7HFKQLFDOFKDQJHVZLWKRXWQRWLFH7HFKQbQGHUXQJHQYRUEHKDOWHQ0RGL¿FDWLRQVWHFKQLTXHVUpVHUYpHVVDQVSUpDYLV

9

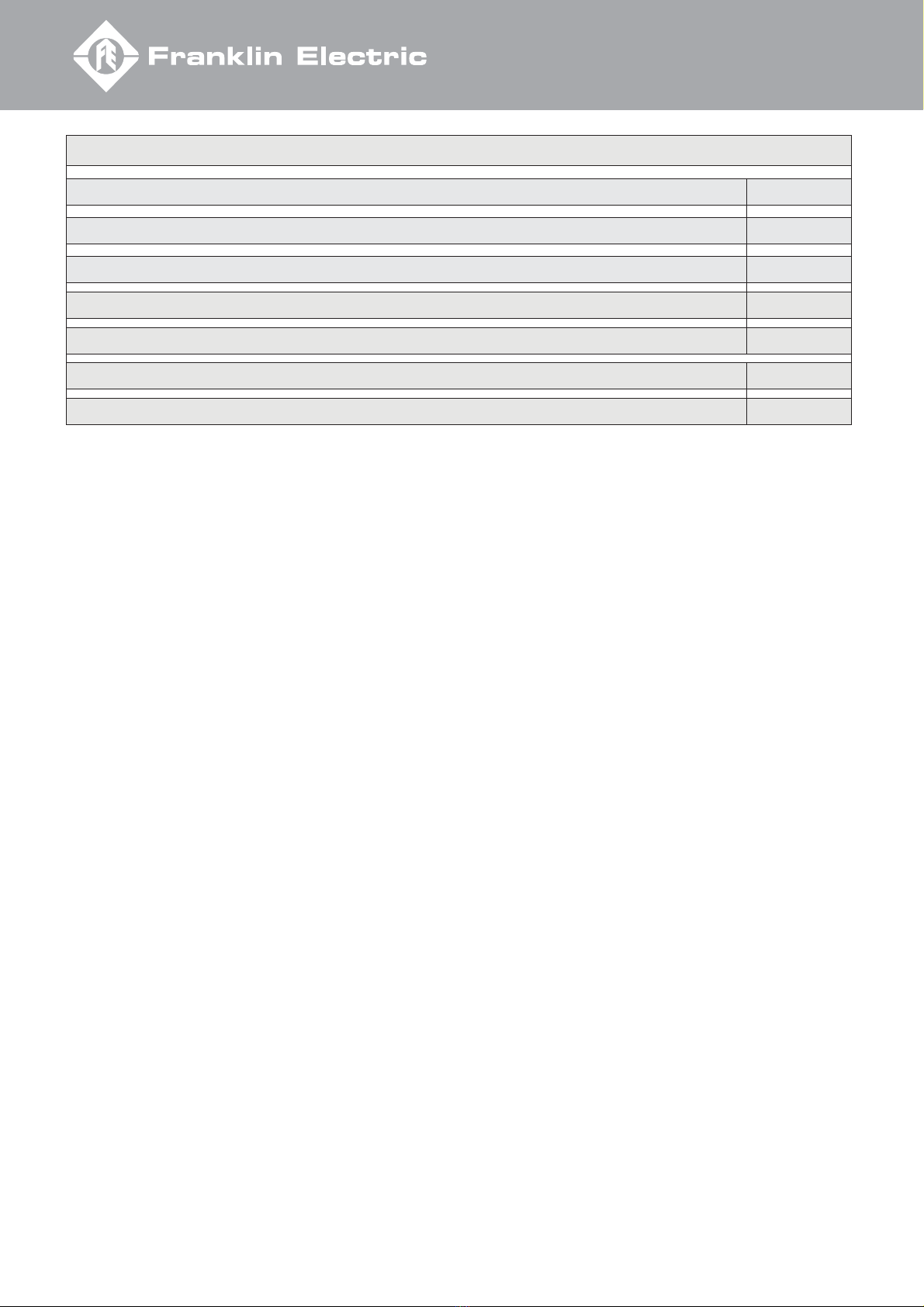

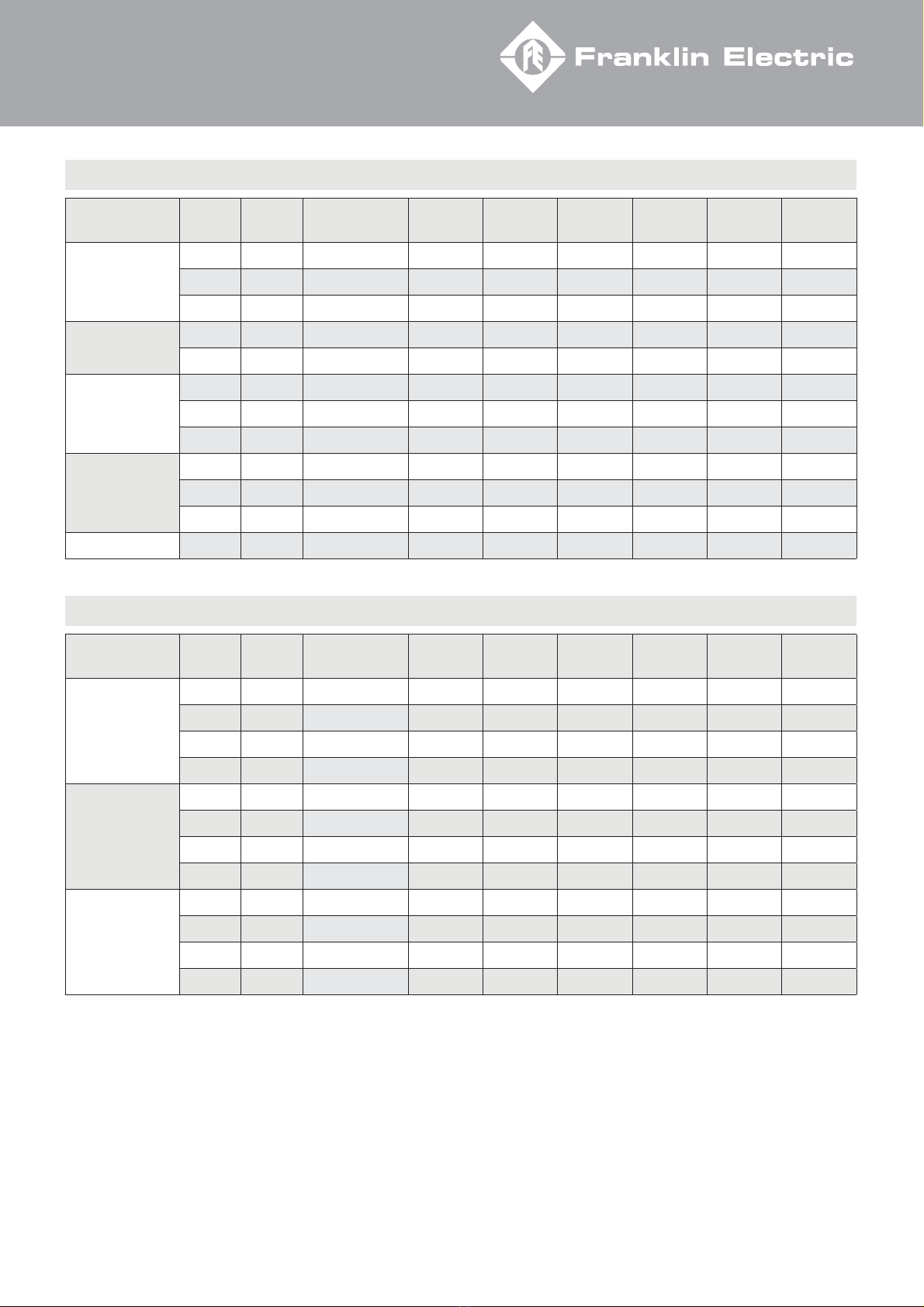

6" HES System Performance Data 400V-50Hz

400V/50Hz PN

[kW]

Thrust

F [kN]

nN

[min-1]

IN

[A]

IA / IN*

[A]

Ș

[%] PF TN

[Nm]

TA / TN*

[Nm]

308 010 X16

4 15,5 3000 8 1 88 0,95 12,9 1

5,5 15,5 3000 10 1 89 0,95 17,5 1

7,5 15,5 3000 13 1 89,5 0,95 23,8 1

308 014 X23 9,3 15,5 3000 18 1 91,5 0,95 29,6 1

11 15,5 3000 20 1 92 0,95 35 1

308 014 X38

13 15,5 3000 23 1 92,5 0,95 41,5 1

15 15,5 3000 26 1 92,5 0,95 46,1 1

18,5 15,5 3000 32 1 92 0,95 59 1

308 016 X61

22 27,5 3000 39 1 93 0,95 70 1

26 27,5 3000 46 1 92,5 0,95 82,6 1

30 27,5 3000 54 1 91,5 0,95 95,5 1

308 016 X87 37 27,5 3000 72 1 90 0,95 117,8 1

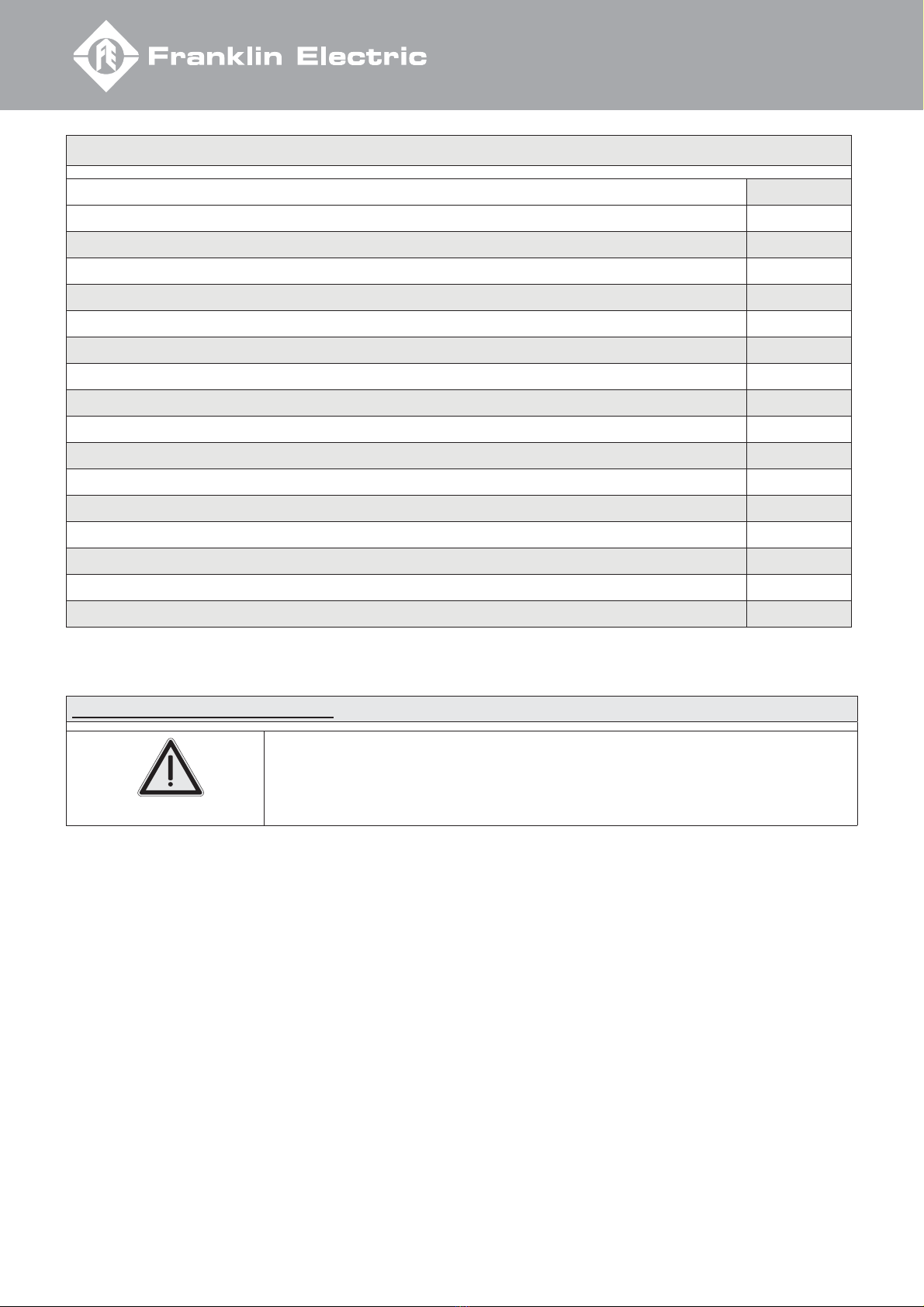

8" HES System Performance Data 400V-50Hz

400V/50Hz P

[kW]

Thrust

F [kN]

nN

[min-1]

IN

[A]

IA / IN*

[A]

Ș

[%] PF TN

[Nm]

TA / TN*

[Nm]

308 014 X01

45 45 3000 74 1 93,3 0,96 143 1

55 45 3000 91 1 93,3 0,96 175 1

67 45 3000 112 1 93 0,96 213 1

75 45 3000 128 1 92,5 0,96 239 1

308 016 X01

75 45 3000 129 1 93,5 0,95 239 1

83 45 3000 143 1 93,3 0,95 264 1

93 45 3000 162 1 93 0,95 296 1

100 45 3000 178 1 92,7 0,95 319 1

308 017 X01

100 45 3000 176 1 94,2 0,94 319 1

110 45 3000 193 1 94,2 0,94 350 1

130 45 3000 229 1 94 0,94 413 1

150 45 3000 270 1 93,4 0,94 477 1

Performance data are based on measurements with Franklin Electric original equipment!

6LQFHWKLVLVDQLQWHJUDWHGV\VWHPPRWRUSOXVHOHFWURQLFVWKHVH¿JXUHVUHODWHWR9)'LQSXW