G18FB & G24FB SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

1-2

Your fryer is equipped with automatic safety

features:

1. High temperature detection shuts off gas to

the burner assembly should the controlling

thermostat fail.

2. An optional safety switch built into the

drain valve prevents burner ignition with

the drain valve even partially open.

1.3 Equipment Description

The G18FB and G24FB Series of gas fryers

are designed as liquid-batter style units. They

are capable of producing up to 50 pounds/25

liters (G18FB) or 65 pounds/36 liters (G24FB)

per hour of uniformly cooked fish, shrimp,

chicken, tempura, and similar products. The

fryers in this series employ an infrared burner

system to generate 80,000 BTU/hr (20,000

kcal, 84.4 megajoules, 23.4 kW).

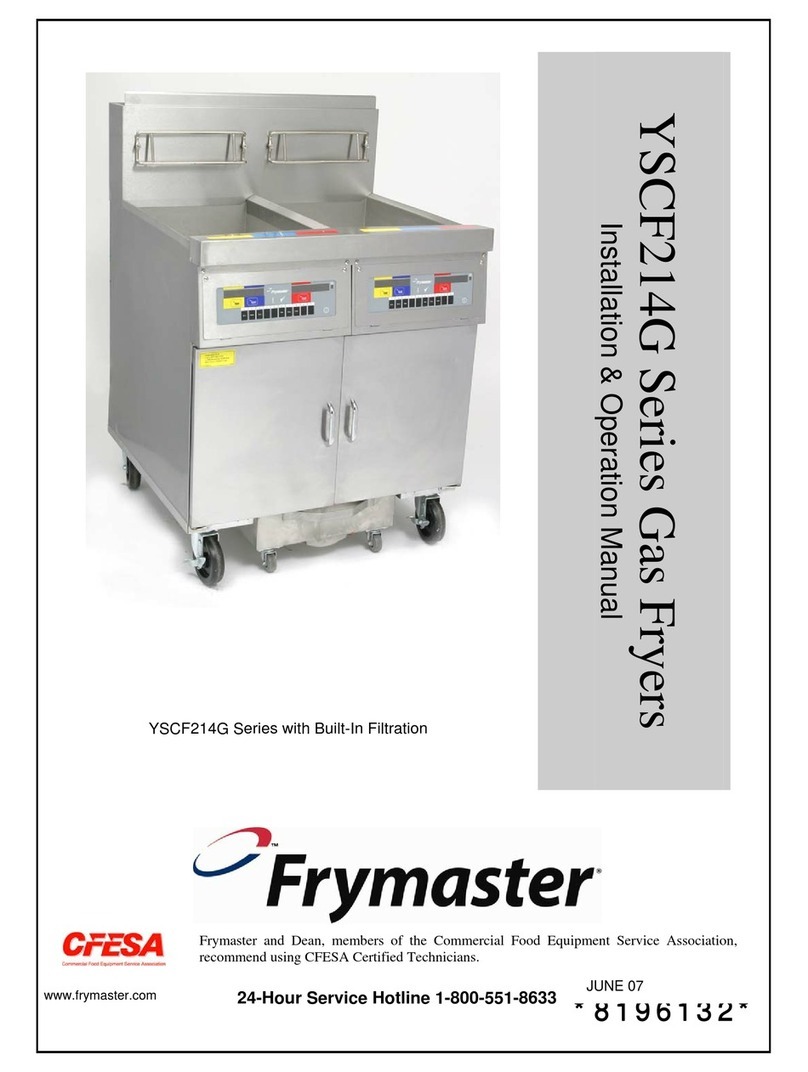

Fryers may be ordered without any built-in

filtration capability (G18FB/G24FB) or ready

for attachment to an existing Filter Magic II

filtration system (FG18FB/FG24FB). The fry-

ers can also be ordered with a Filter Magic II

system positioned on either side of the fryer

(FMG18FB/FMG24FB). Additionally, up to

four units can be batteried to either side of a

Filter Magic II built-in filtration system to cre-

ate a high-production frying station. In

January 1998, the FPG18FB variant entered

production, adding the advantages of the

FootPrint III built-in filtration system to the

earlier Filter Magic option.

All fryers in this series are of an open-pot,

flat-bottomed design with no tubes, which

makes cleaning the frypot quick and easy.

Frypots are constructed of welded heavy-

gauge stainless steel. A drain valve is tapped

into the center of the frypot, with a front-

operated manual ball valve. Heating is sup-

plied by a pair of burner assemblies mounted

beneath the frypot. Combustion air for the

burners is supplied by a dedicated blower.

Each frypot is equipped with a temperature

probe for precise temperature control. The

probe is located on the centerline of the frypot

for rapid response to changes in loads, and to

provide the most accurate temperature meas-

urement.

The fryers in this series can be configured for

natural gas or Propane (LP) gas, as required by

the customer.

All fryers come standard with electronic igni-

tion. Control options include Computer Magic

III computers or solid-state analog controllers.

Each type is covered in detail in Chapter 3,

Operating Instructions.

All fryers in this series require an external

source of AC electrical power. Units can be

configured for voltages ranging from 120

VAC to 220 VAC.

Fryers equipped with FootPrint III built-in fil-

tration systems are shipped completely

assembled. Fryers without the FootPrint III

require installation of legs or optional casters

at point of use. All fryers are shipped with a

package of standard accessories. Each fryer is

adjusted, tested, and inspected at the factory

before crating for shipment.

1.4 Installation, Operating, and

Service Personnel

Operating information for this equipment has

been prepared for use by qualified and/or