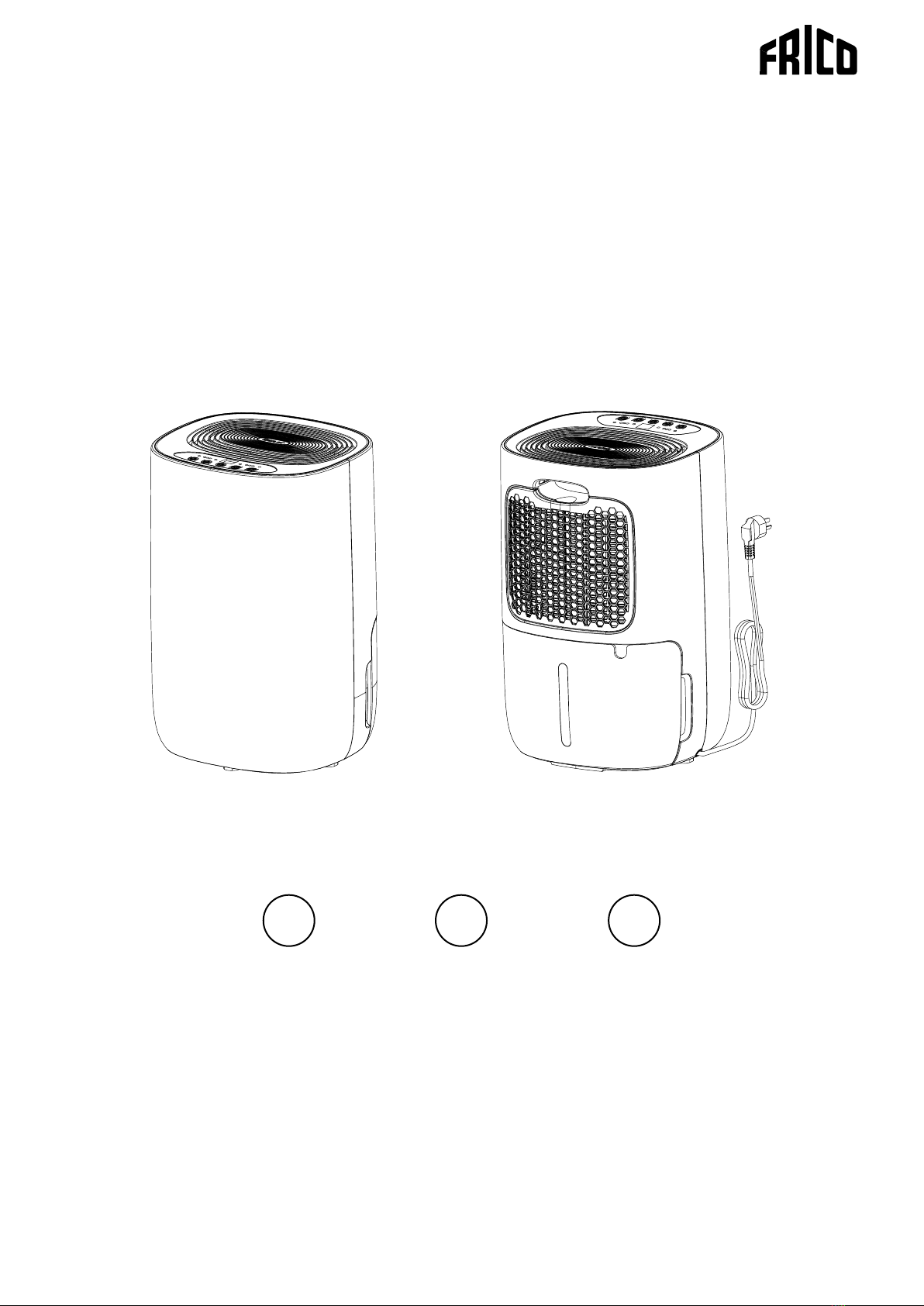

SUN12

3

Product Instructions

The dehumidier is used to remove excessive

moisture from the air. The resulting reduction

in relative humidity protects buildings and their

contents from the adverse effects of excess

humidity.

The environmentally friendly R290 is used

as the refrigerant. R290 has no damaging

inuence on the ozone layer (ODP), a negligible

greenhouse effect (GWP) and is available

worldwide. Because of its ecient energy

properties, R290 is highly suitable as a coolant

for this application.

Special precautions must be taken into

consideration due to the coolant’s high

ammability. The dehumidier is CE marked

and approved by TüV according to EN 60335-1,

EN 60335-2-40, EN 62233, EN 55014-1, EN 55014-

2, EN 61000-3-2 and EN 61000-3-3.

Safety Instructions

• This appliance can be used by children

aged from 8 years and above and persons

with reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

supervision or instruction concerning use of

the appliance in a safe way and understand

the hazards involved. Children shall not

play with the appliance. Cleaning and user

maintenance shall not be made by children

without supervision.

• Children of less than 3 years should be kept

away unless continuously supervised.

• Children aged from 3 years and less than 8

years shall only switch on/off the appliance

provided that it has been placed or installed

in its intended normal operating position

and they have been given supervision or

instruction concerning use of the appliance

in a safe way and understand the hazards

involved.

• Children aged from 3 years and less than 8

years shall not plug in, regulate and clean

the appliance or perform user maintenance.

• The unit is designed only for use with

R-290(propane) gas as the designated

refrigerant.

• The refrigerant loop is sealed. Only a

qualied technician should attempt to

service.

• Do not discharge the refrigerant into the

atmosphere. R-290 (propane) is ammable

and heavier than air.

• It collects rst in low areas but can be

circulated by the fans.

• If propane gas is present or even suspected,

do not allow untrained personnel to attempt

to nd the cause.

• The propane gas used in the unit has no

odor.

• The lack of smell does not indicate a lack of

escaped gas.

• If a leak is detected, immediately evacuate

all persons from the store, ventilate the

room and contact the local re department

to advise them that a propane leak has

occurred.

• Do not let any persons back into the store

until the qualied service technician has

arrived and that technician advises that it is

safe to return to the store.

• No open ames, cigarettes or other possible

sources of ignition should be used inside or

in the vicinity of the units.

• Component parts are designed for propane

and non-incentive and non-sparking.

Component parts shall only be replaced

with identical repair parts.

• If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent or similarly qualied persons in order

to avoid a hazard.

• The appliance shall be disconnected from its

power source during maintenance.

• Ensure the unit is far away from re,

inammable, or explosive objects.