Collar

L

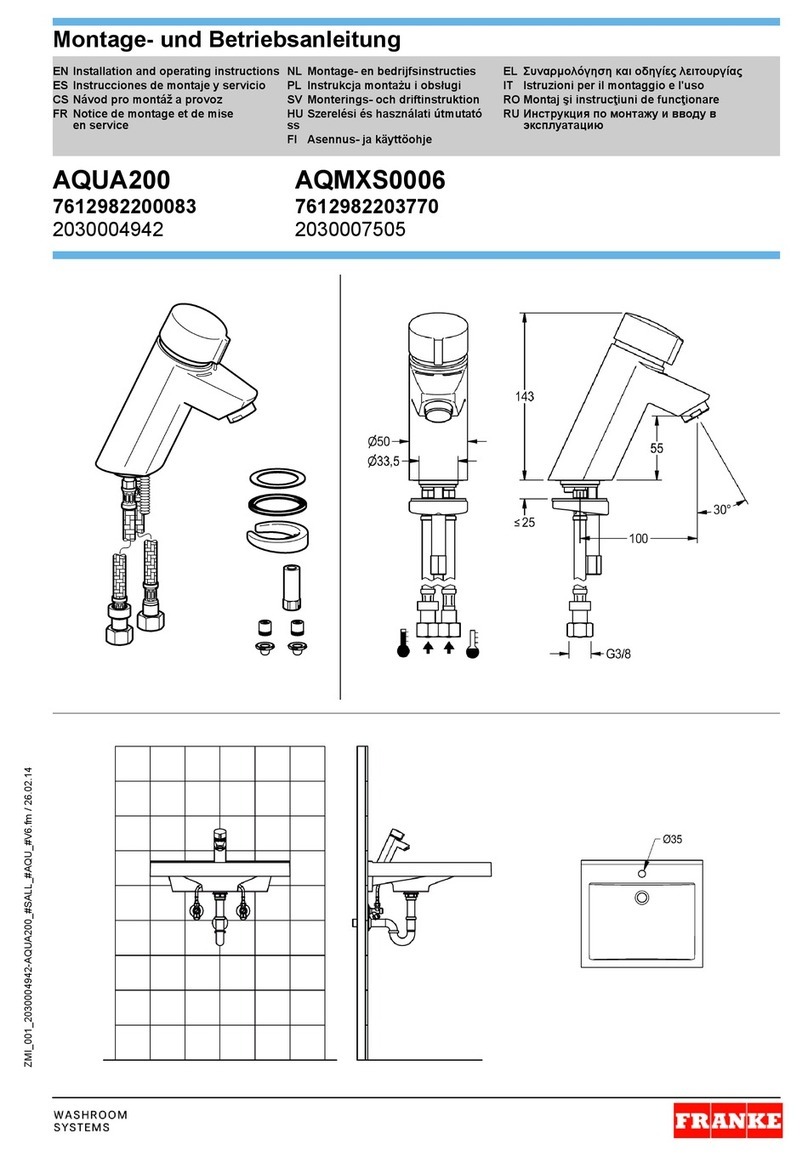

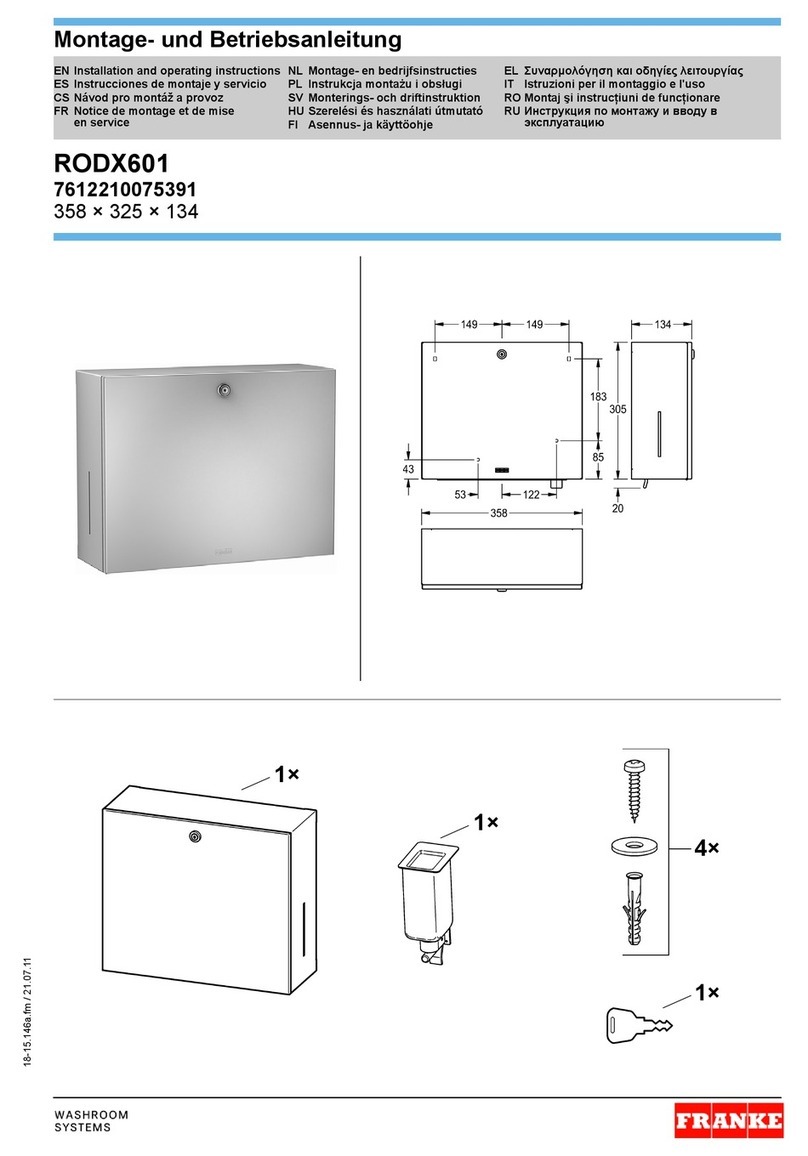

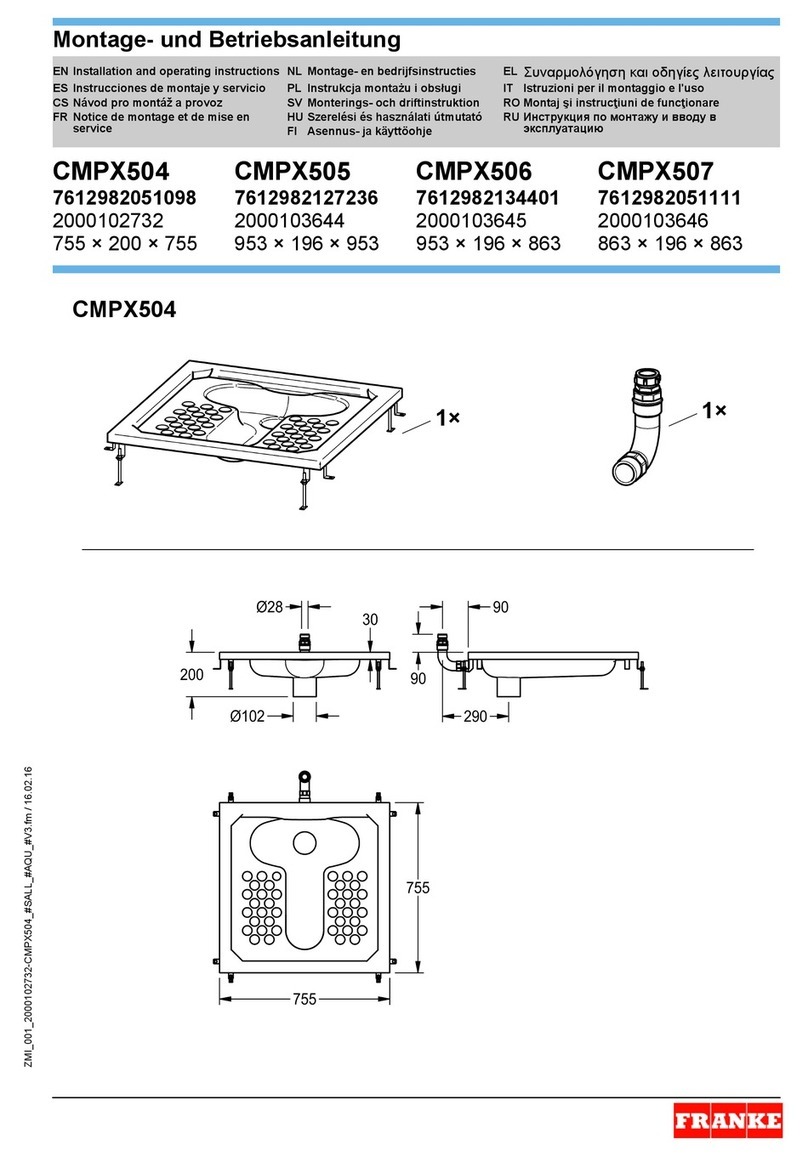

DIAGRAM B -

Push Fit Connections

L= 1" Blue

5

/

8"Green

Cold in (

3

/

8

")

Hot in (

3

/

8

")

SERIAL NUMBER

FR

000000

Franke Triflow

Triflow Concepts Limited

Fairview Industrial Park,

Rainham, Essex, RM13 8UB

Tel: +44 (0) 1708 526361

Fax: +44 (0) 1708 550220

For your replacement

cartridges contact:

Flow

Operation

A unique feature of the Franke Triflow tap is the three

operating valves – one each to control the flow of hot, cold

and filtered water. Each handle is clearly marked: hot/red,

cold/blue and filtered/green. The flow from full-off to full-

on is adjusted by simply rotating the handles – forward for

hot and cold, to the left for filtered water.

Important: Each time the filtered water is turned on, allow

it to run for a few moments to expel the small amount of

residual water in the pipework between the filter and the

tap.

The Triflow Tap

Cleaning –

The Franke Triflow 3 way tap itself requires little

routine maintenance beyond the occasional cleaning of the

plated finish with a soft cloth and warm soapy water,

followed by a polish with a soft cloth.

Do not under any

circumstances use abrasive liquids, powders, or scouring

pads to clean the tap. You will damage the plated finish and

void your guarantee.

The flow straightener fitted to the hot/cold water outlet

may need occasional cleaning. This will be evident when

the water flow slows down to an unacceptable level. This is

accomplished by unscrewing the outlet in an anti clockwise

direction, then rinse thoroughly in clean water and re-

install.

Franke Triflow

Care & Maintenance

Franke Triflow

Introduction and Installation

35mm Diameter Hole

Blue

Tube

Green Tube

FILTERED

Push Fit

UNSCREW

Bracket

L=1" Blue

5

/

8

" Green L

Grey Collar

US

F

L=1" (25mm) Blue

5

/

8

" (16mm) Green L

Grey Collar

Canada

L=25mm Blue

16mm Green L

Grey Collar

UK/Swiss

L=25mm Bleu

16mm Vert L

Collier gris

Push Fit

Diagram B

Push Fit Connections

Push Fit

Introduction

The Franke Triflow is manufactured to

exacting standards. Carefully installed

and maintained it will give many years of

trouble free use.

Ideally installed on an equal pressure

system. The Triflow allows hot and cold

water to mix in the body. If the supplies

are imbalanced, control of the mixing

temperature may be affected. An

additional check valve (not supplied)

should be fitted to the Hot side when

used on an imbalanced system.

Before you proceed... We recommend

you engage the services of a registered

plumber to install this product.

Read the instructions and diagrams in

this leaflet carefully.

CheckList

ICheck the cold water pressure - it

must not exceed 75psi (5 bar)

measured during a low demand

period. Subjecting the system to

pressures above this level will

invalidate your warranty and could

result in the failure of the filter

housing. Where the pressure exceeds

5 bar a pressure limiting device must

be installed (contact Franke Triflow).

Recommended minimum cold water

pressure 25psi (1.7 bar).

IFor optimum filter performance

use the stop valve to set the filtered

water flow to 11/2 - 2 litres/min (23/4 -

31/2 pints/min).

IThe recommended maximum

temperature of the hot water supply to

the Triflow mixer tap in metal finishes

is 85°C.

1Position the filter to allow easy

access for future cartridge changes.

2Make sure the grey collars are in

place in the end of the push fit

connectors – Diagram B

3Take care with the plastic tubing –

correctly installed tubes can withstand

pressures in excess of 500psi (33bar).

However, creasing, stretching,

exposure to a naked flame or locating

near a heat source will impair its

pressure rating and may lead to failure

and subsequent flooding.

4Take care with the plastic tubing –

scratches and scores where the

connectionsare made will cause

leaks. If you need to cut the tubing,

use a sharp blade and chamfer the cut

end.

5Push the plastic tube completely in

when making the ‘Push Fit’

connections into the cap – Diagram B

6Position the plastic tubes neatly to

avoid side strain and the possibility of

accidental damage.

7If you need to remove the tubes

from the ‘Push Fit’ connections, use

your thumb and forefinger to hold in

the grey collar (Diagram B) while

gently pulling the tube out. Before re-

inserting the tube, trim the length

General Information

1

The Franke Triflow is not a water softener, and unlike

some jug filters, does not remove the minerals essential

to good health and taste. In hard water areas, calcium,

perhaps the most essential of these minerals forms a

precipitate when the water is boiled. Most commonly

this forms a scale in the kettle, and in extreme cases,

appears as white flecks in the boiled water or as a

surface film on tea and coffee.

A convenient remedy for this problem is to use one of

the new generation of kettles now available. These

kettles incorporate a special screen which removes the

precipitate but not essential minerals thereby

complementing the use of your Triflow system.

2If you plan to be away from home for more than two or

three days, we recommend turning off the main water

supply to the filter. Once turned on again, allow the

water to run for a few moments before use.

3If you plan to be away from home for extended periods,

or the filter housing may be subject to the risk of

freezing, you must turn off the main water supply to the

filter and remove residual water from the filter housing

(see cartridge replacement sheet). Once turned on

again, allow the filtered water to run for two minutes

before use.

4Take care when moving things under the sink unit or you

may cause a leak by damaging the plastic tubes leading

to and from the filter housing.

5If the ‘Push Fit’ connectors require tightening after

installation, a force of no greater than 1.5Nm torque

(hand tight) should be applied. Overtightening will

damage the fitting and invalidate your guarantee.

6When comparing the taste of the filtered water with the

untreated water use a clean glass and drink the filtered

water first.

15mm

COLD IN

back by 25mm and chamfer the end.

8Water must flow through the filter

in the direction of the arrow moulded

in the top of the cap.

9Check system carefully for leaks.

10 After installation, if building work

is to be carried out near the Franke

Triflow Tap, it should be covered to

prevent paint, tile adhesive etc.,

damaging the surface finish.

11 Please ensure that the installation

complies with the local Water Supply

Bye-laws.

Box spanner

Compression Fit

The connection to the

Stop Valve should be

handtight (1.5Nm max)

only.

DO NOTOVERTIGHTEN

15mm

HOT IN

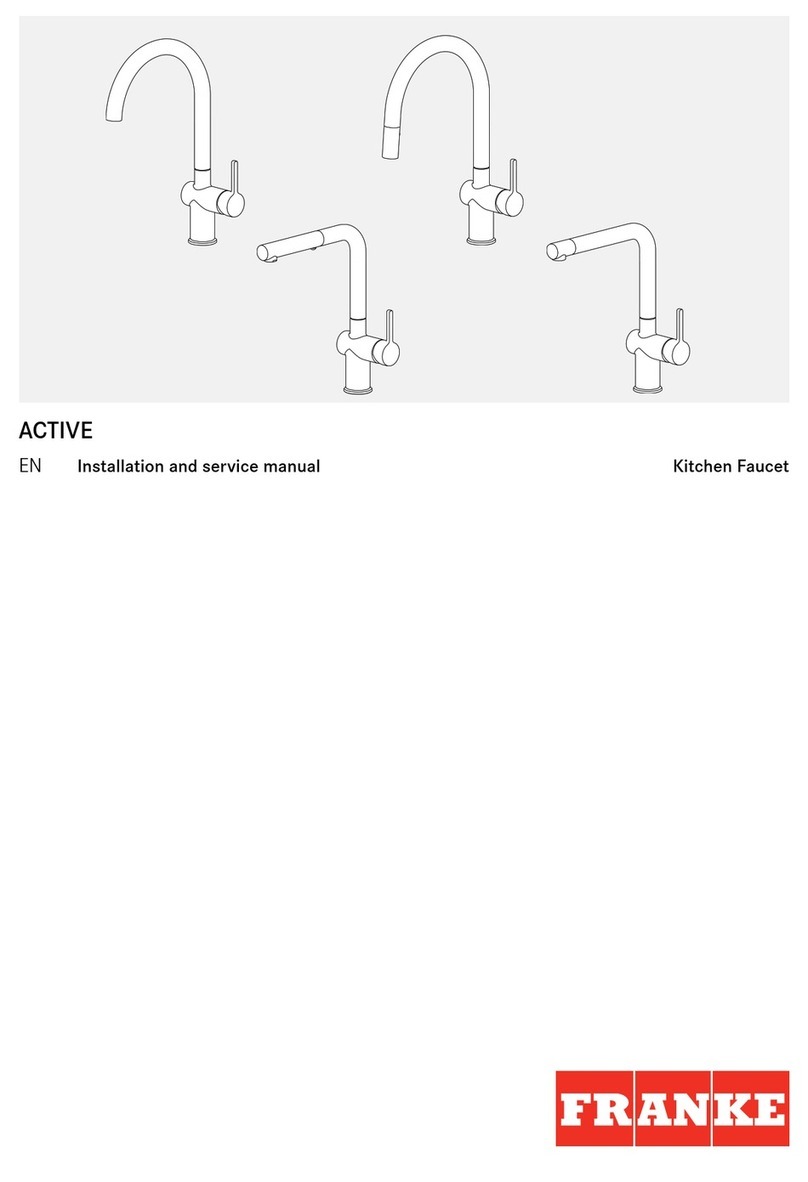

Diagram A

Typical Installation