190.210-IOM (FEB 20)

Page 2

LAZERWELD II PLATE HEAT EXCHANGER

INSTALLATION - OPERATION - MAINTENANCE

Indicates an imminently hazardous situation which, if not avoided, will result in death or seri-

ous injury.

Indicates a potentially hazardous situation or practice which, if not avoided, will result in death

or serious injury.

SAFETY PRECAUTION DEFINITIONS

Indicates a potentially hazardous situation or practice which, if not avoided, will result in damage

to equipment and/or minor injury.

Indicates an operating procedure, practice, etc., or portion thereof which is essential to highlight.

WARNING

CAUTION

DANGER

NOTICE

Contents

General Information

Preface..............................................................................3

Safety considerations........................................................3

Warranty conditions.......................................................... 3

Advice...............................................................................3

Environmental compliance ................................................ 3

Unpacking.....................................................................3

Maintenance................................................................. 3

Scrapping .....................................................................3

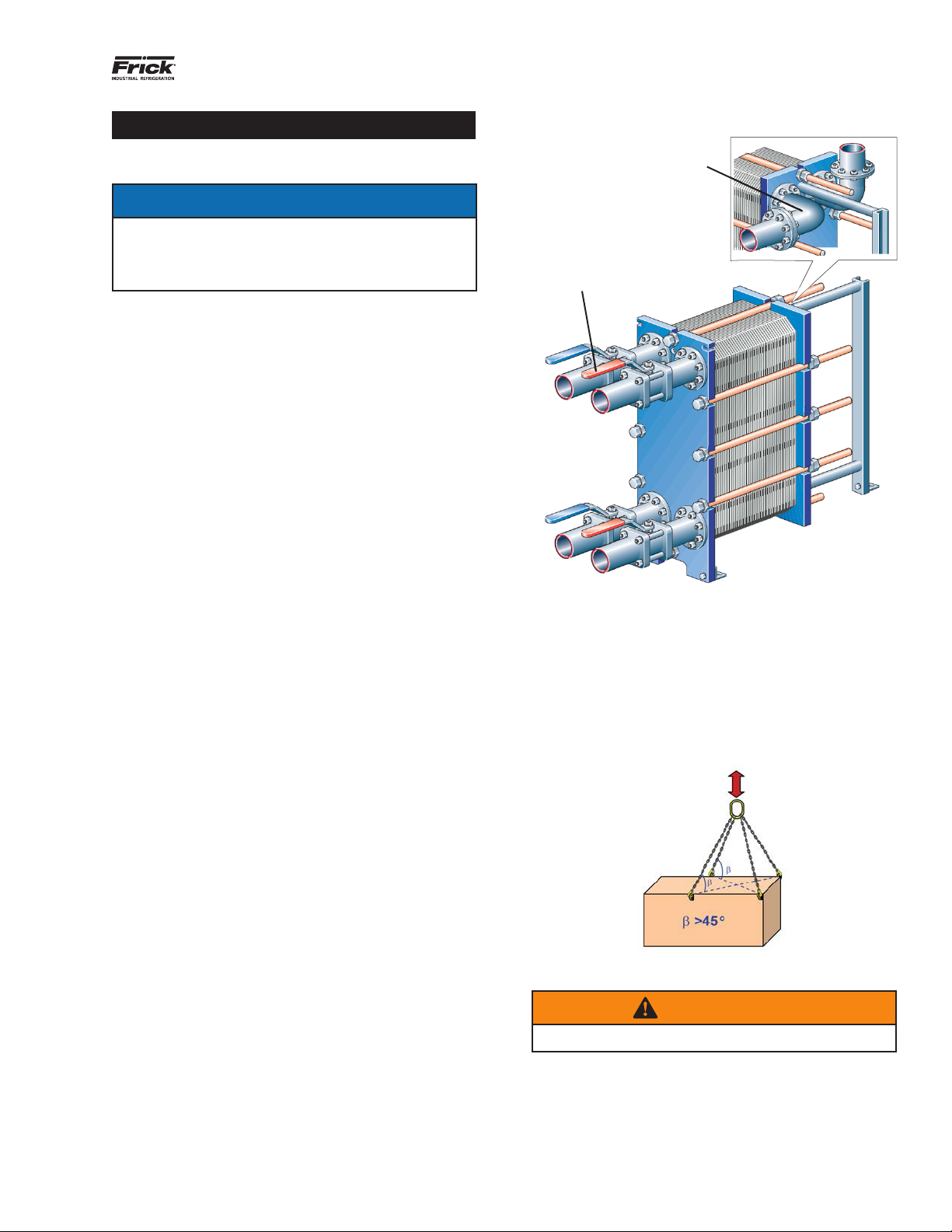

Main components.............................................................. 3

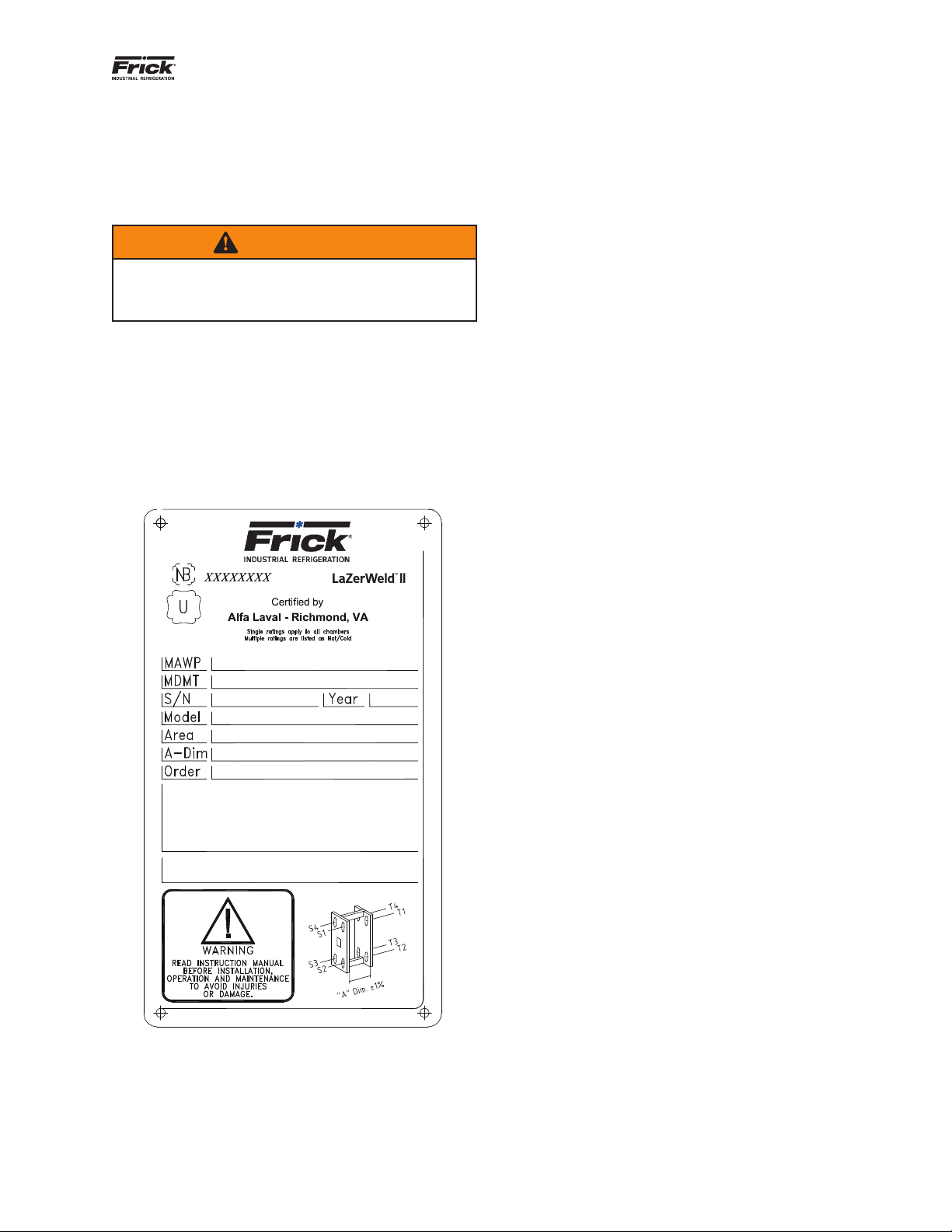

Nameplate......................................................................... 5

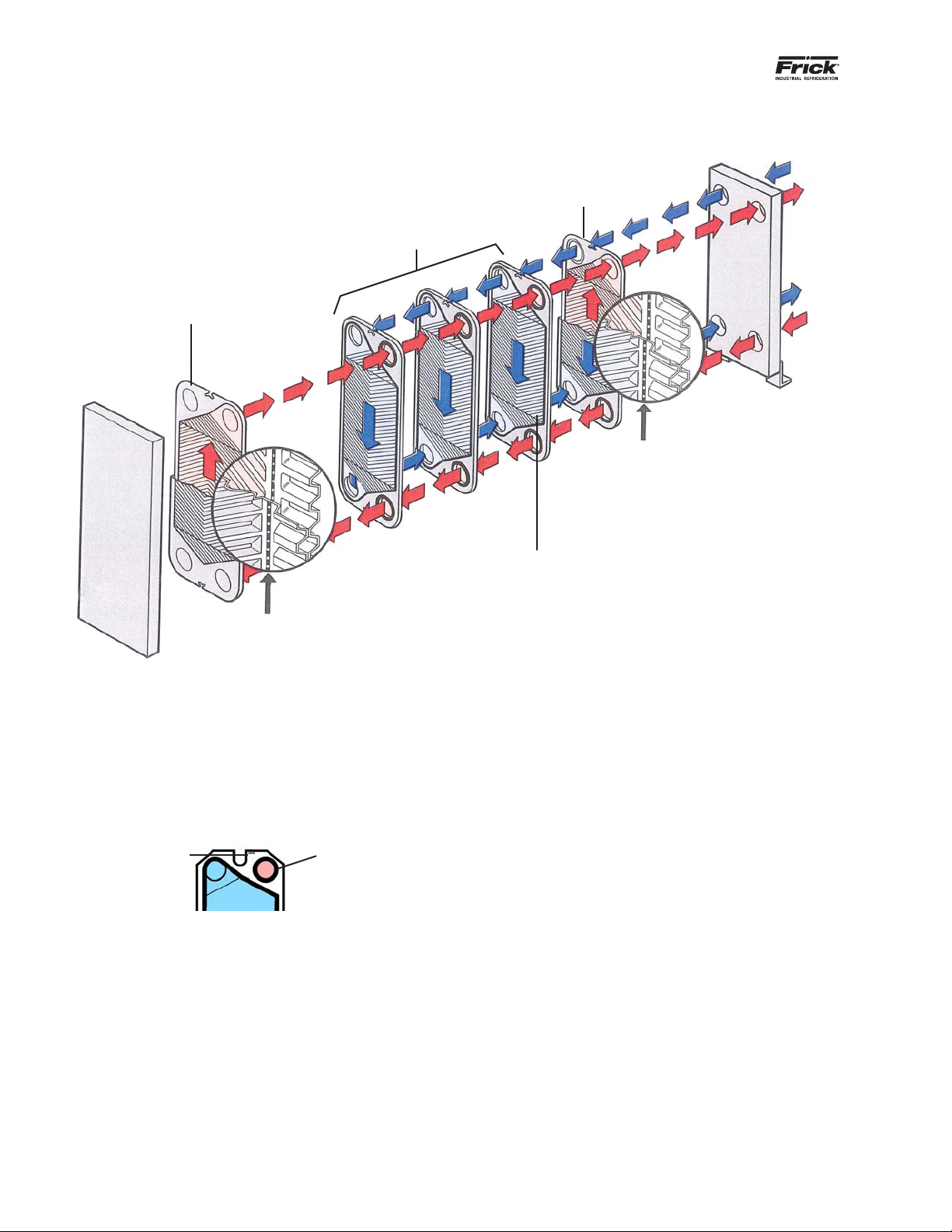

Function ............................................................................5

Identication of plate side................................................. 6

Installation

Before installing ................................................................ 7

Requirements.................................................................... 7

Space ...........................................................................7

Foundation ...................................................................7

Elbow ...........................................................................7

Shut-off valve...............................................................7

Drip tray (optional) ....................................................... 7

Connections in the pressure plate ................................7

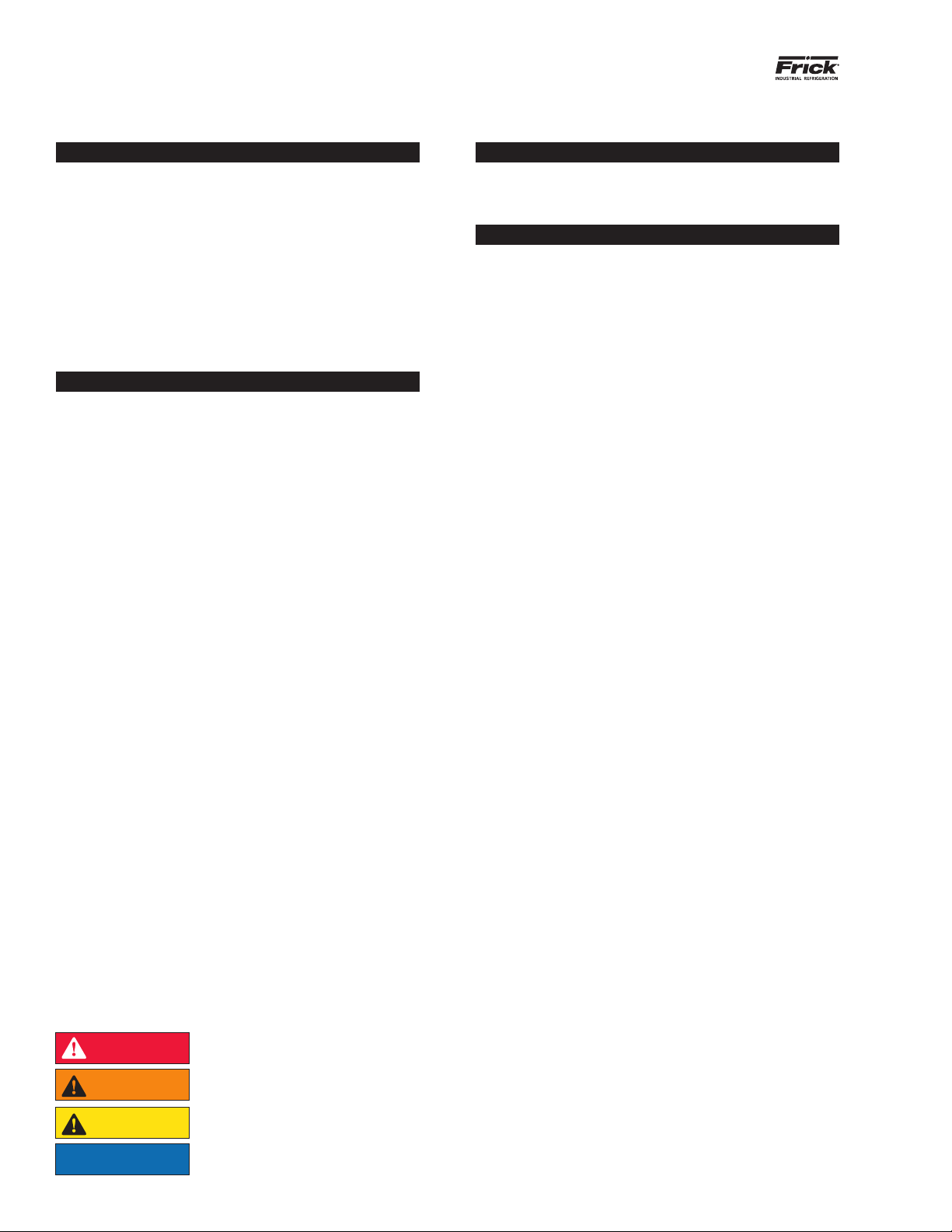

Lifting ...............................................................................7

Raising .............................................................................8

Connecting to the system .................................................9

Operation

Start-up ..........................................................................11

Unit in operation ............................................................. 12

Shut-down ...................................................................... 12

Maintenance

Cleaning-In-Place (CIP)...................................................13

Manual cleaning .............................................................. 13

Opening......................................................................13

Manual cleaning of opened units..................................... 15

Deposits removable with water and brush ................. 15

Deposits not removable with water and brush ..........16

Regasketing .................................................................... 16

Clip-on and Clip-Grip ................................................. 16

Adhesive tape............................................................. 17

Glued gaskets............................................................. 17

Closing ............................................................................17

Max tightening torque................................................18

Pressure test after maintenance ..................................... 19

Storage of the LZWII....................................................... 19

Storage in packing box...............................................19

Taken out of service...................................................20

Installation after long-term storage ........................... 20