FREMCO A/S

ELLEHAMMERVEJ 14 |DK9900 FREDERIKSHAVN, DENMARK |VAT NO.: DK30815416

4. SAFETY

INSTRUCTIONS

•Read and understand this operating manual

before operating the NanoFlow MAX. Follow

all safety instructions. Failure to follow the

instructions may lead to damage on the

machine and mild to severe personal injury.

•Make sure to disconnect the machine from the

air compressor and dismount the battery,

before any kind of adjustment and

maintenance takes place.

•Use only batteries that fit NanoFlow MAX. Do

not use damaged batteries.

WARNING: The use of damaged

battery or charger may lead to

electric shock, superheating or fire.

•The air pressure should never exceed the

recommendations from the suppliers of

microducts and fiber. The pressure may never

exceed 10 bar, which is the maximum

pressure for the Nanoflow MAX blowing

machine.

WARNING: Exceeding max.

pressure may lead to machine damage

and mild to severe personal injury.

•Observe that the machine is placed on a stable

foundation. Make sure that the fiber and duct

are placed correctly in the machine.

•Make sure you do not touch the fiber too

close to the machine because you risk getting

your fingers injured, and make sure the fiber

does not make loops that might be dangerous

to persons around the machine.

•Never wear loose clothing

•WARNING: Loose clothing may

become entangled in the machine

•Use hearing protection, if the air compressor

is placed nearby.

•The operator must make sure that no other

persons are close to the machine and cable

drums in a way that could be dangerous when

the machine is started.

•It is always a clear advantage to be well

prepared so that you can run the blowing

without interruptions. Pausing in the middle of

blowing creates a risk of being unable to start

again.

•Make sure the working environment is clean

and tidy to avoid injuries due to stumbling

over fiber and equipment.

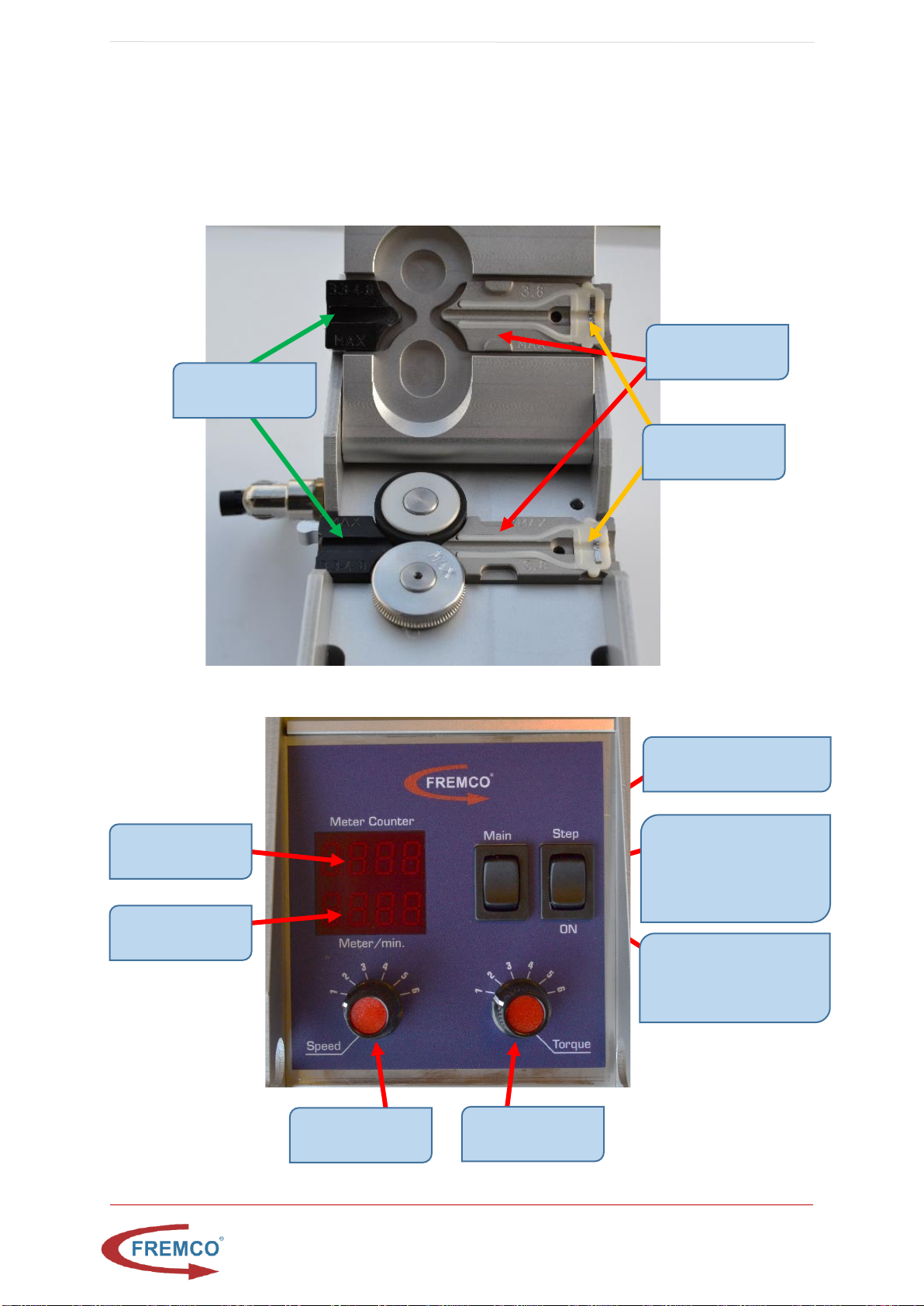

5. MAINTENANCE

The NanoFlow MAX does not require much

maintenance if the following recommendations are

followed:

Compressed air must be clean and dry. Use air

filter and water separator.

Clean the wheels on a regular basis, at least once a

day when the machine is in use. Check duct

adaptors and rubber belts on wheels for wear and

tear on a daily basis, and replace if necessary.

It is easy to remove

and mount the

wheels, as they

simply can be

clicked on and off.