5

10/17 | 036865-047

50112 036865-003

SECTION3: INSTALLATION

WATER COOLER INSTALLATION INSTRUCTIONS, MODELS: KEPWSBF

A. DRILLING HOLE IN THE TOP FOR WATER LINE CONNECTION

1. Disconnect power by UNPLUGGING unit. It might be necessary to remove the front panel to get access to the power.

2. Turn OFF water supply to the unit. It might be necessary to remove the front panel to access the water stop valve.

3. Place hole template onto cooler top so it is aligned with the left side of unit and wall. (TEMPLATE FOUND ON PAGE 17)

4. Mark hole location.

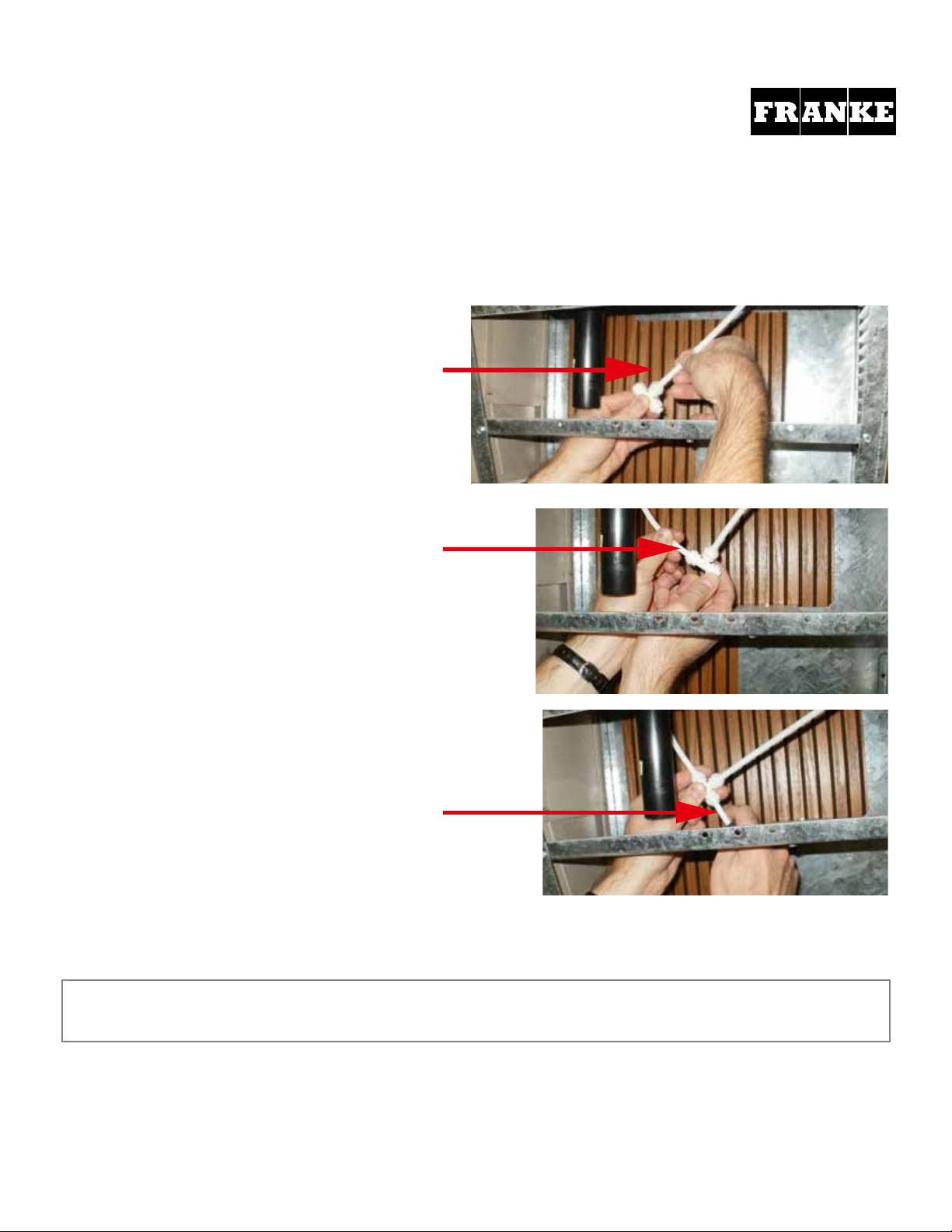

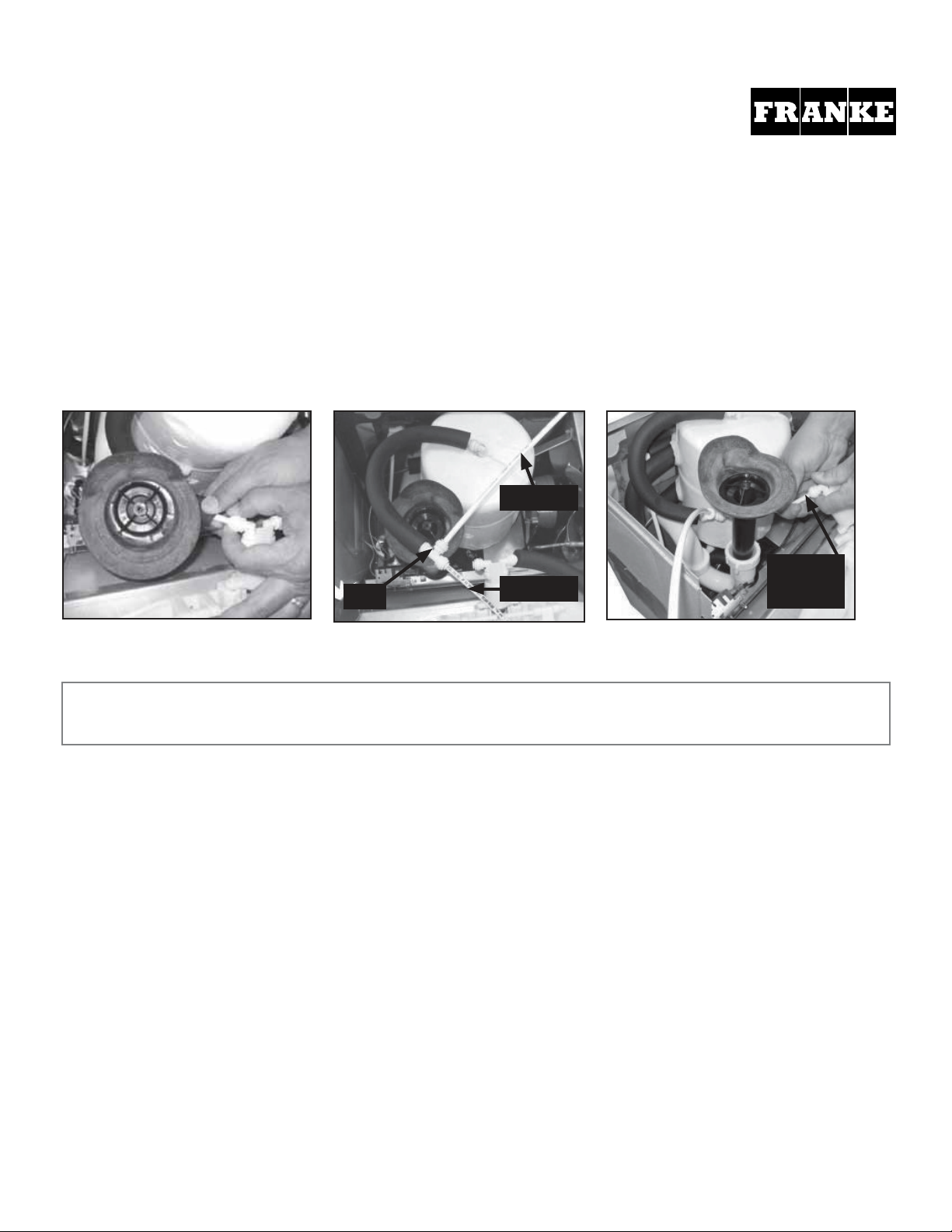

5. Remove top from unit. (Figure 1)

6. Using a 3/8 drill bit, drill a hole through top.

7. Install snap bushing into hole to protect tubing from being cut. (Figure 2)

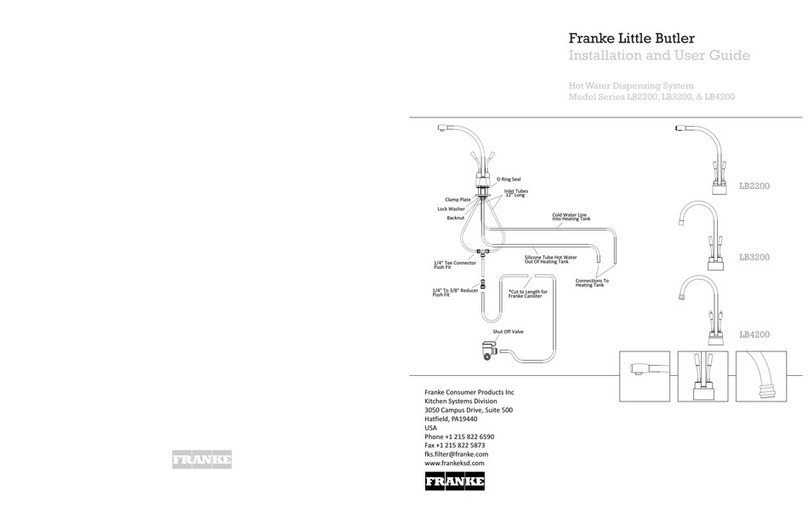

B. CONNECTING THE WATER LINE

If the cooling tank is non-pressurized, then go to the "Pressurizing the cooling tank" addendum section. Otherwise, proceed to

STEP 1 next page. Non-pressurized units are single units made since December of 2009. Refer to the schematic below to identify

the system that you have.

Mark hole location

Template

Remove top from cooler by

removing six #15 torx head

screws on sides of top.

Figure 1 Figure 2

Drill Install Bushing

PRESSURIZED

COOLING TANK

NON-PRESSURIZED

COOLING TANK

Cooling

tank

Water

valve/regulator

Supply

Water

Water

valve/regulator

Supply

Water

Cooling

tank

STEP 1:

a) Disconnect power by UNPLUGGING unit. It might be necessary to remove the front panel to get access to the power.

b) Turn OFF water supply to the unit. It might be necessary to remove the front panel to access the water stop valve.

c) Place hole template onto cooler top so it is aligned with the left side of unit and wall. SEE NEXT PAGE FOR TEMPLATE.

d) Mark hole location.

e) Remove top from unit. (Figure 1)

f) Using a step drill bit OR 7/8" punch die, make a 7/8" hole through top. You may want to drill a pilot hole to get these started.

g) Install snap bushing into hole to protect tubing from being cut. (Figure 2)

SECTION 3: INSTALLATION

A. DRILLING THE HOLE IN THE TOP FOR WATER LINE CONNECTION

PRE-DRILLED UNITS:

If your unit was purchased pre-drilled at the factory as a COMBINATION, go to Section 3, Step 5.