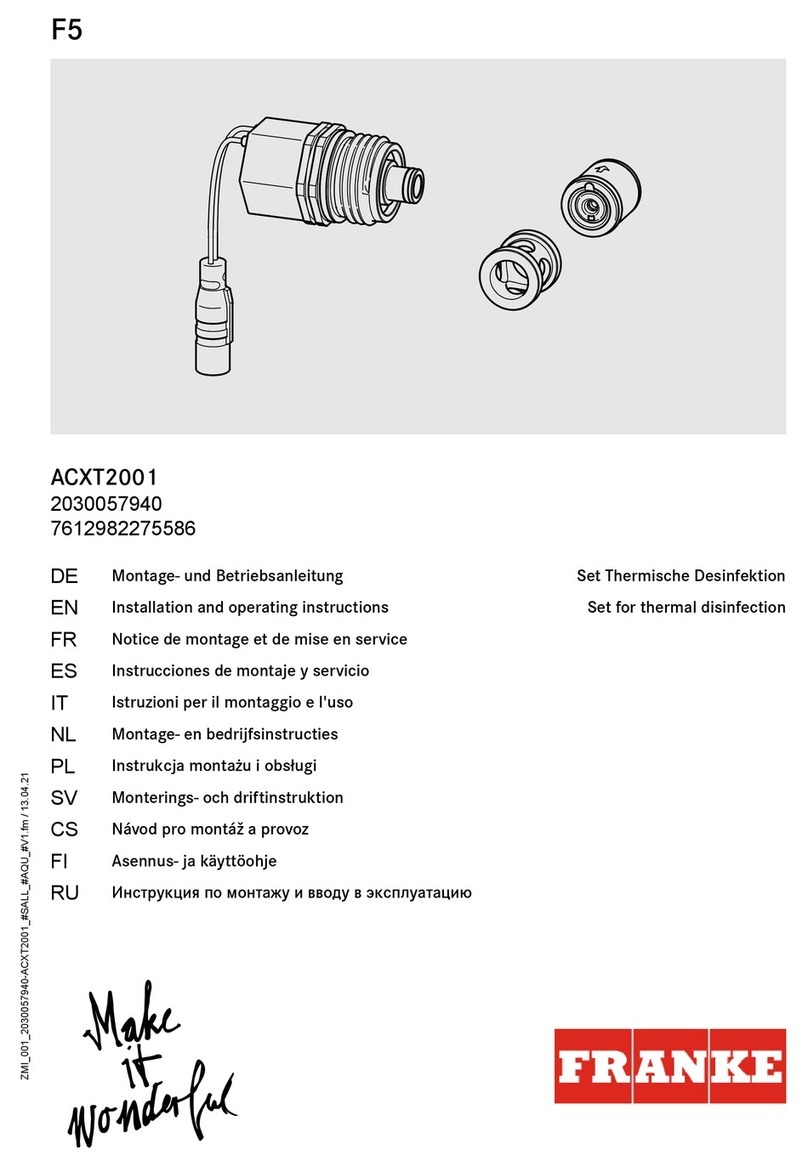

Franke F5E-Therm F5ET2009 User manual

Franke

Franke AQRE432 User manual

Franke

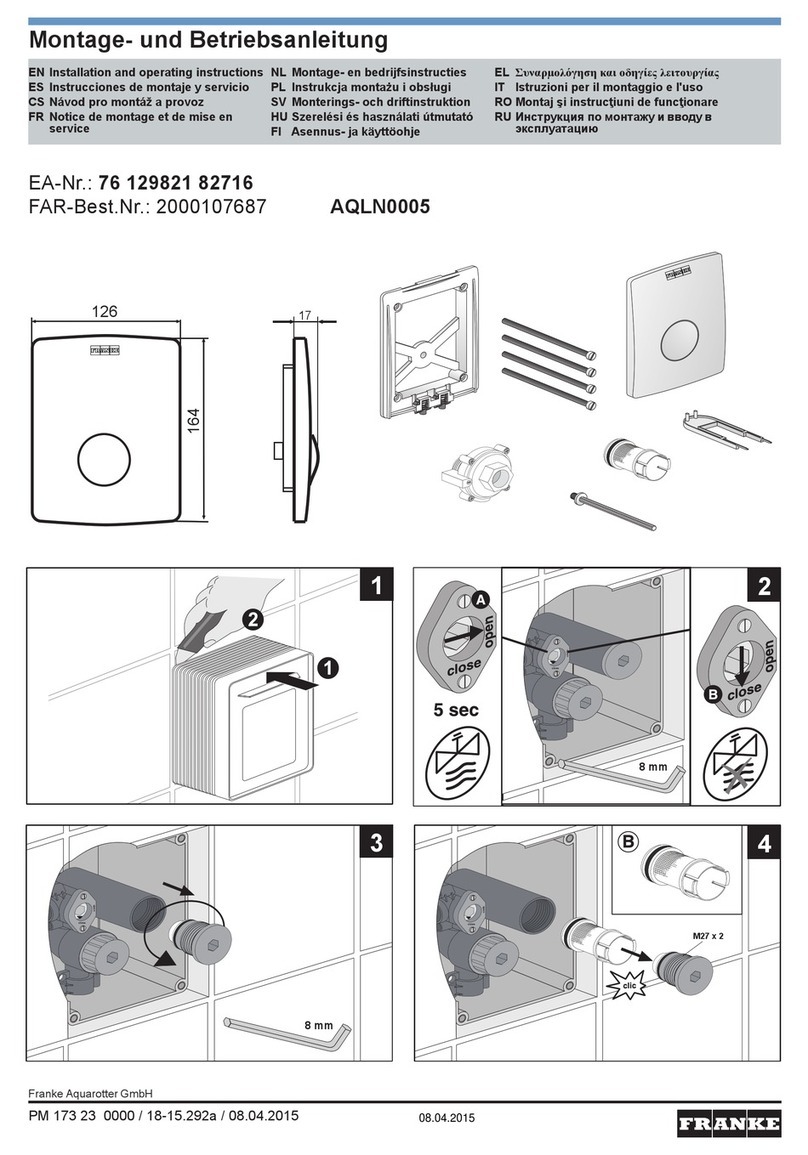

Franke AQLN0005 User manual

Franke

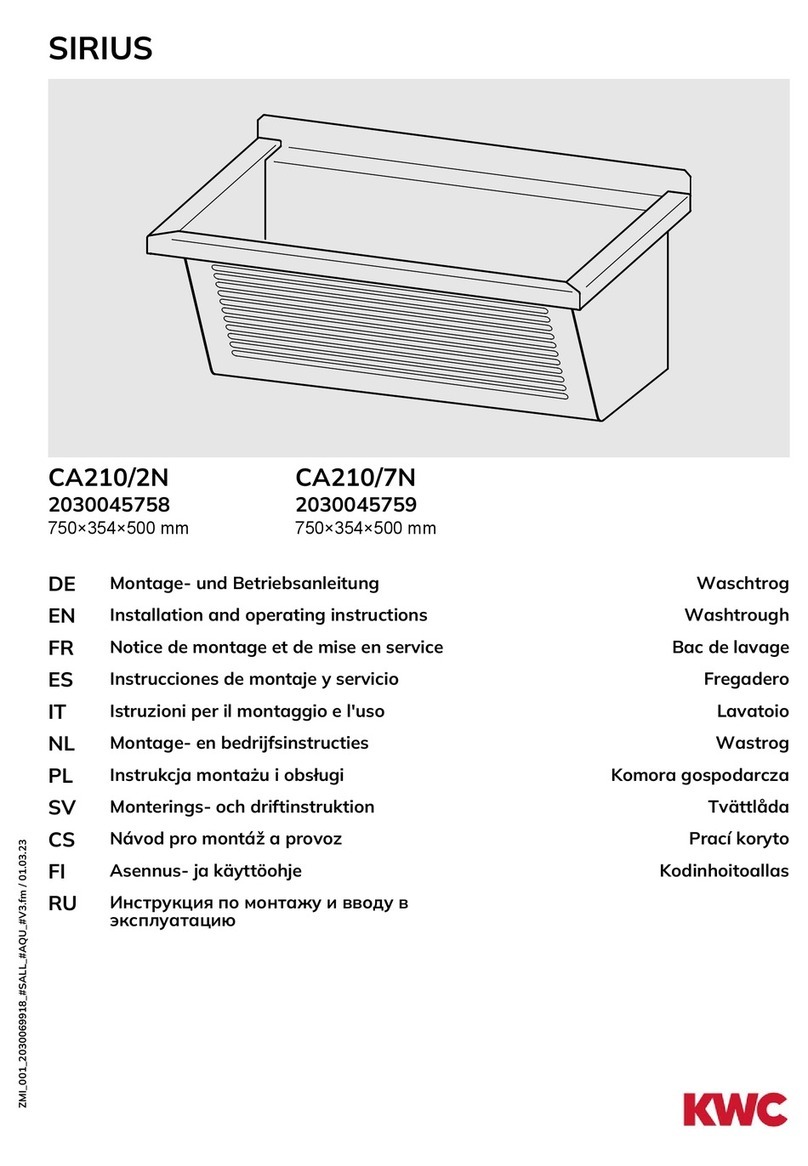

Franke SIRIUS CA210/2N User manual

Franke

Franke MIRANIT F5 Series User manual

Franke

Franke F5 F5LT2005 User manual

Franke

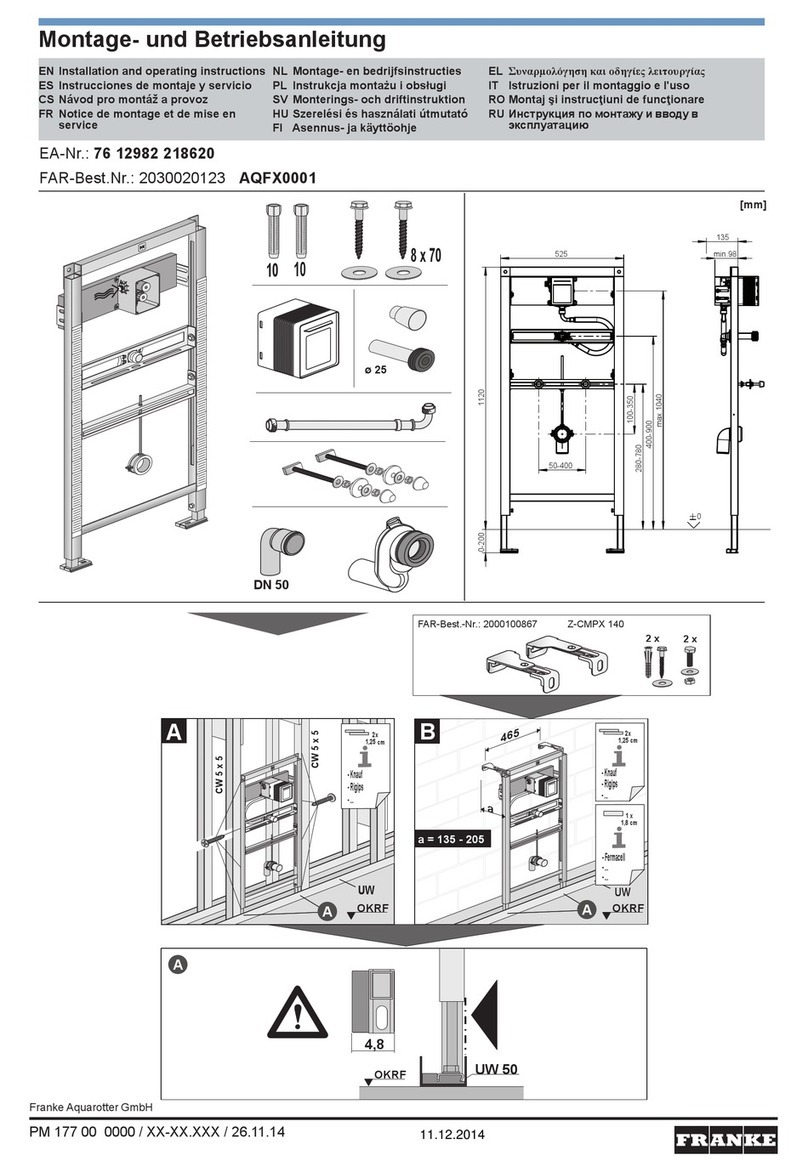

Franke AQFX0001 User manual

Franke

Franke F5L-Therm User manual

Franke

Franke 7612982077265 User manual

Franke

Franke ANCONA ANX 110-48 User manual

Franke

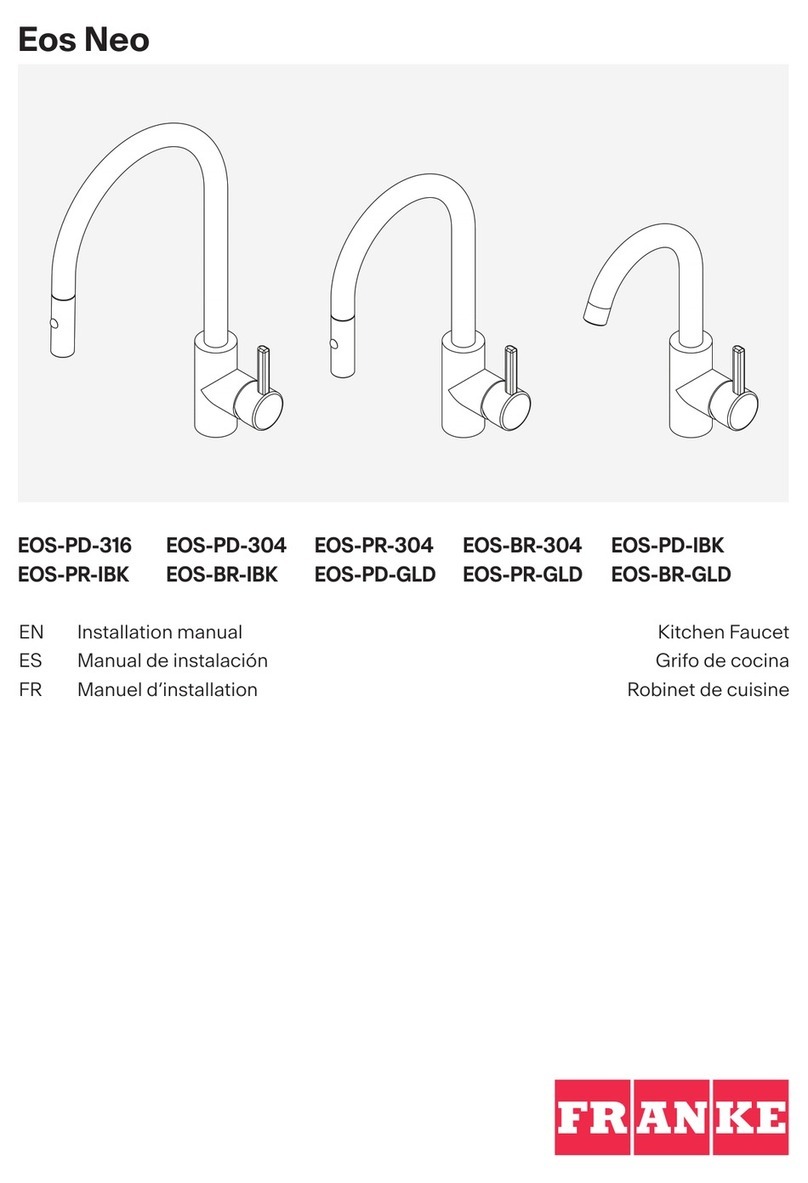

Franke Eos Neo EOS-PD-316 User manual

Franke

Franke AQUA202AUS User manual

Franke

Franke F3 Series User manual

Franke

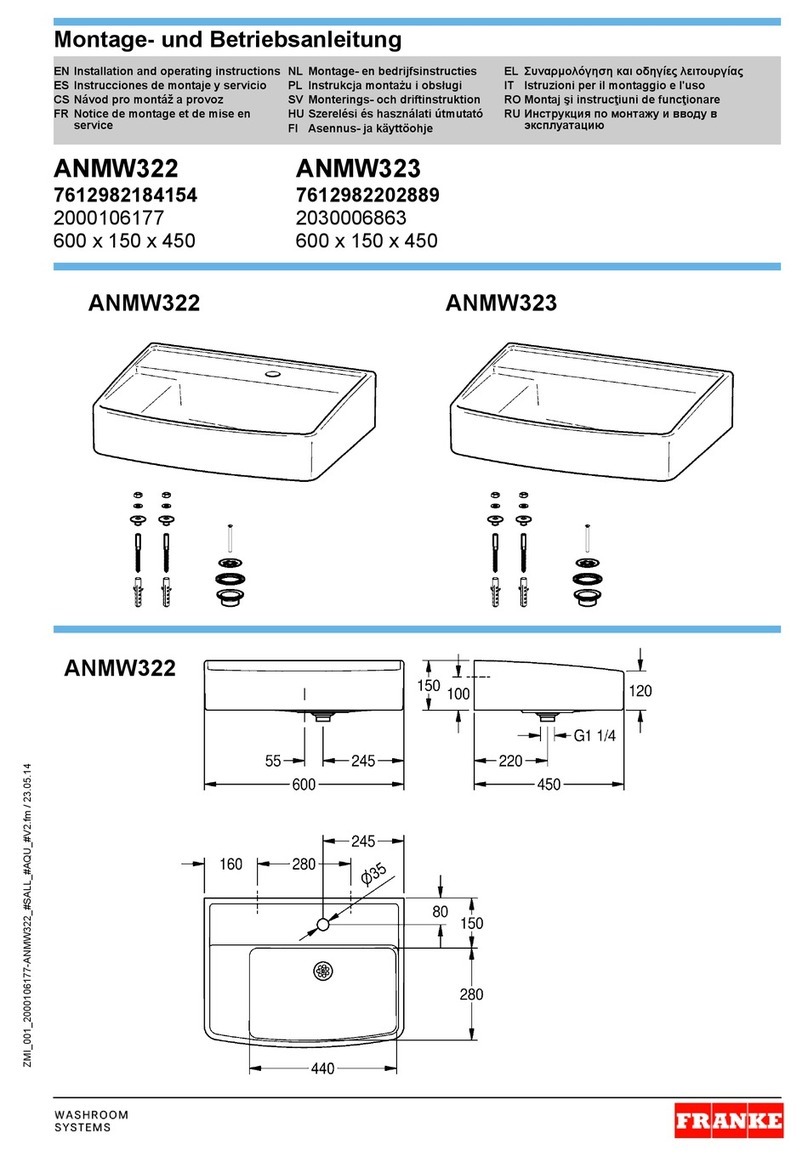

Franke ANMW322 User manual

Franke

Franke F5SV1002 User manual

Franke

Franke DVS AT99-102 User manual

Franke

Franke F5EM1018 2030063665 User manual

Franke

Franke HHF23T User manual

Franke

Franke ANMX Series Manual

Franke

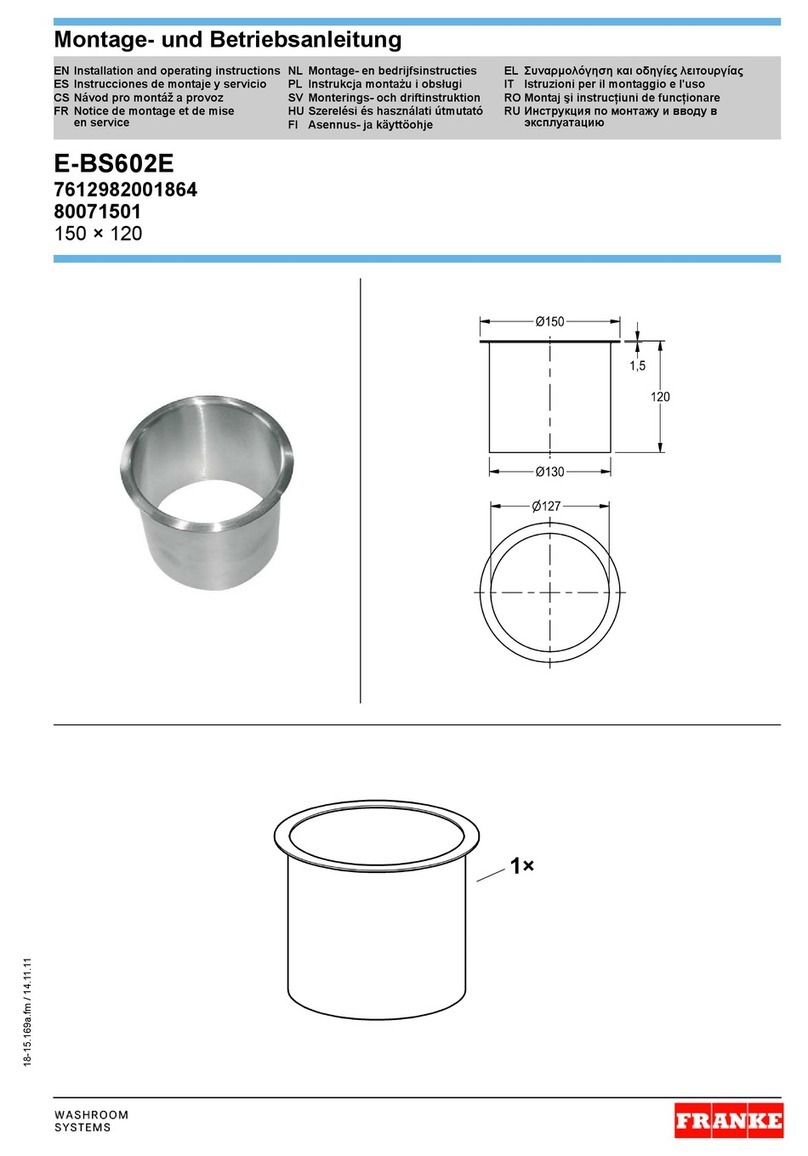

Franke 7612982001864 User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide