3

P356000101enT1.man

1 SAFETY INSTRUCTIONS

Read these instructions carefully. Failure to follow these instructions can result in severe personal injury.

Eye injury hazard

Failure to wear safety glasses with side shields can result

in severe eye injury or blindness. Always wear safety

glasses with side shields which conform to ANSI Standard

Z87.1.

Operation

Tool must not be used by persons not properly trained in

their use. Before tensioning strap, read and understand the

tool operating instructions. Failure to follow the operating

instructions or improper load positioning could result in

strap breakage.

Become familiar with your tool and keep fingers away from

areas that can pinch or cut.

Tool hazards

A well maintained tool is a safe tool!

Check tool regularly for broken or worn parts. Do not

operate a tool with broken or worn parts.

Never modify any tool. Modification can result in severe

bodily injury.

Joints

You are fully responsible to review the joints made by your

tool. Become familiar with the seal control and seal

adjustment described in this operation manual. Misformed

joints may not secure the load and could cause serious

injury. Never handle or ship any load with improperly

formed joints.

Dispensing strap

Only dispense strap from a dispenser specifically designed

for strap.

Tuck strap end back into dispenser when not in use.

Strap warnings

Never use strap as a means of pulling or lifting loads.

Failure to follow these warnings can result in severe

personal injury.

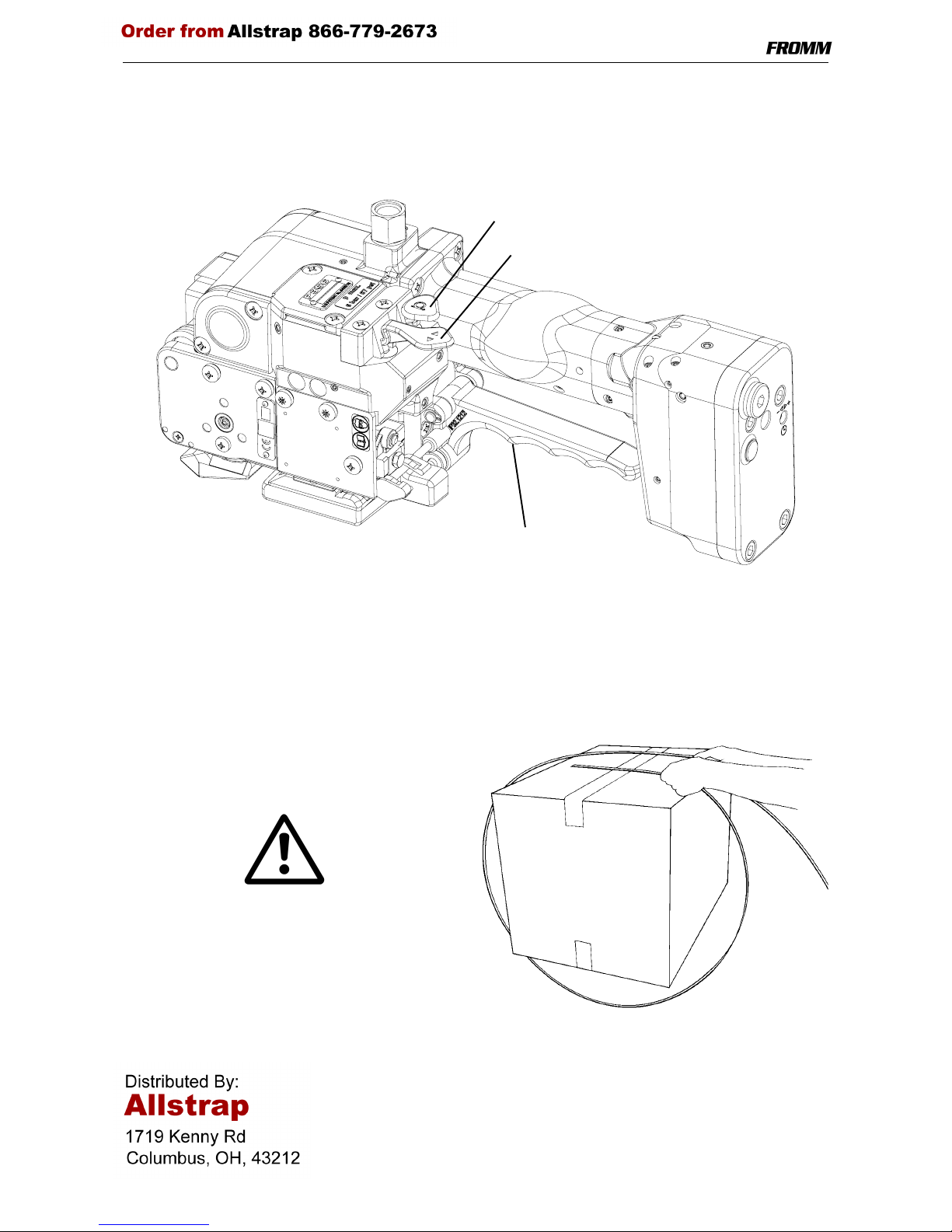

Strap breakage hazard

Improper operation of the tool, excessive tensioning, using

strap not recommended for this tool or sharp corners on

the load can result in a sudden loss of strap tension or in

strap breakage during tensioning, which could result in the

following:

• A sudden loss of balance causing you to fall.

• Both tool and strap flying violently towards your

face.

Note as follows:

• If the load corners are sharp, use edge protectors.

• Place the strap correctly around a properly

positioned load.

• Positioning yourself in-line with the strap, during

tensioning and sealing, can result in severe

personal injury from flying strap or tool. When

tensioning or sealing, position yourself to one side

of the strap and keep all bystanders away.

• Use the correct strap quality, strap width, strap

gauge and strap tensile strength recommended in

this manual for your tool. Using strap not

recommended for this tool can result in strap

breakage during tensioning.

Cutting tensioned strap

When cutting strapping, use the proper strapping cutter

and keep other personnel and yourself at a safe distance

from the strap. Always stand to side of the strap, away from

the direction the loosened strap end will fly. Use only

cutters designed for strap and never hammers, pliers,

hacksaws, axes, etc.

Fall hazard

Keep your working area tidy. Untidiness of your working

area may cause a risk of injury. Maintaining improper

footing and/or balance when operating the tool can cause

you to fall. Before tensioning and especially in elevated

areas, always establish good balance. Both feet should be

securely placed on a flat, solid surface, especially when

working in elevated areas. Do not use the tool when you

are in an awkward position.

Pay attention to the rules and regulations for preventions of

accident which are valid for the work place.