Rittal Support rail cutter MC3 We reserve the right to make technical modifications 5

EN

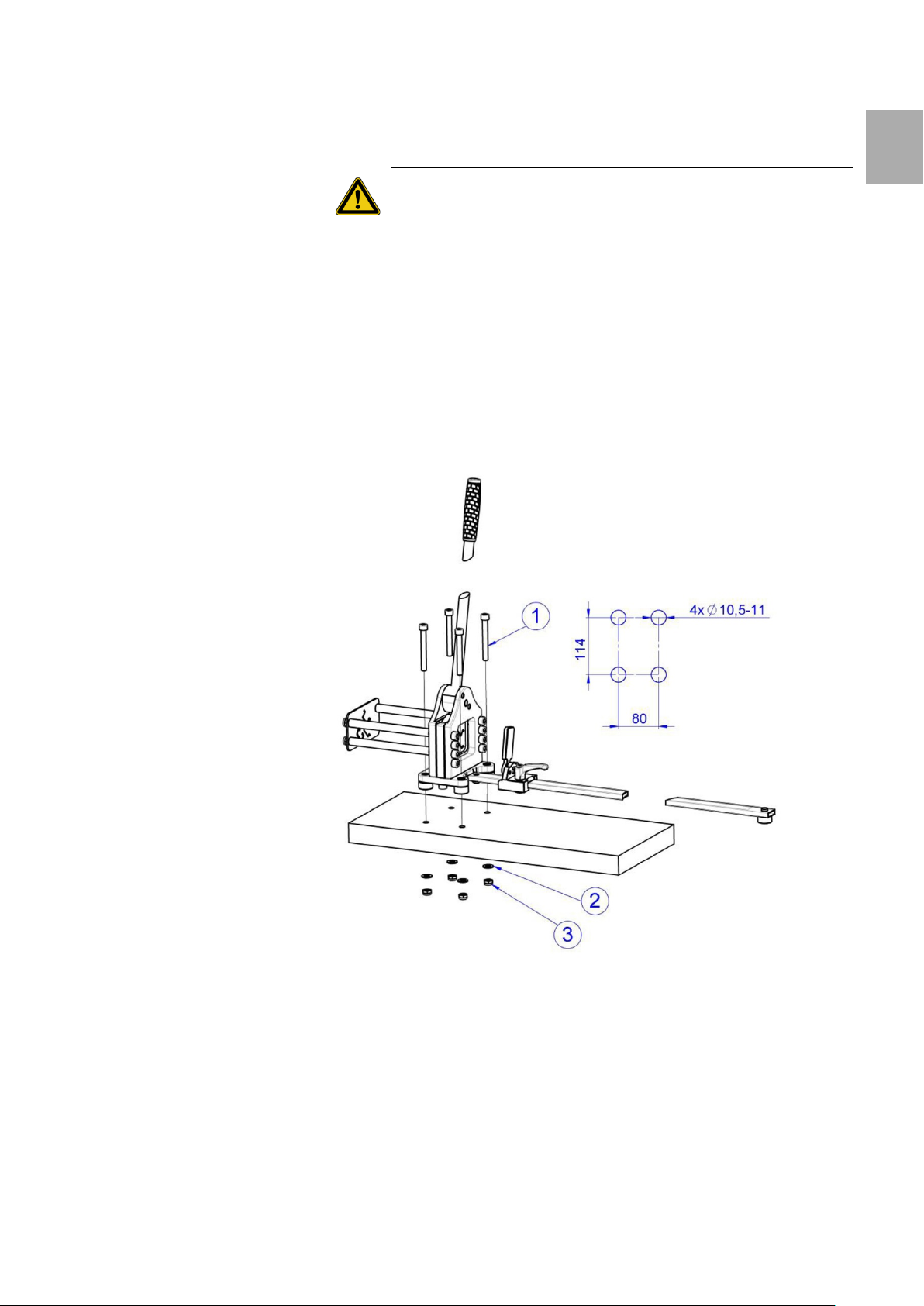

Caution…

–… The unit may be commissioned only when it is fully mounted permanently

on a sturdy, tip-proof surface. The material for attaching the unit is not in-

cluded. Use a suitable, sturdy fastening material appropriate for the sur-

face.

Always...

–… ensure a stable footing and mount the cutting unit permanently.

–… wear safety goggles, gloves and safety boots when working.

–… remove swarf and other cutting waste from the unit.

–… observe the instructions of these operating instructions.

–… instruct new users in the safe use of the cutting unit.

–… store and deploy in a dry environment.

Never...

–… touch the cutting area of the blade.

–… cut cables with the unit.

–… cut several workpieces concurrently.

–… machine rails made of high-strength steels.

–… deploy the cutting unit when parts are damaged or missing.

–… work with a blunt shear blade.

–… subject the unit to corrosive materials.

–… deploy the unit unless the operating instructions have been read and un-

derstood completely.

1.4 Personal safety equipment

The operating and maintenance personnel must always wear personal protec-

tive equipment when working on the unit. The personal protective equipment

comprises at least the following components:

–Safety shoes: for all work on the unit

–Safety goggles: for all work on the unit

–Gloves: for all work on the unit

1.5 Residual risks when using the unit

There is the danger of being injured by the shear blade when using the unit.

Wear your personal protective equipment for all work performed on the unit

(see section 1.4 "Personal safety equipment") and never place hands and

fingers in the area of the shear blade.