FS15-60-120 Rev0204

2

CONTENTS Table of Contents

CONTENTS ............................................................................................................... 2

List of Tables ......................................................................................................... 2

List of Figures ....................................................................................................... 2

INTRODUCTION ...................................................................................................... 3

Overview ............................................................................................................... 3

Features ................................................................................................................. 3

Specifications ........................................................................................................ 4

GENERAL DESCRIPTION....................................................................................... 6

Components........................................................................................................... 6

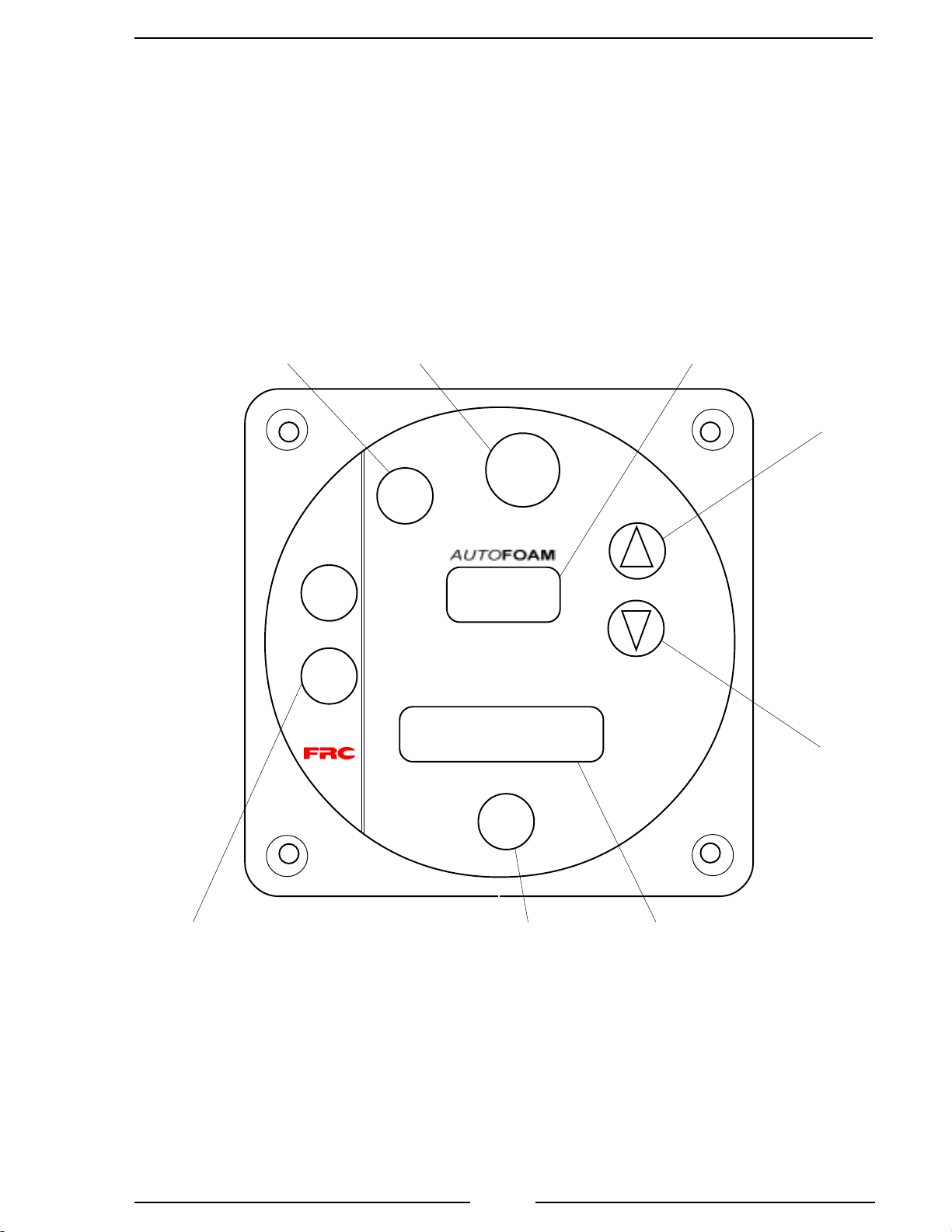

Controls and Indicators ......................................................................................... 8

INSTALLATION......................................................................................................10

Install Control Module ........................................................................................ 10

Install Metering Valve Assembly and Eductor....................................................10

Install Flow Sensor(s) ......................................................................................... 12

Install Summing Device ......................................................................................18

Install Cables ....................................................................................................... 18

THEORY OF OPERATION ..................................................................................... 20

OPERATION ............................................................................................................22

Static Operational Check.....................................................................................22

Pump Intake and Discharge Pressure Requirements...........................................23

Operational Check............................................................................................... 24

CALIBRATION........................................................................................................ 28

TROUBLESHOOTING TIPS .................................................................................. 30

MAINTENANCE.....................................................................................................31

Flushing the System ............................................................................................31

Cleaning the Paddlewheel Sensors ..................................................................... 31

List of Tables

Table 1. Pump Pressure Requirements ....................................................................23

List of Figures

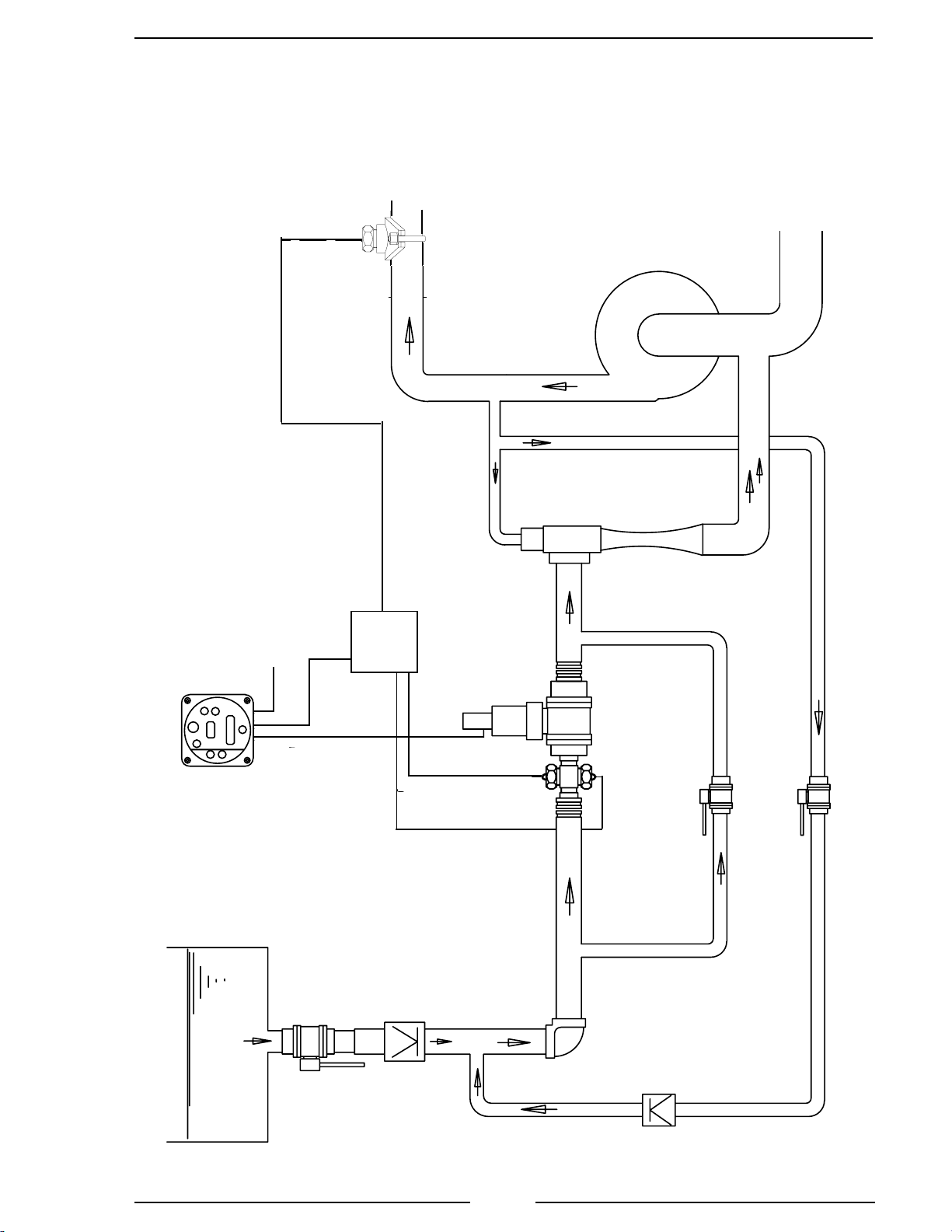

Figure 1. Plumbing Schematic ..................................................................................7

Figure 2. Controls and Indicators.............................................................................. 9

Figure 3. Control Module Dimensions ................................................................... 11

Figure 4. Meteing Valve Assembly and Eductor Installation ................................. 11

Figure 5. Flow Sensor Location Guidelines............................................................ 13

Figure 6. Saddle Clamp Installation........................................................................ 15

Figure 7. Weldment Installation ..............................................................................17

Figure 8. Cables....................................................................................................... 19

Figure 9. Sample Displays....................................................................................... 25

Figure 10. Summing Device.....................................................................................29

Figure 11. Drawings ................................................................................................. 32